The best radiators for home and apartment

When installing or restoring a heating system, radiators most often need to be replaced. Some have already worn out so much that they simply cannot continue to work, others are simply tired. In any case, the question arises: "Which heating radiators are better?" After all, I want them to be beautiful and effective. The appearance of heating devices, of course, is important, but the choice of heating radiators must begin with the selection according to the technical characteristics of your heating system. After all, first of all, this is a part of engineering systems, and working pressure, maximum temperature of the coolant or its composition are much more important than shape and color. And then, having decided on the type of suitable batteries, you can start choosing a model from the point of view of aesthetics, but again, you still have to keep in mind one more technical parameter - the thermal power of a radiator section or a whole battery. So, this is not an easy task - the choice of heating radiators.

The choice of heating radiators is huge today. There are six large groups, differing in structure and / or material:

- cast iron;

- steel (tubular and panel)

- aluminum (cast and extrusion);

- bimetallic (full and partial bimetal);

- convectors (floor, wall, floor);

- baseboard heating.

Radiators are different both in appearance and in characteristics, but they have not yet come up with an ideal and universal heating device. Each has advantages and disadvantages, and it is possible to say for sure which heating radiators are better only in relation to each specific case. So that you can make an informed choice, you need to know about the pros and cons of each group.

The content of the article

Cast iron batteries

The oldest of the heating devices. They are distinguished by high reliability, long service life, calmly tolerate overheating of the coolant (up to + 135 ° C), and react normally to water shocks. All because of the fact that they have thick walls. But the large thickness of the metal is not only pluses, there are also minuses. The first is a large mass. Not all modern building materials can support the weight of cast iron. Even if today they are no longer as heavy as in the days of the USSR, they are still much more massive than all the others. A large mass also means difficulties in transportation and installation. Firstly, powerful hooks are required, and secondly, it is desirable to mount them together - the mass of a radiator for 6-7 sections is 60-80 kg. But that's not all. A large mass of metal means a high heat capacity and significant inertia. On the one hand, this is a minus - until the batteries warm up, the room will be cold, but on the other hand, it is a plus, because they will cool for a long time. There is also a high inertia and one more disadvantage - cast iron batteries are ineffective in systems with thermostats. All this together leads to the fact that cast-iron heating radiators are not installed so often today.

But they have their own area of application - high-rise high-rise buildings. If the number of storeys is higher than 16, such systems create high pressure, which only cast iron and some types of bimetallic radiators (full bimetal) can withstand. Their properties are also optimal in heating systems for private houses and cottages with conventional solid fuel boilers without automation. These boilers have a cyclical principle of operation, then heating the coolant to the boiling point or even higher, then cooling down. Cast iron reacts normally to high temperatures, and also, due to inertia, smoothes temperature drops.

Until recently, cast-iron heating radiators had an unattractive appearance - the well-known and long-boring "accordion". Today there are models that look like aluminum or bimetallic ones - with smooth front edges, painted with powder enamel (most often - white). There are many designer models, mostly on legs, decorated with molded ornaments. This option is generally only found in cast iron, all the others have basically a more strict, ascetic design.

Aluminum

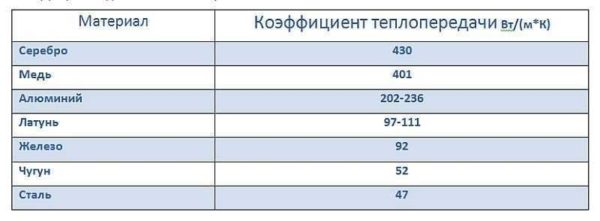

Aluminum radiators are made not of pure aluminum, but of an alloy based on it. This metal was not chosen by chance, since it has one of the highest heat transfer coefficients - 4-4.5 times better than cast iron and 5 times better than steel.

Therefore, aluminum radiators are distinguished by high power (180-190 W per section), no less high heating rate and low inertia. It is they that work very effectively in tandem with thermostats, allowing you to maintain a stable temperature with an accuracy of one degree. The advantages of aluminum radiators include their low weight (one section weighs 1.5-2 kilograms), which facilitates delivery and installation. Another positive point - the shape is designed so that it has a large cross-section of the channels for the coolant (slightly less than that of cast-iron "accordions"). This is good, since there is a low probability that these channels will clog and the radiator will stop heating.

