Installing handrails on stairs, walls - mounting options

The assembly of the stair railing is completed by installing the railing. What can be the fastening of the handrail, how to do it correctly, reliably and imperceptibly not everyone knows. Some common methods for wooden and metal stairs are described here.

The content of the article

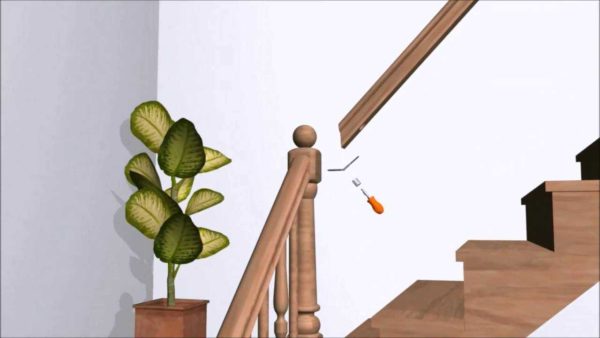

Fastening the handrail to the balusters of a wooden staircase

It turns out that wooden railings are the most difficult to make. This is because there are many different ways and techniques of working with wood and there are almost no ready-made solutions, since each staircase turns out to be individual, has its own characteristics. For example, fastening the handrail to balusters can be done using dowels, screws, nails, bolts, special ties (zipbolt), glue. In addition, the railings can be "pushed" directly onto the balusters and posts, but there are options with an additional bar, which is sometimes called a "sub-rail". And all these are the "correct" ways of connecting the racks with the handrail. Here's how you can do this and we will talk in this section.

First of all, cut off a piece of the handrail to the desired length. It can be a fragment from one support pillar to another, a piece for the entire span - from the upper / lower pillar to the moment of turning. It all depends on the design of the stairs. If there are joints between two fragments, they must be well processed, having achieved a perfect match. Then the handrails for the street must be covered with protective impregnations, and then painted / varnished. After that, you can already deal with the issues of attaching the handrail to the stairs.

How to trim balusters for handrail installation

After installing the balusters on the steps, their tops are at different levels, and you cannot install a handrail on them without cutting - it does not lie like that. To mount the support rail on the ladder, it is necessary to cut the upper part of the racks at a certain angle. This angle is determined by the steepness of the flight of stairs and does not need to be calculated. It is determined "on the spot".

To find the angle of the baluster undercut, you can use a thread stretched between the support posts. We tie it at the same distance from the tops of the pillars, which are installed at the top and bottom of the span. Where, according to the idea, the lower border of the handrail will pass. Using this stretched thread, draw a line with a pencil to the tops of the racks. Instead of a thread, you can use laser level and you can also temporarily fix the guide (any flat bar).

We got the line, now we cut off the tops of the posts on the stairs strictly along it. Then you can continue attaching the handrail to balusters or posts.

Let me give you one piece of advice: if you need to drill holes for dowels or studs for the subsequent installation of the railing, it is better to do this before trimming. This makes it easier to find the center, it is easier to hold the drill perpendicularly. After the holes are made, you can take the saw / jigsaw and file along the marked markings of the rack.

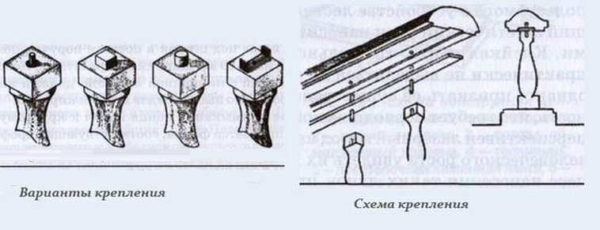

Connecting balusters and railings with dowels and threaded rods

Consider one of the traditional methods: fastening the handrail with dowels or pins.For this type of connection, you need to make matching holes in the handrail and the posts of the stair railings. If you put studs, you can screw them into the holes made in the center of the balusters, set the handrail in the position in which it should stand. After checking that everything is correct, walk along the handrail, banging your fist over each baluster. The protruding ends of the metal studs will leave a mark on the back of the handrail. Remove the handrail, mark the resulting marks for reliability with a marker / pencil. The holes can now be drilled. With this method of marking the handrail, there are almost no problems with its "landing" in place.

