Coating for playgrounds made of crumb rubber and rubber

It is not so difficult to decide which swing slides to put on the playground. How to decide what kind of coverage should be there? There are too many requirements. One option is a rubber coating for playgrounds. Recently, it has become more and more popular, since the knees and elbows on it are not so severely affected. But for the coverage to be safe, you need to know what to choose.

The content of the article

Requirement for coatings for playgrounds

Choose a cover for playground not easy at all. It must meet a number of requirements:

- Non-traumatic. It is desirable that when falling, there is a low probability of injury.

- High strength and reliability. Not all materials are able to withstand the onslaught of children. So the tensile strength and resistance to mechanical stress must be high.

- Waterproof. In order for the water to drain quickly, it is necessary either to make a slope, or the material must be permeable.

- Ease of cleaning. Everything is clear here - you will have to clean it often. The easier it is to remove dirt, the better. Ideally, if it can be washed with a water jet from a hose.

- Maintainability. Even a very durable material can be torn or broken if desired. The ability to repair is very important.

- Non-slip when wet.

In general, it is not easy to find a suitable covering for a playground, to put it mildly. And I also want it to be beautiful and inexpensive. Most of the requirements are met by a rubber coating. For playgrounds, this is perhaps the best option.

Types of rubber coatings

Rubber covers are made from synthetic rubber (virgin material) or recycled rubber (from recycled materials). If it is a crumb rubber coating, a dye is added for the color. Polyurethane glue is used as a binder. All components are unnatural. The binder based on polyurethane is harmless and harmless (when dry).

But the crumb must be chosen. Crumbs made from recycled tires cannot be said to be safe. A characteristic smell comes from it. As the temperature rises, it increases. And on sites in the summer with such a coating there is a distinct smell of rubber. It is hardly useful.

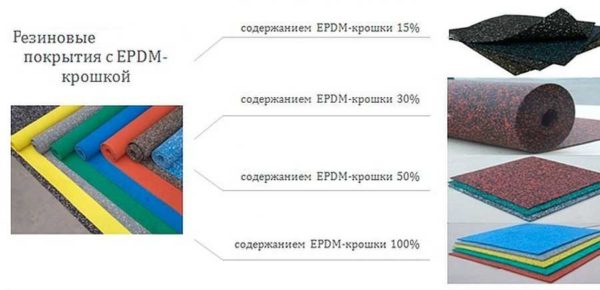

EPDM synthetic rubber is definitely harmless and does not smell even at high temperatures. It can be heated up to 150 ° C without damage. It is even used in the food industry. Another thing is that such materials are more expensive. But harmlessness in the playground is important and it is better not to save money. If you want your playground rubber flooring to be both beautiful and safe, look for materials that are 100% EPDM crumbs and not recycled materials.

There are three types of rubber coatings:

- rubber tiles;

- roll;

- seamless (crumb with glue is laid on the prepared base).

We are now talking about coatings for outdoor playgrounds for children. And we are considering the coating for year-round outdoor use. So they have frost resistance and resistance to the sun. Moreover, all types of coatings are made on the basis of crumb rubber. They just have different forms of release, with their own advantages and disadvantages.

Rubber crumb tile

The rubber tiles are separate pieces.Most often these are squares with a side of 50o mm. Available with straight edges, or with formed cuts / locks. Material thickness can be from 20 mm to 50 mm. With a tile thickness of 20-30 mm, the coating is tough, with low shock-absorbing ability. If you want the rubber covering for playgrounds to give a springy effect when dropped, you need slabs from 35 mm to 50 mm thick.

Which one is better to choose

From the point of view of reliability, options with locks are more attractive. But in any case, everything fits on the area limited by borders (curbs), the tiles are laid close - even if you want to take out one fragment with smooth edges is very difficult. So you don't have to worry about this, and laying flat tiles is easier.

Better to attend to the quality of the tiles. It is made from compressed crumb rubber. Colored, usually, is made multi-layered. At the bottom - a cheaper black crumb, at the top - a colored layer. In any case, it is better to touch and crumple it. Literally. It is clear that a plate with a thickness of 35 mm or more cannot be bent into a bagel, but some elasticity must be present. Having turned it in different directions, you should not see any changes. No cracks or creases should appear on either the front or the seamy side. Edges and edges must not peel off. They must be durable, not subject to mechanical stress.

In tiles with smooth edges, some manufacturers make bevels - this is such a small bevel around the edge of the tile. Perhaps this is how the tiles themselves look better. But it is better to have a rubber covering for a playground absolutely even. So that nothing is poured into these grooves and does not fall asleep. It will definitely be easier to clean. In general, you have to choose, but a flat surface seems preferable from the point of view of practicality.

