Independent biogas production

The rise in energy prices makes us think about the possibility of providing ourselves with them independently. One option is a biogas plant. With its help, biogas is obtained from manure, droppings and plant residues, which after cleaning can be used for gas appliances (stove, boiler), pumped into cylinders and used as fuel for cars or electric generators. In general, the processing of manure into biogas can provide all the energy needs of a home or farm.

The content of the article

General principles

Biogas is a product that is obtained from the decomposition of organic matter. In the process of decay / fermentation, gases are released, which can be collected to meet the needs of your own farm. I call the equipment in which this process takes place "biogas plant".

In some cases, the gas output is excessive, then it is stored in gas holders - for use during the period of its insufficient amount. With a competent organization of the process, there may be too much gas, then its surplus can be sold. Another source of income is fermented leftovers. This is a highly effective and safe fertilizer - during the fermentation process, most microorganisms die, plant seeds lose their germination capacity, parasite eggs become unviable. The removal of such fertilizers to the fields has a positive effect on the yield.

Conditions for gas production

The process of biogas formation occurs due to the vital activity of various kinds of bacteria that are contained in the waste itself. But in order for them to actively "work" it is necessary for them to create certain conditions: humidity and temperature. To create them, a biogas plant is being built. This is a complex of devices, the basis of which is a bioreactor, in which the decomposition of waste takes place, which is accompanied by gas formation.

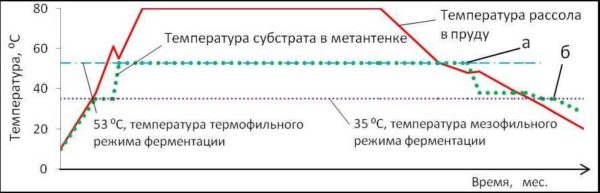

There are three modes of processing manure into biogas:

- Psychophilic regime. The temperature in the biogas plant is from + 5 ° C to + 20 ° C. Under such conditions, the decomposition process is slow, much gas is formed, and its quality is low.

- Mesophilic. The unit enters this mode at temperatures from + 30 ° C to + 40 ° C. In this case, mesophilic bacteria proliferate. In this case, more gas is generated, the processing process takes less time - from 10 to 20 days.

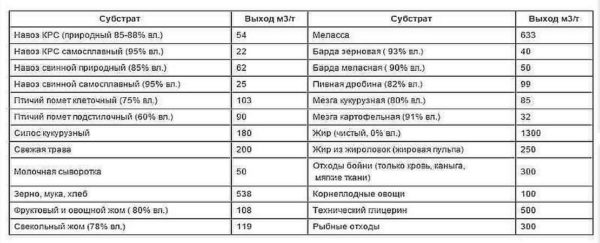

- Thermophilic. These bacteria multiply at temperatures from + 50 ° C. The process is the fastest (3-5 days), the gas yield is the largest (under ideal conditions, up to 4.5 liters of gas can be obtained from 1 kg of delivery). Most of the reference tables for gas recovery from processing are given specifically for this mode, so when using other modes, it is worth making an adjustment downward.

The most difficult thing in biogas plants is the thermophilic regime. This requires high-quality thermal insulation of the biogas plant, heating and a temperature control system. But at the exit we get the maximum amount of biogas. Another feature of thermophilic processing is the impossibility of additional loading. The other two modes - psychophilic and mesophilic - allow daily addition of a fresh portion of prepared raw materials.But, in the thermophilic mode, the short processing time allows the bioreactor to be divided into zones in which its own share of raw materials with different loading times will be processed.

