Interior decoration of a wooden house: technical features

Wood construction will probably always be there. The atmosphere in such buildings is very good, and the appearance of a well-felled house, according to the most conservative estimates, is attractive. Finishing a wooden house inside is a separate topic with many nuances: wood is a special material, the characteristics and properties of which should be taken into account. Let's talk about the technical and technological features of finishing work in a wooden house.

The content of the article

When to start

On a "fresh" log house, you can start finishing work no earlier than the main shrinkage. If the frame is made of glued beams, 3-4 weeks should pass. For all other types of wooden houses, the period is calculated in months, and sometimes years. The exact time of shrinkage depends on the initial moisture content of the raw materials, climatic zone and construction time. This is how complicated it is. In any case, earlier than a year later, in extreme cases - after 10 months, it is not worth starting finishing. During this period of time there is an active shrinkage of wood, logs and beams decrease in size, the insulation laid between the crowns is crushed. If you attach the trim until the basic processes have passed, it will fall off or warp. We'll have to shoot and redo everything. So don't be in a hurry. Moreover, the work will be enough: you need to achieve the tightness of the joints, and this is not easy. Careful competent caulking is needed.

Before starting finishing work, it is tedious to dig a blockhouse from a log or bursa

Usually, the main caulking of a log house takes place in two stages. Primary - a few weeks after the installation of the frame, and secondary - about six months - eight months. Each time the cracks are clogged with insulation - jute, tow, sometimes moss. They do it right away both from the outside and from the inside, otherwise the house will warp. Therefore, the building is bypassed around the perimeter, caulking alternately, each crown, now from the outside, then from the inside. Work begins from the bottom, from the lowest row of logs or timber.

With each caulking, the frame is raised by 5-7 cm. Then, under the force of gravity, it gradually subsides. The sealed mezhventsovy insulation reliably bridges the cracks. The quality of this work is very important: it not least depends on how warm the house will be.

They begin finishing work inside the wooden house after the log house has settled down after the second caulking. To determine whether the process is complete or not, the height of the walls is periodically measured. If there are no significant changes within two to three months, we can assume that the main processes have passed. It's time to start finishing inside and outside the house.

Read how to build a house from a bar here.

Types of wall decoration of a wooden house

If the frame itself has an attractive appearance, it is rarely sheathed. In this case, it makes sense to reduce the cost of interior decoration: to grind a log or timber and tint. Only the floors should be varnished: the varnish will prevent abrasion of the wood. And the walls and ceiling are best covered with tinting antiseptics or water-based paints. They do not paint over the texture of the wood, but only give it a shade, better showing the pattern. You will still have to use antiseptics - to maintain the attractive appearance of the wood.

You will most likely have to use antiseptics, you can take them with a coloring pigment, at the same time emphasize the beauty of the wood pattern

If the log or timber is normal, the caulking seam looks bad, it is sealed with a twisted cord, and the walls are finished as well - they are polished and tinted. Everything looks good too, and the cord in the groove serves as an additional guarantee against drafts.

Ugly seams from caulking can be sealed with a cord - it looks attractive, and even from drafts

How to sheathe the walls in a wooden house inside

If the blockhouse is so crooked or old that you can't help the matter by grinding, you will have to make the interior decoration of a wooden house from lining, wall panels, drywall or other material.

For any of these materials, it is better to make a crate: this way you can level the surface of the walls. In addition, there is room for free air circulation behind the crate. In a wooden house this is important, since only dry wood does not rot or blacken. Free air circulation between the decoration material and the wall will maintain their normal condition.

The lathing in the house from a bar or a log is done in the same way: you need to remember that it must "float" so that the finish does not fly off

The distance behind the crate is still used for laying communications - electrical wiring, for example. In a wooden house it must be made in non-combustible pipes, so there is a lot of space for it. There, if necessary, you can lay insulation - this is if your house turned out to be cold. If you spend a little on heating and the house is warm, it is better not to use any additional materials: no insulation, no vapor barrier. Wood itself does an excellent job of maintaining a stable humidity in the house, and the extra layers only upset the balance.

