What is GVL, GKL, GKLV and where is it better to use them

Recently, “dry” construction and finishing technologies have become more and more popular. It is understandable. With less time, the result is very decent. You just need to choose the right materials. If you want to level walls, ceilings, make a floor or sheathe the frame, but do not want to use materials potentially hazardous to health, containing formaldehyde, you will have to choose from sheet materials made on the basis of plaster. These are gypsum fiber (GVL) and drywall (GKL). But deciding which is better to use - GVL or GKL - is not so easy. Both materials have their pros and cons. And, the most reasonable, use both, but in those areas where their properties will be in demand.

The content of the article

GVL and GKL: what is it in construction

Drywall and gypsum fiber are relatively new building materials. They appeared a couple of decades ago, but they have confidently replaced traditional materials. To understand GVL or GCR you better use, you need to have a clear idea of what kind of materials they are, what are their advantages and disadvantages. Based on this knowledge, you yourself will be able to make the best decisions. Because it is impossible to say unequivocally which is better - GVL or GKL. Somewhere one material is more suitable, somewhere it is better to use the second. So let's figure out what kind of materials they are and what types of gypsum board and gypsum fiber board exist.

GKL: what is it and what types are there

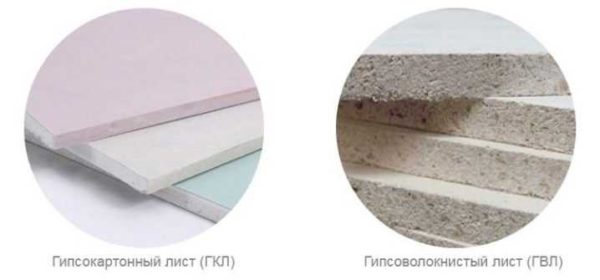

GKL is an abbreviation for the name Gypsum Cardboard Sheet. This material consists of two cardboard sheets, between which there is a layer of gypsum. They are connected to each other using construction glue. It is often called "drywall", or the abbreviation GKL is used, sometimes you can hear "gypsum board". The latter name is found zonal - it is more common in St. Petersburg and the surrounding area. In this region, drywall was supplied by the Finnish company Gyproc ("Giprok"), which gradually became a household name.

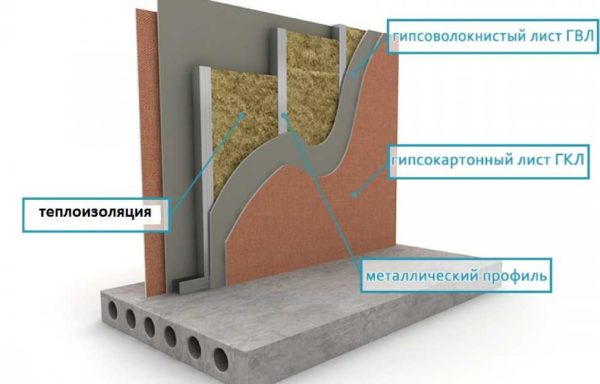

GKL is used for "dry" leveling of walls or frame cladding in frame housing construction. Suitable for indoor use, too fragile for outdoor use. Use drywall for walls, partitions, ceilings.

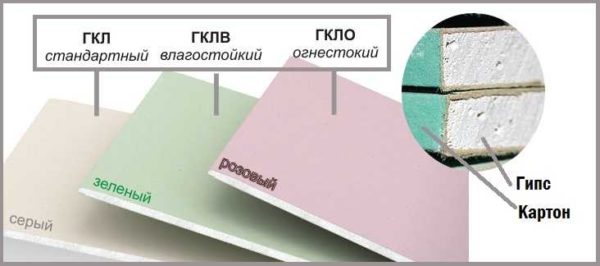

In the production of gypsum board, dense and smooth cardboard is used. It serves as a reinforcing and shaping element. The gypsum layer gives strength and keeps its shape. In most cases, a drywall sheet has a thinner edge along the long side (there are also even ones with right corners). This allows you to carefully putty the joints when joining. So for some types of finishing materials, it is not necessary to putty the entire area.

Plasterboard is produced for different operating conditions; for easy recognition, cardboard of different colors (gray, green, pink) is used:

- For rooms with normal operating conditions - standard gypsum board. It is gray.

- For rooms with high humidity levels - moisture resistant gypsum plasterboard. It is colored green.

- For fire hazardous premises / buildings - fire resistant - GKLO. Has a pink color.

- In rooms with a high fire hazard and high humidity, GKLVO is used - a fireproof moisture-resistant gypsum board.

