Pressure testing of the heating and water supply system

So that the heating system does not fail at the most stressful moment, the heating season passed without problems, it is necessary to periodically check the condition of the equipment and identify all worn out parts. This test is called "crimping the heating system", it is carried out according to certain rules.

The content of the article

What is pressure testing of the heating and water supply system

Heating and water supply - two systems, consisting of a large number of the most diverse equipment. As you know, the performance of any multicomponent system is determined by the weakest element - when it fails, it stops completely or partially. To identify all the weaknesses, the heating and water supply is pressurized. In simple terms, the pressure is deliberately raised much higher than the working one, pumping the liquid. This is done with the help of special equipment, the pressure is monitored with a pressure gauge. The second name for pressure testing is hydraulic testing. It is probably understandable why.

When the heating system is pressurized, the pressure is raised by 25-80%, depending on the type of pipes, radiators, and other equipment. It is clear that such a test reveals all weak points - everything that does not have a safety margin breaks down, leaks appear in worn-out pipes and unreliable joints. Having eliminated all the identified problems, we ensure the operability of our heating or water supply for some time.

When it comes to centralized heating, pressure testing is usually carried out immediately after the end of the season. In this case, there is a decent amount of time for repairs. But this is not the only case when such events are held. Pressure testing still takes place after repair, replacement of any element. In principle, this is understandable - you need to check how reliable the new equipment and connections are. For example, you soldered from polypropylene pipes heating. We need to check how high-quality the connections are. This can be done by crimping.

If we talk about autonomous systems in private houses or apartments, then a new or repaired water supply is usually checked simply by running water, although a strength test will not hurt here either. But it is advisable to test the heating "to the full", and both before commissioning and after repair. Keep in mind that pipelines that are buried in walls, in the floor or under a false ceiling must be tested before they are closed. Otherwise, if during testing it turns out that there are leaks, you will have to disassemble / break everything and fix the problems. Few people will be happy about it.

Equipment and frequency of tests

The pressure testing of centralized systems is carried out by personnel using regular means, therefore it is hardly worth talking about. But not everyone probably knows what private heating and water supply is tested with. These are special pumps. They are of two types - manual and electric (automatic). Manual crimping pumps are autonomous, pressure is injected using a lever, and the generated pressure is controlled using a pressure gauge built into the device. Such pumps can be used for small systems - pumping is quite difficult.

Electric pumps for pressure testing are more complex and expensive equipment. They usually have the ability to create a certain pressure. It is set by the operator, and it "catches up" automatically.Such equipment is bought by professional crimping firms.

According to SNiP, a hydraulic test of heating systems should be carried out annually, before the start of the heating season. This applies to private houses too, but few people comply with this norm. At best, they check it every 5-7 years. If you are not going to test your heating annually, then there is no point in buying a crimping machine. The cheapest manual one costs about $ 150, and the good one - from $ 250. In principle, you can rent it (usually available in companies that sell components for heating systems or in offices for renting equipment). The amount will come out small - you need a device for several hours. So this is a good solution.

Call specialists or do it yourself

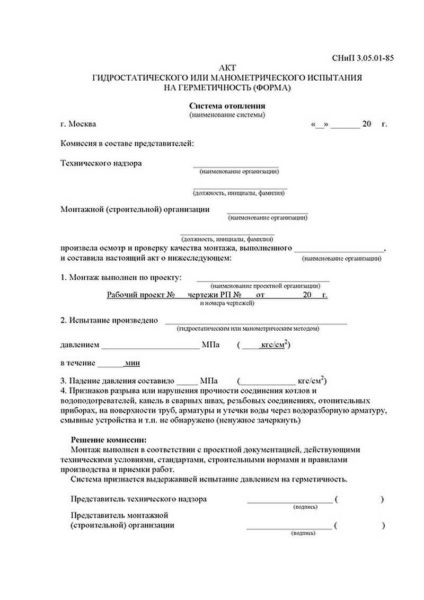

If for some purpose you need an act of pressing the heating or hot water supply system, you have only one way out - to order this service from a specialized organization. The cost of crimping heating can be announced to you only individually. It depends on the volume of the system, its structure, the presence of shut-off valves and their condition. In general, they consider the cost based on the tariff for 1 hour of work, and it ranges from 1000 rubles / hour to 2500 rubles / hour. We'll have to call different organizations and ask them.

If you have modernized the heating or hot water supply of your own home, and you know for sure that your pipes and equipment are in good condition, there are no salts and deposits in them, you can carry out pressure testing yourself. No one will demand from you the acts of hydraulic testing. Even if you see that your pipes and radiators are clogged, you can rinse everything yourself, and then test again. If you just don't feel like doing this, you can call specialists. They will immediately clean the system and carry out its pressure testing, and even give you an act.

Crimping process

Pressure testing of heating systems of a private house begins with disconnecting the heating boiler, automatic air vents and an expansion tank from the heating system. If stopcocks are connected to this equipment, you can close them, but if the taps turn out to be faulty, the expansion tank will definitely fail, and the boiler, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since it is not difficult to do this, but in the case of a boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off with the help of shut-off valves or temporary bridges are installed - squeezes.

