Hole sizes: tables, tools, cutting process

To cut an internal thread on a part, you must first drill a hole. Its size is not equal to the thread diameter, but should be slightly smaller. You can find the diameter of the drill for the thread in a special table, but for this you also need to know the type of thread.

The content of the article

Main settings

Any thread is characterized by two parameters:

- diameter (D);

- step (P) - the distance from one loop to another.

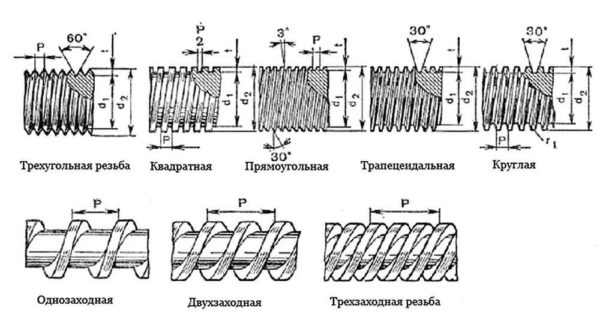

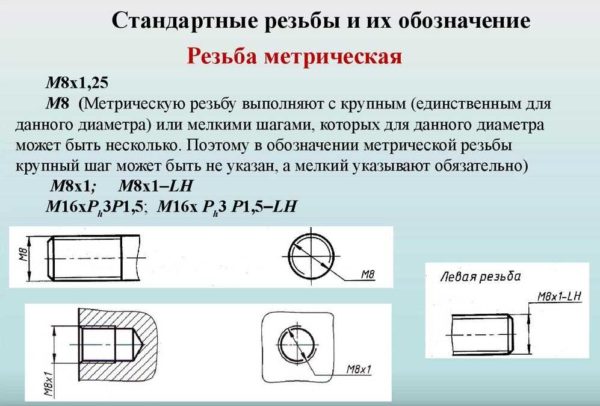

They are determined by GOST 1973257-73. A large step is considered normal, but several smaller ones correspond to it. Small pitch is used when applied to thin-walled products (pipes with a thin wall). They also make a small turn if the applied thread is a way of adjusting any parameters. Also, a small step between the turns is done to increase the tightness of the connection and to overcome the phenomenon of self-screwing of the part. In other cases, a standard (large) step is cut.

There are many types of thread, since each has its own peculiarities of formation, the diameter of the hole for the thread is different in each case. All of them are prescribed in GOSTs, but most often they use triangular metric and tapered metric threads. We will talk about them further.

We usually see triangular threads on bolts and other similar fasteners, and tapered threads on most plumbing products that involve a detachable connection.

Gadgets

For DIY carving, small tools are used:

- dies (they are also called lerki) for applying turns from the outside (usually on a pipe or metal rod (pin);

- taps - for the inside (here you need to make a hole for them beforehand).

All these devices are made of alloys, characterized by increased strength and abrasion resistance. On their surface grooves and grooves are applied, with the help of which their mirror image is obtained on the workpiece.

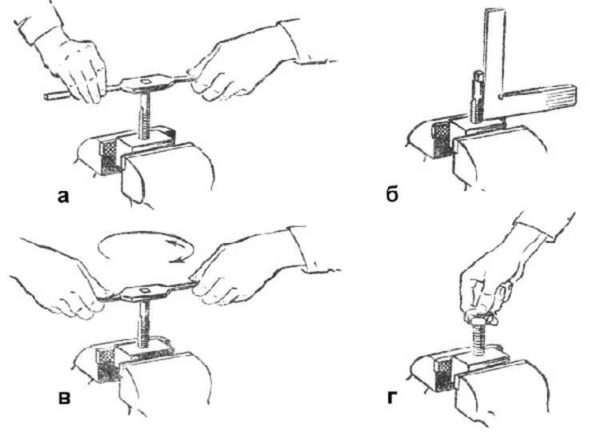

Any tap or die is marked - they have an inscription indicating the type of thread that this device cuts - diameter and pitch. They are inserted into holders - wrenches and die holders - fixed there with screws. Holding the tapping tool in the holder, it is put on / inserted into the place where a detachable connection is required. By scrolling the device, turns are formed. It depends on how correctly the device is set at the beginning of work whether the coils will "lay down" evenly. Therefore, do the first turns trying to keep the structure even, avoiding shifts and distortions. After a few revolutions have been made, the process will be easier.

Small to medium diameter threads can be cut manually. Difficult types (two- and three-way) or working with large diameters with hands is not possible - too much effort is required. For these purposes, special mechanized equipment is used - for lathes with taps and dies fixed to them.

How to cut correctly

You can apply threads to almost any metal and their alloys - steel, copper, aluminum, cast iron, bronze, brass, etc. It is not recommended to do it on a hot iron - it is too hard, it will crumble during operation and it will not be possible to achieve high-quality turns, which means that the connection will be unreliable.

Preparation

It is necessary to work on pure metal - remove rust, sand and other contaminants.Then the place where the thread will be applied must be lubricated (except for cast iron and bronze - you must work with them "dry"). There is a special emulsion for lubrication, but if not, you can use soaked soap. You can also use other lubricants:

- linseed oil for steel and brass;

- turpentine for copper;

- kerosene - for aluminum.

You can often hear advice to use machine oil, mineral oil, or even lard when cutting threads. They work well, but experts say that it is better not to do this - the chips will stick to the viscous substance, which will lead to rapid wear of the tap or die.

