How to weld (solder) polypropylene pipes

All metal pipes are often replaced with plastic ones, in particular, made of polypropylene. They have a long service life (up to 50 years), do not rust, do not rot, weigh a little, and you can also assemble everything with your own hands, without involving specialists. Welding polypropylene pipes requires some skill, but it comes quickly. You can first practice on small trims and inexpensive fittings, and then start creating more serious things.

The content of the article

Types and purpose

Polypropylene pipes are available in four colors - green, gray, white and black. Only black ones differ in characteristics - they have increased resistance to ultraviolet radiation and are used for layingirrigation systems on the ground. All others have similar characteristics and are laid indoors or buried in the ground.

By appointment, polypropylene pipes are of the following types:

- For cold water (temperature up to + 45 ° C). They can be easily distinguished by their longitudinal blue stripe.

- For hot water supply (heating up to + 85 ° C). A distinctive feature is a red stripe.

- Universal (maximum heating up to + 65-75 ° C, depending on the manufacturer). Two stripes are applied side by side - blue and red.

There are pipes with different characteristics for both cold and hot water. This is reflected in the marking:

- PN10 are used exclusively in cold water supply systems (up to + 45 ° C) with low pressure (up to 1 MPa). They have a small wall thickness. Not suitable for high-rise buildings.

- PN16. They are often labeled as universal, but more often they are used for cold water - they can withstand heating of the medium up to + 65 ° C and pressure up to 1.6 MPa.

- PN20. Thick-walled pipes that can transport media with temperatures up to + 80 ° C can withstand pressures up to 2 MPa. Used for distribution of hot water and heating systems.

- PN25. These are reinforced polypropylene pipes (foil or fiberglass). Due to the presence of a reinforcing layer, they often have a smaller wall thickness than PN20. Medium heating temperature - up to + 95 ° C, pressure - up to 2.5 MPa. They are used for hot water supply and heating.

All of them are available in different diameters - up to 600 mm, but in apartments and private houses they are mainly used in sizes from 16 mm to 110 mm. Note that the inside diameter is indicated as wall thicknesses vary.

What is welding of polypropylene pipes

Polypropylene is characterized by increased rigidity, and fittings from the same material are used to create systems of the required configuration. These are various angles, tees, bypasses, adapters, couplings, etc. They are connected to pipes by soldering. This process is also called welding, but its essence does not change: two elements are heated to the melting temperature and, in a hot state, are connected to each other. If done correctly, the connection is monolithic and serves no less than the pipes themselves.

To connect polypropylene to metals, there are combined fittings, in which one part is made of metal and is connected using a threaded connection, and the second, polypropylene, is welded.

Than to solder

Welding of polypropylene pipes takes place using a special device called a soldering iron or a welding machine.It is a small metal platform with an electric coil inside that heats up the surface. Because of this design, this unit is also called an iron.

To connect two elements, the surfaces to be joined are heated to the melting temperature (+ 260 °). To heat the element to the required depth, two different Teflon-coated metal nozzles are installed on the welding platform:

- a mandrel (of a smaller diameter) is used to heat the inner surface;

- a sleeve is placed to warm up the outer surface.

Two elements to be connected are simultaneously put on the corresponding nozzles, kept for a certain period of time (several seconds), then connected. This is how polypropylene pipes are welded.

How to weld

The designs of soldering irons for polypropylene pipes are slightly different, but the principles of working with them are common. There are two main models - flat bed or cylindrical heater. With normal quality, both work, there is practically no difference. Those who are more comfortable choose.

Preparatory work

Before starting work, you need to warm up the soldering iron, but everything is not so simple here. The order of its preparation is as follows:

- First, nozzles of a suitable diameter are installed on the platform.

- A pin is threaded into the hole in the platform, a mandrel and a sleeve are put on it from both sides, tightened with nuts on both sides.

- If the heating element is in the form of a tube, nozzles are sold for it fixed on a plate. The plate is put on the heating element, the fastening bolt is tightened.

- The required heating temperature is set on the regulator. For polypropylene pipes, the welding temperature is + 260 ° C. We put it on the regulator, plug it into the network.

- We are waiting for the signal of the set temperature. Some models have a beep, but mostly the LED turns on or off (different models vary).

The soldering iron is ready to work. But we still need to prepare pipes and fittings. The first condition for high-quality welding is an even cut. The incision must be strictly vertical, free of burrs and burrs. Such a cut can be obtained using special scissors. They have two wide jaws on the bottom that hold the pipe in place, and the cutting part is on top.

The second condition for good soldering of PP pipes is clean, dry, grease-free parts. If you want the plumbing or heating to serve for a long time and not to flow, you should not skip this procedure. The pipe cut and the fitting are cleaned with alcohol or water and dishwashing detergent. Then they wait until everything is dry, and only after that the soldering process begins.

