Gas heating systems for private houses

Gas prices are constantly growing, but heating with this type of fuel is still one of the cheapest. But we are talking about monthly costs - modern boilers have a high efficiency - 95-98%, which reduces costs. The high degree of automation also adds popularity - you can leave the house for quite long periods without much risk (if the electricity is not turned off). That is why many people consider gas heating of a private house in the first place.

The content of the article

What can be gas heating

Two types of gas can be used for heating - main gas and liquefied gas. Main gas under a certain pressure is supplied through pipes to consumers. It is a single, centralized system. Liquefied gas can be supplied in cylinders of different capacities, but usually in 50 liters. It is also poured into gas tanks - special sealed containers for storing this type of fuel.

Cheaper heating - using main gas (not counting the connection), the use of liquefied gas is only slightly cheaper than the use of liquid fuels. These are general statistics, but it is necessary to calculate specifically for each region - prices differ significantly.

Water heating

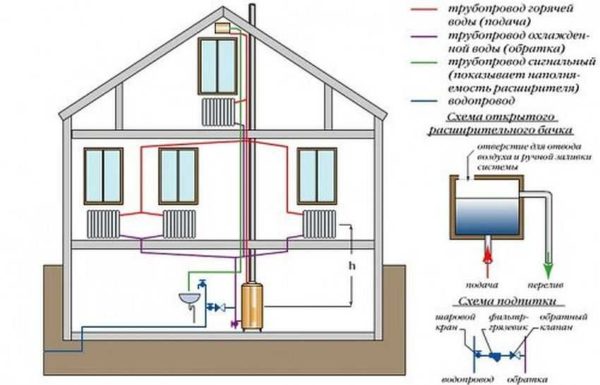

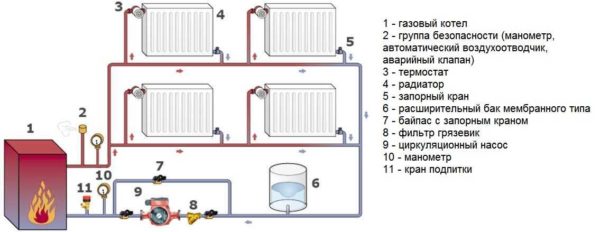

Traditionally, a water heating system is made in private houses. It consists of:

- a heat source - in this case - a gas boiler;

- heating radiators;

- pipes - connecting the boiler and radiators;

- heat carrier - water or non-freezing liquid, which moves through the system, transferring heat from the boiler.

This is the most general description of the water gas heating system of a private house, because there are still many additional elements that ensure operability and safety. But schematically, these are the main components. In these systems, heating boilers can be on natural or liquefied gas. Some models of floor standing boilers can work with these two types of fuel, and there are those that do not even require replacing the burner.

Air (convector) heating

In addition, liquefied gas can also be used as fuel for special convectors. In this case, the premises are heated with heated air, respectively, heating is air. Not so long ago, convectors appeared on the market that can operate on liquefied gas. They require readjustment, but they can operate on this type of fuel.

Gas convectors are good if you need to quickly raise the room temperature. They begin to warm up the room immediately after turning on, but also quickly it stops heating - as soon as they turn off. Another drawback is that they dry the air and burn out oxygen. Therefore, good ventilation is required in the room, but there is no need to install radiators and build a pipeline. So this option also has its advantages.

Types of gas boilers

By the type of installation, two types of gas boilers are distinguished: floor-standing and wall-mounted. Wall-mounted can only work with natural gas, floor-mounted - with two types of blue fuel. The advantage of wall-mounted gas boilers is that they can be installed in kitchens - they are automated and safe. Some floor standing ones can also be installed in the kitchen (up to 60 kW), but this room must meet certain requirements. More about how and where you can install gas boilers read here.

Types of wall-mounted boilers for home heating

First of all, it is worth dividing gas heating equipment by functionality: it will be used only for heating or also for preparing hot water for technical needs. If water is supposed to be heated, a double-circuit boiler is needed, only a single-circuit one works for heating.

