Choosing a double-circuit gas boiler

Today gas heating is still the cheapest. Therefore, if there is a gas pipeline nearby and technical capabilities, it makes sense to install a double-circuit gas boiler. Why double-circuit? Because one device will provide both heat and hot water.

When choosing a double-circuit boiler, be sure to pay attention to several parameters:

- installation method - floor wall;

- power;

- combustion chamber type (open, closed);

- the type of heat exchanger and the material from which it is made;

- set of service functions.

There are many other points, but these are the main ones. Without them, it is impossible to choose a double-circuit gas boiler, and we will talk about them further. And first of all, let's get acquainted with the structure of this equipment and the principle of its operation. Then all the stages of choosing a gas boiler for a house, apartment or summer cottage will be clear.

The content of the article

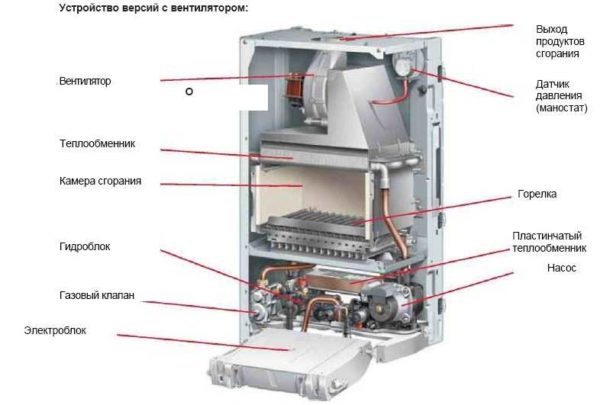

Structure and main differences

The gas boiler consists of three main modules - burner, heat exchanger, control automation. The burner is located in the combustion chamber, above it there is a heat exchanger, in which the coolant is heated. The whole process is controlled by automation. It provides safety and changes the operating modes of the equipment.

Heat exchanger types

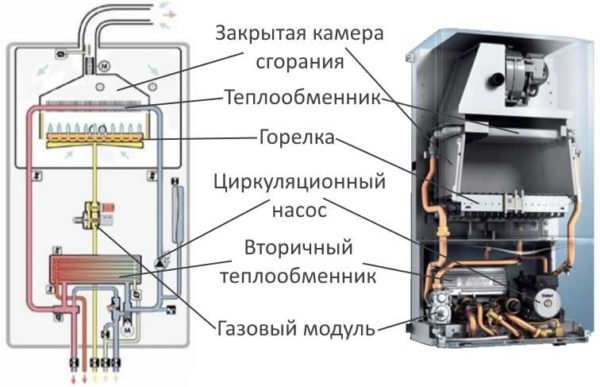

A double-circuit boiler differs in that it can heat both water for heating and for water supply. This must be done separately, because special heat exchangers are needed. There are two types of them:

- Double heat exchanger. Consists of two separate modules - primary and plate. In the primary, the coolant from the heating system is heated, in the secondary - plate - water for domestic needs. The primary heat exchanger is a finned tube, the secondary is a set of plates. They are located in different parts of the boiler - primary at the top, lamellar at the bottom, but they are interconnected because they are read as a single detail.

- Bithermal heat exchanger. It consists of two metal tubes of different diameters, inserted into one another. In the inner tube, hot water is heated, in the outer tube for the heating system.

The system with a double heat exchanger is more reliable. Since the heating is a closed system and the coolant circulates in a circle, little scale is formed. When heating water for hot water supply, the situation is reversed - running water heats up, which means there is a lot of scale. This part of the heat exchanger periodically requires repair or replacement. If in a double heat exchanger it is possible to replace only the part that heats water for domestic needs, then in bithermal separation is not provided, you have to change the entire device, and this is much more expensive. There is one more thing: a double-circuit gas boiler with a double heat exchanger normally works for heating, with a bithermic one the situation is different - it does not work at all.

Heat exchanger material

The choice of a double-circuit gas boiler can also be influenced by the material from which the heat exchanger is made. This could be:

- Stainless steel. Not a bad option in terms of durability, but it has a rather low heat transfer, which reduces the boiler efficiency. However, the price of such a heat exchanger is high.

