Steam heating systems

One of the most important life support systems in our rather unfriendly climate is heating. There are several different ways to make a heating system. And one of them is steam heating. The system is effective, but it is used very rarely - it has too many disadvantages.

The content of the article

What is it and how does it differ from the usual water systems

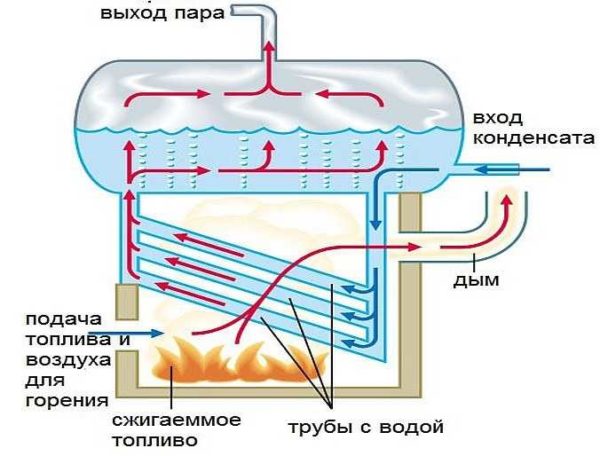

Many people believe that steam and water heating are the same thing. This is a misconception. Steam heating also has batteries and pipes, there is a boiler. But it is not water that moves through the pipes, but water vapor. A completely different boiler is required. Its task is to evaporate water, and not just heat it to a certain temperature, respectively, its power is much higher, as well as the requirements for reliability.

System elements

With steam heating, water vapor moves through the pipeline. Its temperature is from 130 ° C to 200 ° C. These temperatures impose special requirements on the elements of the system. First, the pipes. These are only metal pipes - steel or copper. Moreover, they must be seamless, with a thick wall.

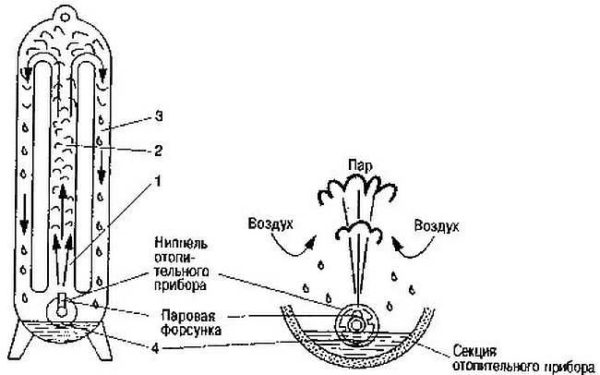

Secondly, the radiators. Only cast iron, registers or finned pipe are suitable. Cast iron under such conditions are less reliable - in a heated state from contact with a cold liquid, they can burst. More reliable in this regard are registers made of pipes, coils or a pipe with ribs attached to it - a convector-type heater. Steel is more tolerant of cold water getting on its hot surface.

Service life and scope

But don't think that a steel steam heating system will last a very long time. Very hot and humid steam circulates in it, and these are ideal conditions for steel corrosion. The elements of the system quickly fail and fail. They usually burst in the most corroded areas. Despite the fact that there is steam under pressure inside with a temperature above erase degrees, the danger is obvious.

Therefore, steam heating is recognized as dangerous and is prohibited for heating public places and apartment buildings. It is also used in some private houses or for heating industrial premises. In production, it is very economical if the steam is a derivative of the technological process. In private houses, steam heating is used mainly in seasonal residences - in summer cottages. This is due to the fact that it normally tolerates freezing - there is little water in the system and it cannot harm, as well as because of its economy at the stage of the device (compared to water systems) and the high speed of heating the premises.

Advantages and disadvantages

Steam heating is not the most popular, but it has both positive and negative points. Moreover, the advantages are quite significant:

- High heating efficiency. The fact is that the steam in the system does not just heat radiators and pipes to a certain temperature. Due to the large temperature difference, it condenses. And upon condensation, 1 liter of steam gives off 2300 kJ of heat. Whereas when the same amount of water is cooled by 50 ° C, only 100 kJ is released. Therefore, a very small number of radiators are required to heat a room. In some cases, a number of pipes are sufficient.

- Since steam heating is a small system, it has little inertia. The room starts to heat up literally a few minutes after the boiler is started.

The disadvantages of steam heating systems are even more impressive:

- High steam temperature leads to heating of all system elements to 100 ° C and above. This leads to the following consequences:

- very active air circulation in the room, which is uncomfortable, and, at times, harmful (if you are allergic to dust);

- the air in the room dries up;

- hot elements of the system are traumatic and they must be closed, and pipes too;

- not all building materials normally tolerate prolonged heating to such temperatures, therefore the choice of finishing materials is very limited (in fact, it is only cement plaster followed by painting with heat-resistant paints).

