Consumption rates of plaster for 1 m² of the wall

For the correct, and most importantly, less costly finishing work, the amount of required building materials should be calculated in advance. Plaster consumption per 1 m2 already predetermined by the manufacturer, and additionally the consumption rates were calculated and repeatedly checked back in the Soviet era and spelled out in SNiP. Simple calculations will help to quickly determine the required amount of material. More about everything later.

The content of the article

What regulatory documents should be used when calculating

The norms for plastering walls were drawn up a long time ago and after years were repeatedly tested in practice by many builders. To determine the consumption of material per 1 m2 only 2 regulatory documents will be required, namely:

- SNiP 3.04.01-87. The standards have been drawn up specifically to determine the thickness and quality of both insulating and finishing coatings.

- Normative indicators of consumption of materials (NPRM) Collection 15.02 Plastering works. The collection is quite extensive and is recommended by the Gosstroy of Russia as an informational material for the development of construction estimates. The norms and types of finishing materials for any surface are given.

Many of the data specified in SNiP 3.04.01-87 or in the more current version of SP 71.13330.2017 is also in the NPRM, but in an abbreviated version. More normative documents are not required to calculate the consumption.

Recommended conditions before starting work

The consumption indicated in the regulatory documentation is relevant for certain environmental conditions, both indoors and outdoors. Before starting finishing work, you should make sure that:

- Room temperature not less than 10 С0... Air humidity - no more than 60%.

- The room is prepared for plastering. To do this, it is necessary to maintain the nominal temperature in it for 2 days before work and 12 days after.

Only if the above conditions are met, plaster consumption per 1m2 will not exceed what is stated in the regulatory documentation.

Permissible plaster layer thickness

To determine such an important parameter as the permissible thickness of the plastered layer, you should look at table 10 of SNiP 3.04.01-87.

Technical requirements of the regulatory document:

- The thickness of the layer when plastering walls in one layer, for all categories of finishing materials except gypsum, should be 20 mm. When using gypsum-based solutions - 15 mm.

- Thickness at splashing stone, brick, concrete walls in several layers - 5 mm. Wooden - no more than 9 mm.

- When superimposed soil based on cement mortar in several layers, its thickness should be no more than 5 mm. Lime mortar (gypsum may be added) - 7 mm.

Covering layer when plastering the surface, it should be no more than 2 mm, but only if it is not a decorative finish - then it is allowed to make it 7 mm.

Calculation of the required amount of mixture

You can determine the required amount of material for plastering using this technique. You need to calculate the average layer thickness for a wall with an area of 12.5 m2... First, the wall is hung in several places, the more they are done, the more accurate the result will be. The results obtained on the curvature of the wall, for example, 1, 4, 2 cm, must be added and divided by the number of sags, in our case three. We get the middle layer (1 + 4 + 2) / 3 = 2.33 cm.

Now you need to calculate the average consumption per square meter and the total amount of material.If you have chosen for plastering "Volma-layer", which has a consumption of 9 kg / m2, then we get 9 * 2.33 = 20.97 kg, this is the average consumption. We multiply it by a total area of 12.5 m2, 12.5 * 20.97 = 262.1 kg.

The mixture is sold in bags of 30 kg, so we calculate how many bags you need to buy: 262/30 = 8.73. Round off the result and get 9 bags. Now it is easier to calculate how much you need to calculate in order to plaster the wall. You can use the online calculator on the network for the calculation.

Mix consumption per 1 m2 surfaces

In the collection 15.02 NPRM you will find all tables with the consumption rates of various types of plaster (lime, cement, cement-lime mortar). For ease of understanding, next to the solution, its GOST is indicated, and the consumption of mesh, gypsum and dowels is additionally given. An inconvenience arises when calculating the amount of mixture per 1 m2when the data is indicated in relation to 1m3/ 100 m2 area.

Consumption for 1 m2 with the condition that the material is applied in one layer (layer thickness - 1 cm):

- Gypsum - 9 kg.

- Cement or cement-lime mortar - 17 kg.

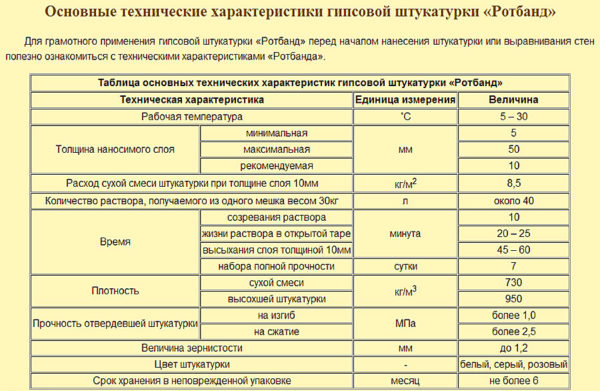

- Rotband. The main difference between the mixture and the standard gypsum mortar is the presence of adhesion-improving additives. Consumption of "Rotband" mixture per 1 m2 is 8.5 kg.

