How to make a smoke generator for a smokehouse

Smoking, as a method of food preservation, has been known for a very long time. Today it has not lost its relevance, and not so much because of the long shelf life, but because of the taste that the product acquires. In this article, we'll talk about how to make a cold smoking smoke generator with your own hands.

The content of the article

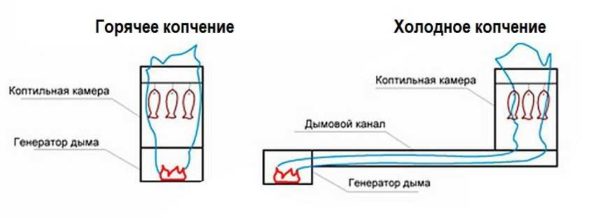

Traditional cold smoke smokehouse

Regardless of the type of smoking, the source of the smoke is the fire. When smoking cold, the main thing is that the smoke is cold or warm, but not hot. The maximum temperature is about + 40 ° C. To do this, a fire is made a few meters from the smoking cabinet, a pipe-chimney is laid between them. Passing along this path, the smoke cools down to acceptable temperatures.

Chimney construction is a lengthy process. The smoke route must ensure normal heat removal and must be airtight at the same time. To create a chimney, you can use a standard metal chimney (but not made of galvanized steel), but in order for the smoke to cool better, it is advisable to bury the pipe in the ground. In general, not an easy task. That is why they prefer to make a hot smoked smokehouse - there are fewer problems - they installed a barrel over the fire and smoke ...

But there is a simple smoke generator for cold smoking, which will cost literally several thousand. But for work you will need welding machine and the ability to handle it. Everything else can be bought at the market or at a hardware store. If you have all the components, you can assemble a smoke generator for smoking with your own hands in an hour or two.

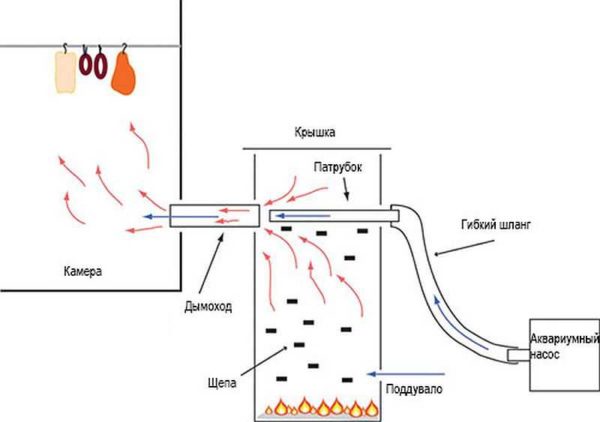

A simple smoke generator for cold smoking with your own hands

If you do not need production volumes, you can make a small and uncomplicated smoke generator from a metal pipe. A body is made from the pipe, into which sawdust or shavings are stuffed. The shavings are ignited from below, the smoke rises upward, where it is removed by means of a welded pipe into the smoking chamber. To increase traction, a low-power compressor is connected in the upper part of the housing - with a capacity of 1.5-2 liters / min. That is, you can use an aquarium compressor or a unit from an old refrigerator. If there is a choice, then the aquarium is preferable, since they can adjust the intensity of the smoke output.

The smoke coming out of this smoke generator is slightly warm. The fire site is very small, the fire spreads slowly, the resulting smoke slowly rises through the sawdust. It cools down, the sawdust dries up. In general, everything works perfectly.

Materials

For the body of the smoke generator, you can use:

- round pipe with a diameter of 80-90 mm;

- profiled pipe with a side of 80 mm and more.

The larger the section, the more sawdust can be put inside, the longer the smoke generator for cold smoking will work on one tab.

The length of the pipe is 60 cm and more. Optimally - about 1 meter. Again, the larger the pipe, the more fuel can be loaded. On the other hand, an oversized smoke generator is inconvenient to fill and clean, as it turns out to be heavy and bulky.

You will also need a 3/4 inch pipe - a piece of 30 centimeters or more. 1/4 inch tube or so. Its length is selected already in the finished state, but 20 cm should be enough.

We also need a mesh.It can be any metal mesh with a mesh of 2-3 mm or a plate with frequent holes. For the legs, find small pieces of bar / rebar / metal strip. Some designs can do without them, but with them the design is more stable.

