How to install the toilet yourself

With straight arms, you can do most of the housework yourself. The installation of the toilet also belongs to this category of work. Knowing the sequence of actions, installation or replacement can be done by hand.

The content of the article

Types of toilets

In this article, we will consider not the features of the flush or the shape of the bowl, but those design features that determine the list of installation work.

By installation method

The toilet itself consists of a sanitary bowl and a cistern. The bowl can be floor-mounted or suspended. If the bowl is suspended, then the tank is concealed - built into the wall. In the case of a floor bowl, there are three options for attaching the tank: to a special shelf on the bowl (compact), separate, connected with a flexible hose, in an installation (a frame hidden in the wall).

The advantage of a floor-standing toilet with a conventional cistern is ease of installation. It can be installed without starting the repair. The disadvantage is that compared to the suspended one, it takes up more space, looks more heavy. Accordingly, the installation of suspended models is complicated - it is necessary to fix the supporting structure - installation - in the wall. Perhaps this is only during the renovation.

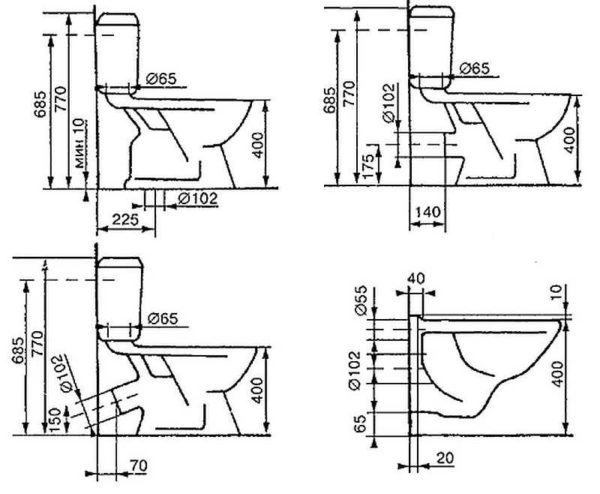

Release to sewer

The choice of the toilet for release into the sewer depends on the location of the sewer pipe. They are:

- with horizontal outlet;

- oblique release;

- vertical.

If the pipe is in the floor, a vertical outlet is optimal. If the exit is in the floor, but is close to the wall, an oblique toilet is most convenient. The horizontal version is universal. Using a corrugated pipe, it can be connected both to the wall and to the floor.

Installation of a toilet bowl with a compact cistern (floor-standing version)

From the store, they usually bring a separate toilet bowl, cistern, drain device and float. Before installing the toilet, everything except the float must be assembled.

Assembly

The process begins with the installation of the drain device. It comes assembled; you only need to install it in the hole in the bottom of the tank. A rubber gasket is placed between the drain and the tank.

On the reverse side, the included plastic washer is screwed onto the pipe. It is tightened by hand, then using a wrench, but very carefully, since it is easy to break the plastic. To prevent the drain device from spinning, it must be held by hand.

The next step is to install the mounting screws on the tank. They are also included in the standard package. These are long thin zinc-plated or stainless steel screws. They are inserted into two small holes at the bottom of the tank, rubber gaskets are put on, then washers and only then the nuts are screwed on.

Before installing the tank on the toilet bowl, a gasket (included) is placed under the tank. To prevent odors from leaking out of the sewer, it must be "planted" on a sealant. First we coat it on one side, put it on the toilet, coat it on the other, put the tank.

We install the tank on the shelf of the bowl, passing the screws through the corresponding holes. We put washers, nuts on the screws from below, tighten.At the same time, we make sure that the tank is level.

Next, we put a float - a device for monitoring the water level in the tank. There are two holes at the top of the tank. Here we insert the device into one of them. It is mounted on the side from which the water supply will be connected.

We wind a little flax on the outlet pipe, coat it with plumbing paste, install a corner (brass or stainless steel). Do not tighten the connection tightly, do not hammer that the branch pipe is made of plastic.

Floor mounting

The toilet is almost assembled, you can put it back. The toilet bowl is connected to the sewer using a corrugated adapter. At the ends it has rubber seals that fit tightly into the pipes and on the toilet bowl outlet.

If the sewer pipe is plastic, the corrugation is simply inserted until it stops. If the riser is cast-iron, and still not new, so that the smell does not seep through the microcracks, the pipe is cleaned to metal, washed and dried. A layer of sealant is applied around the dry, clean metal (slightly more in the lower part), then a corrugation is inserted. For more confidence, you can walk around the outside of the connection with a sealant.