- Recently, soundproof drywall (GKLZ) has become popular. It has a high density gypsum core and is reinforced with fiberglass.Designed to increase the sound insulation of frame sheathing structures of walls, ceilings and partitions. The leaf is purple or blue.

GKLZ - soundproof plasterboard. Knauf sheet (GSP-DFH3IR) has the following properties: increased density, moisture resistance, shock resistance, increased strength

Now you know what gypsum plasterboard is, what types of drywall are and where they are used. It is a popular material for interior decoration. It does not contain harmful substances, although gypsum dust, which may appear during operation, may pose some danger. To decide which is better GVL or GVK, now let's talk about gypsum fiber.

GVL - what is it, what is it made of, what types are there

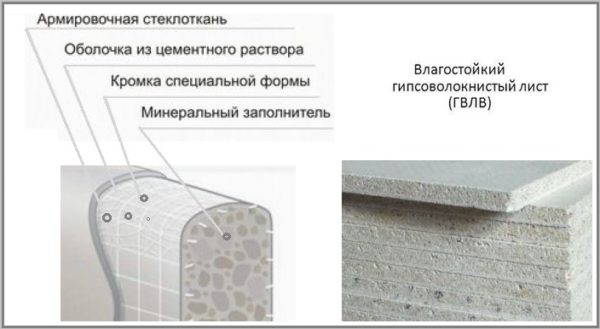

The name GVL is also an abbreviation from the technical name of sheet building material: Gypsum-Fibrous Sheet. This material is made from a mixture of gypsum and cellulose fibers (waste paper is fluffed). The mass is mixed with water, sheets are formed from it under the press, which are brought to normal humidity (dried).

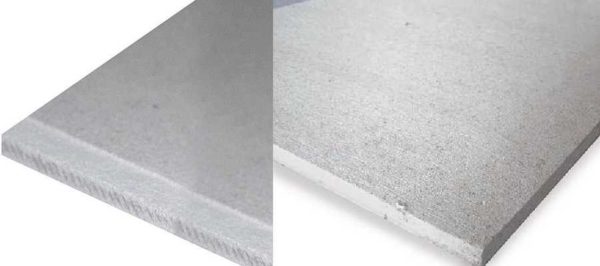

GVL is also used for dry leveling of walls and ceilings, frame cladding, flooring. Unlike gypsum plasterboard, it has a "basic" incombustibility, since cellulose is covered with a layer of incombustible material - gypsum. GVL is produced with two types of edges - flat and folded. The seam edge is removed with a plane, the chamfer depth is about 2 mm, the width is about 30 mm. When installing on walls, this allows you to additionally strengthen the seam (lay a reinforcing mesh) and putty it.

Gypsum fiber boards acquire special properties with the help of special additives. On this basis, there are the following types:

- Standard - GVL. For installation in rooms with normal humidity.

- Moisture resistant - GVLV. They are used in rooms with high humidity levels to level the floor without screed.

- Moisture resistant material of increased strength for flooring. GVLV EP (moisture resistant GVL Floor Element) is marked.

Externally, moisture-resistant sheets are no different from standard ones. If the manufacturer is normal, the sheet has a marking in which, in addition to the size of the sheets, the type is stated - GVL or GVLV. They also differ in the type of surface: GVL are polished and unpolished. Sanded ("Knauf") is significantly higher in price, but does not require compulsory filling of the entire surface before finishing work.

GVL and GKL: properties and comparison

So far, no particular difference between GVL and GCR is noticeable. Both are sheet material that can be used for wall and ceiling sheathing. Only gypsum fiber is suitable for flooring, but drywall is not. This is just the beginning. Let's understand further.

Density, strength

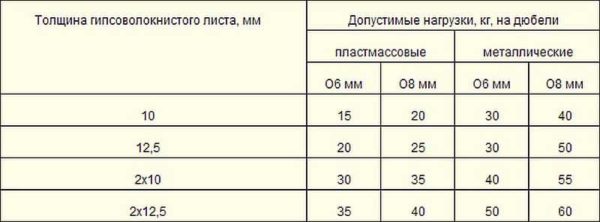

If we compare gypsum fiber board and gypsum board, then gypsum fiber has a high density, and, accordingly, with the same thickness, greater strength and mass. Great strength - it seems to be good. In any case, the GVL is not so easy to break through with a blow. Plus, you can safely hang shelves on a frame wall sheathed with GVL.