Fastening the trim to the crate is not pleasant to everyone: if an animal or insects settle behind the casing, it is difficult to get rid of them. In this case, you can level the surface of the logs by removing the protruding parts and nail the finish to such a surface. A perfectly flat surface is difficult to achieve, but possible. The gaps between the finishing material and the wall, which in this case are still there, were once covered with clay. It will be both thermal insulation and will protect from drafts. Technologically this is not correct, but they also do it.

Whatever materials are used for cladding the walls of a wooden house inside, a gap of at least 2-4 cm must remain to the ceiling. For a "young" log house, this is insurance in case of shrinkage. For the old one - a gap to compensate for changes in the geometry of the wood. She breathes all her life: it gains moisture and swells, then dries up. The gap under the ceiling will allow the wood to expand or shrink easily, without affecting the finish. If it is not done, then either gaps will appear, or bend / tear out the finish. So that the gap does not "cut the eye" it is closed with a ceiling plinth. He is nailed only to the stream, only leaning against the wall. In this case, all progress will be invisible.

Read about the interiors of a wooden house and methods of interior decoration in the article "Design of a wooden house inside in photos and videos"

Clapboard decoration inside the house

Lining is the leader among finishing materials. It is used both inside and outside the house, only with different treatments (impregnations and paints are taken for external or internal work). There are different types of it. It's not just about different types of wood or different widths of the board. There are also different profiles: smooth, wavy, imitating a timber or log house. There are several options in the photo below.

The most popular types of lining for interior decoration of a wooden house inside

Finishing of a wooden house inside can be made from lining with a non-standard profile

For finishing inside the house, the lining is taken not thick: 1.5-2 cm is enough. It costs less, and will fulfill its functions. The slats can be placed horizontally, vertically, at an angle. From the combinations of all these directions, you can get an amazingly beautiful panel, but this is a laborious task.

When nailing the crate or planks, you need to remember about the shrinkage of the log house and the ability of the wood to swell and shrink. Do not nail the trim and battens close to the floor and ceiling, leave 2-4 cm each to compensate for these extensions.

Clapboards are used to trim both the walls and the ceiling. And here and there it looks more than decent, and such a finish is relatively inexpensive. It is cheaper (and easier to perform) only to cover with plywood and paste the wallpaper. By the way, this is a popular option for decorating a country house inside an economy class. With a sufficient level of performance, this method can also be used to decorate premises not only in the suburban version. The only objection is the glue used in the manufacture of plywood. But if you take it to the I class of emission (allowed for use in childcare facilities), then, probably, nothing terrible will happen.

How and what to paint the lining inside the premises, read here.

Mounting methods

Previously, they did not particularly worry and nailed the lining into the face (into the front surface) through and through. In the best case, they used nails without caps or finishing nails (they have very small caps). Sometimes the hats were covered with putty on wood and sanded, sometimes the holes from the screws were closed with pins. This is for the most fastidious and demanding finishes.

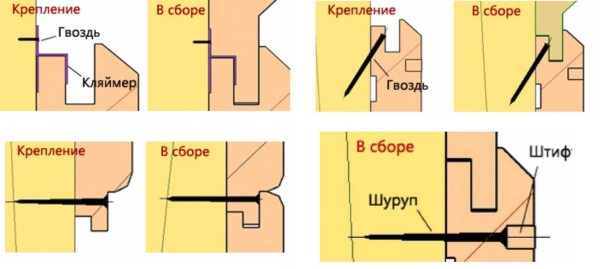

Today, even this method is not considered the most aesthetic: you can still see the traces. To not see anything, they use secret methods:

- nails or screws are driven at an angle into a thorn or groove;

- using cleats (cleats).

Both of these methods require patience and accuracy: thin, small nails are used, they need to be nailed so as not to damage the front surface. To make it easier, you can hit not with nails, but with staples from a construction stapler. Staples are taken with a narrow back and long legs, made of stainless steel with sharpening. Although there are models of staplers that "shoot" nails with a very small head. For fixing the lining - the very thing. They also use self-tapping screws. A comparison of the two methods is made in the video.

