Dimensions of edged board in accordance with GOST

When purchasing materials, it is best to be aware of what size they should be, how to identify the variety and what the differences are between different species. We will discuss all this, and also give the standard dimensions of the edged board and the permissible deviations.

The content of the article

What is edged board, timber and bar

It is not so easy for an ignorant person to understand construction terminology. If you started a construction project, you will have to do it. To begin with, let's figure out what a board is, how it differs from a bar and a bar. All definitions of lumber are given in GOST 18288-87. They are based on size. According to this doc:

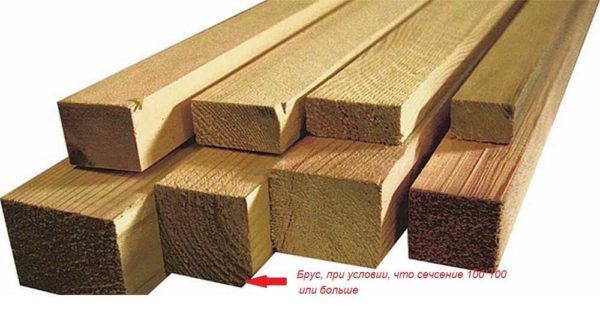

What is the difference between a bar and a bar? The bar in cross-section has the shape of a square with a side of more than 100 mm. The bar can be square, but the side should be less than 100 mm, but most often the bar looks like a rectangle

- A board is a sawn timber with a thickness of no more than 100 mm and a width of more than two times the thickness.

- Bar - more than 100 mm wide and thick. The maximum cant size is not standardized. Only minimal.

- Bar - up to 100 mm thick and no more than double the width.

So, if you look at the timber from the end, all its sides should be equal. The cross section of the bar will give us a square. The board and the bar are rectangles. It's just that the width of the board is more than twice the thickness, and the bar is less. For example, 25 * 75 mm is a board, and 25 * 45 mm is a bar. And by the way, 50 * 50 mm and 75 * 75 mm are also a bar, not a bar, because according to the standard, a bar is a product with a side of 100 mm. They seem to have sorted out these names.

For rough work, a croaker is sometimes used. What it is? By the same standard, this is the side of the log, one side of which is propylene, the other not. There is also a plank slab - this is when the outer part of the slab is partially propylene.

Edged and unedged board

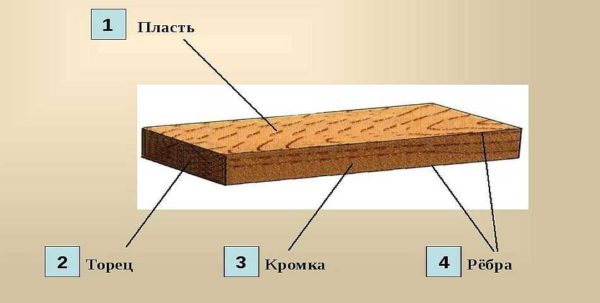

It is also worth deciding what a face and an edge are. It is either of the two wider surfaces in the board or bar, and either of the surfaces in the bar. The edge, respectively, is the narrower part of the lumber.

Now you can find out what an edged board is and how it differs from an unedged board. The edged board has edges that are sawn off perpendicular to the faces. On the edge there may be wane (remnants of bark), but no more than acceptable in terms of grade. An unedged board, respectively, has uncut or partially cut edges. Edged lumber, in which wane exceeds permissible limits, falls into the same category.

There is also a half-edged board. This is when only one edge is flat, and the second can be wane. The timber, by the way, can also be wane. The two-edged one has two opposite sides, the three-edged one has three, and the four-edged one has all four.

Edged and unedged board. The difference is in the form of edges. In edged ones, they are smooth; in low varieties, a small amount of wane is allowed. For unedged boards, the edges are not cut at all or only partially

You may also need such a concept as calibrated lumber. There is a calibrated board, bar and bar. This is lumber dried and processed (on a thicknesser or planer) to the required size. It must be understood that an uncalibrated one may have deviations in size (the limits of deviations are normalized), a calibrated one should not differ in size. Rather, the permissible deviations are very small.

There is also a planed board. It differs from the edged one in smoother sides, as it is subjected to additional processing.The edged board is dried, and after that it is sent for additional processing on a planer. There is removed its roughness, which was left by the saw. Calibration can occur at the same time, but this is not necessary. The planed board may not be calibrated.

Business and construction board: what is the difference

Also in the price lists there is a board with the same dimensions, of the same type, but one is construction and the other is business. The difference is that the business is made from non-dead trunks. It is dried, has no fungal or bacteriological lesions, wormholes, even if they are allowed by the standards. Therefore, it costs significantly more.

The business board is used for roofing. Goes to the logs, rafters. It is also used in frame housing construction. The business board can be processed directly at the enterprise with the necessary compositions, but this is discussed specifically before delivery.

