How to stick fiberglass wallpaper

Painted walls and ceilings are becoming more and more popular. But preparation for painting is another task. The paint shows all the flaws and irregularities and it takes a long time and dreary to do it. To simplify the task, and at the same time to make the wall embossed, you can use fiberglass wallpaper. They are intended for painting and serve for a very long time. How to glue fiberglass and we will discuss further.

The content of the article

What is fiberglass

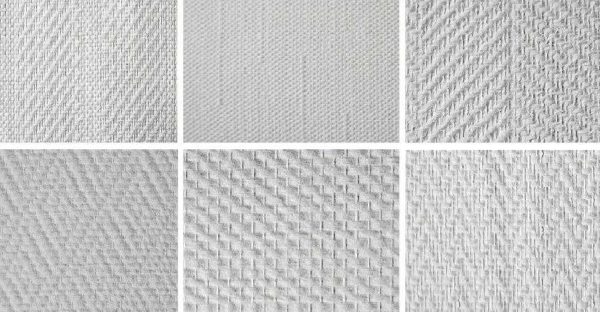

Glass fiber is a finishing material for walls and ceilings. Most often used for painting. From fiberglass on special machines weave cloths, which are called "glass fiber". Different patterns are obtained by using fibers of different thicknesses and their different weaves. There are not so many of them as on ordinary wallpaper, they are not too pronounced. And this is considered one of the disadvantages of this finishing material. But their practicality, durability and the ability to repaint them up to 20 times outweighs this disadvantage.

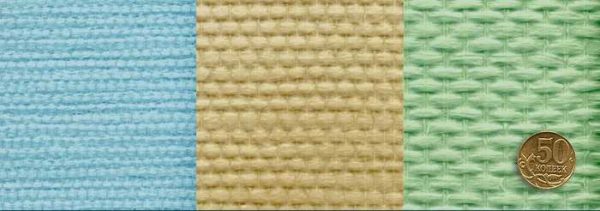

There are drawings that are almost imperceptible, which, after painting, simply give a slightly rough surface. The most common type is matting. It is named so because the weave is made in the same way as a coarse cloth was previously woven - matting. It is small, medium, large. The difference can be seen in the photo.

The herringbone, checkerboard and rhombuses are also widespread. They also have small, medium and large. They differ in the "scope" of the picture. In addition to these types, there are other weaves, but they already belong to the category of copyright or collection and cost more.

This material is sold in rolls, the width is usually 1 meter. Roll length - from 12.5 m (there are also 50). Price per roll - from $ 20 to $ 50. The cost depends on the length of the material in a roll, the complexity of the pattern, the manufacturer.

Advantages and disadvantages

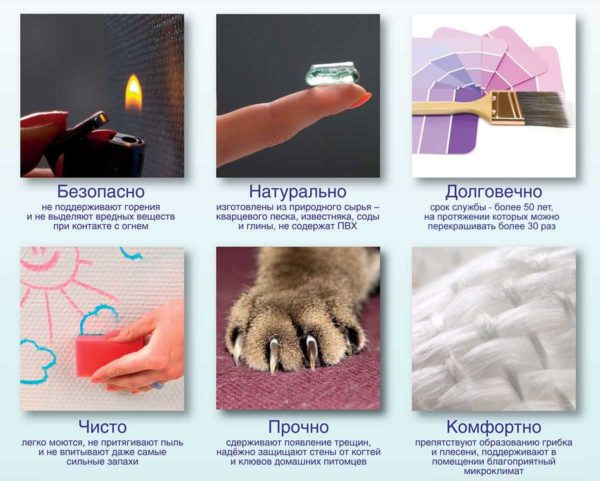

Before gluing fiberglass, let's figure out their pros and cons. Let's start with the pros. They are made from natural raw materials, they are safe, environmentally friendly and do not support combustion. They are characterized by increased strength, service life - from 10 to 30 years. Suitable for painting, which allows you to quickly change the interior. It can be repainted without changing the appearance from 5 to 20 times (depending on the quality).

Glass fiber make it easier to prepare the surface for painting. The walls should be even, but not perfect - all small deviations will be hidden by fiberglass and wallpaper relief. And this is a significant plus.

Another positive point is that they are not afraid of high humidity, therefore they can be used both in the bathroom and in the kitchen. You just need to choose the appropriate paint.

The disadvantages are as follows:

- The assortment is not as large as that of regular wallpapers. The appearance can be diversified by decorating the walls covered with glass fiber wallpaper, using various design techniques.

- Fiberglass splits when gluing, you must work in protective clothing.

- The price is higher than ordinary beautiful wallpaper.

In general, not an ideal option, but if you need a durable finish with the ability to quickly change color, glue the glass wallpaper is your choice.

How to choose

Usually fiberglass is chosen according to the pattern, and the quality is determined by the density of the material in the roll. But it should be said that not everything on the wall looks as voluminous as on a roll. In order to make the pattern look clearer, some manufacturers use fluffy threads. When glued to the wall, all the villi are pressed, the volume goes away.So volume in a roll is not a guarantee that the drawing will be clearly visible on the wall. The way out is to purchase proven brands that guarantee a certain quality.