Now about the disadvantages of aluminum radiators. They are related to the properties of aluminum. As you know, it is a reactive metal. It actively interacts with most of the chemical table, and reacts especially violently with copper. And in modern heating systems, copper parts are common. Such a neighborhood threatens with a quick exit of the copper parts of the system and the system, as well as increased gas formation. We have learned to deal with gases - they install automatic gas valves (valves) in the systems, and they save copper without putting it close to aluminum devices. The process, of course, is still going on, but not with such intensity.

The chemical activity of aluminum is also manifested in the demand for the quality of the coolant. Not in the sense of its contamination, but in the sense of its acidity. Aluminum radiators work normally in systems with a coolant acidity not higher than 7 (Ph 7).

Not very good for the operation of the heating system and the softness of aluminum. In the alloy of which heating radiators are made, there are additives that increase its rigidity, but, all the same, they do not work in high pressure networks. Typical working pressure 8-16 bar, depending on the type and manufacturer.

Based on all of the above, an area emerges where aluminum radiators are the best. These are individual heating systems with boilers controlled by automatics. They also feel good in apartments, but only in low-rise buildings (up to 10 floors), in which a coolant with Ph 7-8 circulates.

Bimetallic radiators

To correct the shortcomings of aluminum radiators, bimetallic ones were invented. Stainless tubes are sealed inside the aluminum jacket. As you know, stainless steel is chemically neutral and very durable. This solves two problems at once. But the cost of bimetallic radiators becomes much higher - the manufacturing technology is more complicated, and the thermal power becomes a little lower. On average, the heat transfer of one section of bimetallic radiators of a standard size is 170-180 W. Another plus is the higher working pressure with which these heating devices can work. On average, it is 20-30 atm, which is more than enough even for high-rise buildings.

At the same time, another problem is added - the cross-section of the channels for the coolant in bimetallic radiators is much smaller than in aluminum. Therefore, it is advisable to install filters in front of the radiator. As you can see, there are not so many cons, but there are nuances. There are simply two types of bimetallic radiators: full and partial bimetal. In a full bimetal, all the collectors (channels through which the coolant moves) are made of stainless steel. If you decide which bimetallic heating radiators are better, then this is exactly a complete bimetal. In partially bimetallic radiators, only vertical collectors are made of stainless steel, and horizontal ones are made of aluminum. That is, such products have a slightly lower chemical activity, but still at a fairly high level and the operating pressure is much lower.

Now heating systems for which bimetallic radiators are the best. These are high-rise buildings with any type of coolant (including highly acidic or alkaline ones). In individual heating systems, their properties will be unclaimed, so you should not overpay.

Steel radiators - panel and tubular

There are two different types of steel radiators, with different characteristics and very different looks. These are tubular and panel ones. Some are made from steel pipes, others from steel sheets. Both those and others have a relatively low price, which is what attracts. But steel in heating systems "does not live" for very long, so it is also the most short-lived heating devices. Of course, there are exceptions - some manufacturers cover pipes or sheets with a protective layer, due to which the warranty period is calculated for a decade or even more. But the price for such steel radiators is also far from small.

Of the rest of the characteristics - a small thermal inertia, exactingness to the coolant. Moreover, both in acidity and in the presence of foreign particles. Panel models are especially demanding - thin channels are formed in them through which the coolant moves. They are even thinner than bimetallic ones, therefore filters at the inlet are strictly required. If we talk about the acidity of the coolant, then the highest rate at which steel radiators work is Ph8. Working pressure - about 10-16 bar.

With power, the spread is very large. The design of both panel and tubular radiators is such that they can be of different dimensions. Serially produced panel radiators with heights from 30 cm to 90 cm, lengths from 40 cm to 3 m. There are special models, elongated in height. Their maximum height is 2.7 meters (by special order, they can be made higher, only there will be problems with transportation).