The second option for marking the handrail for the installation of pins and dowels is carried out before they are installed in the balusters. First of all, we put the cut piece of the handrail in place. Then, with a pencil, mark on both sides where the balusters are installed. Before making marks, check the distance between adjacent posts below and near the handrail. If they match, everything is fine, we put marks, if not, we correct the position of the stand and only then we put marks. Adjustments are needed to ensure that all ladder supports are vertical. This will make the railing more secure.

After all the balusters are marked, remove the handrail. On the reverse side there are marks made by us. Draw diagonals between the pairs of lines that outline the baluster. We put a mark in the place of their intersection. Here it will be necessary to drill a hole for a dowel or hairpin. In the same way, we find the centers on the balusters (if there are no holes in them yet). As you understand, with this method of marking the handrail for the handrail, problems can arise - the slightest inaccuracy and the handrail does not fit with the rack. The good news is that the baluster can be moved within certain limits. Until it is fixed, there is a certain freedom, and it can be used when installing the railing. Just move it so that the spike goes into the groove. In general, you know the fastening of the handrail to the dowels.

To make the installation of the railing more reliable, in addition to dowels or pins, you can coat the connection with glue. This will make the structure more rigid and extend the service life without backlash.

With an auxiliary bar - under the siren

Agree that the simplest installation of a handrail on balusters is through screws or nails. What stops you from such a decision? An overly unsightly result in the form of fastener hats spoiling the whole look. But there is a very similar way to guarantee the good appearance of the stair railings. An auxiliary bar is used, which is also called a sub-sill.

The auxiliary strip is cut with a spike that, in a mirror image, repeats the shape of the groove in the lower part of the handrail. The straight side is placed on the sawn balusters, fastened through and through (screws or nails - your choice). Remember to check the distances between adjacent posts.

Then the upper part of the sub-runner is coated with glue and the handrail is "planted". All. No traces of fasteners on the face of the handrail, everything is in place. The only thing to consider is that the height of the handrail turns out to be slightly larger, since more thickness is added to the auxiliary strip (if the strip is wooden, it is at least 2-3 cm).

There is another way of attaching the handrail to the sub-runner - with small nails or screws from below, at an angle. But with this fastening, the caps are visible. They can be masked in one of the known ways, but it takes a long time ...

As you know, over time, wooden railings "loosen up" due to the fact that under load they stagger, wood fibers are crushed, a backlash appears.To make the possibility of backlash less, when fastening through the bar, you can use two or more screws / nails for each baluster. This will make the handrail more secure.

Also, for greater reliability, the bar can be made of metal. Any thin metal will do. Whether steel or aluminum. But then it will be necessary to either cut the bar to the size of the recess in the handrail, or modify the groove so that the handrail fits well on the structure. And one more thing: if the bar is metal, you need to find a universal glue that adheres well to wood and metal. This stair handrail mount is simple, beautiful, reliable. Suitable for those who decided to make a handrail for a staircase for the first time.

On thorns of different shapes

It is possible to install a handrail made of wood without metal fasteners: on spikes and glue. The spikes are cut at the top of the balusters. Under them, grooves of the same shape are formed in the handrail. Any shape of the tenon / groove. It can be a rhombus, rectangle, circle, oval. The main thing is that the tongue and groove match perfectly. This can be achieved by making a template and repeating it exactly on each fragment. The minimum cleat height is 2.5 cm, so the height of the handrail cannot be less than 4.5 cm.

