Chimney for a gas boiler: device, design, diameter

When installing gas boilers, the standards must be strictly observed. Also, strictly according to the standards, it is necessary to install a chimney for a gas boiler. Although the temperature of the flue gases is low and has no color, it will cause no less harm, but a lot - because leaks are poorly determined. Therefore, you must immediately do everything diligently, paying special attention to the tightness of the joints.

The content of the article

Chimney requirements for gas boilers

All requirements for smoke channels are spelled out in regulatory documents - SNiP 2.04.05-91 and DBN V.2.5-20-2001. Their implementation is mandatory. To summarize, everything can be reduced to several points:

- The cross section (diameter) of the chimney cannot be less than the outlet on the boiler. That is, if the outlet of the gas boiler is 150 mm, then the chimney must have an internal section of at least 150 mm. More is possible, less is not. In extreme cases, they can close their eyes to a difference of several millimeters.

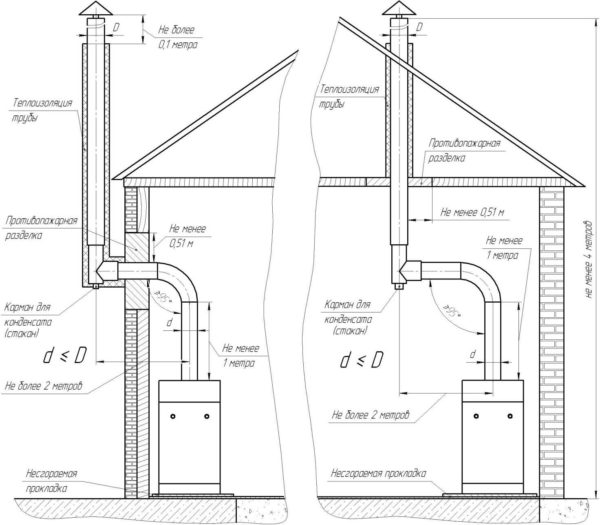

- The chimney should run vertically upwards. It is advisable to develop a structure so that there are no sloping sections. In extreme cases, a slope of 30 ° is allowed. The length of the inclined section is no more than the height of the room.

- Along the entire length of the chimney, it should not have curvatures and narrowings.

- The chimney must be made of gas-tight materials.

- Carefully insulate the joints - they must be airtight (they must not allow gaseous substances and must not allow moisture to pass through).

- Since the flue gases at the outlet of modern gas boilers have a low temperature, condensation is likely to form. Therefore, when installing a chimney, a condensate trap must be provided in its lower part. It is a removable glass made from chemical resistant materials. The best option is a stainless steel condensate trap, the cheaper one is plastic. Galvanized steel is a cheaper option but degrades quickly.

- The chimney for a gas boiler in a private house must be of such a height that will provide good draft. To do this, it must rise 50 cm above the ridge of the roof, if displayed in the immediate vicinity of it.

- At the top of the pipe, it is advisable to install a protective visor - an umbrella. It protects the pipe from clogging and precipitation.

These are the basic requirements. They must be followed. They provide the required degree of security. After all, the fact that the exhaust of a gas boiler has no color does not mean that it is harmless. Therefore, all aspects of security must be given maximum attention.

Boiler designs and chimney construction methods

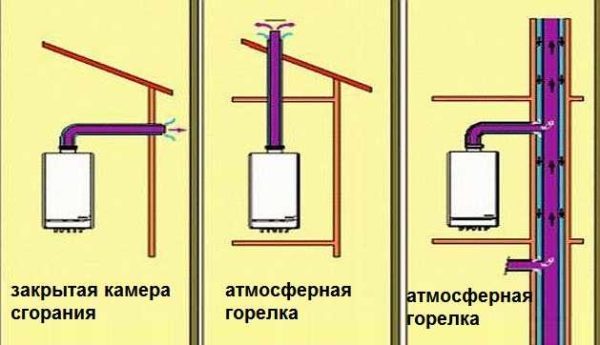

There are two types of burners for gas boilers:

- Open. In them, oxygen for combustion is taken from the room in which the boiler is installed. Therefore, this type of burners or trapping is also called "atmospheric". In such gas boilers, flue gas discharge requires a pipe with outlet to the atmosphere and good draft.