- Cink Steel. This is the cheapest type of heat exchanger, but also the most short-lived.

- Copper.An excellent option for heat transfer (boilers have high efficiency) and durability, but the price is high. But this does not scare anyone - it outweighs the ability to pay less for gas during operation. It is for this reason that most good double-circuit gas boilers are equipped with a copper heat exchanger.

It is not so difficult to choose a double-circuit gas boiler for this parameter. Copper seems to be the best option. Not without drawbacks - high chemical activity and low melting point - but they have long been learned to compensate. The boiler automation controls that there is no overheating. Chemical activity is neutralized by using chemically neutral materials in the heating system - using polymer pipes - polypropylene or cross-linked polyethylene.

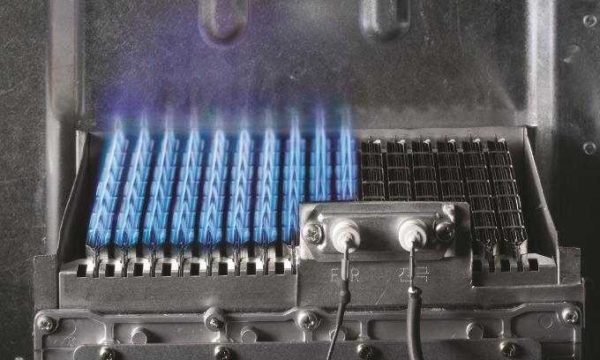

Types of burners for gas boilers

In wall-mounted double-circuit gas boilers, atmospheric gas burners are installed. By the method of controlling the flame, they are:

- Single stage. The burner is either on or not. There are no intermediate provisions. To maintain the required heating mode, the burner alternates between igniting and extinguishing. Not the best work algorithm.

- Two-stage. There are two modes of operation - 100% power and 50-60%. Automation itself regulates the required power. Such burners are more economical, they allow you to maintain the temperature more accurately. By reducing the number of on / off switches.

- Modulated. The most expensive type of burner, but also the most economical. It is controlled by automatics, the power is set to the one that is needed at a given time from 10% to 100%. A double-circuit gas boiler with such a burner has a minimum of on / off cycles, which has a positive effect on durability. In addition, fuel consumption under equal conditions is 10-15% less.

If we talk about the optimal choice, then these are modulating burners. They allow not only to maintain the heating temperature accurately, but also heat the water exactly to the specified parameters. If you want to choose an economical double-circuit gas boiler, it must have a modulating burner.

Automation

Automation in gas boilers is mandatory - it ensures safety, switches operating modes. There are three main parameters that are constantly monitored:

- the presence of draft in the chimney;

- gas pressure;

- flame control.

These are key points that just need to be controlled. If at least one of these parameters is not correct, the boiler will not turn on. In addition, there is an extensive list of additional functions:

- Maintaining a stable temperature. There are two types of automation: one controls the temperature of the coolant, the other controls the air in the room. More comfortable conditions are created with air control - the weather changes, but regardless of this, the set mode is maintained in the room.

- Post-circulation mode. After turning off the burner, the heat exchanger is very hot. If the circulation pump is turned off immediately, the water in the heat exchanger may boil, leading to its failure. To avoid such a situation, the pump drives the coolant for some time and turns off only when the temperature becomes acceptable.

- Anti-freeze. If a double-circuit gas boiler is in a country house where you live only periodically, you can set the economy mode. The boiler will maintain a stable temperature of + 5 ° C. The same function can be used at the time of departure.

- Summer mode. In summer, the heating does not turn on, the boiler only works to heat the water. So that stagnation does not occur in the system at this time, so that the elements do not clog, the automation turns on the circulation of the coolant for some time once a day.

These are the functions that are common, but there are also specific ones: the ability to connect (and control) solar panels, floor heating systems. There is a weather-dependent automation. In this case, there are remote sensors that are installed outdoors. According to their data, the operation of the boiler is adjusted.

