Corrugated pipe for laying cables and wires

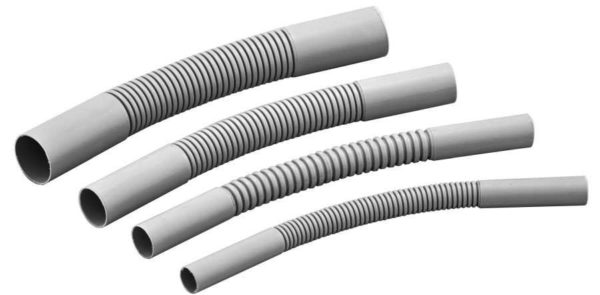

When reconstructing the wiring or installing a new one, it is recommended to "pack" it in a protective shell. The most commonly used corrugated electrical pipes, which are usually referred to as "corrugation for cables and wires." It is a round hose with a ribbed surface. Due to the ribbing, its flexibility is significantly increased.

The content of the article

Why do you need corrugation

The laying of an electric cable and wires in a corrugation is recommended for various reasons:

- When laying in flammable walls (wooden or frame), behind flammable finishing (lining, PVC plates), when fastening to wooden floors - for fire safety reasons. In this case, non-combustible shells are selected.

- When laying behind finishing materials - behind clapboard, drywall, PVC plates, etc. - for security reasons. So that when you try to hang something on the wall, it is more difficult to damage the cable. In this case, the most important indicator is the hardness of the shell.

- When laying the cable in a screed or under the floor, for finishing, corrugation is used for several purposes. Firstly, to protect against crushing when pouring concrete. Secondly, to be able to change the cable in case of damage without destroying the floor. Third, to protect against damage.

- When laying outside, the sheath is needed to protect the cable from weathering (ultraviolet light) and mechanical damage.

- Open air routing requires a corrugation with a wide temperature range (to withstand heat and frost) and durability. to ultraviolet light. If the cable is suspended, reinforcement is also needed to increase the bearing capacity.

- When laying underground, water resistance is important as well as rigidity.

In general, corrugations, even metal ones, are not the best protection against mechanical destruction. One can only hope that having felt that the drill has failed, it will be possible to stop in time. And in order not to get into the wiring for sure, it is better to have an accurate plan of its laying with measurements and reference to the corners. After all, a cable in a corrugation, even under load, is not determined by everyone wiring detector... So do not forget to take pictures, sketch and mark the distances before pouring the screed, before finishing.

Types of corrugations for cable routing

The corrugation for the cable is of different strength:

- Lightweight. It has a thin wall and the highest degree of flexibility. Recommended for installation under cladding in walls and ceilings. The mechanical load is weak.

- Average. Slightly thicker than light, but not as stiff as heavy. Can be used in walls and screeds. They are good in the walls, but in the screed it is better to lay heavy corrugation.

- Heavy. The walls are thick, the flexibility is low. Can be laid in a screed, buried in the ground. For turns, it is better to use corners or special couplings, since the minimum bend radius is quite large. They provide a normal degree of protection in terms of both moisture and dust resistance.

- Reinforced. The plastic sheaths are applied over the coiled steel wire. This is the best option for burying and hanging.

As you can see, the classification is based on strength properties, which determines the area of use.

Varieties

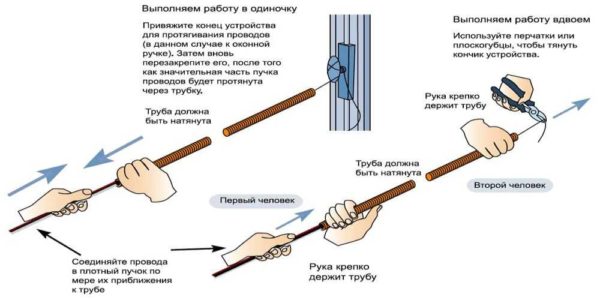

In addition to all this, there is also a corrugation with and without a broach. A pull-through is a thin cable or wire that makes it easier to pull the cable into the corrugation. The cable is tied to the end of the cable, pulled by its other end, tucking the cable inward. It is problematic to cope with this task without a broach - with sufficient rigidity, several meters of cable can simply be pushed inside, but if the route is long, it will be too difficult.

If we talk about the types of plastic corrugation, it should be mentioned that there is a two-layer corrugation. Outside, it has the same ribbed surface, but inside it is smooth. Corrugation for a cable of this type is expensive, but if necessary, you can really stretch a new cable into it. In those types where the inner wall is ribbed, this is far from always possible - if the track has a minimum of turns, and even those along a wide radius.