In order for the installation of a toilet bowl on old cast iron to be airtight, a layer of sealant can be laid under the corrugation

In any case, we insert a corrugation into the sewer pipe.

The other end of the corrugation is put on the outlet of the toilet. This is the connection of the toilet to the sewer. It's that simple. There is only one caveat. So that it can then be removed, the outlet of the corrugation and the outlet of the toilet bowl are lubricated with soap soaked in water, only then the bell is put on. If this is not done, it will be problematic to remove the toilet without damaging the corrugation. But you still have to drill holes for fasteners. It will be much more convenient to remove, rather than try to move a partially fixed device.

Putting the corrugation on the outlet, we expose the toilet the way it will stand. Having installed a lid on the tank, we check that there is a place for it. Next, you need to sit down, check the comfort of use, if necessary, correct the position. Then take a pencil or marker, inserting it into the holes in the sole, mark the places for installing the fasteners.

After removing the toilet, holes are drilled for the dowels in the marked places. If the kit includes plastic fasteners, do not use it - it will break after a few days. It is necessary to immediately install powerful dowels.

If the toilet is installed on a tile, so that it does not crack, it is better to screw the glazed surface. They take a self-tapping screw, put it in a mark, hit it with a hammer several times. This is called "screwing". Then they take a drill or hammer drill and drill the tile, turning off the percussion mode. After the tile is passed, you can turn on the perforation mode.

We put plastic plugs from the dowels into the holes. They must be in the same plane with the floor. If there is a thicker edge, cut it off with a sharp knife.

We sweep the floor, removing dust from the installation site of the toilet. We put it in place, insert the dowels into the holes, tighten them with the appropriate key. It is necessary to tighten the bolts alternately on one side, then on the other. Tighten until the toilet is firm and free of play.

The final touch is the connection to the water supply. Connect the outlet of the water pipe with a tap installed on it with a corner on the tank, which was connected earlier. This requires a flexible hose. At its ends there are union nuts (American), so there will be no problems with fastening. We tighten it well, but without fanaticism.

Next, put the lid, install the release button, make a test run of water. If drops are found somewhere, tighten the connections. That's all. Do-it-yourself toilet installation is complete.

How to install a wall-hung toilet with installation

To install wall-hung toilet bowls, the outlet of the sewer pipe must be near the wall. The specific distance from the wall is indicated by the manufacturer, but should be small - about 13-15 cm from the far edge. If the exit from the floor, there is a solution - a special overlay, with which the drain is carried closer to the wall.

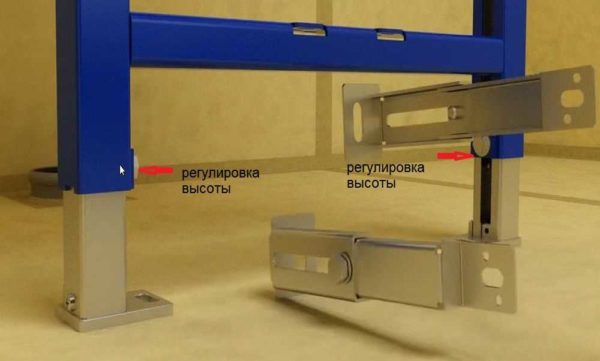

The installation of a wall-hung toilet begins with attaching stops to the wall to the frame. They are attached two at the top and two at the bottom. With their help, the distance to the wall is adjusted, the frame rises and starts.

The upper stops are in the form of rods, are adjusted using a socket wrench and a screwdriver. The lower stops are more like plates, they are also adjusted with a socket wrench but with a lateral head.

The assembled frame is placed against the wall, its center is exposed above the middle of the sewer outlet. The mark on the frame rises or falls to the height required by the manufacturer (there is a mark on the frame, also indicated in the passport, usually it is 1 meter).

Using a bubble level, the horizontal and vertical installation of the wall-hung toilet is checked.

By adjusting the height of the stops, an equal distance from the wall, specified by the manufacturer, is set. How convenient it is to do, look at the photo.

The exposed frame must be fixed to the wall. Marks are made in the appropriate places with a pencil or marker, holes are drilled. They are fitted with plastic dowel cases. Most of the hanging toilet bowls are imported, and they recommend that the dowel bodies be planted with a sealant. Some part of the sealant is squeezed out into the drilled hole, a dowel is inserted. Then, before installing the fasteners themselves, the sealant is applied to the plastic case.