- Closed combustion chambers (turbocharged boilers). They work in tandem with coaxial-type chimneys - from two pipes inserted into each other. Combustion products are removed through one pipe, air enters through the other to maintain combustion. The coaxial pipe is usually led out through the wall to the street. Therefore, they say that such gas boilers do not have a chimney.But, if you wish, you can also bring the chimney into the atmospheric chimney. In this case, a normal thrust is needed (it does not matter when entering a wall, since the movement of gases is provided by a turbine).

It is clear that the choice of the type of chimney primarily depends on the type of combustion chamber. In one case, it should be a coaxial pipe, in the other - a conventional one. But besides this, there are many more nuances in design.

What material

A chimney for a gas boiler in a private house can be made from different materials. The main requirement is resistance to chemically aggressive substances, inability to pass gases. Several materials are traditionally used. Let's talk in more detail about the advantages and disadvantages, assembly features of each of them.

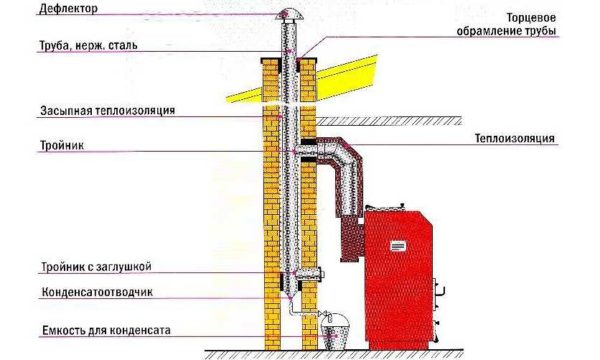

Brick chimney

Today it is no longer the most popular type of chimney. It turns out to be heavy, at high altitudes it requires a foundation. In addition, laying a brick chimney takes a lot of time.

At the same time, this type of chimney has a number of negative qualities. The first is inIts inner walls are not smooth, which contributes to the accumulation of soot, worsens traction. Second - toirpich is hygroscopic. Therefore, condensate flowing down the walls is absorbed, which contributes to rapid destruction.

To solve these problems, a smooth pipe of a suitable diameter is inserted into the brick chimney. This is usually a stainless steel or asbestos pipe. When building such a combined chimney, attention must be paid to the following things:

- The joints of the liner pipe must be sealed. If these are ordinary or stainless steel sandwich pipes, everything happens as standard - we collect the chimney using condensate. If the liner is made of asbestos-cement pipes, you will have to take care of the tightness of the joints. Moreover, covering the joint with cement is not an option. Such a connection is in no way airtight - condensate will be absorbed. We'll have to come up with sealed clamps, use hydrophobic (water-repellent) compounds. Moreover, they must also be chemically resistant. Alternatively, you can consider smearing the joints with heat-resistant sealants with an operating temperature of about 200 ° C.

- In order for the condensate to form as little as possible, it is better to insulate the pipes (even inside the brick casing). To do this, it is advisable to use insulation that is not afraid of getting wet.

- At the bottom of the liner pipe, a condensation trap must be attached. Access to it must be free.

If you make a chimney for a gas boiler according to these rules, then even with abundant condensate it will be easy to deal with it.

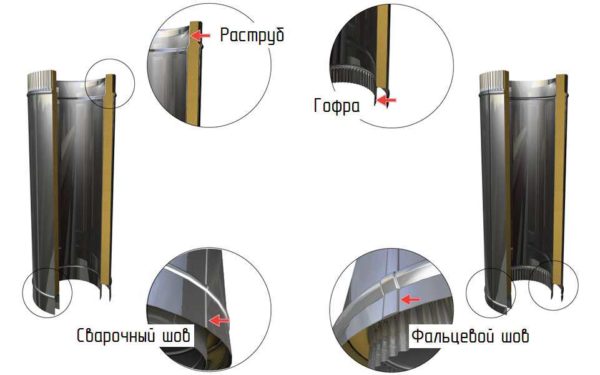

Stainless steel - single wall pipes and sandwich

Modern gas boilers are designed so that the outlet temperature of the flue gases is not very high. Therefore, condensation always forms. With good traction, most of it flies into the pipe, with good insulation, the rest evaporates. So it turns out that liquid is not always present in the condensate trap. But the condensate itself forms during the operation of the gas boiler all the time. Sometime in more, sometime in less. In this regard, the requirements for stainless steel for the chimney are high: it must withstand prolonged contact with corrosive substances. Mainly food grade stainless steel meets these requirements. Yes, it costs a lot, but only it will serve for years.