- Simple steam heating has very limited options for regulating heat transfer. There is only one way to change the temperature - to make several parallel branches and turn them on as needed. The second way is to turn off the boiler when it overheats and turn it on after the room has cooled down. This process is controlled by automation, but this method is far from the most comfortable, since constant temperature fluctuations are observed.

- The system is noisy. Steam makes a lot of noise when moving. In production workshops, this does not really interfere, but in a private house it can be a problem.

As you can see, steam heating is not the best choice, although it is quite inexpensive to equip.

Types of steam heating systems

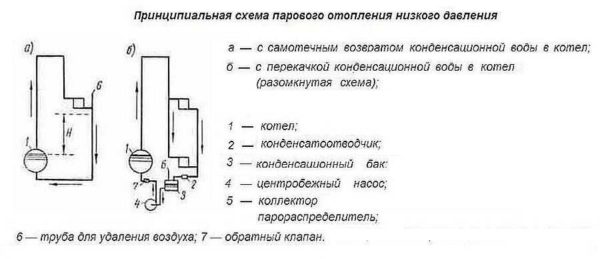

According to the method of the device, steam heating of two types is distinguished: with a closed and an open system. In a closed system, condensate flows into a special intake pipe, which is led to the corresponding inlet of the cat. It is laid with a slight slope so that the condensate flows through the system by gravity.

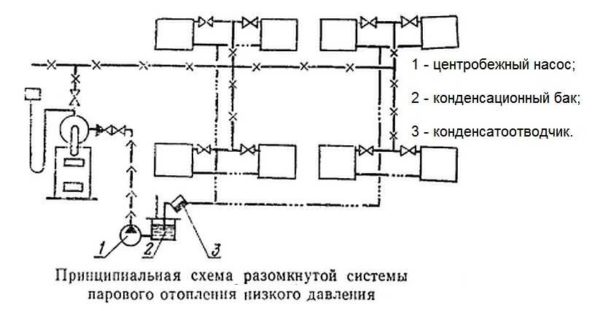

In an open system, condensate is collected in a special container. When it is filled, it is fed into the boiler using a pump. In addition to the different construction of the system, various steam boilers are also used - not all of them can work in closed systems.

In general, there are steam heating systems with pressures close to atmospheric or even lower. Such systems are called vacuum-steam systems. Why is this setup so attractive? The fact that at low pressure the boiling point of water decreases and the system has a more acceptable temperature. But the difficulty in ensuring tightness - air is sucked in all the time through the connections - led to the fact that these schemes are practically not found.

Steam heating with low pressure is more common. Existing steam boilers for domestic use can create a pressure not exceeding 6 atm (at a pressure of more than 7 atm, the use of equipment requires a permit).

Wiring types

By the type of wiring, steam heating is:

- With top wiring (the steam line is under the ceiling, pipes go down from it to the radiators, a condensate line is laid below). This scheme is the easiest to implement, since hot steam moves through some pipes, cooled condensate through others, the system is stable.

- With bottom wiring. The steam line is located at floor level. This scheme is not the best choice, since hot steam moves upward through one pipes, condensate moves downward, which often leads to water hammer and depressurization of the system.

- With intermediate wiring. The steam line is laid just above the radiators - approximately at the level of the window sills. The system has all the benefits of overhead routing, except that hot pipes are within reach and there is a high risk of burns.

When laying, the steam line is made with a slight slope (1-2%) in the direction of the steam movement, and the condensate line - in the direction of the condensate movement.

Boiler selection

Steam boilers can operate on all types of fuel - gas, liquid and solid fuels. In addition to the choice of fuel, it is necessary to correctly select the power of the steam boiler. It is determined depending on the area that needs to be heated:

- up to 200 m2 - 25 kW;

- from 200 m2 to 300 m2 - 30 kW;

- from 300 m2 to 600 m2 - 35-60 kW.

In general, the calculation method is standard - 1 kW of power is taken for 10 square meters. This rule is valid for houses with a ceiling height of 2.5-2.7 m. The following is the choice of a specific model. When buying, look for a quality certificate - the equipment is dangerous and must be tested.

What pipes to use

Only metals can tolerate temperatures in steam heating. The cheapest option is steel. But welding is required to connect them. It is also possible to use threaded connections. This option is budgetary, but short-lived: steel corrodes quickly in a humid environment.

Galvanized and stainless steel pipes are more durable, but their price is not at all modest. But the connection is threaded. Another option is copper pipes. They can only be soldered, they are expensive, but they do not rust. Due to their higher thermal conductivity, they transfer heat even more efficiently. So such a heating system would be super efficient but also very hot.

The Jews, more precisely, the crypts themselves occupied the southern regions. You don't need to drown there.

And you were given poisonous steam heating under a plausible pretext.