How to install balusters and poles on stairs

When assembling a fence for a staircase, you need to decide how to install balusters, posts, support posts. Everything is not so simple, because the installation of balusters depends on the type of staircase, the material from which the staircase is made and the railings themselves. At the same time, aesthetic preferences are also taken into account.

The content of the article

Number of balusters and support posts

First of all, you need to decide on whether one baluster will be on a step or two. Both options are acceptable. The second point: it is necessary to decide where and with what frequency the support pillars will stand. There are several options:

- At the beginning and end of the span.

- Through a step.

- Two steps later.

- Three steps later.

A large number of pillars on the stairs is necessary if the balusters are thin or the filling is not vertical, but longitudinal "threads", which do not carry a load, but perform protective and / or decorative functions.

Marking the place for pillars and balusters

In any case, all the posts and balusters on the span must be on the same straight line. Moreover, if the radius / size of the balusters / support pillars is different, their centers are set on the same line. After installing all the balusters and poles, if you look along the line, they should all be in the same plane.

The first stage of the installation of the handrails - marking the installation sites of pillars and balusters

At what distance from the edge of the step to place the balusters

On average, the center of the baluster is set at a distance of 6-10 cm from the edge, but it is also possible at the very edge. Choose how you like. But you need to choose this distance in order to determine the place where you will need to make holes for mounting the balusters.

There is an algorithm for determining the distance. It is usually assumed that the staircase or baluster should be located at a distance of 2-5 cm from the side edge of the step. Divide the size of the post or baluster by two, add the selected distance to the edge and get the desired value.

Let's give an example, calculating the installation site of the baluster. Let them have a square section at the bottom, 80 * 80 mm. From the edge of the step, they should be 3 cm away.Total, we get: 8 cm / 2 + 3 cm = 7 cm.That is, when marking the place of attachment of the balusters on the stairs from the edge of the step, it will be necessary to put aside 7 cm.We also do if the balusters are round: diameter 7 cm, from the edge - 3 cm. 7 cm / 2 + 3 cm = 6.5 cm. That is, in this case, the hole for mounting stair balusters is made at a distance of 6.5 cm from the edge of the step.

Algorithm for installing balusters

The process of marking balusters itself can be described step by step as follows:

- On the upper and lower steps of the span, a certain distance is laid from the edge of the step, which depends on the size of the pillars / balusters.

- A straight line is drawn between the found points. This can be done:

- driving / screwing nails / screws into the designated points, pulling a thread between them;

- putting the line on laser level;

- setting a level bar / guide along the marks.

- A straight line is transferred to the steps.The easiest way to do this is with a large square and a pencil. At each step, it turns out there is a line along which we will level the centers of the pillars and balusters.

- Now you need to mark where the posts for the stairs will be installed. They must be at the top and bottom of the span. The first are the posts for the stairs at the bottom and top of the span. Then, we mark where the balusters will stand. We make sure that the distance between them is the same or almost the same. The permissible difference is 1 cm (for example, 9 cm is obtained between all balusters, and 8 cm between one post and the baluster).

The main task of this stage is to transfer the straight line to the steps as accurately as possible. The second is to choose such a distance between the posts and balusters so that there are no visible differences. If you can't do everything the same, you can do it symmetrically - leave larger or smaller distances at the edges or alternate them after one or two. There are no universal solutions, since each staircase is unique, with its own parameters and features.

Handrail assembly procedure

To install the railing on the stairs without surprises, you need to clearly understand the whole process.

- Two extreme pillars are fastened - at the top and bottom of the span. They are set so that there is the same distance from the edge of the post to the edge of the step (usually 3-6 cm). If the ladder is made on a stringer, they are exposed by aligning the edges, or making sure that there is the same distance on both sides.

- A rope is pulled between the two mounted posts. Self-tapping screws are screwed into their center, twine is pulled, along which it will be necessary to set the centers of the installed balusters and poles, it will be possible to watch the height, etc. Instead of a rope, you can install a guide if you are sure that it is level and does not sag anywhere.

- Balusters are attached, pillars are placed according to the existing markings. Their position is strictly vertical and so that the top is flush with the thread / guide.

- When installing each element, its position is verified:

- Pillars / balusters should be strictly vertical, without the slightest deviation. It is necessary to check in two planes.

- They should be in line with those already installed, "do not walk" to the right or left.

- Railings are put on the exposed pillars (with or without a support rail - it depends on your desire).

Then the process is repeated for the second span. The last thing that ends with the installation of the railing is the union of the support pillars at the turn. The specific method depends on the type and material of the handrail, but you need to contrive to make this section a transition from one span to another, while being convenient and not seem alien.