Now about making a chimney for a gas boiler from a single-wall pipe or from sandwich pipes. In order for condensate to form in minimal quantities, it is advisable that the chimney does not cool down. That is, it must be insulated. And although the sandwich chimney has a gasket made of insulation, it is also better to insulate it with an external gasket (on the street) - it will last longer, the draft will be better. But in this version, less insulation will be required - one layer, while an ordinary pipe may have to be wrapped in two or even three layers.So the costs of arranging a chimney from a single-wall stainless pipe and sandwiches will be comparable. It's just that in the first case, you will have to use more insulation, in the second less.

If we talk about reliability, then sandwich chimneys are more reliable, if only due to the fact that they consist of two layers of metal. By the way, if you insulate the chimney, the outer pipes can be made of galvanized steel - they do not come into contact with condensate, the temperatures are low, and the appearance is unimportant, since everything will be wrapped with insulation.

Ceramic chimneys

Ceramic chimneys are good for everyone: they are durable, reliable, they tolerate contact with aggressive substances well. But they have two significant drawbacks. First, they are expensive. The second - they are heavy, so when installing a high chimney, they require a foundation. And this is an additional cost to the already considerable amount. But the service life of such a chimney is calculated in decades.

Asbestos-cement pipes

It was once the most popular type of material in the construction of chimneys for a gas boiler in a private house. The material is, of course, porous, has rough walls, and its cross-section is imperfect (not round, but rather oval). But this is perhaps the cheapest option.

When using asbestos-cement pipes for the chimney of a gas boiler, you must:

- Make it as straight as possible, trying to make the joints even.

- Seal the joints. As already mentioned, simply covering it up with cement is not an option. A tight connection is required. Several solutions to the problem are the use of hydrophobic additives in the mortar, coating the dried cement mortar with a sealant, and the use of sealed clamps.

- To reduce the amount of condensate, make the pipe high, insulate well.

In general, nothing new, all the same rules as for the materials described above, but a hassle with joints is added. So, as a result, for the price, the chimney from asbestos pipes is practically the same as from stainless steel.

For boilers with an open combustion chamber

For gas boilers with an atmospheric burner, a chimney is required that provides good draft - the removal of combustion products occurs due to the movement of air through the pipe. Therefore, it is made as straight as possible, preferably with smooth walls. There are two versions:

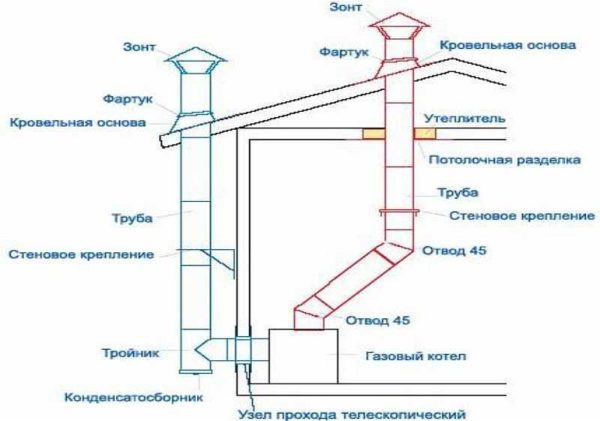

- Route horizontally through the wall, then along the outer wall up to the required height. This option is also called an outdoor chimney.

- Lead the pipe up from the boiler, go through all the ceilings, the roof, and bring it over the roofing material. If necessary, you can take the pipe away from the wall by making two 45 ° elbows. It is better not to make bends at 90 ° with this design.

