How to expel air from the heating system

Properly working heating in winter is a vital necessity. You cannot survive in our climate without heating. But periodically the previously normally operating system begins to malfunction - the radiators do not heat up or do not heat well, there is extraneous noise (gurgling). All these are signs that air has appeared in the heating system. The situation is far from rare, but it brings discomfort.

The content of the article

What threatens the air in the heating system

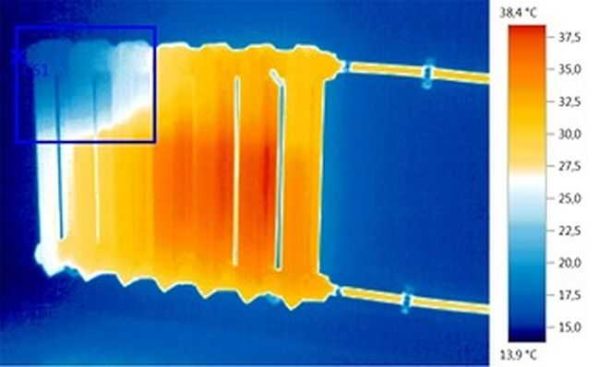

Everyone, probably, more than once met with the fact that the heating is on, and some radiator or a whole group heats up badly or even stands cold. The reason for this is the air in the heating system. It usually accumulates at the highest point, displacing the coolant from this place. If it accumulates enough, the circulation of the coolant may stop altogether. Then they say that an air lock has formed in the heating system. Professionals in this case say that the system is airborne.

To resume normal heating operation, the accumulated air must be removed. There are two options for this. The first is more commonly used in district heating systems. On the extreme radiators, taps are installed in the branch. They are called drains. This is a conventional valve. After filling the system with a coolant, it is opened, kept open until an even stream of water without air bubbles comes out (then the water pours in jerks). If we talk about multi-storey buildings, then during the start-up of the system, the air outlets on the risers must first open, and the remains can already be taken out to apartments.

The air in the heating radiator interferes with the normal circulation of the coolant. This leads to the fact that the battery does not heat well.

In private systems or after replacing radiators in apartments, not ordinary taps, but special air valves are installed to bleed air. They are manual and automatic. They are placed in the upper free manifold on each radiator (preferably) and / or at the highest point of the system.

What else threatens the air in the heating system? It promotes faster destruction of heating system components. Although polymers are used more and more today, metal parts are still plentiful. The presence of oxygen promotes the activation of oxidation (ferrous metal rusts).

Reasons for the appearance

Air in the heating system can appear for various reasons. If this is a one-time problem, you can simply delete it and not search for the source. If airing is required several times per season, you will have to look for the reason. The most common ones are:

- Repair, modernization of the heating system. During repair work, air almost always enters the pipeline. It `s naturally.

- Filling the system with a coolant. If you pour water into the system slowly, it carries a little air with it, simultaneously displacing the one that is in the pipes and radiators. This process is also understandable, and does not require special measures.

- Depressurization of joints and welds. This defect requires elimination, since airing will occur constantly. In individual heating systems, this phenomenon (leaking connections) is also accompanied by a drop in pressure. And this is another reason to look for faults. The most likely place is the joints of pipes and radiators. They may be leaking. It is very difficult to look for them, since they do not always appear outwardly. If you notice that some of the compounds "breaks in" everything is much easier - you eliminate the drops.But if everything is outwardly normal, and air accumulates all the time, you have to coat the joints and seams with soapy foam and observe whether new bubbles appear. After finding each "suspicious" connection, they are tightened, coated with sealant or repackaged (the method depends on the type of connections).

- If the heating system already has air vents (air vent valves) and plugs begin to appear in it, it is necessary to check the serviceability of the valves, as well as the tightness of the connections.

- The appearance of air in the heating system may be associated with a ruptured membrane expansion tank... In this case, the membrane will have to be changed, and for this it is necessary to stop the entire system.

These are the most common places and ways in which air gets into radiators and batteries. It is necessary to expel it from there from time to time, but with the autumn start-up of heating it is necessary.