On the other hand, high density - more difficult installation. Not every self-tapping screw can be screwed into a gypsum fiber board without pre-drilled holes. You can do without drilling, but only if you use self-tapping screws and a powerful screwdriver. Moreover, without preliminary countersinking (drilling a hole of a larger diameter), it will not be possible to "drown" the cap in gypsum fiber. When sheathing gypsum fiber board in two layers without preliminary drilling of holes, it may turn out that the screw twisted into the second sheet "tries" to squeeze the lower one.

Drywall has less strength, it can be pierced with a fist blow. But ordinary self-tapping screws easily "enter" it. When installing the gypsum board, the most important thing is not to overtighten or break the cardboard with the screw head.Otherwise, it falls into the gypsum layer, which bursts. We have to twist in another place. If you "screw up" several times in a row, you will have to change the sheet, as it simply will not hold.

And, by the way, on a wall sheathed in one sheet of gypsum fiber board, a correctly installed special dowel (butterfly or also called chamomile) can withstand a weight of 80 kg for a long time. The question is that the technology must be followed.

GKL and GVL weight

Now what is bad about high density. The first minus has already been described: it is more difficult to install fasteners. Second, high density means high mass. That is, for the installation of GVL under the same conditions, a more powerful frame is required. When transporting, you will have to take into account the tonnage, it is more difficult to work with heavy sheets. The weight of one sheet of GVL is calculated in tens of kilograms. For example, Knauf gypsum-fiber boards ("Knauf") have the following parameters:

- a sheet with dimensions 2500 * 1200 * 10 mm weighs about 36 kg;

- GVL 2500 * 1200 * 12.5 mm has a mass of 42 kg;

- the floor element 1550 * 550 * 20 mm has a mass of about 18 kg.

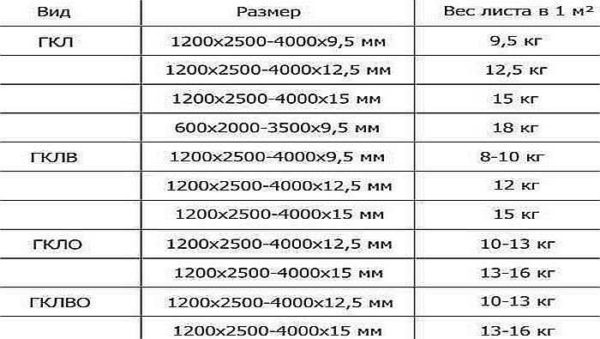

Plasterboard sheets are much lighter (see table).

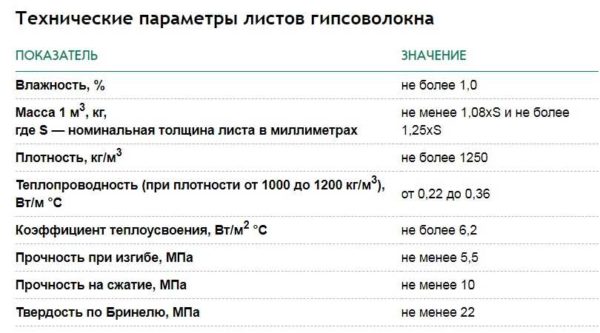

If we talk about the mass of a square meter of gypsum fiber sheet, it can be calculated by the formula:

- The mass of the GVL square cannot be less than 1.08 * S,

- but it cannot be more than 1.25 * S.

Where S is the nominal sheet thickness in millimeters. So the range of values is easy to determine. At the same time, manufacturers for some reason do not indicate the mass of one sheet. This data can only be found from Knauf. According to their information, we get something like this:

- GVL 10 mm thick - 12 kg / m²;

- GVL 12.5 mm thick - 14 kg / m²;

- EP 20 mm thick - 21.5 kg / m².

Compared with the average mass of gypsum boards, fiber gypsum boards are 3.5-4 times heavier. Lifting even one sheet alone is already a problem. Even if you figure out how to do it and not break it. Naturally, they must be fixed on a more powerful base.

Flexibility and fragility

Drywall, due to the fact that gypsum is located between two layers of cardboard, is more flexible. Cardboard performs the task of reinforcement, taking a significant part of the load on itself. Especially under bending loads. For example, a plasterboard sheet can be lifted from one side by grasping the short side. It will bend, but not crack. If you try to carry out the same operation with a gypsum fiber sheet, it will crack.