Which option is better? An external chimney is easier to implement - with an outlet through the wall. It is only important to correctly pass through the wall (observe the fire gap if the walls are flammable). But this option requires good insulation, high-quality fastening to the walls. Even under these conditions, there is usually a lot of condensation. Therefore, the installation of a tee and a condensate trap at the outlet is mandatory.

In the case of the outlet of the chimney through the roof, there are at least two difficult moments - the passage through the ceiling of the first floor and through the roof. In these places, special pass-through nodes are installed. They provide an adequate degree of fire safety.

More about how to run sandwich pipes through a wall or ceiling read here.

Features of the assembly of metal pipes

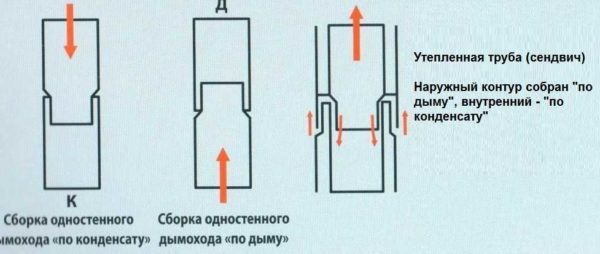

If sandwich pipes or single-walled metal pipes are used, then the external chimney for a gas boiler is collected "by condensate". That is, inserting the upper tube inside the lower one. This is possible due to the presence of a corrugated edge on one side.

When assembling a chimney inside a building, the structure is assembled "by smoke". In this case, it is more important that gases do not enter the room. Therefore, the pipes are turned so that the upper element is put on the already installed one.

There is a third option - to assemble two circuits in different ways: external for smoke, internal for condensation. For such an assembly, it is imperative to use sandwiches, since only they have two circuits. This is the best option, since the protection is complete, but the assembly is complex.

Chimneys in the shaft (box)

To prevent communications from spoiling the interior, they are often "packed" in a mine - a specially built box. Inside there are, as a rule, a chimney (or chimneys, if several devices work), ventilation ducts, there may be risers of water supply, heating, sewerage. In any case, it is better to close the chimney pipe with thermal insulation. If it is still possible not to use the insulation in a heated room, then in the attic (especially if it is cold), insulation should be mandatory. Basalt wool is used with an operating temperature of at least 300 ° C.

Thermal insulation will have a positive effect on the temperature inside the chimneys, which will increase the draft and reduce the amount of condensate. But do not forget that we are talking specifically about gas boilers, and their combustion products have a low temperature.

For closed combustion chambers

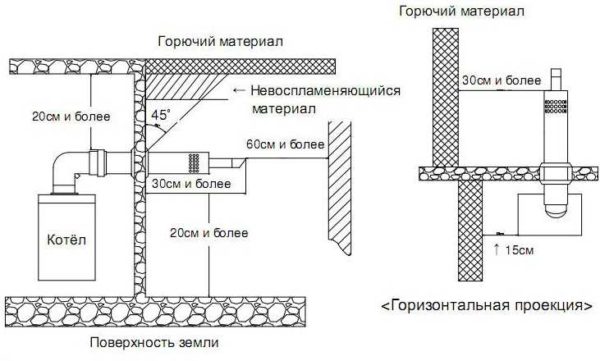

A coaxial chimney looks like a pipe in a pipe. The structure is delivered ready-made, assembled quickly and without problems. You only need to know the diameter of the outlet pipe and the parameters - height, length.

The coaxial chimney device is the simplest. The pipe rises above the boiler and turns 90 °. It should be at least 20 cm from it to the ceiling. Then it is passed through a hole in the wall, from the outside it should end at least 30 cm from the wall.

The height relative to the ground level is also normalized - the exit of the pipe must be at least 20 cm above the ground, and the distance to the nearest wall - from the end of the pipe to the wall must be at least 60 cm.

Dear author, tell me! I want to run the chimney of a gas boiler directly above the boiler, without sandwich bends. Two floors. Is it possible to do without a condensate trap, because I do not want to make a knee under the condensate trap.

Hello! It is best for you to look at the installation recommendations in the boiler manual. There the answer will be for sure.