After a thorn is formed on each baluster, and a groove is cut in the corresponding place on the handrail, they are glued. When installing the handrail on the balusters, you can move them slightly to align the holes. You can use the installed handrail after the glue dries (there is time on the package).

Handrail and support post connection

Often, the handrail does not go over the post, but connects to its side edge. How, in this case, do the handrail and post? The easiest way is to fix it on screws or nails driven in at an angle after cutting the handrail at the desired angle. The disadvantages are obvious - the fastener caps are visible.

Another way is to use a zip bolt, which consists of two movably connected studs and a gearbox. For its installation, a technological hole is required, which is made at the bottom of the handrail. It is then closed with a plug to match the wood and it becomes almost invisible. The second plus of such a connection: it can be tightened (to a certain extent), if suddenly a backlash appears.

- This is what a zipbolt looks like for joining parts at an angle

- The principle of installing a zipbolt for connecting the handrail and the stair pole

Even under the zipbolt, you need to drill holes for the studs - one each in the post and in the handrail. The technological hole is usually made in the handrail. It is positioned so that it is possible to tighten the thread under the gearbox (the length of this thread is usually 10 mm). The depth of the holes is by the size of the studs (from the junction to the edge), the diameter is 1-2 mm less than the diameter of the stud.

Studs are installed in the drilled holes. It is screwed into the post, it is simply inserted into the handrail. A gearbox is installed in the prepared technological hole, in which there is a hole for a hex key (6 mm). We expand the gearbox so that it is convenient to use the key. Turning the key, tighten the thread, pulling the handrail to the post. This should be done after the balusters are connected to the handrail. By attaching the handrail to the post, you can assume that the handrail is installed.

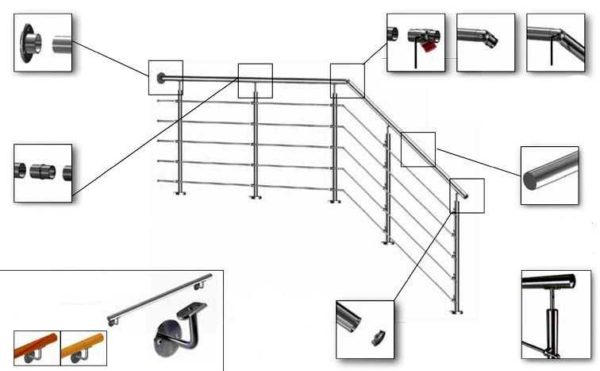

Installation of a handrail on prefabricated metal fences

In general, the assembly of handrails from metal (stainless, nickel-plated, chrome-plated) pipes is similar to a constructor. There are pipes of different diameters, decorative elements for them, and a whole range of different fasteners. The railing is assembled from all these details. That is why they are called "teams". When deciding how to attach handrails to metal balusters / poles / posts, your task is to choose those elements that are best suited to your task or you like more than others.

To connect metal posts / balusters with a handrail, there are special tips that are attached to a round / square / rectangular pipe on one side, and to a handrail on the other. There are different types of models.You just need to find the most suitable one, choose the one you need: by the size of the posts and the type of handrail.

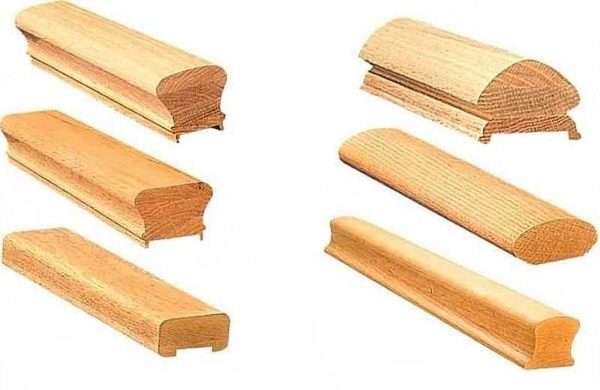

In metal prefabricated fences, handrails can be different:

- round metal pipe;

- profile (rectangular, square) metal pipe;

- plastic handrail (round, oval or original shape);

- wooden of any profile.