Fastening wooden balusters and poles

Many will agree that the installation of handrails is more difficult than the manufacture of the actual staircase: there are too many different units, there are no standard solutions suitable for everyone. This is where the difficulty lies. Perhaps the hardest thing to install is a wooden rail. The material is plastic, but that's the problem: an element that is well fixed at first, after a year or two it can dangle with a decent amplitude. Therefore, they approach the fastening of pillars and wooden balusters very, very carefully, reinsure themselves, use combined methods, adding glue if possible. This makes the connections tighter.

In general, a baluster or a pillar is attached either to the step board itself or to a stringer - it depends on the design of the stairs. Internal staircases on kosoura are rarely made today, therefore, basically, we will talk about the installation of railings to the steps.

Using a bolt (wood grouse) to the step through and through

There is a simple option - through fastening of balusters and support pillars to the step. The only requirement: the thickness of the step must be decent - more than 40 mm.

In this case, for mounting the baluster or pillars at the selected point, a through hole is made in the step board through which a bolt with a minimum diameter of 8-10 mm is passed (12 and 14 mm are possible, depending on the section of the baluster). The minimum length of the wood grouse is 80 mm (the rest can be sawed off). A hole with a larger diameter is drilled for the bolt. After installation, it must be recessed so that at least 5 mm remains to the edge of the board. The resulting hole is closed with a decorative overlay (you can choose a plastic of a suitable color or made of wood).

A bolt is inserted into the hole, a hole 2-3 mm smaller in diameter than the diameter of the bolt used is drilled in the center of the baluster. The specific diameter depends on the type of wood: the harder the wood, the smaller the difference between the drill and bolt diameters should be. The hole depth is equal to the bolt length.

The bolt is screwed in from below, goes through the step, enters the body of the baluster. It is screwed onto the thread, Exposed. Finally tighten from below using a socket wrench of the required diameter. The option is good because, in theory, the connection can be tightened - if you remove the plug and, using the key, reduce the backlash. But the "tightening" works until the hole in the wood becomes too large from play. And it (backlash) will appear sooner or later - from loads that are directed in different directions, from natural processes taking place in wood. So the connection is not eternal.

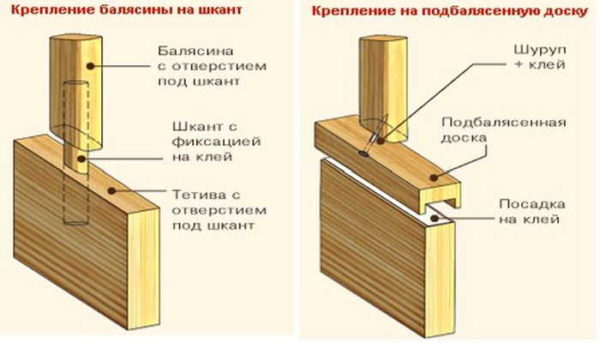

On dowel or threaded rod

If it is impossible to get to the steps from below, there is an option for attaching the balusters to the dowels (50 * 10, 60 * 12, 70 * 14, 70 * 16 mm). The dowel is chosen large, large diameter. The installation of balusters in this case is as follows: a hole is drilled in the step with a depth equal to half the length of the dowel. We drill the second hole in the lower part of the baluster. Drill diameter - 1-2 mm less than the dowel diameter.

Epoxy glue is poured into both holes, the dowel is inserted into the hole in the steps until it stops, then a baluster is put on it. For greater reliability of such an attachment, you can grease the entire lower part of the baluster with glue.

One point: look for dowels from the same wood from which the steps and railings are made. They have the same coefficient of thermal expansion, react in the same way to shrinkage, increased humidity. This will make the connection more durable. Installing balusters on dowels is a traditional, but not the most reliable method today. Firstly, the dowels can break, and secondly, the connection itself is still loose. So after a few years, you will have to find a way to fix the dangling railing.

A threaded rod can be used instead of a dowel. The baluster installation process is no different. Everything is the same, only you can not fill the hole with glue, although ...

For self-tapping screws

The most "collective farm" method, which professionals do not like very much, but which is easier to understand and implement, is to install balusters on self-tapping screws. For fastening to the steps, self-tapping screws for wood with a diameter of at least 6 mm and a length of 60 mm or more are used. On each side they put two (in total, 8 screws for each).

The easiest and most "wrong" way. And one more thing: a lot of hassle in order to close the unsightly tracks

It is necessary to screw them on the floor at an angle of 30-40 °, pre-drill the holes under the caps. Install self-tapping screws, then close the holes with plugs cut from the same wood or cover with wood putty.

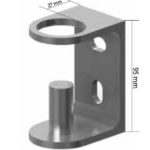

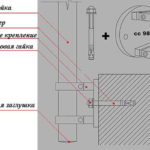

With Zipbolt (zipbolt)

A relatively new fastener that can be used to attach balusters to both steps and handrails. It is easy to use but expensive. If you install the railings with your own hands and "for yourself", this is a good option. Installing balusters with a zipbolt is also good in that the connection can subsequently be tightened, eliminating the resulting backlash.