Practically the same is the case with the density of fiberglass "to the touch". To give them extra strength, some manufacturers impregnate the canvas with starch. When glued from glue, this impregnation gets soaked, the surface turns out to be loose, which is why it absorbs a large amount of paint.

We look at the technical characteristics

How to determine in this case good fiberglass? Look in specifications. There is a line - density. The higher the number, the denser the wallpaper (normal weight is about 145 g / m22). If this indicator is not available, there is a roll weight. In this case, too - the heavier the roll, the greater the density of the material. But in the case of weight, you also need to look at the length of the canvas in a roll - it can be very different - from 12.5 meters to 50. There is another way out - trust trusted manufacturers or try on a small piece - glue it, then paint it. Only the question of where to get this piece remains open ...

What else is worth knowing about cullet ... that they come in two varieties - the first and the second. The first grade is of good quality and is usually covered by a warranty. The second grade is something like a lottery. They may be wow, they may not stick well, have a large number of defects, etc.

A few words about marriage. It is found even in good manufacturers - the threads broke, went wrong, etc. This place is marked on one of the edges of the roll with a glued black stripe, and 50 cm (penalty) is added to the length of the roll. When purchasing a roll in a transparent package, inspect the ends. The fewer black "markers", the easier it will be when cutting.

Manufacturers

And finally, about proven manufacturers. We can definitely recommend the Wellton and Oscar trademarks. Any collection, any roll, they have good quality. Even the second grade is not about quality, but about non-standard length (so you can save money).

As for the pricing policy: Welton - more expensive, the choice of drawings is larger, you can repaint up to 20 times; Oscar - cheaper, fewer textures, you can repaint up to 10 times. So there is a choice for every wallet.

How to glue fiberglass

Fiberglass wallpaper for painting is glued to special glue or PVA and its analogues. Regular wallpaper glue will not work, and you shouldn't try. If this is your first experience, it is better to take a special composition, and not in powder, but ready-made, in a bucket. Yes, it is more expensive, but the quality is guaranteed, it will be easier to glue, there will be fewer problems.

Surface preparation

Before gluing fiberglass, you need to prepare the walls or ceiling. The walls should be flat, without potholes, protrusions. It is necessary to remove stains, dust, it is desirable to cover with a primer. A diluted 1 to 10 PVA is suitable as a primer. This composition is applied to the walls with a roller, they wait until it dries, then they begin to glue the fiberglass.

A few tips for preparing for gluing for different substrates:

- Old wallpaper. They are removed completely. To do this, they must be soaked with water, removed with a spatula. If the wallpaper was vinyl, first remove the vinyl layer, moisten the remaining substrate with water and remove with a spatula. If necessary, level the surface - putty, level with sandpaper, apply a primer.

- If old fiberglass wallpaper is pasted on the walls, it is not necessary to remove them. If there are bubbles somewhere, they are pierced or cut, glue is injected, the canvas is pressed so that there are no bubbles. After drying, a layer of putty is applied, leveled (sandpaper), primed. Then you can glue new fiberglass.

- If you want to glue the fiberglass wallpaper onto drywall, you must only putty the joints.They are filled with a compound for drywall joints, glued on top with a reinforcing tape (not a mesh), pressed with a spatula the tape into the putty, then everything is leveled. After drying, they are leveled with sandpaper, dust is removed and primed, but not only the joints, but the entire surface of the gypsum board. When everything is dry, you can start gluing the fiberglass wallpaper.

- Concrete, brick walls are prepared in the same way. First, large potholes are sealed, then putty with the first layer, after drying, they are leveled, covered with a layer of soil. When it dries, apply a second layer of putty - leveling. The dried wall is covered with soil, after drying, you can glue the fiberglass wallpaper.

As you understand, when preparing the base, it is important to close up significant depressions, remove protrusions. It is possible not to achieve a perfectly flat surface, as for painting, but significant differences are visible. Therefore, they are smoothed with sandpaper. If there are cracks, they can not be filled, but glued with reinforcing paper (which is used for drywall) before applying the putty.

Pasting with fiberglass

Now, specifically about how to glue fiberglass. The process itself is no different from gluing conventional ones - vinyl, acrylic, etc. The techniques and sequence are the same. The peculiarity is that the glue is applied only to the wall, the wallpaper is not smeared. Otherwise, everything is the same:

- Glue is evenly applied to the wall or ceiling. It is faster to do this with a roller, in the corners and joints from the ceiling and walls use a narrow brush. Spread the adhesive evenly. Where there is too much of it, "dips" will form, and handprints may be visible. In places where there is little glue, the fiberglass will not stick, a bubble forms. Until the wallpaper is painted over, the bubble is not visible, only felt by the hand (after drying). When painting, they all appear. Therefore, we try to distribute the glue evenly over the entire surface.

- The canvas is cut along the length of the wall + a small margin (5-10 cm).

- The first sheet of fiberglass is glued to the wall strictly vertically. The verticality of the edge is checked (preferably with a plumb line). The canvas is smoothed with movements from the center, to the edges - this way the air escapes better. For this, it is advisable to use a plastic wallpaper spatula. They work conveniently and quickly.