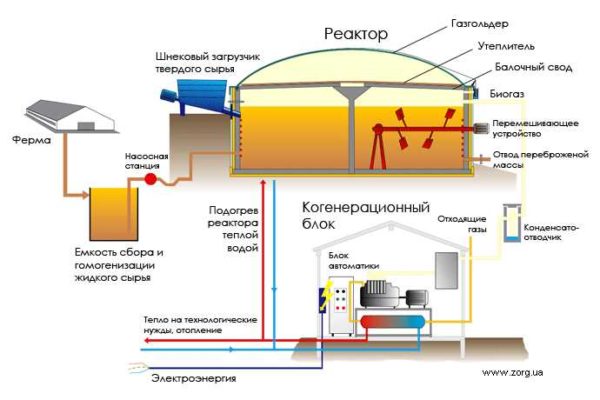

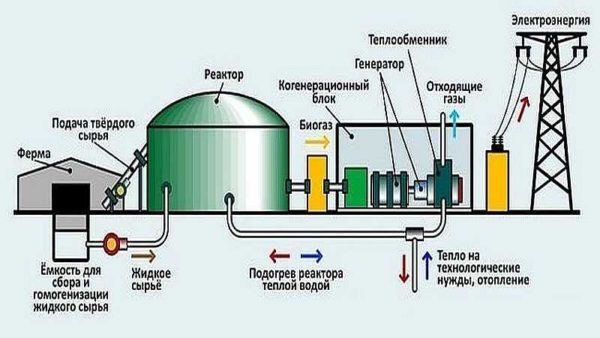

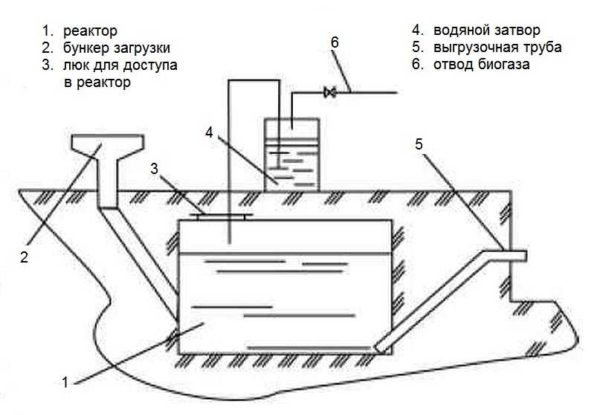

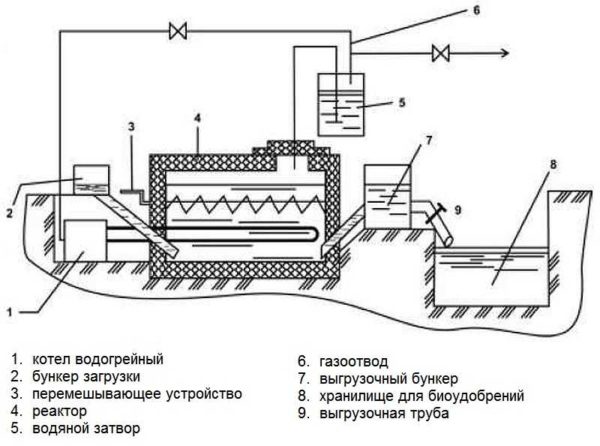

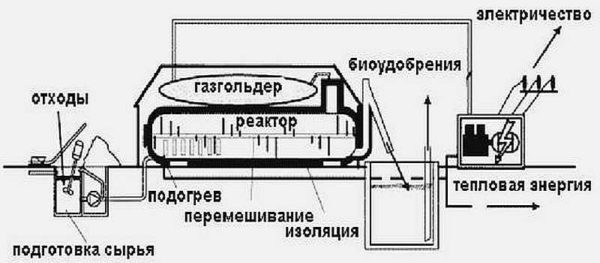

Biogas plant diagram

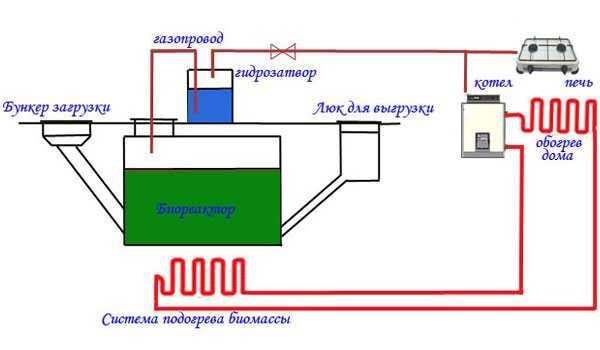

The basis of a biogas plant is a bioreactor or bunker. The fermentation process takes place in it, and the resulting gas accumulates in it. There is also a loading and unloading hopper, the produced gas is discharged through a pipe inserted into the upper part. Next comes the gas treatment system - cleaning it and increasing the pressure in the gas pipeline to the working one.

For mesophilic and thermophilic modes, a bioreactor heating system is also required to reach the required modes. For this, gas boilers that run on the produced fuel are usually used. From there, the pipeline system goes to the bioreactor. Usually these are polymer pipes, as they are best suited to being in an aggressive environment.