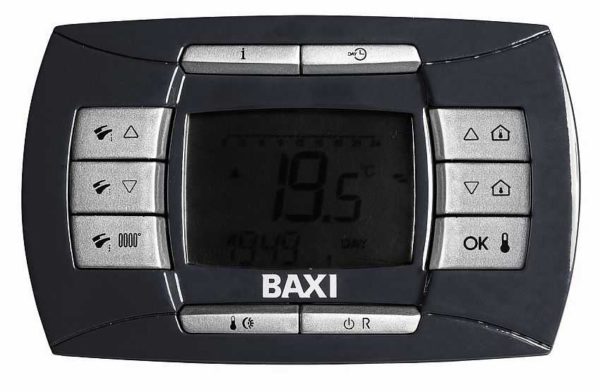

All these functions are embedded in the microprocessor, which controls everything. An ordinary user from all automation only comes across a remote thermostat, which can be installed in any room and according to the indications of which the temperature can be adjusted (another additional feature). Basically, all interaction with the boiler and its automation is limited to a small socket. All necessary information is displayed on the screen. There are also buttons with which you change modes, set the temperature.

Principle of operation

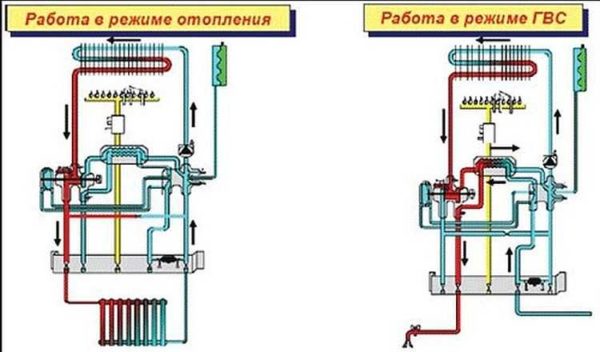

A double-circuit gas boiler can operate in two modes - heating and water heating. In the boiler itself there are two circuits along which the coolant moves. One of them - with a primary heat exchanger - works for heating, the second - with a plate heat exchanger - for preparing hot water. Switching takes place using a three-way valve.

The exact mode of operation of a double-circuit boiler is set by the manufacturer, but usually the mechanism of operation for heating is as follows:

- When the room temperature drops below a certain level, the automation sends a signal to turn on the circulation pump. The coolant begins to move, creating a vacuum in the return pipe. The burner starts up at the same time.

- Flowing through the heat exchanger, the coolant heats up, carrying heat around the system.

- Bypassing the radiators, it cools down and returns to the boiler inlet with a lower temperature.

- Heats up again by passing through the heat exchanger.

- When the set temperature is reached (there is control by the temperature of the coolant, there is - by the temperature of the room), the burner turns off, the coolant circulates for some time, driven by the circulation pump (post-circulation mode). When the temperature of the heat exchanger drops to a certain level, the circulation pump stops. The boiler does not work until the temperature is within the normal range. As soon as it falls 1 ° C below the set limit, the boiler turns on again.

With some variations, this algorithm of operation is repeated in different boilers. When heating water for domestic needs, everything happens about the same, only the signal to turn on the burner is the appearance of a water flow in the circuit. That is, you open a hot water tap, the burner ignites. Only in this operating mode, the three-way valve switches and closes the coolant inside the boiler. The secondary heat exchanger is heated from the hot coolant, and running water is heated from it. Heating stops when the water overheats (when the threshold is reached) or after the tap is closed. The burner goes out, the circulation pump runs until the heat exchanger cools down, then it turns off.

Installation method

According to the installation method, gas boilers are floor-standing and wall-mounted. Wall mounted - compact units, the size of a small kitchen cabinet. They do not require the equipment of a separate room, they can be installed in the kitchen or in another suitable room. The maximum power of a wall-mounted gas boiler is 30-35 kW. This is usually enough to heat rooms with a total area of 250-350 sq. m.

Floor standing gas boilers are more powerful, respectively, have larger dimensions and weight. There are models that can stand in a residential area, others require a dedicated room - a boiler room. The requirements for the installation are prescribed by each manufacturer separately, but usually the distance from the top of the boiler to the ceiling, the volume of the room and the presence of ventilation are stipulated.

Regardless of the type, a certified project is required for the installation of gas boilers. A gas meter is necessarily present in the circuit, so if it is not there, it will have to be purchased. Connection work must be carried out by a campaign licensed for this type of activity. Only in this case the boiler will be put into operation.