You also need a compressor with a capacity of 1.5-2 liters / min, preferably with the ability to adjust the capacity. Aquarium compressors meet these requirements. And you need a fitting so that you can connect tubes from the compressor through it.

Assembly

We will describe a smoke generator for cold smoking based on a profile pipe with a cross section of 100 * 100 mm. With a round pipe, the process is almost the same, but welding the pipes is more difficult, if you have little experience in welding, it is better to use a profiled (square) pipe.

- At a distance of 2 cm from the bottom edge with a grinder, we make cuts on two opposite sides.

- Cut out a square from the mesh, slightly larger than the pipe section. We insert it, securing it in opposite cuts.

- On the other side, weld on a 3/4 inch piece of pipe.

- On the contrary, it is necessary to weld the union for connecting the compressor. It must be positioned so that its center coincides with the center of the already welded three-quarter pipe.

- Now we take a thin tube. It must be inserted into the fitting, it must pass through the body and enter the tube opposite by 1 cm. No more, but no less. Air from the compressor flows through this tube. By creating cravings, it stimulates combustion. By adjusting the power of the compressor, the intensity of the smoke output is regulated.

- We make a cover. We cut out a square from a piece of metal, slightly larger in size than the section of the body pipe. We make a hole in the center, install the handle. Wooden preferably. Although the smoke is not hot, the body is heated by the "fire" that burns at the bottom. Such a cover is not very convenient, as it flies off. Having outlined the contour of the pipe, we retreat from the resulting line a couple of millimeters and weld on a strip of metal 1 cm wide or so. This cover does not come off anymore.

- From the bottom, where the mesh is fixed, we weld four pieces of bar / reinforcement. These are the legs.

That's all. Homemade smoke generator for cold smoking. Ready. It can be tested. For ease of use, you can still weld on the legs. And remember that coals and ash will pour out through the mesh, so you need to install a smoke generator for cold smoking on a non-flammable area.

How does it work

Dry shavings are placed in the pipe. You can use sawdust, but then a spring is put on a thin tube located in the upper part, which reaches the length of the net itself. The condition and quality of the spring is not important. Its diameter is important - about 2 cm. Why is it needed? For more active combustion and normal smoke output.

When the body is filled with sawdust, they lie tightly, making it very difficult for the smoke to escape, the air intake is very weak, everything burns barely. The spring is needed to activate combustion. Smoke comes out through it, a thrust is created (from the grid - through the spring - to the outlet pipe.

After filling the housing with sawdust, they are set on fire from below. This can be done with a gas burner, tilting the smoke generator on its side. When the shavings start to burn, put on the cover, turn on the compressor. If the shavings / sawdust are dry, the smoke begins to actively enter the stasis. That's all. You have made a cold smoking smoke generator with your own hands.

Modernization

The design described above is fully functional. But it has many drawbacks and is not very convenient. Based on the results of its use, improvements and improvements were made.

Adjustable traction

One of the main disadvantages of the described design is poor regulation of the combustion intensity. It can be slightly changed by adjusting the compressor capacity. An adjustable blower can be added to the design. It can be done according to the gate principle:

- In the lower part of the body (above the place where the stack is attached), weld a piece of round pipe 10-15 cm long.

- Drill two holes that are located exactly opposite one another.

- Take the bar that goes through these holes. Its length is 20 cm longer than the pipe diameter.

- Cut a circle out of a sheet of metal (2-3 mm thick). Its diameter is slightly less than the inner diameter of the pipe.

- Make a "handle" from the bar (bend it).

- Insert the handle into the holes, weld the cut out circle.

That's it, the adjustable damper is ready. Turn it, adjust the intensity of the air intake, adjusting the intensity of combustion.

Ash pan

Another drawback is that ash wakes up through the mesh. You can put the smoke generator on a metal plate, but you can make an ash pan. By the way, the gate can be made in an ash pan. This will be more correct, since the air intake can be almost blocked, which you cannot achieve with a gate in the housing - the air enters through the mesh.

The ash pan is made from a piece of pipe of a slightly larger section than the pipe on the body. If not, you have to cook. The bottom is welded to a piece of pipe, and a thin strip of metal is welded to the body along the perimeter. The body is inserted into the ash pan (the legs are also welded to it).