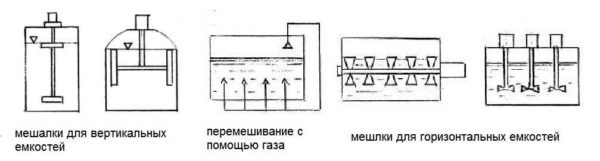

A biogas plant also needs a system for mixing the substance. During fermentation, a hard crust forms at the top, heavy particles settle down. All this together worsens the gassing process. To maintain a homogeneous state of the processed mass, agitators are needed. They can be mechanical or even manual. They can be started by timer or manually. It all depends on how the biogas plant is made. An automated system is more expensive to install, but requires a minimum of attention during operation.

A biogas plant by type of location can be:

- Aboveground.

- Semi-recessed.

- Recessed.

Buried ones are more costly to install - a large amount of land work is required. But when used in our conditions, they are better - it is easier to organize insulation, less heating costs.

What can be recycled

The biogas plant is essentially omnivorous - any organic matter can be processed. Any manure and urine, plant residues are suitable. Detergents, antibiotics, chemistry negatively affect the process. It is desirable to minimize their intake, since they kill the flora that is involved in processing.

Cattle manure is considered ideal, since it contains large quantities of microorganisms. If there are no cows on the farm, when loading the bioreactor, it is advisable to add some part of the manure to populate the substrate with the required microflora. Plant residues are pre-crushed, diluted with water. The bioreactor mixes plant material and excrement. Such a "filling" takes longer to process, but at the exit, with the correct mode, we have the highest product yield.

Locating

To minimize the costs of organizing the process, it makes sense to locate the biogas plant near the waste source - near buildings where poultry or animals are kept. It is desirable to develop a design so that loading occurs by gravity. From the barn or pigsty, you can lay a pipeline downhill, through which the manure will flow by gravity into the bunker. This greatly facilitates the task of maintaining the reactor, and manure removal too.

Usually buildings with animals are located at some distance from a residential building. Therefore, the generated gas will need to be transferred to consumers. But stretching one gas pipe is cheaper and easier than organizing a line for transporting and loading manure.

Bioreactor

Rather stringent requirements are imposed on tanks for processing manure:

- It must be impervious to water and gases. Watertightness should act in both directions: the liquid from the bioreactor should not contaminate the soil, and groundwater should not change the state of the fermented mass.

- The bioreactor must be of high strength. It must withstand the mass of a semi-liquid substrate, the gas pressure inside the container, and the external soil pressure. In general, when building a bioreactor, special attention should be paid to its strength.

- Serviceability. More convenient to use cylindrical containers - horizontal or vertical. In them, mixing can be organized throughout the volume; stagnant zones are not formed in them.Rectangular containers are easier to implement when building with your own hands, but cracks often form in the corners in them, and the substrate stagnates there. Mixing it in the corners is very problematic.

All these requirements for the construction of a biogas plant must be met, as they ensure safety and create normal conditions for the processing of manure into biogas.

What materials can be made

Resistance to aggressive media is the main requirement for the materials from which the container can be made. The substrate in the bioreactor can be acidic or alkaline. Accordingly, the material from which the container is made must tolerate various environments well.

Not many materials answer these requests. The first thing that comes to mind is metal. It is durable, you can make a container of any shape from it. What's good is that you can use a ready-made container - some kind of old tank. In this case, the construction of a biogas plant will take very little time. Lack of metal - it reacts with chemically active substances and begins to break down. To neutralize this minus, the metal is covered with a protective coating.

An excellent option is a polymer bioreactor container. The plastic is chemically neutral, does not rot, does not rust. You just need to choose from materials that can tolerate freezing and heating to sufficiently high temperatures. The walls of the reactor should be thick, preferably glass fiber reinforced. Such containers are not cheap, but they serve for a long time.

It is possible to build a bioreactor for the production of biogas from bricks, but it must be well plastered with the use of additives that ensure hydro and gas impermeability

A cheaper option is a biogas plant with a tank made of bricks, concrete blocks, stone. In order for the masonry to withstand high loads, it is necessary to reinforce the masonry (in each 3-5 rows, depending on the wall thickness and material). After the completion of the wall erection process, to ensure water and gas impermeability, subsequent multilayer wall processing is necessary both from the inside and outside. The walls are plastered with a cement-sandy composition with additives (additives) that provide the required properties.