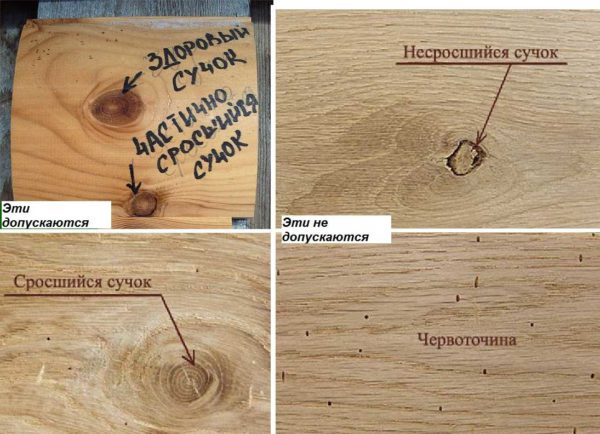

To understand the lumber or business lumber in front of you, look at the knots. Only healthy (light) intergrown knots can be in a business board or bar.

Sometimes you can see in the price list two items with the same name, but one has GOST, the other either has no mark, or it says "without GOST". The difference in price is significant. What is the difference between the material? First, the size may be smaller. Everything that does not pass within the tolerances goes into this category. For example, the width or length, the inclination of the bevels does not fit into the standards. Is it possible to take such a board or timber? Depends on where you are going to apply it. But such material must be examined by yourself. The whole batch. The lower price is not always beneficial.

Wood requirements and grade

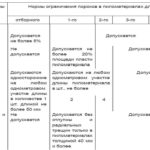

The type of board or its grade is a classification in which the permissible defects of wood and their quantity are indicated. The board and bars can be of five grades - perfect, 1st, 2nd, 3rd and 4th. The bar is not perfect, so it has only four varieties, indicated by numbers.

Selected lumber, first, second and third grades are made:

- from dry wood with a moisture content of not more than 22%;

- from raw;

- raw, treated with antiseptics.

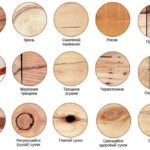

- What defects and flaws can be on the boards, beams and bars, how they look (photo)

- Knots, their types and number, depending on the grade of lumber

- Knots, their types and number, depending on the grade of lumber

- Cracks can also be, but small and blind

- Wood flows depending on the grade of the board

- Wood flows depending on the grade of the board

- There may be some types of fungal infections

- What other disadvantages can there be?

Wood for the fourth grade is not regulated. The grade is determined by the worst face or edge. That is, find the worst part, and by the presence and number of defects and flaws, determine the grade. All of them are given in the tables, and the possible defects themselves are in the form of pictures.

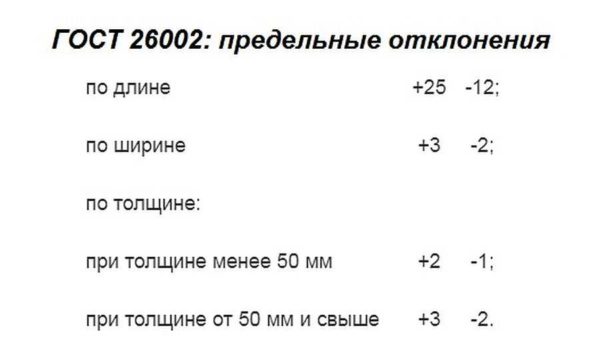

Please note that grade data are taken from GOST 2140. It is used for sawn timber for the domestic market and exported. Recently, another standard was adopted: GOST 26002 for sawn timber, which is sold only on the domestic market. There varieties are defined differently (and size tolerances too). So be careful, check according to which GOST the grade was determined.

How to determine the grade of the board

Do you know how the board grade is determined in production? Approximately. No one counts knots, cracks and other defects. And the difference between, say, first and second grade is very small. And not all manufacturers try to sort it out correctly. So it's better to control everything yourself. But the tables are so large, and there are a lot of defects - it's impossible to remember everything. But there are certain criteria that can help you determine how the quality meets the stated.

- If there is at least one knot that has fallen out, this is definitely not a perfect and not the first grade. At least the second, or even lower.

- Planks and beams of the first grade should be free of rot, fungi and core. These are all places that are destroyed in the first place. So they shouldn't be.

- When choosing a bar, pay attention to the number of annual rings. The more there are, the higher the quality of the wood.

It's also worth looking at storage conditions. In general, high grade planks should be stored at least under a canopy. It should be stacked in ventilated piles, not in bulk. Ventilated stacks are with spacers that separate one row from another and allow the wood to dry evenly.

Standard edged board sizes

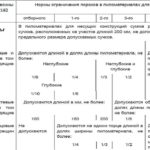

According to GOST 24454-80, there are coniferous sawn timber of standard dimensions. The thickness and width of the board are shown in the table. Deviations in the thickness of the edged board, bar and timber are permissible, but they cannot be greater:

- ± 1 mm for boards and bar up to 32 mm thick;

- ± 2 mm for lumber from 40 mm to 100 mm;

- ± 3 mm at a thickness of 110 mm or more.

