How to cut ceiling plinth in corners

The quality of the ceiling finish greatly affects the appearance of the room. Therefore, they try to do everything perfectly, or very close to it. The finishing touch to the design is the ceiling plinth. They give the finish a complete and holistic look. The strips themselves are mounted on flat surfaces simply: on special white glue, but problems arise with the design of the corners. Without knowing how to make the corner of the skirting board correctly, a lot of material deteriorates. We will tell you about how and what to cut it in the corners.

The content of the article

What is it made of and what is it called

The very first skirting boards on the ceiling were made of plaster. They were cast in special molds and then installed on the ceiling with mortar. Such figured ornaments were called fillets. Today, you can rarely see them: they are expensive, and outwardly they are almost indistinguishable from the cheaper options. And the name is almost lost.

The most popular ceiling skirting boards are made of polyurethane or polystyrene. They are inexpensive, look great, are easy to install, have a wide range of profiles and patterns. The width can be from 5 mm to 250 mm. They are used in almost any room, decorated in any style. An exception - wooden houses with a suitable interior. Wooden products are most often used here - the style dictates its own conditions.

Part of the assortment in a specialized store

There is also a similar plastic finish. It is mainly installed in bathrooms. But even in damp rooms, you can safely mount polyurethane strips - they are not afraid of dampness.

You need to cut the ceiling plinth in the corners of any material in one of the ways described below. The only exception is plastic skirting boards: you can arrange such a corner only using ready-made corners.

What and how to cut

Working with skirting boards made from different materials means using different cutting tools. When working with a wooden ceiling plinth, it is more convenient to work with a saw on wood. All others, including plastic ones, made of foam and other polymers, are better cut with a blade for metal. The result is a smoother cut, less burr. Saws are usually used when working with a miter box.

Corner design is attractive

When working with polystyrene skirting boards without special devices, they are cut with a good office knife. Its blade is quite thin and even, the cut is smooth, not wrinkled. If you work with a saw with polyurethane or polystyrene, do not press hard: you can wrinkle.

In general, in order to get used to the tool and material a little, take a piece and practice on it: cut, saw, trim. So there will be fewer problems when working.

You can read about the design of the ceiling in this article.

How to get the correct angle

Most of the problems when working with skirting boards arise in the design of corners. Since the surface of the products is complex, it will not be possible to simply cut off at the desired angle: it is also necessary to cut so that they dock and, preferably, without large gaps. There are actually several ways to make the corner of your skirting board perfect (or nearly so).

Using a miter box

If the corners and walls in the room are even, you can use a special carpentry tool - a miter box. This is an inverted U-shaped chute with lines for cutting at 90 ° and 45 °. The part in which you need to make a saw is laid inside, a saw is inserted into the guides.The part is held in place and cut at the desired angle.

This is what the miter box looks like. Can be plastic, wood or metal

In the case of skirting boards, not everything is so simple: they must simultaneously adhere to two surfaces, therefore they must be pressed against one or the other wall of the miter box. When working with ceilings, they are pressed against the side closest to you.

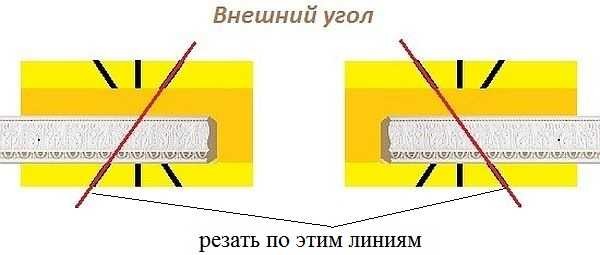

The sequence of actions when finishing the outer corner, you need to make a gash at an angle of 45 degrees. Place the miter box in front of you. Trying on how the plinth will be located, determining which part of it will be attached to the ceiling. In order not to get confused and cut off the ceiling plinth correctly, place the strip that will be located on the right on the right, the one on the left on the left.