Reactor sizing

The volume of the reactor depends on the selected temperature for processing manure into biogas. Most often, mesophilic is chosen - it is easier to maintain and it implies the possibility of daily additional loading of the reactor. The production of biogas after reaching the normal mode (about 2 days) is stable, without bursts and dips (when normal conditions are created). In this case, it makes sense to calculate the volume of the biogas plant depending on the amount of manure generated on the farm per day. Everything is easily calculated based on the average data.

| Breed of animals | Excrement volume per day | Initial moisture |

|---|---|---|

| Cattle | 55 kg | 86% |

| Pig | 4.5 kg | 86% |

| Chickens | 0.17 kg | 75% |

The decomposition of manure at mesophilic temperatures lasts from 10 to 20 days. Accordingly, the volume is calculated by multiplying by 10 or 20. When calculating, it is necessary to take into account the amount of water that is needed to bring the substrate to an ideal state - its moisture content should be 85-90%.The found volume is increased by 50%, since the maximum load should not exceed 2/3 of the volume of the tank - gas should accumulate under the ceiling.

For example, the farm has 5 cows, 10 pigs and 40 chickens. In essence, 5 * 55 kg + 10 * 4.5 kg + 40 * 0.17 kg = 275 kg + 45 kg + 6.8 kg = 326.8 kg are formed. To bring chicken manure to 85% moisture, you need to add a little more than 5 liters of water (this is another 5 kg). The total weight is 331.8 kg. For processing in 20 days, you need: 331.8 kg * 20 = 6636 kg - about 7 cubes only for the substrate. We multiply the found figure by 1.5 (increase by 50%), we get 10.5 cubic meters. This will be the calculated value of the volume of the biogas plant reactor.

Loading and unloading

Loading and unloading hatches lead directly to the bioreactor tank. In order for the substrate to be evenly distributed over the entire area, they are made in opposite ends of the container.

In the case of a buried installation of a biogas plant, the loading and unloading pipes approach the body at an acute angle. Moreover, the lower end of the pipe must be below the liquid level in the reactor. This prevents air from entering the container. Also, rotary or shut-off valves are installed on the pipes, which are closed in the normal position. They open only during loading or unloading.

Since the manure can contain large fragments (bedding, grass stalks, etc.), small diameter pipes will often become clogged. Therefore, for loading and unloading, they must be 20-30 cm in diameter. They must be mounted before starting work on the insulation of the biogas plant, but after the container is installed in place.

The most convenient operating mode of a biogas plant is with regular loading and unloading of the substrate. This operation can be performed once a day or once every two days. Manure and other components are pre-collected in a storage tank, where they are brought to the required state - they are crushed, if necessary, moistened and mixed. For convenience, this container can be equipped with a mechanical stirrer. The prepared substrate is poured into the access hatch. By placing the collection container in the sun, the substrate will be preheated, which will reduce the cost of maintaining the required temperature.

It is desirable to calculate the installation depth of the receiving hopper so that the waste flows into it by gravity. The same applies to discharge into the bioreactor. The best case is if the prepared substrate will move by gravity. And a damper will fence it off during preparation.

To ensure the tightness of the biogas plant, hatches on the receiving hopper and in the unloading area must have a sealing rubber seal. The less air there is in the tank, the cleaner the outlet gas will be.

Collection and disposal of biogas

The biogas is removed from the reactor through a pipe, one end of which is under the roof, the other is usually lowered into a water seal. This is a container with water, into which the resulting biogas is discharged. There is a second pipe in the water seal - it is above the liquid level. Cleaner biogas goes into it. A gas shut-off valve is installed at the outlet of their bioreactor. The best option is ball.

What materials can be used for the gas transmission system? Galvanized metal pipes and gas pipes from HDPE or PPR. They must ensure tightness, seams and joints are checked with soap foam. The entire pipeline is assembled from pipes and fittings of the same diameter. No contractions or extensions.

Purification from impurities

The approximate composition of the biogas produced is as follows:

To remove hydrogen sulfide, a metal chip filter is used.You can load old metal sponges into the container. Purification takes place in the same way: gas is fed into the lower part of a container filled with metal. Passing through, it is purified from hydrogen sulfide, collects in the upper free part of the filter, from where it is discharged through another pipe / hose.

Gas tank and compressor

The purified biogas enters a storage tank - a gas holder. It can be a sealed plastic bag, plastic container. The main condition is gas tightness, shape and material do not matter. The biogas stock is stored in the gasholder. From it, with the help of a compressor, gas under a certain pressure (set by the compressor) is supplied to the consumer - to the gas stove or boiler. This gas can also be used to generate electricity using a generator.

