Plasterboard cutter - a tool for quickly connecting profiles

Partitions, ceilings, false walls are often built from drywall. And it is mounted on a frame made of metal profiles. Much of the time is spent on the installation of this very frame. Cutting time without losing quality allows a cutter for a metal profile. It is a hand-held tool that connects two profiles in seconds.

The content of the article

What is a sheet metal notch

A cutter or pliers are hand tools for joining sheet metal products. The connection takes place by forming a through hole in the parts to be joined. The parts to be joined are fixed by bending the formed metal petals. That is, no fasteners or additional steps are required to connect sheet metal products using a cutter.

We put the working part of the tool in the right place, pressed the handles. The metal breaks through, its pieces are bent. All. Due to the fact that the metal "breaks through", another name for this tool has gone - a punch for a profile. The same tool can be found under the name "pliers for connecting HA-profiles". This is how some manufacturers position it. There are other names - notching, hole punch for a profile. This is already out of the jargon of builders and home craftsmen.

Externally, the cutter is the same pliers, but with long handles and an unusual structure of the working part. Like normal ticks, they have two lips, but they are different in shape. On one side a stop, on the other a punch. A punch is a protruding part that makes a hole in the metal. The stop is a thickened part with a hole into which the punch goes.

Photo of how the cutter works. He makes a through hole in the parts to be joined and bends metal petals

The shape of the working part is designed so that the metal petals that are formed when making a hole are slightly bent. This ensures reliable fixation of the products relative to each other. The hole shape is usually rectangular, but can be square or round. Rectangular is preferred because it gives a more "rigid" connection.

Pros and cons of using cutters

This type of instrument is not very popular yet. The reasons are difficult to name, because the thing is really good. Especially for those who are engaged in the installation of plasterboard systems, and for home craftsmen, too, a necessary thing. What are the pros:

- Fast and reliable connection of profiles. The speed of installation of the frame for drywall increases significantly. The principle of operation is simple: they brought the parts to be joined between the jaws, squeezed the handles, moved them, and repeated. And so as many times as required.

- No hardware required. This saves time and money.

- The tool is hand-held, so no electricity is needed. You can work on any object.

- There is no protrusion at the junction of the profiles. When mounted on rivets or self-tapping screws, the head protrudes above the profile surface. The screw has more, the rivets have less. This prevents the drywall sheet from lying flat, without bends. When using a cutter, the folds remain on the "seamy" side of the profile. The front is obtained without protrusions. The sheet lies flat, which reduces the time for putty and its consumption.

Few of those who tried to work with a cutter return to self-tapping screws. Although, I must say, there are some. Sometimes in difficult places, the connection is "grabbed" with a self-tapping screw, then a cutter is used, and the self-tapping screw is unscrewed. But these are those who like to play it safe. With some skill, additional fixation is not required.

disadvantages

Now about the cons. The use of a cutter for a drywall profile really reduces the time required. But the tool is manual and requires the application of muscle strength. With large volumes of installation, namely, structures made of profiles, fatigue quickly accumulates. And by the end of the working day, the speed of work drops. The better the tool, the less effort is needed, but it is needed anyway. And this is a minus.

The second drawback is the complexity of disassembly. To separate the two profiles, you need to unbend the metal petals. It takes more time than unscrewing the screws. But less than when removing rivets. It seems that these are all the difficulties and disadvantages of working with a cutter.

There is one more drawback, which is due to the shape of the working part. Some nodes - jumpers, clamps - are simply impossible to "reach" with a cutter. The punch does not fit there. There are models with very large "windows", but they are not very good for general connections. It's okay for professionals to have several different models, but for home use it is overkill.

Self-tapping screws or notching

The fact that when using cutters the sheet falls smoother has already been said. And this is a clear plus in favor of a perforated connection. The second unconditional plus is time saving. The third is the lack of consumables.

The disadvantages of connecting the profiles with a cutter record the insufficient strength of the fastening. Self-tapping screws are more reliable. Perhaps, but the strength of the frame is needed only until the moment it is sheathed with gypsum board. And it will be enough with your head, even if you make only one fastener for each connection. But it's up to you to decide which is better - a cutter or self-tapping screws.