The variation in the sizes of tubular radiators is even greater. They can be from 19 cm to 3 m high, from 10 cm wide (two sections) to 3 meters, and a depth from 6 cm to 21 cm.The power of these radiators depends not only on the number of sections, but also on the number of columns (pipes in one row). There can be from two to six columns. Two or three columns can be hung on the wall, wider ones are often placed on the floor. Unlike all others, the sections of tubular radiators are one-piece, that is, they cannot be expanded or reduced. They are welded together. On the one hand, there are fewer leaks, but on the other, less mobility. But this is compensated by their high plasticity - tubular steel radiators can be curved - even though they are installed around the columns or wrap large containers with plants (there is a minimum bending radius). There are, by the way, models in the form of benches or tables.

Convectors

Recently, glazing from floor to ceiling has become more and more popular. Really beautiful, but here's what to do with the heating .... question.You can put low radiators on legs, but then all the chic is smeared. That's when floor convectors are used. A niche is made under them in the floor and the device itself is installed on the floor, closing it with a grate. In order to increase heat transfer at the same time (necessary for the period of cold weather), fans are built inside. The solution is aesthetic, but such systems are decent. There is also a nuance - the fans, even the quietest ones, make noise. Someone is not bothered by this noise, someone is very much in the way. In any case, there are more and less noisy models.

So, if you need to heat a French window from floor to ceiling, the best option is a floor convector.

Skirting heating

In shape, plinth heating resembles old-style plate radiators - these are two pipes with a large number of thin plates. The difference is that these pipes are thin, usually copper, have such a small height and width that they hide behind a high skirting board of a special shape (open at the top). Due to the high heat transfer coefficient of copper, the power of these small radiators is high, it is gained due to the length - at least around the entire perimeter of the room.

In addition to being invisible, baseboard heating has one more advantage - most of the heat is transferred not by convection, but in the infrared range - from heated walls. A stream of warm air rises along the walls, warming them up. When the walls get hot, they begin to emit heat, which our bodies perceive as more comfortable. Cons of this system

The disadvantages of plinth heating are the demands on the heat carrier and thermal regime (you cannot overheat), low operating pressure (up to 10 atm). All this suggests that such systems can work only in individual heating, and with boilers controlled by automation.

What heating radiators are best for an apartment and a house

Now we will systematize all the information a little from a different point of view - which batteries are better to choose for an apartment, and which ones for a private house or cottage. First, let's talk about what you can put in apartments. To get it right, you first need to visit a housing maintenance office or talk to plumbers. You need to find out what is the pressure in your heating system and what is the acidity of the coolant and its operating temperature (at least according to the documents). It would be nice to know what jumps in temperature and pressure are. Armed with these numbers, you will need to choose a specific model from those types of radiators that are suitable for your situation.

Now about what kind of heating radiators are better for an apartment. Here are your options:

- If you live in a high-rise building (more than 12 floors), most likely, bimetallic ones will do, if the pressure is not very high, cast-iron radiators can work. When choosing, look mainly at the working pressure, acidity, and they will withstand the temperature (however, only a full bimetal will do).

- If the working pressure in your system is not higher than 14 atm, and the Ph (acidity) is not higher than 7-8 and not lower than 5, then steel and aluminum radiators can be added to cast iron and bimetal. Only for them, when selecting a manufacturer and model, it is necessary to monitor all three parameters - temperature, acidity, pressure.

- If the system has a high Ph - from 8.5 and above, only bimetallic radiators (full bimetal) are suitable. They will also be output at high operating pressure (from 20 atm and above).

Once again, we draw your attention to the fact that when choosing a specific model, you must definitely look at the technical parameters. Only in this case the radiators will work for a long time without repair or replacement.

Now about which radiators are best for a private house and a cottage.These systems have a small volume, differ in that in them you control the state of the coolant yourself, you can adjust the acidity, clean the filters. So the selection by acidity in this situation is irrelevant. What to consider is the type of boiler. If the system has a solid fuel boiler and there is no heat accumulator in it to smooth out temperature fluctuations, cast-iron batteries are the best choice. They will withstand overheating and, with their thermal inertia, will smooth out temperature fluctuations.

In all other cases, the best choice is aluminum radiators. They have low inertia, react quickly to temperature changes. They heat up literally in minutes, and a noticeable flow of heat comes from them. True, they also cool down quickly, so that in case of an emergency stop, the house will be chilled out quickly.

Steel radiators will also be good. This is an economical option, but even with normal operation they do not last long - a short service life. For aesthetes, the option with plinth or convector (built into the floor) heating is suitable. Both systems work perfectly with any automated boiler.