- "Bark beetle". "Bark beetle" is often used when decorating building facades and much less often indoors. This type of plaster has several varieties, but on average its consumption is 3 kg per 1 m2.

- Volma. Volma plaster is popular because of the variety of products - there are at least 22 types. One of the most common is “Volma-layer”, and its consumption is from 8 kg.

- Venetian plaster. It is more suitable as a filling option, since its layer should be very thin, so the consumption of the Venetian is as economical as possible: 200 g per 1 m2.

- "Vetonit". It is widely used due to its relatively low consumption. Vetonit mainly consists of cement (base), sand, limestone and microfiber. Consumption: 1.5 kg per 1 m2.

- "Teplon". Gypsum-based plaster is appreciated for its high environmental friendliness, affordability in terms of price policy and high-quality vapor permeability. Teplon consumption is 1.8 kg.

Important! If the surface is too deformed or there are cracks and potholes, some material should be added to the already calculated one. Sometimes it is just enough to round up the estimate number upwards if it came out not whole.

Gypsum plaster according to GOST

Now the most popular mixtures for plastering premises are made on the basis of such a universal building material as gypsum. But not all manufacturing companies, due to the constant saving of constituent materials, strictly follow the letter of GOST. The main regulatory document, which precisely specifies the requirements for the manufacture of a gypsum mixture, is GOST R 57957-2017.

In GOST, the following are available:

- Notation.

- Types of gypsum plasters.

- Marking and packaging.

- The values of the thermal conductivity of the material after it has solidified.

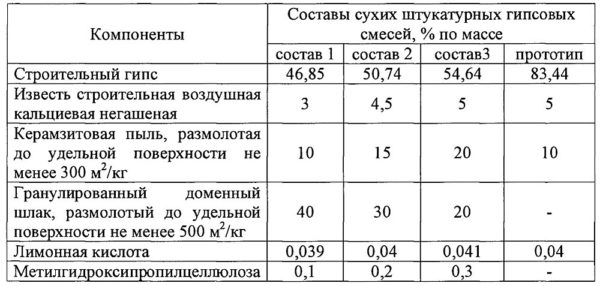

But most often buyers are not interested in the composition of the plaster, but in its proportions. To find out the components of the dry gypsum mixture, just look at GOST 31377-2008, which consistently lists all the requirements for this product:

- The presence of grains larger than 5 mm is not allowed in the dry mixture. GOST permits the presence of grains with a size of 1.25 mm - no more than 1%, 0.2 cm - no more than 12% and 0.125 - no more than 15%.

- Gypsum, which is added to the dry mix, must be made in accordance with GOST 125.

- After adding water to the dry mixture, the setting of the resulting solution should occur with manual application in at least 45 minutes. When using any technique for application - not less than 90 minutes.

- The water holding capacity should not be lower than 95%.

Important! If this GOST is indicated on the box of the purchased mixture, but the quality of the plaster, its hardening time or other characteristics do not meet the requirements of the regulatory document, then each buyer has the right to receive monetary compensation.

Knauf Rotband plaster

Knauf Rotband is very popular with art decorators. Firstly, because of its versatility (suitable for concrete, brick, cement surfaces, as well as for gypsum partitions). Secondly, because of its affordable price.

When buying KNAUF-Rotband plaster, you should not pay attention to its color, since such products can be white, gray or pink. Different colors and shades of the mixture are given by polymer additives, which are mixed with the main ingredients specifically to impart good tackiness to the finished solution.

Rotband consumption is much less than cement-based mortars, since gypsum predominates in these products. 8.5 kg of mix is sufficient to cover an area of 1 mm2... Drying of a layer 1 cm thick occurs in no more than 1 hour, but for a full set of strength, the plaster should be allowed to brew for at least 7 days.

Gypsum solutions are whimsical to some nuances, therefore Rotband has several minor disadvantages:

- A layer of Rotband plaster is inferior in strength to the same layer, but based on a cement component.

- It quickly enters into the process with metal parts (nails, screws, screws, screws), which leads to their rust. Therefore, over time, yellow streaks may appear on the plastered surface.

- It is best not to apply Rotband in damp rooms.

Important! The building materials market is filled with fakes, which in their appearance and cost are practically no different from the original. The main feature of Knauf Rotband unnatural plaster is the presence of sand in the package. This product should be returned to the seller immediately!