Types and designs

The assortment of cutters in our stores is not so great, but in large hardware stores you can see about a dozen different models. What are they? First, there are sheet metal models (pictured below). They have a very small gap in the working part, which is also called the "window". For sheet metal cutters, this window is only about a centimeter wide. Any metal will fit there, but drywall profile only guide (PN) or rack-mount (PS) with small shelves. And that could be the problem.

If we talk about models for connecting drywall, then they have a larger "window". It is made in the form of a square, rectangle or with rounded corners. The larger the window, the easier it will be to fasten rack profiles with any shelf width. But then the size of the "head" increases, which is not always convenient. Professionals just have several different tools, and for repair and domestic use they choose something in between.

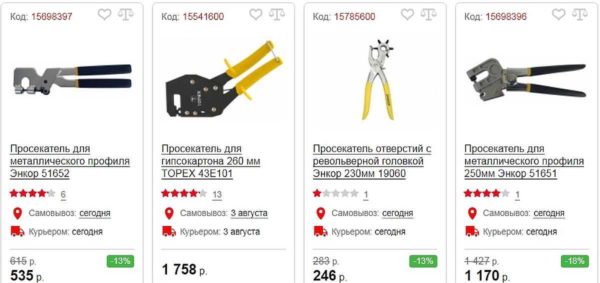

There are also different shapes of holes: rectangular, round, square. They are available in different sizes. The thicker the metal, the larger the punch (or bit) is required. There are models with interchangeable punches, and there are rotary ones. In rotary or revolving (pictured above), the nozzle is changed by turning a wheel with bits of different shapes and sizes. If you plan to work with sheet metal often, that's a good thing. For occasional use, this luxury is useless.

At the ceiling and floor, you can fasten the profiles with an ordinary tool, but it is more convenient to work with a special

There is also a metal profile cutter for convenient fastening of profiles under the ceiling or at the floor. Their handles are not a continuation of the working part, but are installed at an angle. For some (Ultra Profil EDMA) at 90 °, others at 45 °. This tool makes it even faster to create wireframes for false ceilings.

One-handed and two-handed and working principle

It is also worth remembering that there are one-handed and two-handed models. The one-handed ones have a return spring that opens the handles after the tension is removed.

One-handed operation is far from easy. Especially on good normal metal profiles. So often one-handed ones are still operated with two hands. In this case, the procedure for working with a cutter for KG profiles is as follows:

- We set profiles by level.

- With the left hand we fix them in the desired position.

- The tool is on the right. We bring its working part to the desired point, compress it until the bit hits the metal.

- We remove the left hand (the profiles "hold" the cutter), squeeze the handles with both hands.

Two-handed work differs in that the handles are at such a distance that you cannot even pick them up with one hand. Well, they are also designed to connect thicker metal.

How to choose a cutter for a metal profile

Perhaps the most difficult thing is the choice of a specific model of the cutter. They are divided, as usual, into household and professional ones. The difference in price is more than tangible. The cheapest and most acceptable in quality can be purchased for about $ 10, normal ones - from $ 20-30, and really good ones can cost $ 100 and more.

What is the difference? In work resource and usability. This means that the more expensive ones use more durable and expensive metals, rubber and plastic for handles, etc. They have a more complex structure of the working part, there is a mechanism that reduces the force required to connect. In general, there is something to pay for. But nevertheless, for periodic work, for home, you can find quite good and efficient copies in the cheap segment.

When choosing a cutter for a profile from any category, look at the following parameters:

- The maximum thickness of the fastened parts. Please note that the total thickness of the metal that this tool can pierce is indicated. That is, if 1.2 mm is indicated, this means that you can take two sheets of 0.6 mm or 0.8 mm + 0.4 mm, but not two sheets of 1.2 mm.

- The shape and size of the "window". Rounded corners make work easier.

- The presence of a roller that pushes the punch. Such models are more expensive, but much less effort is needed.

- The body is free of defects, cavities, cracks, massive and heavy.

- We evaluate ergonomics.

- The handles should be comfortable, with stops.

- Ideal if the grips have rubberized tabs. Otherwise, you will have to work with gloves - there will be corns.

- When opened, the handles can be grasped with one hand.

- Smooth running under compression.

- No backlash.

For professionals, such a tool is a godsend, but for amateurs and home craftsmen the price is too high.

And it is very desirable that the company is well-known. Although, there are also unnamed "Chinese", which are very good for home use.