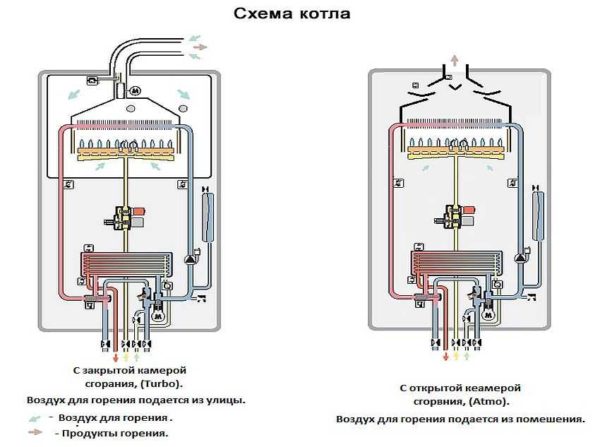

Next, you should decide on the type of smoke extraction. There are gas boilers with atmospheric chimneys and open combustion chambers, there are turbocharged ones (they have a closed combustion chamber). Atmospheric ones require a good chimney and a draft in it, oxygen for combustion comes from the room in which the unit is installed, therefore there must be an air flow channel and a working chimney (when the system is started, all this is checked).

Forced draft boilers (turbocharged) can be installed without a chimney. The boiler flue outlet through a coaxial pipe (also called a pipe in a pipe) can be discharged directly into the wall. In this case, smoke comes out through one pipe (it is pumped by a turbine), through the second air for combustion flows directly into the combustion chamber.

This type of equipment is good for everyone, except that in winter the coaxial is overgrown with frost, which worsens traction. With a poor draft, the automation extinguishes the boiler so that combustion products do not enter the room. Turning on is possible only when traction is restored, that is, it will be necessary to knock off or in some other way remove snow growth.

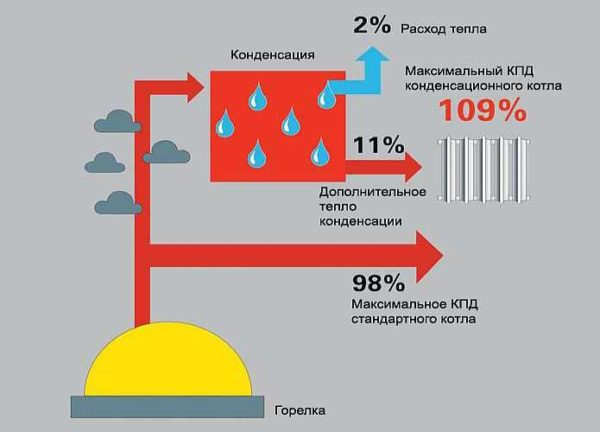

There is also a separate type of boilers - condensing. They are distinguished by a very high efficiency due to the fact that heat is removed from the flue gases (vapors are condensed). But high efficiency is achieved only when operating in low-temperature mode - in the return pipe, the coolant should not have a temperature higher than + 40 ° C. If the temperature is even lower, even better.

Such conditions are suitable for heating with water-heated floors. So if you have conceived such gas heating of a private house - with warm floors, then a condensing boiler is what you need. It has few minuses - a high price (compared to conventional ones) and caustic condensate, which makes special demands on the quality of the chimney (made of good stainless steel).

Floor standing gas boilers

If you need more power, the wall-mounted version will not work - they have a maximum capacity of 40-50 kW. In this case, a floor-standing boiler is installed. Here they have large capacities, and there are also models that can operate in a cascade. So in general it is possible to heat large areas.

Some of the floor-standing boilers can operate not only from mains gas, but also from liquefied gas. Some can also handle liquid fuels. So these are pretty handy units. Their body is made of steel, and the heat exchanger can be steel or cast iron. Cast iron ones weigh and cost more, but have a longer service life - by 10-15 years. Inside the body there is a burner, automation and a heat exchanger.

When choosing, you need to pay attention to the functionality of the automation. In addition to the standard set - gas, flame and draft control, there are many more useful functions:

- maintaining the set temperature,

- the ability to program modes by day or hour,

- compatibility with room thermostats;

- adjusting the boiler operation to the weather,

- summer mode - work for heating water without heating;

- the ability to work in parallel with solar panels or other alternative heat sources, etc.

The wider the functionality of the automation, the more expensive the boiler and its maintenance. But also many programs allow you to save fuel, which is just as important. In general, you choose.

Gas heating schemes at home

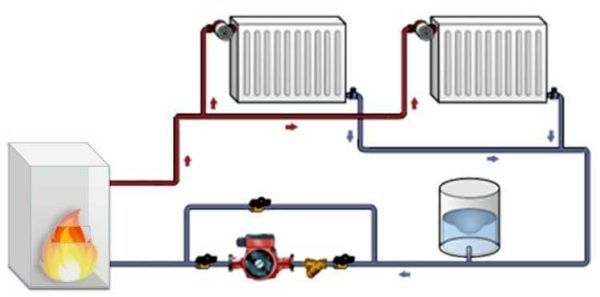

It will be about water heating using gas. It is immediately worth deciding on the type of coolant circulation. It can be natural (such systems are also called gravitational) or forced (with an obligatory pump).