Installing air relief valves

To remove air from the heating, air vents are installed on the radiators - manual and automatic air valves. They are called differently: a vent, an air vent, a bleed or air valve, an air vent, etc. The essence does not change from this.

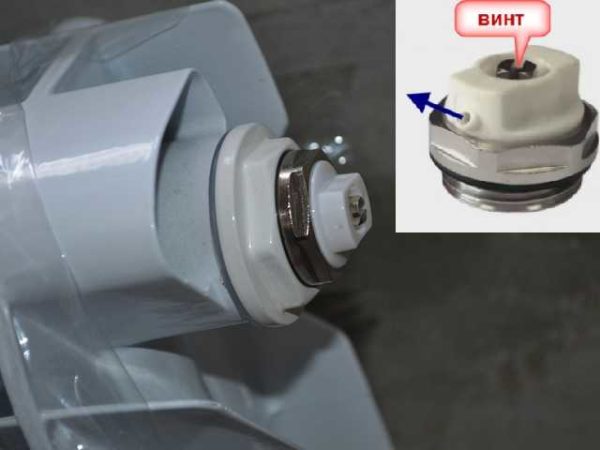

Mayevsky air valve

This is a small device for manually bleeding air from heating radiators. It is installed in the upper free radiator manifold. There are different diameters for different sections of the collector.

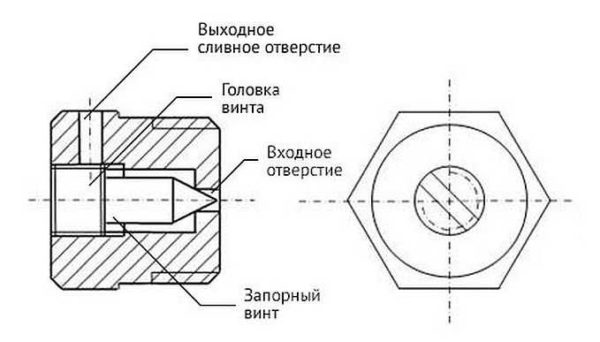

It is a metal disc with a conical through hole. This hole is closed with a tapered screw. By unscrewing the screw a few turns, we allow air to escape from the radiator.

To facilitate air outlet, an additional hole is made perpendicular to the main channel. Through it, in fact, the air comes out. While airing with a Mayevsky crane, direct this hole up. After that, you can unscrew the screw. Unscrew a few turns, do not twist too much. After the hissing stops, return the screw to its original position, go to the next radiator.

When starting up the system, it may be necessary to bypass all the air collectors several times - until the air stops coming out altogether. After that, the radiators should be heated evenly.

Automatic air relief valve

These small devices are installed both on radiators and at other points in the system. They differ in that they allow you to bleed air in the heating system in automatic mode. To understand the principle of operation, consider the structure of one of the automatic air valves.

The principle of operation of the automatic escapement is as follows:

- In the normal state, the coolant fills the chamber by 70 percent. The float is at the top, presses the stem.

- When air enters the chamber, the coolant is displaced from the body, the float is lowered.

- He presses the projection-flag on the jet, squeezing it out.

- The wrung out orifice opens a small gap, which is enough for the air that has accumulated in the top of the chamber to escape.

- As the water escapes, the air vent body fills with water.

- The float rises, freeing the stem. It returns to its place due to the spring.

Different designs of automatic air valves work according to this principle. They can be straight, angular. They are placed at the highest points of the system and are present in the security group. They can be installed in identified problem areas - where the pipeline has an incorrect slope, due to which air accumulates there.

Instead of manual Mayevsky taps, you can put an automatic drain for radiators. It is only slightly larger in size, but it works in automatic mode.

Salt cleaning

The main trouble with automatic valves for venting air from the heating system is that the air outlet is often overgrown with salt crystals. In this case, either the air does not come out or the valve starts to "cry". In any case, you need to remove and clean it.

So that this can be done without stopping heating, automatic air valves are paired with non-return ones. A check valve is installed first, an air valve is installed on it. If necessary, the automatic air collector for the heating system is simply unscrewed, disassembled (unscrewed the lid), cleaned and reassembled. The device is then ready to bleed air from the heating system again.