How long to warm

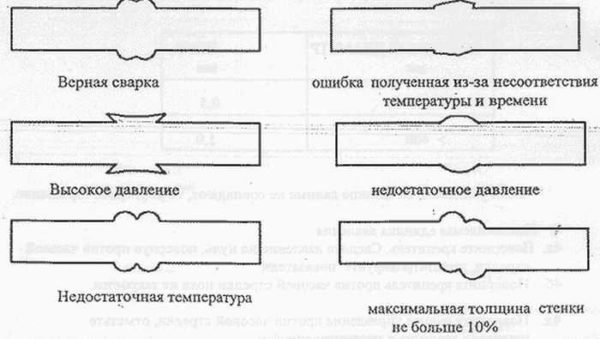

When welding, polypropylene must be heated strictly to the required temperature. Overheating and underheating significantly reduce the quality of the seam. A too overheated and softened pipe simply will not fit into the fitting, and an insufficiently heated material will not fuse.

The heating time depends on the pipe diameter, air temperature and is indicated in the table.

| Polypropylene pipe diameter | Welding depth | Heating time | Welding time | Cooling time |

|---|---|---|---|---|

| 16 | 12-14 mm | 5 sec | 6 sec | 2 minutes |

| 20 | 14-17 mm | 6 sec | 6 sec | 2 minutes |

| 25 | 15-19 mm | 7 sec | 10 sec | 2 minutes |

| 32 | 16-22 mm | 8 sec | 10 sec | 4 minutes |

| 40 | 18-24 mm | 12 sec | 20 sec | 4 minutes |

| 50 | 20-27 mm | 18 sec | 20 sec | 4 minutes |

| 63 | 24-30 mm | 24 s | 30 sec | 6 minutes |

| 75 | 26-32 mm | 30 sec | 30 sec | 6 minutes |

In general, soldering is possible at + 5 ° C, but the data is given for + 20 ° C. In hotter weather, the holding time of the elements on the soldering iron is reduced by 30-60 seconds, in colder weather, it is increased.

Pay attention to the column "depth" of welding in the table. This mark is placed on the pipe. Before it will need to press it into the fitting. This creates a small bead of molten plastic in front of the fitting edge. This will mean that the seam is made correctly.

Another column needs clarification - "welding time". This is the time for which it is necessary to squeeze and fix the welded elements.

In general, if you try to insert a cold pipe into a fitting, it should be difficult to fit - the outer diameter of the pipe is slightly larger than the inner diameter of the fitting. This is done intentionally, to provide some excess material from which the bead is formed on the seam. In order for the welding of polypropylene pipes to be reliable, it is better to take all the components from one company. So the sizes are guaranteed to match. Otherwise, it is necessary to try on - so that the fitting does not "slip", but is pulled with difficulty.

Technology

As already mentioned, when welding polypropylene pipes, they and fittings must be cleaned, degreased and dried. And only after that you can start soldering.

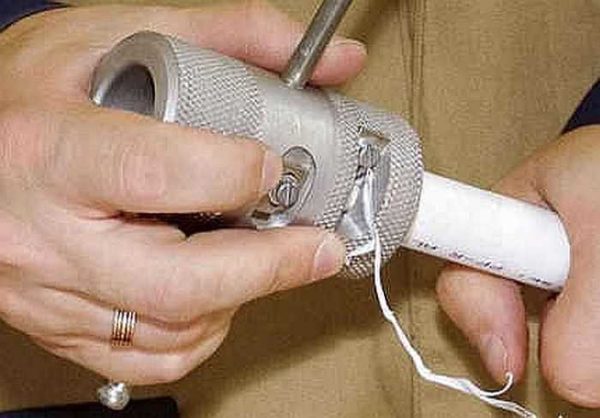

This preparation is suitable for all types of pipes except foil-reinforced pipes. In this case, after the desired piece has been cut off, the cut is cleaned to the foil with a special device - a shaver. A pipe is inserted into it and rotated several times. This removes the top layer of plastic, after which you can degrease and solder.

After the surface has dried, a mark is drawn on the pipe, marking the distance at which it is necessary to press it into the fitting (the easiest way is with a thin marker or a sharply sharpened simple pencil).

Soldering polypropylene step by step

Further, the technology of welding PP pipes is as follows:

- We put the cut section of the pipe on the mandrel, insert the fitting into the sleeve. This must be done simultaneously, as a last resort, the fitting is put on earlier, since it has a large wall thickness. The delay should be very small.

- We sustain the elements for the required amount of time.

- We remove from the nozzles, connect, pressing the pipe into the fitting to the mark. The connection is exclusively linear, you cannot rotate the elements about the horizontal axis (do not twist, although you really want to). It is possible to level the horizontal immediately after the connection if a discrepancy is noticed.

- When connecting, you have to make a lot of effort. The same force is kept for several seconds (in the table in the column "welding time").

- After the specified time has elapsed, we stop pressing, and the connection cannot be disturbed for several minutes (in the table, the column “cooling time”). After that, it can be considered that the soldering of the polypropylene pipe is completed. You can proceed to the next seam.