Gravitational systems require the installation of a large diameter rub, that is, there is a lot of coolant in the system. The second point is that due to the fact that the coolant moves through the pipes at a low speed, the heating efficiency is not very high. Distant radiators in long branches can be cold. It's about the disadvantages. There are a lot of them, but there is one big plus - systems with natural circulation do not depend on electricity. This is important in those regions where the lights are turned off frequently.

Now a little about systems with forced circulation. They are more efficient - the coolant moves at a given speed, delivering heat to all corners of the system. The presence of the pump allows the use of pipes of small diameters. This means that there is not a lot of coolant in the system and it warms up quickly. In general, they provide a greater level of comfort, but they have a serious disadvantage - they need electricity to work, that is, they require a backup power supply. If the light is rarely turned off, it is enough to install an uninterruptible power supply unit with several batteries. They can keep the boiler running for tens of hours. If the light is turned off often and for a long time, you will have to build a generator into the system. In any case, these are additional costs and considerable ones.

There are also combined systems - they are designed as gravity, but have a built-in circulation pump. This solution can be called ideal from the point of view of practicality: as long as there is light, the heating works as forced, as soon as the power supply is lost, everything works like a gravitational system. In general, a good option, except that the pipes will be large and too visible.

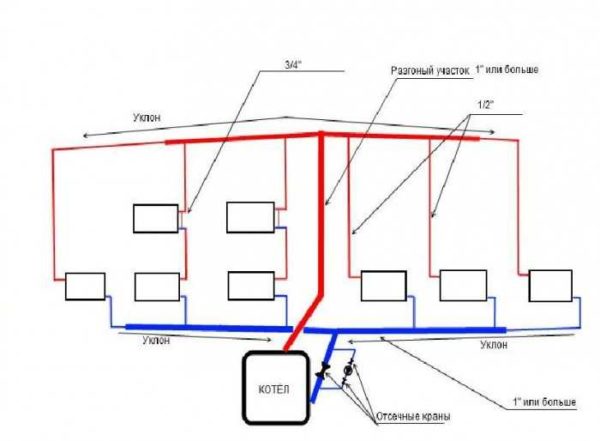

Wiring method

There are three types of systems - one-pipe, two-pipe, and beam. In single-pipe radiators are connected in series to one pipe. This wiring method is economical - fewer pipes are required, but difficult to compensate for - it is difficult to achieve the same heat transfer from the radiators. The thing is that the coolant enters the first radiator in the branch hot - immediately from the boiler. It passes through it, cools down a little, falls on the next one, cools down a little more. So all over the branch.

It turns out that the coolant comes to the last radiator much colder than to the first. The only way out is to take this phenomenon into account when designing the system and to increase the number of sections in the radiator with distance from the boiler. But the last radiators will still be the coldest.

It is more or less easy to balance the system shown in the photo above. It contains thermostats on each radiator - devices that allow you to change the amount of coolant passing through the radiator. In order not to "crush" the circulation in the entire system, a bypass is placed under each radiator - a jumper along which the coolant flows, which did not go through the radiator.

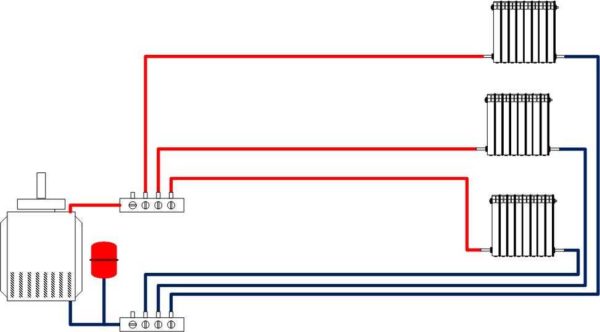

In a two-pipe system, the radiators are connected in parallel - to the supply and return pipelines. In this system, the pipe consumption is much higher, since two lines are drawn simultaneously. But in this case, a coolant with the same temperature is supplied to each heater, due to which the heat transfer of the radiators will be the same (if you put the same batteries).

In this scheme, thermostats can also be installed, but this does not require bypasses - only the flow to one radiator is regulated. So in spite of the higher pipe flow, two-pipe systems are more popular.

The beam method is the most expensive in terms of the number of tubes. In them, a separate supply and return pipe goes to each radiator. It connects to a manifold, a single-input, multiple-output device. In this case, regulation is possible both on the manifold and on the radiator using a thermostat.

Gas heating of a private house made according to this scheme will be the most reliable: if one of the pipelines is damaged, all the others will work. Therefore, this method is often chosen if the pipes are hidden in a screed.