It is easy to choose a double-circuit gas boiler according to the installation method. If there is enough power, they usually take the wall version, if not, the floor version.

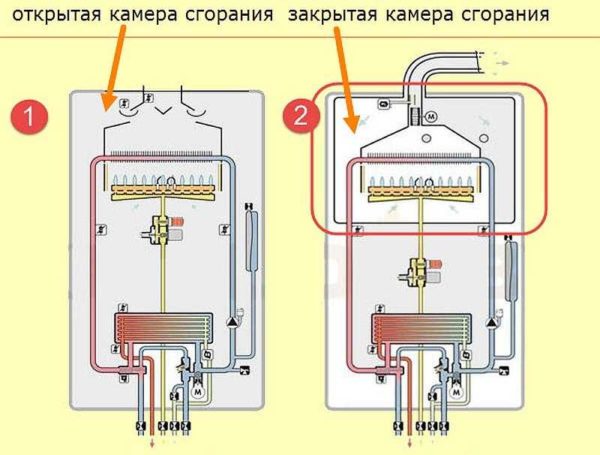

Combustion chamber type

The gas burner is located in the combustion chamber. There are two types of it - open (atmospheric) and closed (with a turbine, forced). A double-circuit gas boiler with an open combustion chamber can only be installed in rooms with good ventilation. During operation, the oxygen necessary for combustion is taken from the room, and the combustion products are discharged into the chimney with good draft. Therefore, a good air flow and a properly working exhaust ventilation duct are needed.

Gas boilers with a closed combustion chamber are distinguished by the fact that at the outlet of the chamber there is a coaxial chimney (pipe in pipe) equipped with a fan. They bring the chimney out into the street, you can - into the wall near the boiler. Air is taken from the street through one pipe, combustion products are removed through the second, their movement is provided by a fan-turbine.

Which combustion chamber is the best? A boiler with a closed combustion chamber operates more stably - air flows directly into the combustion zone. But there is a minus in this: with a side wind, the air flow can be so strong that it blows out the burner, the boiler turns off. The second disadvantage of this solution is freezing and ice formation in winter. Well, and the third drawback - such a boiler works only if there is electricity - it turns off without a turbine. Well, and another small minus - the turbine is not silent. It is almost inaudible, but it is “almost”. Apparently for these reasons, if there is a possibility (a working ventilation duct), they put boilers with an open combustion chamber. After all, it is much easier to ensure a constant flow of air.

Boiler power

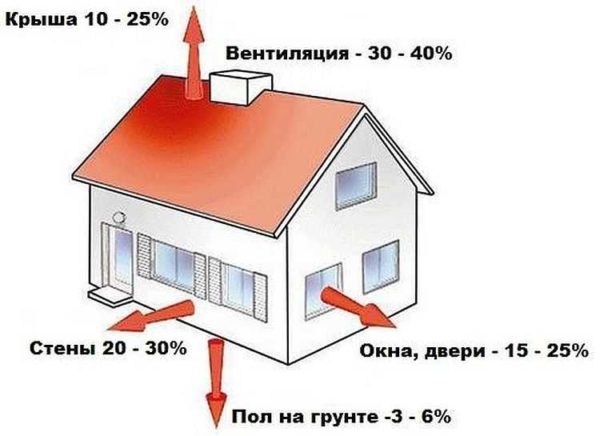

One of the key points in choosing a heating boiler is determining the required power. If we approach this with full responsibility, it is necessary to consider the heat loss of each room, if we are talking about an apartment or a building as a whole, if the boiler is selected for heating a private house. The calculations take into account the materials of the walls, their thickness, the area of windows and doors, the degree of their insulation, the presence / absence of an unheated room below / above, the type of roof and roofing material. Geographical location and a whole bunch of factors are taken into account.

Such a calculation can be ordered in a specialized organization (even in GorGaz or a design bureau), if you wish, you can master it yourself, or you can follow the path of least resistance - calculate it based on the averaged norms.