There are also restrictions on width deviations: the takeoff run can be up to 2 mm with a width of up to 100 mm, and up to 3 mm with a width of 125 mm or more.

| Edged board dimensions | Volume of one board (length 6 m), m3 | Number of boards in m3 | Edged board dimensions | Volume of one board (length 6 m), m3 | Number of boards in m3 | Edged board dimensions | Volume of one board (length 6 m), m3 | Number of boards in m3 |

|---|---|---|---|---|---|---|---|---|

| edged board 16 * 75 | 0,0072 | 138,9 | edged board 32 * 75 | 0,0144 | 69,4 | edged board 44 * 250 | 0,066 | 15,2 |

| 16*100 | 0,0096 | 104,2 | 32*100 | 0,0192 | 52,1 | 44*275 | 0,726 | 13,8 |

| 16*125 | 0,012 | 83,3 | 32*125 | 0,024 | 41,7 | edged board 50 * 75 | 0,0225 | 44,4 |

| 16*150 | 0,0144 | 69,4 | 32*150 | 0,0288 | 34,7 | 50*100 | 0,03 | 33,3 |

| edged board 19 * 75 | 0,0086 | 116,3 | 32*175 | 0,0336 | 29,8 | 50*125 | 0,0375 | 26,7 |

| 19*100 | 0,0114 | 87,7 | 32*200 | 0,0384 | 26,0 | 50*150 | 0,045 | 22,2 |

| 19*125 | 0,0143 | 69,9 | 32*225 | 0,0432 | 23,1 | 50*175 | 0,0525 | 19,0 |

| 19*150 | 0,0171 | 58,5 | 32*250 | 0,048 | 20,8 | 50*200 | 0,06 | 16,7 |

| 19*175 | 0,0189 | 52,9 | 32*275 | 0,0528 | 18,9 | 50*225 | 0,0675 | 14,8 |

| edged board 22 * 75 | 0.0099 | 101 | edged board 40 * 75 | 0,018 | 55,6 | 50*250 | 0,075 | 13,3 |

| 22*100 | 0.0132 | 75.8 | 40*100 | 0,024 | 41,7 | 50*275 | 0,0825 | 12,1 |

| 22*125 | 0.0165 | 60.6 | 40*125 | 0,03 | 33,3 | edged board 60 * 75 | 0,027 | 37,0 |

| 22*150 | 0.0198 | 50.5 | 40*150 | 0,036 | 27,8 | 60*100 | 0,036 | 27,8 |

| 22*175 | 0.0231 | 43.3 | 40*175 | 0,042 | 23,8 | 60*125 | 0,045 | 22,2 |

| 22*200 | 0,0264 | 38,9 | 40*200 | 0,048 | 20,8 | 60*150 | 0,054 | 18,5 |

| 22*225 | 0,0297 | 33,7 | 40*225 | 0,054 | 18,5 | 60*175 | 0,063 | 15,9 |

| edged board 25 * 75 | 0,0125 | 80 | 40*250 | 0,06 | 16,7 | 60*200 | 0,072 | 13,9 |

| 25*100 | 0,015 | 66,7 | 40*275 | 0,066 | 15,2 | 60*225 | 0,081 | 12,3 |

| 25*125 | 0,0188 | 53,2 | edged board 44 * 75 | 0,0198 | 50,5 | 60*250 | 0,09 | 11,1 |

| 25*150 | 0,0225 | 44,4 | 44*100 | 0,0264 | 37,9 | 60*275 | 0,099 | 10,1 |

| 25*175 | 0,0263 | 38 | 44*125 | 0,033 | 30,3 | edged board 75 * 100 | 0,045 | 22,2 |

| 25*200 | 0,03 | 33,3 | 44*150 | 0,0396 | 25,3 | 75*125 | 0,0563 | 17,8 |

| 25*225 | 0,0338 | 29,6 | 44*175 | 0,0462 | 21,6 | 75*150 | 0,0675 | 14,8 |

| 25*250 | 0,0375 | 26,7 | 44*200 | 0,0528 | 18,9 | 75*175 | 0,0788 | 12,7 |

| 25*275 | 0,0413 | 24,2 | 44*225 | 0,0594 | 16,8 | 75*200 | 0,09 | 11,1 |

Standard edged board dimensions are indicated for wood with a moisture content of 20%. For materials of higher and lower humidity, vary. The amount of shrinkage is prescribed in GOST 6782.1.

In addition, the length of the lumber is standardized. It can be from 1 meter to 6.5 meters. Graduation step - 25 cm. Allowable length tolerances - 25 mm or +50 mm.

In the new standard for the domestic market, other deviations from the standard sizes of edged and unedged boards are acceptable

Please note that GOST 26002 has been introduced, in which other deviations are allowed for the domestic market. But there is a postscript: in agreement with the consumer. That is, when buying a board of "standard sizes", see GOST. In 24454-80, the requirements are more stringent. By the way, it also establishes other grading criteria. So, really, it is worth asking what GOST the products are labeled according to.