Another plus of the gypsum board is that it can be used to trim curved surfaces. There are several technologies thanks to which you can make arches, columns, smoothly curved reliefs on walls and ceilings. GVL does not provide such an opportunity. It takes bending loads very poorly both along and across the sheet: the cellulose fibers are very short and the board simply breaks. So if you need to finish curved surfaces, the choice between GVL or GKL is simply made in favor of the latter.

Sound insulation and thermal conductivity

When choosing a material for cladding, indicators such as thermal conductivity and sound insulation are important. As you know, they depend on density, since GOSTs allow a wide enough fork in the density of gypsum fiber board, these characteristics should be looked at for each specific manufacturer. So that you can at least roughly navigate, there is such data:

- Thermal conductivity of GVL with a density from 1000 kg / m3 to 1200 kg / m3 has a thermal conductivity from 0.22 W / m ° C to 0.36 W / m ° C.

- The thermal conductivity of the gypsum board is approximately in the same range - from 0.21 to 0.34 W / (m × K).

If we talk about soundproofing, the same picture is observed: the characteristics are approximately equal. GVL gives only 2 dB better protection compared to GCR. It is also worth remembering that you can find acoustic drywall if you wish. It has special characteristics, it is used for covering shops, concert halls, studios. If we talk about private housing construction, it should be used in bedrooms.

If you look at the characteristics, there is no difference in sound insulation between GKL and GVL. But this parameter takes into account the "conduction" of the sound. There really is no big difference here. It feels like it is. And significant. A room lined with gypsum fiber boards is much quieter. It's not so booming. Sounds from the smooth cardboard are reflected, and in the non-uniform surface of the fiber boards "stick". So if silence in the house is important to you, choosing between gypsum fiber board and gypsum board, opt for gypsum fiber.

GVL or GKL: which is better?

Both the one and the other material have admirers and opponents. You will have to decide what is better for GVL or GCR on your own. In this section we will try to compare them by the most significant parameters. Let's go over the dimensions right away. Drywall is produced in a wider range, both in sheet sizes and in thickness:

- GKL sheet thickness: 6.5 mm, 8 mm, 10 mm, 12.5 mm, 14 mm, 16 mm, 18 mm, 24 mm. The last three are very rare.

- The height of the GKL sheet can be from 2000 mm to 4000 mm with a step of 50 mm.

- GKL width - 600 mm or 1200 mm.

As you can see, the assortment is more than wide. Another thing is that there are usually two or three types on sale. But, with a strong desire, everything can be found / ordered. Although, it is usually easier (and cheaper) to buy what is available.

The size of the GVL was less fortunate. We have only two options for gypsum fiber boards: 2500 * 1200 mm (standard) and 1500 * 1000 mm (small format). Both are available in 10mm and 12.5mm thicknesses. All. There are no other sizes by standards. There is also GVL for the floor. Its dimensions are 1200 * 600 mm, thickness is 20 mm. Can be chamfered or not.

| GKL | GVL | |

|---|---|---|

| Cost per square | from 70 rubles / sq.m. | from 180 rubles / sq. m. |

| Shock loads | crumbles | tolerates normally |

| Bending loads | tolerates normally, bends | breaks down |

| Cut | easily cut with a stationery knife | a serious tool with a special disc is needed |

| Installing fasteners | special screws can be easily tightened | hard to twist, you need to pre-drill holes or use self-tapping screws |

| Resizing with increasing humidity / temperature | 1 mm per meter | 0.3 mm per meter |

| Fire resistance | high - G1 | non-flammable - NG |

| Mounting on curved surfaces | available | no |

As a result, it is possible to say that it is better than GVL or gypsum board only specifically for the scope and operating conditions. In short, here's how you can subdivide applications:

- GVL for walls and ceilings is better if fire resistance is required or it is necessary to increase the rigidity of the structure (in frame frames).

- It is better to put GVL on the floor, since it reacts less to moisture, does not change its properties.

- GKL is indispensable if you need smooth lines or complex multi-tiered structures. Tiered ceiling, arches, columns, rounded walls and corners - these are only drywall.

- If you need to achieve good sound insulation of the second floor, it is better to hem the ceiling with GVL.

As you can imagine, there is no way to definitively say that it is better than GVL or GKL. In some conditions, one material is better for performing one task, the characteristics of another are more suitable for another.

Due to the fact that drywall appeared relatively recently, just 10 years ago, you are wrong! Yes, amateurs! History needs to be taught, everything is the head of the USA! And Germany! Back in the 1960s, the Knauf brothers will sell 2 factories to the Soviet Union with all the secrets of production, then the Soviets were very happy that they had found a way out, the construction speed appeared thanks to drywall.