Slicing process

When cutting external threads, the die is placed strictly perpendicular to the surface of the pipe or rod. When working, it should not wag, otherwise the turns will turn out to be uneven and the connection will be ugly and unreliable. The first turns are especially important. It depends on how they "lay" whether the connection will then be skewed.

By applying an internal thread, the part is fixed motionless. If it's a small piece, you can grip it in a vice. If the plate is large, secure it with available methods, for example, by fixing it with bars. M

The tap is inserted into the hole so that its axis is parallel to the axis of the hole. With a little effort, little by little, they begin to twist in a given direction. As soon as you feel that the resistance has increased, unscrew the tap back and clean it of chips. After cleaning, the process continues.

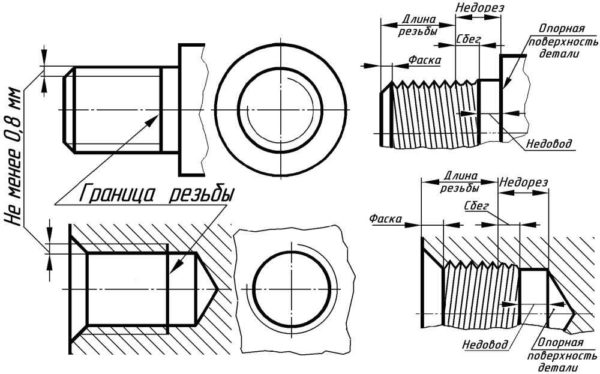

When tapping a blind hole, its depth should be slightly deeper than required - this excess should include the tip of the tap. If this is structurally impossible, the tip is cut off from the tap. At the same time, it is not suitable for further operation, but there is no other way out.

In order for the turns to be of high quality, two taps or dies are used - a rough and a finishing one. The first pass is done roughing, the second - finishing. There are also combined threading devices. They allow you to do everything in one go.

Another practical tip: so that the chips do not fall into the working area, when cutting, make one full turn clockwise, then half a turn counterclockwise. After that, return the tool to the place where it stopped and make one revolution again. This is continued until the required length.

Tables for selecting the diameter of the drill for the thread

When making an internal thread, a hole is pre-drilled for it. It is not equal to the thread diameter, since when cutting, part of the material is not removed in the form of chips, but is squeezed out, increasing the size of the protrusions. Therefore, before applying, you must select the diameter of the drill for the thread. This can be done using tables. They are available for each type of thread, but here are the most popular ones - metric, inch, pipe.

| Metric thread | Inch thread | Pipe thread | |||||

|---|---|---|---|---|---|---|---|

| Thread diameter, inches | Thread pitch, mm | Drill diameter, mm | Thread diameter, inches | Thread pitch, mm | Drill diameter, mm | Thread diameter, inches | Thread hole diameter, mm |

| M1 | 0.25 | 0,75 | 3/16 | 1.058 | 3.6 | 1/8 | 8,8 |

| M1.4 | 0,3 | 1,1 | 1/4 | 1.270 | 5.0 | 1/4 | 11,7 |

| M1.7 | 0,35 | 1,3 | 5/16 | 1.411 | 6.4 | 3/8 | 15,2 |

| M2 | 0,4 | 1,6 | 3/8 | 1.588 | 7.8 | 1/2 | 18,6 |

| M2.6 | 0,4 | 2,2 | 7/16 | 1.814 | 9.2 | 3/4 | 24,3 |

| M3 | 0,5 | 2,5 | 1/2 | 2,117 | 10,4 | 1 | 30,5 |

| M3.5 | 0,6 | 2,8 | 9/16 | 2,117 | 11,8 | - | - |

| M4 | 0,7 | 3,3 | 5/8 | 2,309 | 13,3 | 11/4 | 39,2 |

| M5 | 0,8 | 4,2 | 3/4 | 2,540 | 16,3 | 13/8 | 41,6 |

| M6 | 1,0 | 5,0 | 7/8 | 2,822 | 19,1 | 11/2 | 45,1 |

| M8 | 1,25 | 6,75 | 1 | 3,175 | 21,3 | - | - |

| M10 | 1,5 | 8,5 | 11/8 | 3,629 | 24,6 | - | - |

| M12 | 1,75 | 10,25 | 11/4 | 3,629 | 27,6 | - | - |

| M14 | 2,0 | 11,5 | 13/8 | 4,233 | 30,1 | - | - |

| M16 | 2,0 | 13,5 | - | - | - | - | - |

| M18 | 2,5 | 15,25 | 11/2 | 4,33 | 33,2 | - | - |

| M20 | 2,5 | 17,25 | 15/8 | 6,080 | 35,2 | - | - |

| M22 | 2,6 | 19 | 13/4 | 5,080 | 34,0 | - | - |

| M24 | 3,0 | 20,5 | 17/8 | 5,644 | 41,1 | - | - |

Once again, we draw your attention to the fact that the diameter of the drill for the thread is given for a coarse (standard thread).

External thread rod diameter table

When working in an external thread, the situation is very similar - part of the metal is squeezed out, not cut off. Therefore, the diameter of the rod or pipe on which the thread is applied should be slightly smaller. How accurate - see the table below.

| Thread diameter, mm | 5,0 | 6 | 8 | 10 | 12 | 16 | 20 | 24 |

|---|---|---|---|---|---|---|---|---|

| Rod diameter, mm | 4,92 | 5,92 | 7,9 | 9,9 | 11,88 | 15,88 | 19,86 | 23,86 |

Thread table. First column. Metric thread d.b. already in mm, it is therefore metric.

Amendment. Female thread table, 1st column heading