The zipbolt consists of a threaded rod and a removable gear head. There are two types:

- of two movably connected threaded rods of approximately equal length;

- from one threaded rod (type 13.600).

The option with movably connected studs is good when connecting balusters and railings, railings with support pillars. The straight zip bolt is good for concealing perpendicular bars. Just the case of installing balusters on the steps, supporting pillars on the floor, overlapping the second floor. The dimensions of this fastener are solid - the diameter is 8 mm, the length is 96 mm, so that it will withstand the post well, and there is no doubt about the reliability of fastening the balusters.

The algorithm itself is similar to mounting on a stud: you need to drill a hole in the steps and the baluster for installing the threaded stud. The length of the hole in both parts should be equal to the length of the stud minus the height of the head.

The difference is that to install the head, you need a technological hole perpendicular to the main one. In size, it should be slightly larger than the diameter of the head, and its center should coincide with the axis of the hole for the stud. After the stud is installed, a removable gear head is inserted into the technological hole. It has special key slots. Install the head so that the slots are accessible. Using a 6 mm hex wrench, which is inserted into these slots, the head is turned until it stops, pulling the baluster to and fixing the hairpin.

When installing the support posts of the railing on the floor using a zip bolt, questions may arise about the method of fastening. If the floor is wooden, the threaded part is simply screwed in. If the floor is concrete, chemical anchors can be used. If there are metal inserts, the bolt can be welded. The last method, by the way, is the most reliable: at least the bolt will no longer dangle.

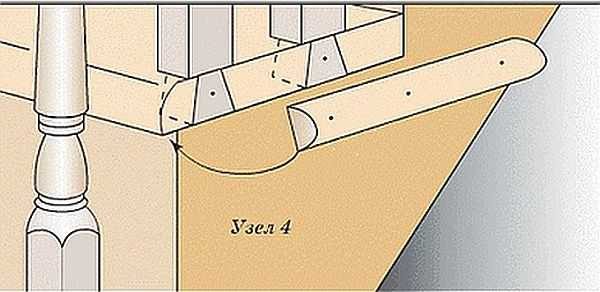

Dovetail joint

Another way to connect balusters and steps is carpentry. With a groove and a spike of a special shape - a dovetail. This option is possible if you make the balusters yourself or if they have a solid margin of length at the bottom.

A similar installation of balusters is possible if the railings are planned to be made almost from the very edge of the steps. Then holes in the shape of a trapezoid are cut into the steps from the end, the same ones are formed on the balusters. The ends of the cuts are lubricated with wood glue or epoxy resin, aligned and fixed.

When attaching the "dovetail", you can also use nails to strengthen the connection of the baluster and the steps

With this method of connection, the stands for some time - until the glue dries - must be fixed in a vertical state, as they may deviate. For this, a temporary support structure is erected, which is disassembled after the glue has hardened.

To make the steps look better from the side, the ends are closed with overhead decorative strips. Planks can be "planted" on glue, nails, screws, dowels. The choice is absolutely arbitrary, but the most correct and invisible are dowels. Such an installation of balusters is based entirely on the art of carpentry, requires precise adherence to dimensions.

Installing balusters on kosour (bowstring)

When installing balusters on a bowstring or kosour, you can use all the same methods of installing balusters: on dowels, pins, screws, zipbolts. You can even make a dovetail, but you will have to cut it in a different plane, which is not at all more difficult, and perhaps even easier. For decoration, you can use strips on both sides.

The difference between mounting balusters on a kosour (bowstring) is that the rack must be filed at a certain angle so that they stand strictly vertical. But, in a surface cut at an angle, it is difficult to drill a hole that goes along the axis of the element. To avoid this problem, first drill the holes, then cut at the desired angle. A simple trick that makes the job much easier.

There is one specific method designed specifically for a ladder with a bowstring. They make an underbill: a bar that "sits" on the bowstrings thanks to the groove cut out in the lower part. The racks are attached to the podbalyasennik through and through - with bolts, dowels or self-tapping screws (the worst option). The choice is yours, and then the whole structure is installed on the string. The connection is adhesive, you can use bots, screws, nails for reliability. But they are for additional fixation.

There is another method that is usually used only for this type of stairs: the balusters are fastened with nails or self-tapping screws, decorative strips are installed from the sides, the gaps between the balusters are closed with fixing strips. With this method of fixing, you can also additionally use glue - it will not be superfluous.