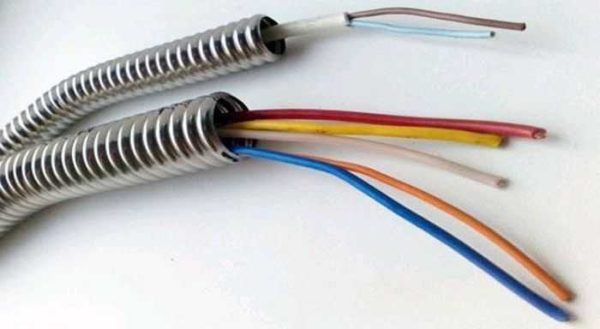

Metal corrugation for cables is also different. It is made of galvanized or stainless steel. In addition, there is a polymer-coated metal corrugation. It has the best characteristics for protection against dust and moisture. This protective shell is also called metal-polymer.

What materials

Corrugation for cables and electrical wires is made of plastic and metal. The materials used are different, with different characteristics. They must be chosen based on the tasks that they must perform.

- Polypropylene (PPR). This corrugation is usually blue in color, the material is self-extinguishing, does not support combustion. Differs in high water resistance can be used for laying cables outdoors or in rooms with high humidity.

- PVC (polyvinyl chloride). Color - gray pipes, self-extinguishing. PVC corrugation is not waterproof, can only be used in dry rooms.

- HDPE (low pressure polyethylene). In color - orange, black, the material is combustible, but resistant to chemical attack and water. Applications - screed gaskets and strobes in non-combustible walls, outdoor laying.

- Metal (stainless or galvanized steel). Non-flammable material, resistant to mechanical and chemical influences. Recommended for wiring in combustible buildings (wooden, frame). Also good for outdoor installation.

If we talk about compliance with fire safety standards when installing gaskets in combustible walls, the ideal option is a metal pipe. It saves from the stresses that can arise when the size of the building changes. Rodents cannot cope with it either. It is also the best option from the point of view of fire safety: even in the event of short-circuit currents and non-operation circuit breaker the probability of burning through a pipe with a wall thickness of 2 mm is very small. This means that the fire will not start. If laying electric cables in pipes does not appeal to you at all, then you can use metal cable channels or corrugation made of stainless steel or galvanized.

Corrugation for cable, dimensions, prices

Corrugated pipes for power grids are available in sizes from 16 mm to 65 mm. When choosing a size, it must be borne in mind that these products have two diameters - outer and inner. If you are going to lay several conductors - wires or cables - the diameter must be selected so that there is a gap of at least half the radius. This requirement is based on the fact that when laying in a group (it is necessary, by the way, to take a special cable), it will heat up more and the presence of an air gap will contribute to better heat dissipation.

Size selection

The choice of the corrugation diameter also depends on the area where it will be laid:

- to lighting devices - 16 mm;

- to sockets and switches - at least 20 mm;

- from the main junction box to the next box, from the shield - at least 25 mm;

- the connection between the two switchboards is at least 32 mm, and it is better to have a spare second line;

- passage through the floor overlap - with a rigid corrugation of at least 40 mm in diameter;

- laying of low-current cables (telephone, internet, antenna, etc.) - from 25 mm.

The diameter of the corrugation for laying the cable is selected depending on the number and cross-section of wires. Data for copper conductors are given in the table.

Selection table for the diameter of the corrugation for cables and wires depending on the cross-section and number of wires

This information is for reference, but you can focus on it. You can take a larger, but not smaller diameter.

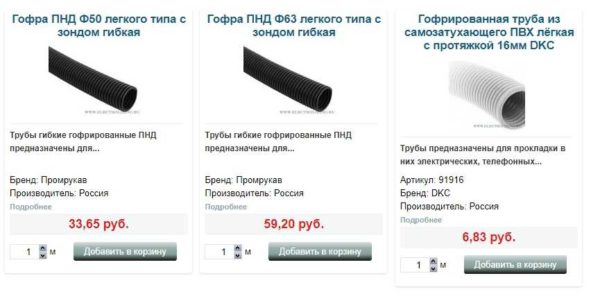

Prices

Generally speaking, the cheapest is corrugation for PVC cable, in the middle range - PP and HDPE, the most expensive is metal corrugation. Moreover, the option with a broach is slightly more expensive than without it. When buying, you need to pay attention to the same wall thickness, color uniformity.