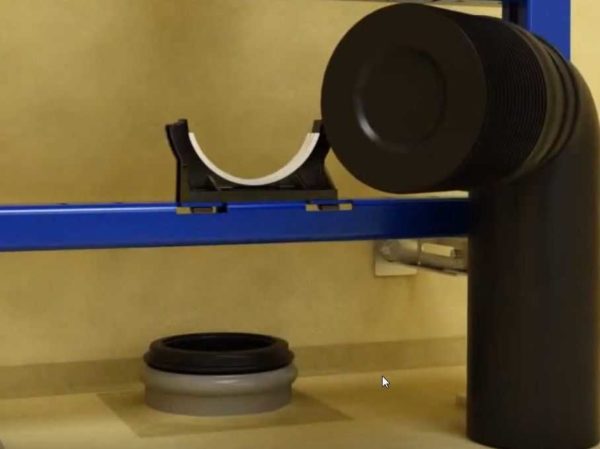

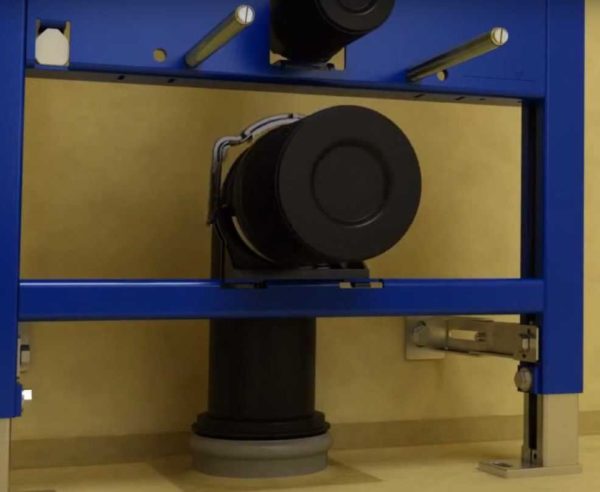

The fixed installation can be fitted with connecting elements - pipes, couplings. All of them come in a set, just fixed in place.

Next, metal rods are installed on which the toilet bowl will hold. They are screwed into the corresponding sockets, silicone seals are put on top of them (in the bottom photo these are two rods above the sewer outlet).

The sewer pipe is pulled out to the required distance, fixed in a given position with a bracket. It covers the branch pipe from above, is inserted into the groove until it clicks.

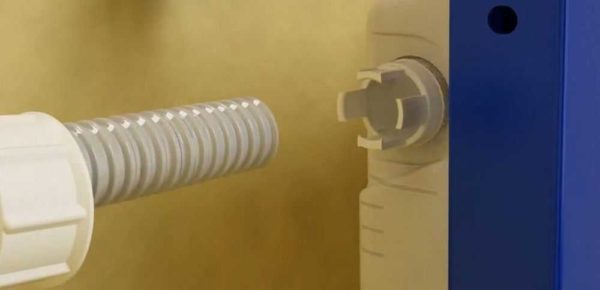

Next, water is connected to the tank. Open the tank lid (it is latched), remove the cap on the side surface. Right or left - depends on where you have your water supply. A corrugated pipe is inserted into the opened hole, a counterpart is inserted from the inside, everything is connected using a union nut. It is necessary to tighten without applying excessive force - it is plastic.

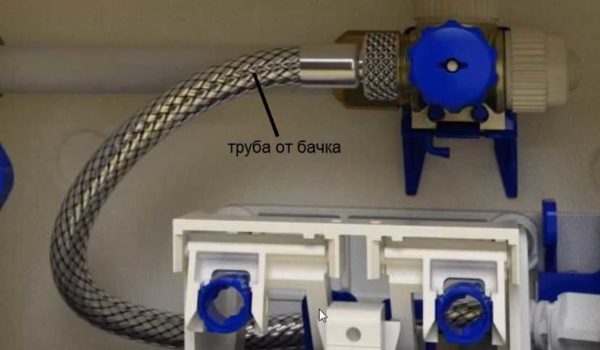

A tee is installed inside the tank, a pipe (usually plastic) is connected to the desired outlet. This is done using an adapter and an American.

A hose from the tank is connected to a special tee inlet. It is flexible, with a metal sheath. Tightened with a union nut.

Replace the cover. Basically, the toilet installation has been installed. Now we need to close it. To do this, make a false wall of moisture-resistant drywall. It is recommended to put two sheets, but one is possible. The plasterboard is attached to the installation frame and to the mounted profiles.

Next, the wall is finished, after which the toilet bowl is hung and a decorative panel of the flush device with buttons is installed.

The toilet is put on the pins, its outlet goes into the plastic socket. The connection is tight, no additional measures are required. This completes the installation of the toilet bowl.