That's all spelled out specifically! No need to listen to everyone in a row, but you should read it yourself, and do it according to the requirements !!! DBN V.2.5-20-2001. Appendix G. Combustion Products Removal

DBN V.2.5-20-2001 "Gas supply"

Appendix G. Combustion Products Removal

G.1 This appendix provides for the requirements that must be taken into account when designing smoke ducts from gas equipment and household heating and heating-cooking stoves. When designing chimneys from gas-using installations of industrial buildings and boiler rooms, one should be guided by the requirements of technological design standards and SNiP II-35. When converting existing boilers, industrial furnaces and other installations from solid and liquid to gas fuel, a verification calculation of the gas-air path must be performed.

Zh.2 The arrangement of smoke and ventilation ducts must comply with the requirements of SNiP 2.04.05.

Zh.Z The removal of combustion products from household gas appliances, stoves and other household gas equipment, the design of which provides for the removal of combustion products into the chimney, should be provided from each device, unit or stove through a separate chimney. In existing buildings, it is allowed to provide for the connection to one chimney of no more than two water heaters or heating stoves located on the same or different floors of the building, provided that combustion products are introduced into the chimney at different levels, not closer than 0.5 m from one another, or at the same level with a device in the chimney cut to a height of at least 0.5 m.

G.4 Chimneys from gas equipment should be placed in the inner walls of the building or provide additional channels to these walls. In existing buildings, it is allowed to use existing chimneys made of non-combustible materials in the outer walls or provide additional chimneys for them.

G.5 It is allowed to connect a gas water heater, used for hot water supply, or other gas appliance that does not work continuously, to the chimney of a heating stove of intermittent operation, with a sufficient chimney cross section, which should be determined by the calculation of the device. The connection of the flue pipe of the gas appliance to the chimney turns of the heating stove is not allowed.

G.6 The cross-sectional area of the chimney should not be less than the cross-sectional area of the branch pipe of the gas appliance connected to the chimney. When connecting two appliances, stoves, etc. to the chimney. the cross-section of the chimney should be determined taking into account their simultaneous operation. The design dimensions of the chimneys should be determined by calculation. Non-household gas appliances (restaurant stoves, cooking kettles, etc.) may be connected to both separate and common chimneys. It is allowed to provide for connecting flue pipes common to several units. The introduction of combustion products into a common chimney for several devices should be provided at different levels or at the same level with the diffusion device according to Zh.Z. The cross-sectional area of chimneys and connecting pipes should be determined by calculation, based on the condition of the simultaneous operation of all devices connected to the chimney.

Zh.7 Chimneys should be made of frost-resistant bricks (Mrz 125), clay bricks, heat-resistant concrete for multi-storey buildings and asbestos-cement pipes for single-storey buildings. It is allowed to discharge the combustion products through steel chimneys. Flue duct designs can also be factory-made, supplied with gas equipment. When installing asbestos-cement and steel pipes outside the building or when passing through the attic of the building, they must be thermally insulated to prevent condensation. The design of the flue ducts in the outer walls and ducts attached to these walls must also ensure that the gases leaving them are above the dew point. It is forbidden to make channels from slag concrete and other loose or porous materials.

G.8 Chimneys should be vertical, without ledges. The slope of chimneys from the vertical up to 30 ° with a deviation to the side up to 1 m is allowed, provided that the cross-sectional area of the inclined sections of the chimney is not less than the cross-section of the vertical sections. For the removal of combustion products from restaurant stoves and other non-household gas appliances, it is allowed to provide horizontal sections of chimneys with a total length of no more than 10 m. It is allowed to pass chimneys through ceilings, provided that the fire safety of combustible ceiling structures is ensured.