How to cut a corner on a ceiling plinth: install it correctly in a miter box

With the part that is on the ceiling, press it against the bottom of the miter box. The other side is closer to you and raised. Lean it on the wall of the device so that it does not stagger when cutting. That is, the front of the skirting board turns out to be turned away from you. Do the cutting direction as shown in the photo below. By putting the two cut pieces together, you get a protruding outer or outer corner.

How to make the outer corner of a skirting board using a chair

First put the sawn-off parts in place "dry", without applying glue. If the geometry of the corner is not so perfect, you can tweak it a little with a knife. It is easier to cover small errors with a special putty.

The situation is very similar with the inner corner of the skirting board. First you try on which side will be on the ceiling, press this part to the bottom of the miter box, lean the second part on the wall closest to you and make cuts as shown in the photo below.

How to make an inner corner of a ceiling plinth using a miter box

And again, first try on without applying glue, if necessary, slightly adjust. Then apply a thin bead of glue to both surfaces that will adhere to the wall or ceiling.

Your own version of how to use the miter box correctly is shown in the video.

How to make a corner of a ceiling plinth without a miter box

Few people in apartments or houses have angles exactly at 90 °. Small deviations are easily corrected after fitting. But not always. Then you have to mark everything "in place" - under the ceiling.

You will need a finely contoured pencil (hard - it is not so visible on the ceiling, but leaves quite clear marks near it), a small piece of plinth, a ruler and a good stationery knife if you work with polyurethane (polystyrene) baguettes or a metal saw for working with other materials.

Apply the plinth to the corner, draw along the outer edge with a pencil. Apply to the other side of the corner, also mark. You have a cross on the ceiling, the center of which marks the place where the plinths of the ceiling plinth should converge (see the photo). Having installed a piece of plinth in the corner, which will be glued there and resting its end on the wall, transfer the mark to it.

How to make corners on skirting boards without using special tools

Now take a ruler and connect the edge of the skirting board with the marked mark. If you just put the plinth on the table and cut it along a line, the two parts in the corner will still not fold: the inner part will interfere. It can be trimmed later by trying on the ceiling. The second way is to set the piece to be cut on the table with the piece that will be on the ceiling. And cut along the line, but holding the knife at an angle of about 45 °. It will still need to be corrected, but much less (and less likely to make a mistake).

Repeat the same operation with the second bar. Attach it to the desired wall, rest the butt against the adjacent wall, mark the place where the cross is drawn, draw a line and then cut it off. Correction Carried out "dry" without applying glue.

You repeat exactly the same steps for the outer (protruding) corner. Now you know another way to make a corner of a ceiling plinth, and without a scissor or other special devices.

You can read how to install sliding interior doors here.

With decorative corners

There is one more, the easiest way. For skirting boards made of polyurethane or polystyrene, use ready-made, factory decorative corners. They are installed in a corner, strips are glued to them closely. It is very easy to cut them if necessary: by a few millimeters with an ordinary clerical knife.

Examples of finished fillet corners

How to join in corners

If the installation of the first corner is completed, we can assume that you have already learned almost everything. "Almost", because you still need to learn how to join the corners and cut the planks to length. When some part is already glued and there is a small distance to the corner, how not to be mistaken with the length? The answer is simple: leave some stock.

At first, you can cut a piece 10-15 cm longer: it will be possible to redo it several times if something does not work out right away. Then you make a corner in the way described above, try it on dry, adjust everything so that the result suits you. Only then can you attach the already cut bar to the corner and mark the place to which it can be shortened. The trim must be exactly 90 °. It is not necessary to use a miter box. Just try to place the knife (hacksaw) perpendicular to the surface.

Since one skirting board is cut in a strictly mirror image in relation to the other, it is very important to maintain an exact 45 ° angle when cutting at the same time. It is necessary to fold the two skirting boards with the inner side to each other, put them in the miter box and fasten tightly. After that, a cut is made with a fine-toothed hacksaw. Without a miter box, the corner will surely "run away"!