How to get rid of an airlock

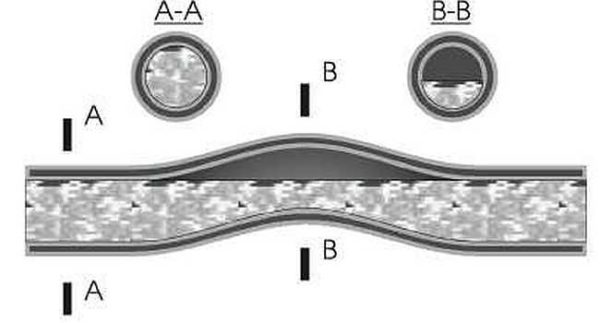

Unfortunately, the airlock is not always in an easily accessible place. With design or installation errors, air can accumulate in the pipes. Bleeding him out of there is very difficult. First, we determine the location of the plug. At the place of the plug, the pipes are cold and a murmur is heard. If there are no obvious signs, they check the pipes by sound - they tap on the pipes. In the place of accumulation of air, the sound will be louder and louder.

The found airlock must be expelled. If we are talking about the heating system of a private house, for this, the temperature and / or pressure is raised. Let's start with the pressure. Open the nearest drain valve (in the direction of travel coolant) and a make-up tap. Water begins to flow into the system, raising the pressure. It forces the plug to move forward. When air hits the vent, it comes out. Stop making up after all the air is gone - the drain valve will stop hissing.

Not all air locks give up so easily. For extra stubborn ones, the temperature and pressure must be raised simultaneously. These parameters are brought to values close to the maximum. You cannot exceed them - it is too dangerous. If after that the plug has not gone away, you can try to open simultaneously the drain valve (to drain the system) and the make-up valve. Maybe this way it will be possible to move the airlock or get rid of it altogether.

If a similar problem occurs constantly in one place - there is an error in the design or layout. In order not to suffer every heating season, a valve for air exhaust is installed in the problem area. A tee can be cut into the line and an air vent can be installed at the free entrance. In this case, the problem will be solved simply.

Hello!

I have a 3-storey house in which there are three circuits for heating, two for underfloor heating, one for the pool, one for ventilation and one for an indirect heating boler. All circuits with circulation pumps. All circuits and return lines have automatic air relief valves. Moreover, only the boler circuit regularly catches air, especially after adjusting the temperature on the radiators. I tried to change the pump on the circuit - it didn't help. What to do?

Most likely, it is in this circuit that there is an air leak somewhere. Try to test all connections with foam.

Let's try, but unlikely. Air is collected in the boler pump when the radiators on other circuits are being adjusted or the pool heating pump is turned on. Maybe this is due to the low temperature at the outlet from the boiler? Now the boiler with a capacity of 87 kW is installed at 57 degrees.This is enough to maintain the temperature in the house at 22 degrees with the radiators almost closed and the temperature in the bolere 48 degrees.

Is your system closed? If so, no adjustment or temperature change can cause air to enter the system. If air appears regularly, then there is a leak somewhere. In principle, this can be not only in the boiler circuit, but is collected there because there is the highest point. And an automatic valve can indeed be installed to remove this air. And the place of the suction will come to light sooner or later.

Maybe you should install a deaerator and / or a separator?

Hello, I have an automatic machine on each radiator, it seems as if there is no air in the system, but the pressure falls on the shelf per day. Can close the spool on the safety valve. This can help ?

Those. at the moment it is guaranteed that the pressure in the system drops precisely because of the automatic air vents? Has the system been put into operation long ago? Is the water filled?

Has been running around on gravy for a week. Naturally there is water, but the monometer does not seem to be air. Everything is dry. Kicked a couple of times with pressure and speed - it does not help. Where does xs go ..

There was something similar. The problem was in the American women - the O-rings had dried out, the water seemed to be slowly etched away, immediately evaporated from the heated batteries and it was impossible to understand the reason. The dried conical rings were replaced with round ones and everything became normal.