G.9 Connection of gas equipment to chimneys should be provided with connecting pipes made of roofing or galvanized steel with a thickness of at least 1.0 mm, flexible metal corrugated pipes or unified elements supplied with the equipment.The connecting flue pipe connecting the gas appliance to the chimney must have a vertical section. The length of the vertical section of the connecting pipe, counting from the bottom of the smoke outlet of the gas appliance to the axis of the horizontal section of the pipe, must be at least 0.5 m.In rooms up to 2.7 m high, for devices with draft stabilizers, it is allowed to reduce the length of the vertical section to 0.25 m, without draft stabilizers up to 0.15 m. The total length of horizontal sections of connecting pipes in new houses should be no more than 3 m, in existing houses - no more than 6 m. The slope of the pipe should be at least 0.01 towards the gas appliance. On chimneys, it is allowed to provide no more than three turns with a radius of curvature not less than the diameter of the pipe. Below the place where the chimney is connected from the device to the chimney, a “pocket” device should be provided with a cross-section of at least the chimney cross-section and a depth of at least 25 cm, with a hatch for cleaning. Flue pipes laid through unheated rooms must be covered with insulation if necessary. The laying of smoke pipes from appliances and stoves through living rooms is not allowed.

G.10 The distance from the connecting pipe to the ceiling or wall made of non-combustible materials is taken at least 5 cm, and from combustible and hardly combustible materials - at least 25 cm. It is allowed to reduce the distance from 25 to 10 cm, provided that combustible and hardly combustible structures are protected by an asbestos sheet with a thickness of at least 3 mm. The thermal insulation should protrude 15 cm beyond the dimensions of the connecting pipe on each side.

G.11 Suspension and fastening of connecting pipes must exclude the possibility of their bending. The links of the connecting pipes must fit tightly, without gaps, into one another along the course of the flue gases by at least half the pipe diameter. The connecting pipe must be tightly connected to the flue duct. Its end should not protrude beyond the channel wall, for which limiting devices (washer or corrugation) are used.

G.12 Connecting pipes of restaurant stoves and cooking kettles should be covered with thermal insulation. The connecting pipes made of black sheet steel must be painted with a fire-resistant varnish.

G.13 When connecting devices with draft stabilizers to the chimney, installation of dampers is not allowed. When connecting several devices to a common chimney: restaurant stoves, boilers and other gas appliances that do not have draft stabilizers, gates (dampers) with an opening with a diameter of at least 15 mm must be provided on the chimneys from the devices.

Zh.14 In the dampers installed on chimneys from boilers, holes with a diameter of at least 50 mm must be provided.

G.15 Chimneys from gas appliances in buildings should be removed:

above the boundary of the wind support zone, but not less than 0.5 m above the roof ridge when they are located (counting horizontally) no further than 1.5 m from the roof ridge;

level with the roof ridge, if they are at a distance of up to 3 m from the roof ridge;

not lower than a straight line drawn from the ridge down at an angle of 10 ° to the horizon, when the pipes are located at a distance of more than 3 m from the roof ridge.

The zone of the chimney wind support is the space below the line drawn at an angle of 45 ° to the horizon from the highest points near the structures and trees located.

In all cases, the height of the pipe above the adjacent part of the roof must be at least 0.5 m, and for houses with a combined roof (flat roof) - at least 2.0 m.

The installation of umbrellas and other nozzles on chimneys is not allowed.

G.16 Chimneys in the walls are allowed to be performed together with ventilation ducts. At the same time, they must be divided along the entire height by sealed partitions made of wall material, at least 120 mm thick. The height of the exhaust ventilation ducts located next to the chimneys should be taken equal to the height of the chimneys.

G.17 The removal of combustion products from gasified installations of industrial enterprises, boiler houses, public utilities is allowed to be provided through steel chimneys.

G.18 Discharge of combustion products into the atmosphere through the outer wall of the gasified room without a vertical channel from heating gas equipment with a sealed combustion chamber is allowed.

G.19 It is allowed to discharge combustion products into the atmosphere through the roof of the building into a vertical smoke channel.

Zh.20 The length of the horizontal section of the smoke channel from heating equipment with a sealed combustion chamber when exiting through the outer wall is taken no more than 3 m.

G.21 It is prohibited to provide for the exit of the smoke channel through the outer wall:

in entrances (arches), covered walkways;

in closed balconies, loggias, bay windows;

in buildings that are historical or architectural monuments, without the permission of the department under whose protection they are;

through the walls of the facades of buildings overlooking squares and streets that have historical, architectural and urban planning value, as well as those located in the immediate vicinity of the sites of preschool institutions, schools and healthcare institutions;

in buildings where the installation of gas appliances is prohibited by the requirements of DBN V.2.2-9, SNiP 2.08.01, SNiP 2.04.05.