There are two important points: pressure testing can be carried out at an air temperature not lower than + 5 ° C, the system is filled with water at a temperature not higher than + 45 ° C.

Further, the process is as follows:

- If the system was in operation, the coolant is drained.

- A crimper is connected to the system. A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even at the place of the removed expansion tank or instead of the drain cock.

- Water is poured into the tank of the pressure pump, and is pumped into the system with the help of the pump.

- Remove all air from the system before raising the pressure. To do this, you can pump the system a little with the drain valve open or drain it through the air vents on the radiators (Mayevsky taps).

- The system is brought up to working pressure and kept for at least 10 minutes. During this time, all the remaining air descends.

- The pressure rises to the test pressure, and is maintained for a certain period of time (regulated by the standards of the Ministry of Energy).During the test, all devices and connections are checked. They are examined for leaks. Moreover, even a slightly damp compound is considered a leak (fogging also requires elimination).

- The pressure level is monitored during pressure testing. If during the test its fall does not exceed the norm (spelled out in SNiP), the system is considered to be in good order. If the pressure has dropped even slightly below the norm, it is necessary to look for a leak, eliminate it, and then start pressure testing again.

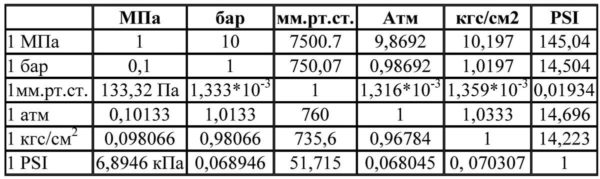

As already mentioned, the pressure test depends on the type of equipment and system under test (heating or hot water supply). The recommendations of the Ministry of Energy set out in the "Rules for the technical operation of thermal power plants" (clause 9.2.13) are summarized in the table for ease of use.

| Type of equipment under test | Test pressure | Test duration | Permitted pressure drop |

|---|---|---|---|

| Elevator units, water heaters | 1 MPa (10 kgf / cm2) | 5 minutes | 0.02 MPa (0.2 kgf / cm2) |

| Cast iron radiator systems | 0.6 MPa (6 kgf / cm2) | 5 minutes | 0.02 MPa (0.2 kgf / cm2) |

| Systems with panel and convector radiators | 1 MPa (10 kgf / cm2) | 15 minutes | 0.01 MPa (0.1 kgf / cm2) |

| Hot water supply systems from metal pipes | working pressure + 0.5 MPa (5 kgf / cm2), but not more than 1 MPa (10 kgf / cm2) | 10 minutes | 0.05 MPa (0.5 kgf / cm2) |

| Hot water systems made of plastic pipes | working pressure + 0.5 MPa (5 kgf / cm2), but not more than 1 MPa (10 kgf / cm2) | 30 minutes | 0.06 MPa (0.6 kgf / cm2), with further verification within 2 hours and a maximum drop of 0.02 MPa (0.2 kgf / cm2) |

Please note that for testing heating and plumbing from plastic pipes, the holding time of the test pressure is 30 minutes. If no deviations are found during this time, the system is considered to have successfully passed the pressure test. But the test continues for another 2 hours. And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf / cm2).

On the other hand, SNIP 3.05.01-85 (paragraph 4.6) has other recommendations:

- Tests of heating and water supply systems should be carried out with a pressure of 1.5 from the worker, but not less than 0.2 MPa (2 kgf / cm2).

- The system is considered serviceable if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf / cm).

What rules to use is an interesting question. While both documents are valid and there is no certainty, both are eligible. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast iron radiators is no more than 6 atm, respectively, the test pressure will be 9-10 atm. It is about the same to be determined with all other components.

Air pressure testing

Not everywhere and not always there is an opportunity to rent a pressure operator, as well as to buy one. For example, you need to test the heating in the country. The equipment is specific and the chances that friends have it are very small. In this case, the heating system is pressurized with air. Any compressor can be used to pump it, even a car compressor. The pressure is monitored by a connected pressure gauge.

Such crimping is less convenient and not entirely correct. Heating and plumbing are designed to transport liquids, and they are much denser than air. Where the water won't even ooze out, the air will come out. Therefore, with a high degree of confidence, we can say that you will have an air leak - somewhere, there will be a loose connection. Moreover, it is difficult to determine the place of leakage during such testing. For this, a soap solution is used, which is used to coat all joints and joints, all places where air can escape. Bubbles appear at the leak. Sometimes you have to search for a long time. That is why such pressure testing of the heating system is not very popular.

Pressing a warm floor has its own characteristics - you must first check the comb and all the devices attached to it.To do this, close all the supply and return valves of the loops, filling only the underfloor heating manifold, check it by raising the pressure. Having dropped it to normal, the loops of the warm floor are filled in turn, and only then excess pressure is created. The process is described in more detail in the video.

Well done text, very clear inside and out.