Under each of these handrails there is a mount, and usually more than one. Choose what you like. Fixing them is simple: clamping bolts. But, for reliability, and if the thickness of the metal allows, all joints of two metal parts can be welded. Welding thin metal - the thing is not easy, but if you know how to handle a welding machine, nothing is impossible. It takes more time to weld, but the handrail attachment will be very reliable.

When connecting elements of a metal staircase with plastic or wood, use the fasteners recommended by manufacturers. Additionally, you can glue the joints with universal glue. However, in the case of stainless steel, there is no particular sense in this: the adhesion will be very low. But still…

Attaching the handrail to a welded or forged stair rail

A wooden handrail is usually placed on a forged or welded fence. In its lower part, a cut is made according to the dimensions of the upper lintel of the finished fence. The depth of the handrail is about 2 cm. It is possible more or less - it depends on the desire. The railing is connected to the handrail with self-tapping screws, which are twisted through the holes in the upper lintel. It is important to choose the length of the fastener: it should be slightly (at least 5 mm) less than the height of the handrail so that the screw does not stick out on the surface.

In this case, installing the handrail on the stairs is simple:

- In the upper jumper, holes are made that are slightly larger than the diameter of the selected self-tapping screws, but less than the diameter of the cap. Step - from 50 cm to 1 meter.

- The handrails are cut where necessary, the joints are adjusted to an ideal condition.

- The handrails are installed in place, having achieved a perfect coincidence of the joints, fix them in this position with clamps.

- Fasteners are installed through the holes in the lintel.

- Remove the clamps. The railing is now complete and the railing is ready for use.

It is also possible to glue a wooden handrail to a welded or forged metal handrail. When choosing an adhesive, you need to look so that it can bond wood and metal. For outdoor stairs (on porch, for example), one must also pay attention to the operating temperature range. Otherwise, there are no difficulties:

- spread glue according to the instructions;

- press the parts, fix with clamps;

- leave until the glue dries;

- remove the clamps.

Both methods can be used to securely attach the handrail to a steel ladder. One does not interfere with the other.

Methods for attaching the handrail of the stairs to the wall

A handrail is attached to the wall if the width of the steps on the stairs exceeds 120 cm. The second handrail is made of the same material and the same shape as on the balusters, but is attached to the wall.

To mount the handrail on the wall, there are a number of fasteners - brackets - for different profiles (round, oval, curly). On one side of the fastener there is a round or square fragment with a flat surface and holes made in it. We install this part on the wall. We select fasteners depending on the material from which the wall is made. We use self-tapping screws if the walls are wooden, dowels for walls made of concrete and bricks, and special dowels for fixing to lightweight concrete.

We select the number and size of fasteners for installing a stair rail on a wall based on reliability considerations.Manufacturers make at least four holes on each bracket. Here are four screws / dowels / nails for each and put. When choosing a length, it is better to proceed from considerations "the longer the better." Still, the wall handrail can carry a heavy load, so it's better to play it safe than to fly down ...

The second part for wall mounting of stair railings - where the rail itself is attached - may be different. For round pipes there can be a ring of a certain diameter, for rectangular or square handrails there is usually a flat platform. There are also holes in this part of the stair rail bracket so you can fix the rail. And in this case, the number of fasteners should be equal to the number of holes (for the same reasons).

There are brackets for wall mounting of handrails with different angles. They are chosen based on their own ideas about the convenience and the planned height of the support. There are also telescopic models that allow you to set the distance to the wall and / or the angle of inclination. There are also end wall brackets, which, simultaneously with fixing the edges of the handrail, also decorate them.

The number of brackets depends on the length of the handrail. Usually one element is placed at the edges, and between them the calculated number, with a distance of 40-60 cm. The lower the load-bearing capacity of the wall, the more often we install wall holders for the railing.