Based on the results of all calculations, the norm was derived: for heating 10 square meters of area, 1 kW of heating power is required. This standard is suitable for rooms with 2.5 m ceilings and walls with an average degree of thermal insulation. If your room falls into this category, divide the total area that needs to be heated by 10. You get the required boiler power. Then you can make adjustments - increase or decrease the resulting figure, depending on real conditions. It is necessary to increase the power of the heating boiler in the following cases:

- The walls are made of a material with high thermal conductivity and are not insulated. Brick, concrete fall into this category for sure, the rest - according to the circumstances. If you are choosing a boiler for an apartment, you need to add power if the apartment is corner. For "internal" heat losses through them are not so terrible.

- The windows are large and do not provide airtightness (old wooden frames).

- If the ceilings in the room are higher than 2.7 m.

- If in a private house the attic is not heated and poorly insulated.

- If the apartment is on the first or last floor.

Reduce the design power if the walls, roof, floor are well insulated, energy-saving double-glazed windows are installed on the windows. The resulting figure will be the required boiler power. When looking for a suitable model, make sure that the maximum power of the unit is not less than your figure.

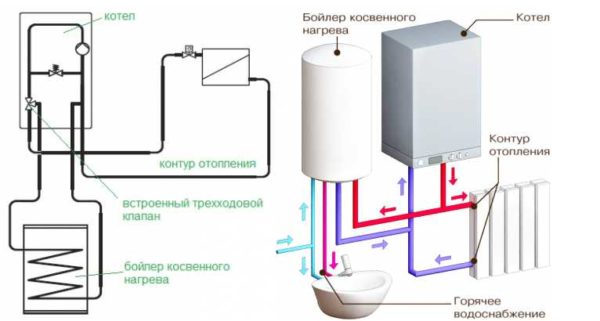

With or without boiler

It's about how the water is heated. A conventional double-circuit gas boiler acts as an instantaneous water heater. Hot water is often not needed constantly, but in small portions, which leads to frequent switching on / off of the boiler. This mode leads to rapid wear of the equipment, but it is not too expensive to turn off the water. The solution to this problem is a double-circuit gas boiler with a boiler.

A gas boiler has a small built-in storage tank that stores a certain amount of heated water. When the hot water tap opens, the flow comes from the tank, when the stock comes to an end, the burner turns on and continues to heat the water. After the tap is closed, the boiler works for some time, filling the boiler, then turns off. This mode of operation leads to less wear and tear on the equipment. The disadvantage of gas boilers with built-in boilers is their large size, because you need to place the boiler somewhere else. There are models with a remote boiler, then the container is connected to the boiler, and the floor can be installed by the boiler or next to it.

Double-circuit gas boilers: manufacturers

Having decided on the technical characteristics, it remains to find a suitable model and choose a manufacturer. It is not easy at all - there are many firms on the market, prices differ decently. As usual, there are three segments - expensive, mid-priced and cheap.

Dear ones are products of European manufacturers:

- Italian gas boilers - Ferroli (Ferroli), Beretta (Beretta), Ariston, Baxi (Baksi).

- German ones are not inferior to them in quality: Viessmann (Weismann), Wolf (Wolf), Vaillant (Vialant).

- Korean Navien (Navien) are a worthy competitor to the leaders.

This equipment works reliably and without failures, but only under certain conditions. The first is a stable power supply, without significant fluctuations in frequency and voltage. Our networks do not sin with stability, therefore a voltage stabilizer is needed, and better - an electronic one. The second condition for normal operation is a certain gas pressure in the line. Most of the German and Italian gas boilers work if the gas pressure is 2 atm or more. The exception is the boilers Ariston and Navien.

Wall-mounted double-circuit gas boilers of Russian production - Danko, Protherm (Proterm) - have proven themselves quite well in the market. They have approximately the same functionality as the "Europeans", but they are less sensitive to deviations in the power supply and operate at low gas pressure. What is not encouraging is the Russian "service".

There are also Bosch boilers (Bosch). The company itself is German, but there are factories in Russia, so it is not easy to determine the geographical origin of these boilers - some are produced in Russia, some at other plants in other countries. The Bosh campaign specialists have developed a new boiler model adapted to our conditions - Gaz 6000 W.

Wall-mounted or floor-standing boiler - a specialist must decide