Condensate collection

During the operation of the smoke generator for cold smoking, condensate is released. This makes life difficult, especially if the temperature outside is not high. You can solve the problem by making a condensate collector. For this:

- the outlet pipe of the smoke generator is lowered down,

- at the lowest point, we install a container for condensate, having welded two pipes to it - one opposite the other;

- from the opposite side, the pipe rises again and enters the smoking cabinet.

With such a device, a significant part of the condensate is in the tank. The problem is not so acute.

The simplest electric cooker smoke generator

If you need smoked meats "right now", you can use a very simple method: you need an electric stove, a barrel without a bottom or a piece of large-diameter pipe, a wire mesh with a cell of at least 10 * 10 cm, a sheet of plywood or iron. Also - sawdust and "object of smoking".

The simplest cold smoking smoke generator can be built on the basis of an electric stove and a barrel

Such a cold-smoked smokehouse is usually placed outside, in the backyard. It is necessary to clear the patch of vegetation, install an electric stove. On it - a metal container (which is not a pity to throw away). Sawdust is poured into the container.

In the upper part of the barrel / pipe, stepping back 10-5 cm from the upper edge, drill four holes. They are located diametrically or opposite each other. We pass the pins into them. You can use metal rods or sticks. The choice depends on the weight of the products to be stacked or what is available. The rods themselves can be arranged crosswise or as two parallels, located approximately 1/3 of the diameter of the smokehouse body. On top of this support we lay a grid with products attached from below. Cover the smokehouse with plywood or a sheet of metal.

We turn on the tile. After a while, the sawdust begins to smoke. The "work" time on one tab depends on the amount of poured sawdust, but on average it is 3-5 hours. Then you have to set aside the case, add sawdust, put everything in place. It is hard, uncomfortable and fraught with "accidents". But the design is very simple, it is a "travel" option, which does not imply convenience.

Another disadvantage is to adjust the smoke intensity with a mono tile regulator, but doing it in this form is inconvenient - again, you have to move the case. You can get rid of these shortcomings if you make a door at the bottom. With its help, it will be possible to regulate the flow of air and change sawdust.

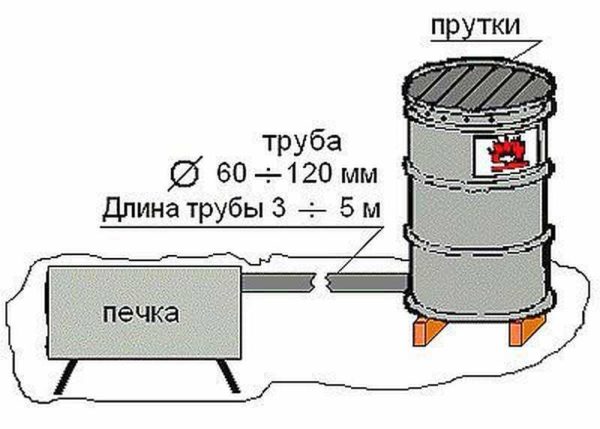

Oven-smoke generator for cold smoking

If a higher capacity installation is required, a simple stove is brewed. It can be made from the same large diameter pipe or a rectangular body can be welded from metal. Weld the door, make the chimney fixed at an angle. That's all the difficulty. It is also necessary to divide the inner space into two parts with a horizontally fixed metal sheet. The bottom is larger, the top is smaller. A fire is kindled below, sawdust is poured onto a sheet. Further, the process is known.

A pipe is laid from the stove chimney to the smoking cabinet. It should have an upward slope, albeit a small one. In this case, the entrance to the cabinet should be located at the bottom - so that the smoke envelops all the products. Therefore, the cabinet is installed on a dais, legs, pedestal. To save space, you can install a smoke generator stove under the cabinet by welding a structure from a metal corner.

However, with this design, the smoke can be too hot. Additional measures are required to cool it. Alternatively, find a pipe with a larger diameter, put it on the main chimney. Install the cooler so that the air flow is directed into the gap between the pipes.

Another option is to do something like a water jacket, getting hot water while smoking. But what to do with it is a question. Although, warm water is always useful on the farm.

A smoke generator for cold smoking of this type requires more costs - metal or a thick-walled pipe, plus a chimney. Moreover, it is better not to make a chimney of galvanized steel - zinc, this is not a metal that is good for health. You shouldn't use asbestos either. First, it removes heat poorly, and secondly, it is even more harmful than zinc. Therefore, the choice in this regard is small - to order pipes made of black steel or buy from stainless steel. Here everyone decides for himself.

Related Videos