Styling features

Lay the crumb rubber tile on a flat base. It can be concrete, dry screed, asphalt. There is a special type for laying on a compacted gravel bed, on top of which a layer of sand is laid and leveled. Special tiles are thicker and have a layer of denser backing. The laying technology itself is similar to the order of laying paving slabs - level the sand into a level, lay out the tiles, and precipitate it with a rubber mallet. To make the coating more stable and the seams not to rise, screeds are driven into the ends of the tile (into the already laid tile, then the next one is placed on it).

Rubber flooring for playgrounds: Laying crumb rubber tiles on a sandy base is similar to laying paving slabs

There is another technology that allows you to get an almost monolithic coating of rubber tiles. When laying, we coat the end with polyurethane glue, join tightly with the previously laid row. The joint is fixed with several staples from a construction stapler (steel staple 10 mm long). There are 3-4 staples for each seam. When laying the first row, we coat only the right or only the left end, in the second and all subsequent ones - two adjacent ones. After the glue dries (about 24 hours, but you need to look at the package), we take out the staples with a stationery staple remover (it is also a stapler, a staple remover, a staple remover, a dragon) or prying off with a screwdriver. As a result, we get an almost monolithic rubber coating for playgrounds.

Also, rubber tiles for playgrounds can be laid on a concrete screed. In this case, polyurethane glue is required. Consumption - 1-2 kg per square meter.

First, the screed is cleaned, dried, then covered with a layer of primer (60% glue + 40% white spirit). There is no need to wait until the primer is dry or absorbed, so you can prime in small pieces to make it easier to work.Then each tile is coated with glue, laid on the base and pressed well. For high-quality gluing, each laid 1-2 square meters is rolled with a heavy (at least 20 kg) roller.

In both cases, when laying the rubber covering for the playground, try not to stain the front surface with glue. It doesn't rub off. The trace still remains. Yes, this is not so noticeable after a couple of weeks, but it still spoils the mood.

Seamless crumb rubber (rubber asphalt)

Another form of release is the rubber coating for playgrounds, made from crumbs mixed with polyurethane glue. Crumb rubber comes in two categories:

- From recycled tires. It is black, cheaper. Using this crumb, it is advisable to first sift it, remove sand, extract (using magnets) metal fragments that may be found there.

- Made of EPDM synthetic rubber. This type of crumb comes from factories, it is produced on purpose. More expensive, but it is used even in the food industry, so it is definitely not harmful.

In order for the crumb to acquire a certain color, pigment is added to it. It wraps around every piece, so it should be of good quality. The pigment can be almost any color, but crumb rubber was originally developed for stadiums and other sports facilities, so the most common colors are red, blue and green. They are available in any company, and often several manufacturers to choose from.

Styling features

There are no special styling secrets. If you've ever worked with concrete, this is something very similar. It can be laid on compacted fine gravel, sand, dumping. Concrete and asphalt are excellent in any condition. The good news is that they don't even need to be aligned. In general, a large number of irregularities increases the consumption of crumbs, and this is costly. Therefore, many people prefer to pre-patch the intended place of application.

Before applying the composition, the base is coated with a primer (polyurethane glue diluted with white spirit). Can be primed in parts - it is difficult to walk on glue. It is not necessary to wait for the primer to dry.

The crumb is mixed in a container with glue (the percentage is indicated by the manufacturer), the finished viscous mass is spread on the base and leveled with a large spatula or trowel. To prevent the composition from sticking to the spatula, it can be sprayed with WD aerosol grease or any other silicone oils. But not plant or animal. EPDM rubber reacts poorly to them - it dissolves.

The minimum layer when applying crumb rubber to the coating is 1 cm. To avoid problems with peeling, try not to make less. The time until the glue sets may vary, but on average, plasticity is maintained for 30-40 minutes. Therefore, do not seal too large volumes. After a piece has been laid out, it is advisable to compact it with a roller. To make the surface more dense, the skating rink can be dipped in turpentine.

The rubber crumb coating for playgrounds is seamless. Although it is laid in parts, the transitions are almost imperceptible. Unless you take a long break, during which the edges of the laid fragment will completely dry out. But for a playground, usually small volumes are needed, so this is not common. And over time, the difference is erased. Not literally. It just becomes invisible.

Roll coating

Rolls are also formed from crumb rubber. They are homogeneous, single-layer. They can be of different sizes - depends on the manufacturer. You can find these:

- thickness from 8 mm to 40 mm;

- roll width - from 60 cm to 122 cm;

- length - from 10 meters, but depends on the thickness.

The laying process is described above, in the section about rubber tile covering for playgrounds. It differs only in that it is not necessary to smear the coating with glue, but to apply it to the base, then roll it out onto the coated area. It must be pressed well, not allowing air to enter. This is easier to achieve by pressing simultaneously across the entire width.

If you need to lay more than one roll, the joints can also be made almost invisible and monolithic. Smear the edge with glue, dock and secure with staples from a stapler. After the glue has dried, remove the staples.