To create a stable pressure in the system after the compressor, it is advisable to install a receiver - a small device for leveling pressure surges.

Mixing devices

In order for the biogas plant to work in normal mode, it is necessary to regularly stir the liquid in the bioreactor. This simple process solves many problems:

- mixes a fresh portion of the load with a colony of bacteria;

- promotes the release of produced gas;

- evens out the temperature of the liquid, excluding warmer and colder areas;

- maintains the uniformity of the substrate by preventing the subsidence or floatation of some constituents.

Typically a small home-made biogas plant has mechanical agitators that are driven by muscle power. In systems with a large volume, the agitators can be driven by motors, which are switched on by a timer.

The second way is to stir the liquid, passing a portion of the produced gas through it. To do this, after leaving the meta tank, a tee is placed and part of the gas is poured into the lower part of the reactor, where it comes out through a tube with holes. This part of the gas cannot be considered a flow rate, since it still enters the system again and, as a result, ends up in the gasholder.

The third method of mixing is to pump the substrate from their lower part using fecal pumps, pour it out at the top. The disadvantage of this method is dependence on the availability of electricity.

Heating system and thermal insulation

Without heating the processed slurry, psychophilic bacteria will multiply. The processing process in this case will take from 30 days, and the gas yield will be small. In summer, in the presence of thermal insulation and pre-heating of the load, it is possible to reach temperatures up to 40 degrees, when the development of mesophilic bacteria begins, but in winter such an installation is practically inoperative - the processes are very sluggish. At temperatures below + 5 ° C, they practically freeze.

How to heat and where to place

For best results, use heating. The most rational is water heating from the boiler. The boiler can operate on electricity, solid or liquid fuel, it can also be started on the produced biogas. The maximum temperature to which the water must be heated is + 60 ° C. Hotter pipes can cause particles to adhere to the surface, resulting in reduced heating efficiency.

You can also use direct heating - insert heating elements, but firstly, it is difficult to organize mixing, and secondly, the substrate will stick to the surface, reducing heat transfer, heating elements will quickly burn out

A biogas plant can be heated using standard heating radiators, simply with pipes twisted into a coil, welded registers. It is better to use polymer pipes - metal-plastic or polypropylene.Corrugated stainless steel pipes are also suitable, they are easier to lay, especially in cylindrical vertical bioreactors, but the corrugated surface provokes the adhesion of sediment, which is not very good for heat transfer.

To reduce the possibility of particles settling on the heating elements, they are located in the mixer zone. Only in this case everything must be designed so that the mixer cannot touch the pipes. It often seems that it is better to place the heaters at the bottom, but practice has shown that such heating is ineffective due to sediment at the bottom. So it is more rational to place the heaters on the walls of the biogas plant metatenka.

Water heating methods

According to the method of arrangement of pipes, heating can be external or internal. When installed internally, heating is effective, but repair and maintenance of heaters is impossible without shutting down and pumping out the system. Therefore, special attention is paid to the selection of materials and the quality of the connections.

Heating increases the productivity of the biogas plant and shortens the processing time of raw materials

When the heaters are located outside, more heat is required (the cost of heating the contents of a biogas plant is much higher), since a lot of heat is spent on heating the walls. But the system is always available for repair, and the heating is more uniform, since the environment is heated from the walls. Another plus of this solution is that agitators cannot damage the heating system.

How to insulate

At the bottom of the pit, first a leveling layer of sand is poured, then a heat-insulating layer. It can be clay mixed with straw and expanded clay, slag. All these components can be mixed, can be sprinkled in separate layers. They are leveled into the horizon, the capacity of the biogas plant is installed.

The sides of the bioreactor can be insulated with modern materials or classical antiquated methods. From the old-fashioned methods - coating with clay and straw. It is applied in several layers.

From modern materials, you can use extruded high-density polystyrene foam, low-density aerated concrete blocks, foamed polyurethane foam... The most technologically advanced in this case is polyurethane foam (PPU), but the services for its application are not cheap. But the result is seamless thermal insulation, which minimizes heating costs. There is one more heat-insulating material - foamed glass. In slabs, it is very expensive, but its battle or crumb costs very little, and according to its characteristics it is almost perfect: it does not absorb moisture, is not afraid of freezing, it tolerates static loads well, has a low thermal conductivity.