A corrugation for a cable is sold in coils of 50 and 100 meters, less often it can be found by meters, but the price is then slightly higher. In general, the price depends not only on the material, but also on the wall thickness. The cheapest is a lightweight PVC corrugation for a cable, but sometimes it looks more like just a film. From what this can protect, it is difficult to say. If you are concerned about quality, it is better to purchase everything related to electrics not in building supermarkets such as Leroy, etc. and in specialized. The quality is usually better there, and the prices, if higher, are reasonable. So that you have an idea of the possible range of prices, in the table we will summarize several types of corrugations with a brief technical description.

| Name | A type | External diameter | Inner diameter | Broach | Price per meter | IP | Appointment |

|---|---|---|---|---|---|---|---|

| PVC corrugation | easy | 16 mm | 11.4 mm | Yes | 2,4 rbl | ||

| Black HDPE corrugated pipe | BCS | 15.7 mm | 11.3 mm | Yes | from 7.5 rubles / m | 55 | for concealed laying |

| Black HDPE corrugated pipe | BCS | 19.5 mm | 14.5 mm | Yes | from 8.9 rub / m | 55 | for hidden wiring |

| Red double-walled HDPE pipe | tough | 50 mm | 41.5 mm | Yes | 78.5 rub / m | 44 | for concealed laying |

| HDPE pipe heavy | heavy | 31 mm | 23.4 mm | Yes | from 9.7 rubles / m | 55 | hidden gasket |

| PPL (polypropylene) corrugated pipe | easy | 19.7 mm | 14.8 mm | Yes | from 28 rub / m | 55 | open, hidden gasket |

| Corrugated pipe polyamide | black | 21.2 mm | 16.8 mm | no | from 52 rub / m | 68 | open, hidden gasket, UV resistant |

| Corrugated pipe polyamide | gray | 21.2 mm | 16.8 mm | Yes | from 48 rub / m | 68 | open, hidden gasket |

Installation of corrugated pipes

For outdoor (open) installation, special plastic clips are used to fix the corrugations for cables and wires, which are selected for the outer diameter of the pipe. Clips are attached every 20-30 cm to screws or dowels - depending on the type of wall. In the installed clips, a corrugation for kbalay is wound up, pressed until it clicks. When mounted in a chase, it is fastened with plastic ties or dowel ties. You can also use homemade fasteners - strips of tin with nails or self-tapping screws in the middle.

When designing a route, the following recommendations should be considered. It is assumed that the route should be without sharp turns - so that, if necessary, you can tighten a new piece of cable. Because:

- The maximum possible length of the section is 20-25 meters. Provided that the track has no more than 4 turns.

- The turns should not be located side by side. The distance between them is at least 4-5 meters. If there is a need to make turns nearby, it is better to put a junction box or an inspection hatch near them.

- The angle of rotation is not less than 90 °, the radius is the larger the better.

- If the routes for electrical wiring and low-current cables and wires go side by side, the minimum distance for laying two corrugated sleeves is 200 mm. They can only intersect at right angles.

These rules relate to the design of the route for ground (suspension) and underground cable laying including. If the route is long and you want to be able to pull the cable “if something happens” without replacing the corrugation, design the route with these rules in mind.

Corrugated wiring

When installing wiring in a house or apartment, pieces of corrugation are fixed between junction boxes, from them to switches / sockets, to lighting fixtures. Here the sections are usually small, straight, with a maximum of one or two turns. So there are no problems with the cable tightening.

If you tighten several conductors into the corrugation for the cable, they are folded, they are fastened along the entire length with tape or tape in increments of 30-50 cm (depending on the stiffness). Rigid insulation is stripped 10-15 cm from one edge, the wires are twisted into a common bundle, a loop is formed from it (fix the loop with tape or electrical tape). If the tourniquet is too thick, you can form loops separately, just stretch the twine through everything. A cable is tied to this loop, and then they begin to pull it from the opposite side, pulling the sheath over the cables. In this case, it is necessary to pull without jerks, smoothly - so as not to damage the cable or cable.

During installation, make sure that the broach does not slip out. To be sure, you can secure the cable with a piece of tape. There are two approaches to editing:

- First, fix the corrugation, then tighten the cable or wires into the finished piece.

- First stretch the cable, then mount.

The first method is good for installing internal wiring, where the distances are small - from box to box, from box to outlet, etc. The second method is more suitable when installing long sections.

Features of open laying on the street

When wiring outdoors, it is usually suspended from a cable. For outdoor use, metal stainless steel is suitable, or better - metal-polymer corrugation for the cable, as well as plastic polyamide (black or blue). All these materials are resistant to ultraviolet light and remain flexible at subzero temperatures.

During installation, the cable stretched into the corrugation is suspended on a cable. The cheapest mounts are ordinary plastic ties. There are also special suspensions.

I liked the article. I would like to do the wiring like this!

On the basis of what regulatory documents (PUE, SNiP, etc.) is this work carried out, the laying of electrical wires in the corrugation?

Thank you.