G.22 Openings of smoke ducts on the outer wall of a building when exhausting combustion products from heating equipment through an outer wall without a vertical duct should be placed in accordance with the manufacturer's instructions for installing gas equipment, but at distances not less than those indicated in Table G .one.

Table G.1

Place of withdrawal The smallest distances, m

to a device with natural draft to a device with a fan

Heat load Heat load

up to 7.5 kW 7.5 - 30 kW up to 12 kW 12 - 30 kW

Below the air inlet

2,5

2,5

2,5

2,5

Near the ventilation hole

0,6

1,5

0,3

0,6

Under window

0,25

—

—

—

Next to the window

0,25

0,5

0,25

0,5

Over the air vent, window

0,25

0,25

0,25

0,25

Above ground level, walkable surface

0,5

2,2

2,2

2,2

Under parts of the building protruding more than 0.4 m

2,0

3,0

1,5

3,0

Under building parts protruding less than 0.4 m

0,3

1,5

0,3

0,3

Under another bend

2,5

2,5

2,5

2,5

Next to another branch

1,5

1,5

1,5

1,5!

Dear author, tell me. Is the length of the chimney regulated with a horizontal device of the coaxial chimney

The maximum length of the coaxial chimney depends on the type, type of boiler (see the passport in the installation recommendations).

Hello! Where did the information about chimneys of boilers with a closed combustion chamber come from: "the distance to the nearest wall - from the end of the pipe to the wall must be at least 60 cm"?

Hello!

Please tell me where to buy a chimney for a Ukrainian gas boiler, it is displayed in the wall, without a draft pipe.

Dear author, good afternoon. I am very worried about the arrangement of the neighbor's chimney, which is 2 meters from my house. Or rather, half a brick pipe, two of some gray ones stick out of it, and this whole structure reaches only the middle of the height of his house and almost close to a wooden house made of timber. This half of the destroyed brick chimney remained from his old house, which he added one more floor, and the chimney left the old one. In doing so, he uses a gas boiler. I tried to tell him about my fears, but he doesn’t care in life and it doesn’t bother him. Says it is not dangerous. Tell me please, how can this threaten me, or is it really not dangerous?

If your neighbor has a boiler with high efficiency, then the temperature of the exhaust gases will be low.For example, I have an Italian boiler "Ariston" (with a closed combustion chamber) installed, so the sealing ring of the coaxial chimney is made of rubber, and the head is made of plastic.

I don't know for sure, but most likely he has some kind of the simplest and cheapest boiler. Could his wooden house catch fire in some way because of this chimney? And most likely the gas company is not aware of these alterations. I am very worried about this. Thank you so much!

The exhaust from a gas boiler is not as dangerous as from a solid fuel boiler. If the boiler is working properly, there are no sparks, so there is no particular danger for a wooden house.

And you got the right answer. Everything really depends on the temperature of the exhaust gases, and this, in turn, on the type of boiler. Apparently, your neighbor's draft is normal, otherwise the boiler would simply not work. To make you calmer, the temperature of the gases can be indirectly estimated from the condition of the wall next to the pipe (after all, it passes close to the wall, right?). If there are no changes in color, there are probably no problems either.

You know, there are small changes on the timber, a kind of dark halo and one of the thin gray pipes sticking out of the brick as if charred. But maybe it's some kind of soot, I don't know. I understand that it is difficult for you to make a diagnosis without seeing all this, but I really am very worried about this issue. Maybe I should drip on it in the gas service, so to speak? It makes sense, do you think, or not everything is so scary. I just have no one to consult with. Thank you so much!

Good day. In my house, they installed an AOGV with an outlet diameter of 100 mm. Accordingly, the chimney was made for this diameter. When registering with a fire company, I was told that the diameter of the chimney should be 150 mm according to current standards. What should I do? Do they make a new chimney or am I just bribed for money?

150 mm and that has been for a long time. According to these standards, AOGV was installed for me at the beginning of 2000, then in 2008 in a new house, then somewhere in 2014 in a bathhouse. I have not seen pipes of 100 mm from anyone.