A few words about improving reliability

All baluster fasteners - on studs, self-tapping screws, dowels, bolts - loosen over time, a backlash appears. This is an inevitable process. Under load, the railings wobble slightly. At first, the deviation is a fraction of a millimeter, absolutely imperceptible. With use, the deviation increases, the handrail is already noticeably "walking". The softer the wood, the faster the play appears. You have to shoot and redo. In order to delay this moment as much as possible, use any available additional fixation methods.

Most often, glue is used as an additional fixing force. You can use any wood or epoxy resin. There is no point in looking for more expensive ones - these work very well. All the joints are coated with glue. You can even grease screws / nails with glue. For better adhesion, the place where the glue will be applied is cleaned of dust / debris, rubbed to remove grease.

Installation of metal balusters

Installation of metal balusters is easier: there are special clamps - thrust bearings, which are screwed into the steps or to the side of the stairs. The baluster itself, the stand, the post are then attached to the installed elements. All that is needed is to select elements of a suitable shape / size.

There is one point: most of the fasteners offer to fix the balusters in them using clamping screws. So, the screws are not very reliable, such a connection quickly begins to "play". They, of course, can be tightened a couple of times, but welding is much safer. If the thickness of the metal allows - from 1 mm or more - it is better to use welding.

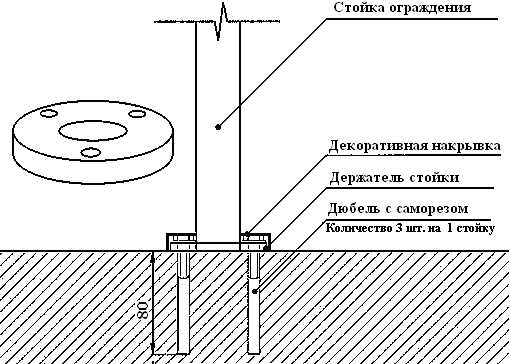

We attach to the step

The marking of the places for installing metal balusters is as described above. First, we choose one rack to stand on a step or two, then distribute them so that all distances are the same. Heel pads are installed at the designated places. They usually "sit" on 3-4 fasteners. Self-tapping screws are used if the steps are wooden or dowels are concrete or brick steps.

Metal balusters / racks are inserted into the installed thrust bearings, set strictly vertically, welded. It is better to "grab" from four sides - to exclude the possibility of deviation in any direction. This completes the installation of metal balusters (stainless, nickel-plated, chrome-plated steel). Then you just need to install a handrail, which is also not particularly difficult.

Something like this looks like a standard fastener for installing metal balusters for prefabricated railings

If the wall thickness of the tube of prefabricated metal railings is too small for welding, it is not possible to select the appropriate welding mode, you have to fix the pipes to the heel pads with bolts. We do not recommend clamping. This kind of connection gets loose really quickly. You can drill through holes in the pipes, screw bolts of a suitable diameter into them.

Another option for installing balusters from a bar: weld a hairpin to the bottom, screw it into a step.If desired, a nut can be glued into the hole in the step.

Side (end) fastening of balusters and pillars

Fastening the racks to the steps is the traditional method of installation, but there is another way: fasten to the sidewall. Similarly, you can fix any type of railings: wood, metal, glass. For metal and glass, special fasteners are required - clamps, which are attached to the wall, and themselves have a groove and a system for fixing the racks for the stairs. Wooden posts and balusters are fastened through with a zip bolt or pins / screws, hiding the heads under decorative covers.

- Bracket for lateral mounting of a round support post

- Option for prefabricated metal railings

- When lateral fastening of wooden poles to the stairs, the attachment point can be made as a decoration

- The options are different

- Bracket for fixing round ladder posts to the wall

With end fastening of the racks, stairs are usually made with support pillars installed at a certain distance. A filling is installed between the pillars, which is not associated with the base of the stairs, but only with the support posts. Of course, this is not a rule, but most of the stairs with a similar fastening of balusters and support pillars have this look.

The side attachment method is suitable for any ladder with a closed sidewall. Naturally, the sidewall material must have sufficient bearing capacity. The very method of fastening the ladder struts looks somewhat unusual, which adds decorativeness.

- Side attachment is also possible for steps, but not for all types of stairs

- Forged stair rail with side attachment. The fasteners are made immediately "built-in" into the railings

- Another option for forged railings with side attachment to the stairs

- For those who do not suffer from claustrophobia

- You can attach each stand separately

- Unconventional approach

- Side fastening of glass railings - on special clips

- Prefabricated metal ladder with side uprights to the ladder

Usually, two clamps are used for each post, which are located at a distance of 5-10 cm from one another. When marking, you can also use a tensioned thread, a guide or a laser level. The location is chosen mainly in the center of one of the steps. The number of racks is chosen based on the bearing capacity of the base to which they will be screwed. For wood, the normal step is 50-80 cm, for brick, concrete, etc. long distances can be done.