There is one caveat. If you bought non-chamber drying lining (its moisture content is 7-8%), it will gradually dry out. There will be gaps between the planks and you will either have to put up with them, or nail all the planks again. Sometimes two or three times. It is impossible to avoid this. You can only choose a profile in which the gaps will be invisible (profiles "Softline" and "Standard" in the figure in the previous section). In this regard, you need to think carefully about the better to fix the lining for the first time: it will have to be removed. Therefore, it is advisable to do so that it is easy and that it does not collapse. Here everyone decides for himself: it is more convenient for someone to work with self-tapping screws, someone with nails. Both methods are not ideal (it is difficult to pull out the nails, and you need to drill a hole under the screw head), but both are acceptable.

Sometimes it becomes necessary to dock the lining with a wall of logs. Difficulty can arise due to the fact that the wall has a non-linear shape. You can outline it using a small piece of lining, to which a simple pencil is attached. Putting the plank and leading along the wall with a piece of lining with a pencil, transfer the shape of the log to the plank. By carefully sawing out along the marked line, you can achieve an almost perfect match.

You may be interested to read about how to lay laminate.

Wall panels for interior decoration

Decorating a wooden house inside with wall panels gives completely different stylistic results. This finishing material is made from different materials with different textures:

- wood;

- bamboo;

- MDF (laminated and veneered);

- glass (smooth with applied photo printing, embossed, colored, transparent, matte);

- plastics and plastics;

- skin.

They are type-setting or panel board. Typesetting - long thin elements, connected according to the principle of "thorn-groove".Lining is in fact also wall panels. It's just that it has long been used as an independent category of finishing materials. Panelboard wall panels differ in geometry - they have a comparable length and width.

Everything is usually assembled on a crate (like a lining), the bars of which are stuffed taking into account the dimensions of the chosen finish. This material is loved by designers: materials, textures and colors allow you to realize a variety of ideas. Such interior decoration of a wooden house can be very expensive - leather - or cheap - MDF panels. But the appearance is quite decent.

If the wall panels according to the technology should be laid on glue (gypsum, for example), then the backing plates - plywood, gypsum fiber board, etc., are attached to the crate (you remember that in a wooden house it must be made floating). Plates are placed on this substrate with glue. An example is shown in the video.

About features read the design of a wooden house inside here.

How to sheathe a wooden house from the inside with drywall

The technology of work in a house made of wood or other material is no different: the frame is assembled, and drywall is attached to it. Only, as in the case of the lathing for the lining, you need to leave gaps near the floor and ceiling. The only condition: this type of interior decoration of a wooden house is possible only after complete shrinkage (at least several years must pass and the house must be heated). Gypsum is a fragile material and will simply tear with significant changes. The only option that will allow you to ignore them to some extent is to make a floating frame, fixing the profiles to the walls not rigidly, but leaving freedom of movement. Then the blockhouse will settle by itself, and the drywall will remain in place.

With the help of what and how to make a floating crate for fastening rigid finishing materials (drywall, ceramic tile bases, etc.), see the video.

Another feature of finishing a wooden house with plasterboard: all joints, seams and corners must be glued with a polymer reinforcing mesh. It will prevent the formation of cracks in the most problematic areas (or slow down their formation). If you need to make a house cladding from a bar inside with drywall, but you really do not want to lose precious centimeters of area due to the installation of profiles, you can do it as in the next video. There are some practical tips.

The layout of the interior of a country house is described here.

Features of the interior decoration of an old wooden house

If a house made of timber or logs has stood for several decades, first of all, you need to assess the condition of the wood. To do this, remove the entire finish and "pick" all suspicious spots - a darker or lighter color, differing in structure or texture. This can be done with a screwdriver, chisel, even a knife. If the wood is dense everywhere, there are no signs of destruction, everything is fine, you can start finishing. Perhaps you need to impregnate walls and other structures with protective impregnation first - to protect the wood for several more decades. But not all owners of wooden houses agree to chemical treatment, so it's up to you.

If the wood crumbles from your efforts, you need expert advice. It is necessary to determine what caused the damage - insects, fungi or microorganisms - and what measures should be taken. Then the damaged pieces or elements are changed, paying special attention to the treatment with antiseptics and protective impregnations of the adjacent areas.

After evaluating or "treating" the wood, you can start to update the look. The interior decoration of the old wooden house is no different from those described above. Unless only by the fact that shrinkage is not worth taking into account: there are no significant shifts. So from this side, everything is somewhat simpler.