One note: immediately after finishing welding, inspect the soldering iron tips. If there is material residue, remove it with a soft, lint-free, fade-free (white) cloth. You cannot leave the plastic on the soldering iron - the next fragment will stick, it will be difficult to tear it off. You can not clean the nozzles using abrasives - they have a Teflon coating, they are scratched easily. And even microscopic scratches will lead to the fact that the fragment on the soldering iron (iron) sticks.

By the way, it is better to work in cotton gloves - there will be less burns.

Before putting the system into operation, it must be checked. This is done by crimping. What it is and how to do it, read here.

Layout of polypropylene pipes

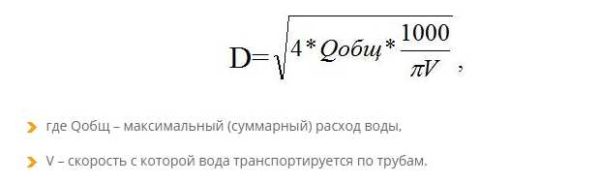

Polypropylene pipes are used for installing a comb of cold or hot water, heating. The choice of the diameter is individual in each case - it depends on the volume of liquid that must be pumped per unit of time, the required speed of its movement (formula in the photo).

Calculation of pipe diameters for heating systems is a separate topic (it is necessary to determine the diameter after each branch), for water pipes everything is easier. In apartments and houses, pipes with a diameter of 16 mm to 30 mm are used for these purposes, and the most popular are 20 mm and 25 mm.

We count fittings

After determining the diameter, the total length of the pipeline is considered, depending on its structure, fittings are purchased in addition. With the length of pipes, everything is relatively simple - you measure the length, add about 20% to the error and possible defects in the work. A piping diagram is required to determine which fittings are needed. Draw it, indicating all the taps and devices to which you want to connect.

To connect to many devices, a transition to metal is required. There are also such polypropylene fittings. They have a brass thread on one side, and a regular soldering fitting on the other. Immediately you need to look at the diameter of the nozzle of the connected device and the type of thread that should be on the fitting (internal or external). In order not to be mistaken, it is better to write everything down on the diagram - above the branch where this fitting will be installed.

Further, according to the scheme, the number of "T" and "L" shaped connections is considered. Tees and corners are bought for them. There are also crosses, but they are rarely used. The corners, by the way, are not only at 90 °. There are 45 °, 120 ° each. Do not forget about couplings - these are fittings for joining two pipe sections. Do not forget that polypropylene pipes are not at all elastic and do not bend, therefore, each turn is done using fittings.

When purchasing materials, agree with the seller about the possibility of replacing or returning part of the fittings. Problems usually do not arise, since even professionals cannot always immediately determine the exact range of products required. In addition, during the installation process, it is sometimes necessary to change the structure of the pipeline, which means that the set of fittings changes.

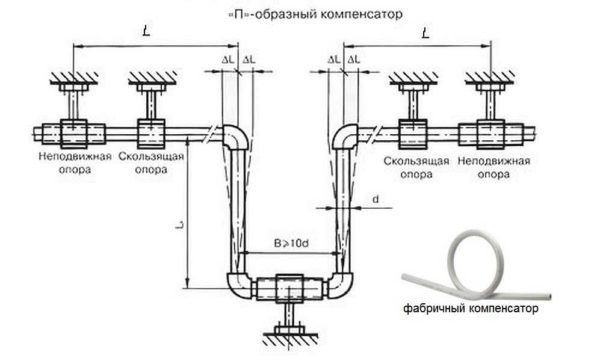

Polypropylene has a fairly significant coefficient of thermal expansion. If a polypropylene hot water supply or heating system is being installed, it is required to make an expansion joint, with which the lengthening or shortening of the pipeline will be leveled. This can be a factory-made expansion joint loop, or an expansion joint assembled according to the scheme from finishes and pieces of pipes (pictured above).

Laying methods

There are two ways to install polypropylene pipes - open (along the wall) and closed - in grooves in the wall or in a screed. On the wall or in the groove, polypropylene pipes are attached to clip-holders. They are single - for laying one pipe, there are double - when two branches run in parallel. They are fastened at a distance of 50-70 cm. The pipe is simply inserted into the clip and held due to the elastic force.

When laying in a screed, if it is a warm floor, the pipes are attached to the reinforcing mesh; no other additional fastening is required. If the piping to the radiators is monolithic, the pipes may not be fastened. They are rigid, their position does not change even when filled with a coolant.

The option of hidden and external wiring in one pipeline (behind the bathroom the wiring was made open - less work)

Soldering nuances

The process of welding polypropylene pipes itself, as you saw, does not leave much work, but there are a lot of subtleties. For example, it is not clear how, when joining pipes, fit the sections so that the pipes are exactly the length that is required.

Another point of welding polypropylene pipes is soldering in hard-to-reach places. It is not always possible to put a pipe and a fitting on the soldering iron on both sides. For example, we solder in the corner. The soldering iron, you have to stick it into the corner, on one side the nozzle rests directly on the wall, you cannot pull the fitting over it. In this case, a second set of nozzles of the same diameter is placed and the fitting is heated on it.

How to solder polypropylene pipes in a hard-to-reach place

How to switch from an iron pipe to polypropylene.