Excess lengths (top and / or bottom) are trimmed. In the right place, apply a steel ruler or a wide spatula, cut the fiberglass with a sharp blade or a clerical knife.

We glue the second canvas

The next sheet is glued end-to-end. It is applied to the edge of the already glued one, aligning the pattern. Then smooth it to the surface first with your hands, then with a spatula. You should not use a rolling roller for gluing the joint - it "rolls out" the pattern, and the knock stands out even more. The canvas fits well with the hands.

When gluing the outer corner, there are two options:

- Stick the canvas so that its edge sticks out about 10 cm. Apply glue to the other side of the corner, wrap the canvas with your hands or a sponge, press it against the corner. The next strip is glued with an overlap (2-3 cm), but so that the pattern matches, glue it to the wall. Take a metal ruler or wide spatula and cut both blades at the overlap. This line is made at some distance from the corner - the cut strip should be 1-2 cm wide. Next, we remove both cut strips (one on top, the other on the bottom). We coat the joint again with glue (with a brush), connect the canvases. If the drawing is selected correctly, almost nothing is visible even before painting.

- Stick the canvas on one side of the corner, cut off the excess with a sharp knife or blade along the corner line. Glue the canvas to the second part of the corner and cut it off in the same way. At the junction, connect both canvases.

When gluing the inner corner, there is usually one technique. The last canvas on the wall should go to the next wall by 1-2 cm.If it is wider, it is cut off.This makes it easier to lay glass wallpaper, even if the angle is uneven. The next strip is overlapped. There is a double layer at this point, but usually it is almost invisible. If you really do not like it, you can make the entry a little more than 3-4 cm, glue it with an overlap, and then cut off the excess, stepping back from the corner of 1-2 cm.

Modifying the little things

In those places on the wall where the sockets meet, the switches work when the power is off. It is best to turn off the machine on dashboard. Remove the outer parts of the sockets and switches, stick the canvas. At the outlet of the power grid, the fiberglass is cut crosswise. Take a spatula, applying it to the outlet. cut off the excess with a knife, press well.

While you are gluing fiberglass wallpaper for painting and while they are drying, there should be no draft in the room. You should also curtain the window so that the sun does not dry out the surface (bubbles may form).

You probably already realized that if you have pasted ordinary wallpaper at least once, you know exactly how to glue glass fiber. Because there are almost no features. All the same. Features begin later - the wall needs to be painted. That's what's unusual.

How to glue glass wallpaper is described in the video clip. Everything is accessible and understandable.

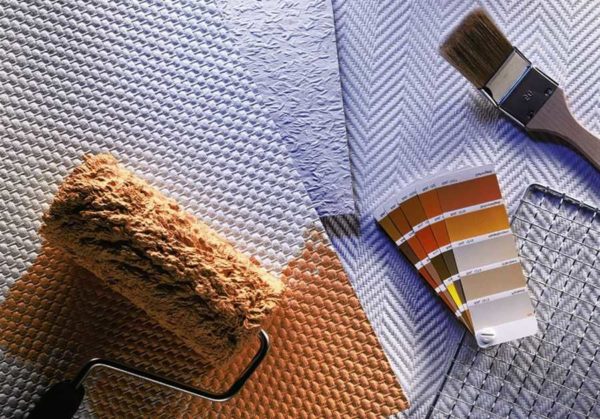

Fiberglass Wallpaper Paint

You know how to glue fiberglass, we will figure out what and how to paint them. Most often, water-based and water-dispersion paints are used for painting glass wallpapers. Acrylic and latex dispersions are easy to clean, some with a brush and detergents. Some of these compounds withstand thousands of brushing cycles (vandal resistant up to 20,000). Therefore, they can be used even in rooms with active use - in the corridor, hallway, in the kitchen, in the bathroom.

Water emulsions are also washable, but they are not as durable. They, at best, can be wiped with a damp cloth several times. But they do not reduce the vapor permeability of the walls. Therefore, they are often used to paint living quarters.

There are also special enamels designed for painting wallpaper. They are good too, but they cost more. When selecting, pay attention to the area of use - there should be an inscription that this composition is suitable for wallpaper (or fiberglass).

How thick is the paint needed? Basically, it doesn't matter. If it is liquid, you will have to apply more layers, if it is thick, less. In any case, the same amount of dry matter will be required to obtain a good effect. Another thing is that sometimes thicker ones are more profitable, although they are more expensive. In this case, it is necessary to look at the spreading rate and the required number of layers.

Features of paint for fiberglass

Pay attention also to the type of surface obtained when painting. The relief is best emphasized by a silky matte paint, but simply matte will partially hide it.

There is one more thing. Glass fiber is a porous material and paint consumption, especially when the first layer is applied, is large. To reduce it, it is advisable to prime them. As a primer, you can use a base paint diluted 1 to 1 with water (if the paint is water based). Its covering power will become lower, but due to the large amount of water, it will better penetrate the pores. The pigment will fill them when dry. The next layer of "normal" density will lie better, it will be absorbed less. This, albeit not very much, will lower the overall paint consumption.