Epoxy resin table top - we make an original table

Some building materials find applications in other areas. This is how ordinary plaster turned into artistic or decorative. Now they even make panels from it. Another such example is epoxy. Very beautiful and non-standard furniture is made from it. In particular, tables, bar counters, chairs. Here are just the price tag is completely inhumane, but very beautiful. As it turned out, the technology is not that complicated, although there are many subtleties. But making a table from epoxy resin and wood with your own hands is quite realistic.

The content of the article

Wood preparation

The choice of wood for an epoxy countertop is a whole business. The brighter the woody pattern is, the more interesting the result will be. But the wood must be seasoned, dry. And cuts are needed of considerable thickness, with interesting edges. In fact, this is an unedged board, but of expensive types of wood. In order not to be confused with building material, such cuts are called slabs and they must be chamber drying.

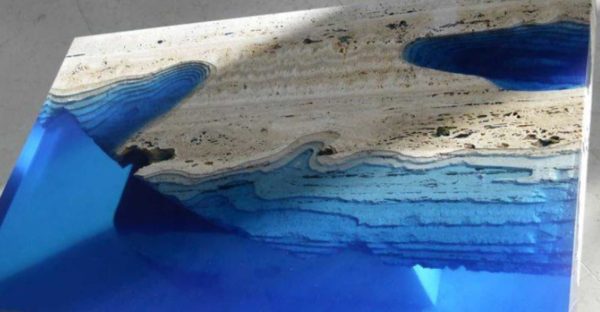

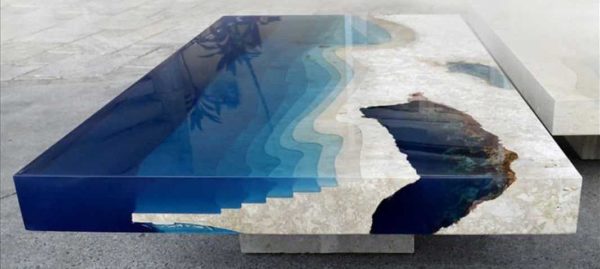

Having received wood, you need to figure out how to decompose it. The tabletop can be assembled from several boards "with a river" of epoxy between them. The edges can be resin or wood. The array can be located on one side, the second will be transparent. You can use round dies, which are obtained when cutting thick and not very trees. If there is no wood with a beautiful edge (or it is too expensive), the relief can be done manually - with a router. If the boards are narrow, we glue them together, planting them on dowels. In general, there are a lot of opportunities.

After we figured out how everything will look like, we start processing the wood. It is necessary to remove the bark, remove defects. Defects - dry and crumbled knots, holes gnawed by insects, chips, cracks. If there is rot or "blue", remove it with a router to clean wood. In general, we clean everything, grind it, preserving its natural shape or adding relief to the best of imagination and ability. We also grind the plane of the board, exposing the wood pattern, emphasizing it if desired. You can use any means. The same stain, oil for wood, can be burned with a lamp, then sanded using a wire brush, etc.

Before the main pouring, the wood must be “primed” with the epoxy resin that you will use in your work. First fill in all the small cavities, holes that were found during cleaning. We filled it in and for two to three hours periodically warm up the filled areas. Air comes out of the caverns and pores of the wood. If the resin is not heated, bubbles will remain in the resin. If you want transparency, you need to remove the bubbles. So we warm them up. After drying, we grind the poured areas, leveling them into a plane with the board. Then we completely cover the board with a thin layer of resin - we stabilize it, simultaneously expelling air from the pores.

Create a fill shape

After the wood has been prepared, it is filled with a thin layer of the composition, while it dries, we proceed to create the shape. It will be necessary to place a wooden blank in it. In size, the form can be either end-to-end with the board, or larger. In the second option, there will be epoxy strips along the edges.

Any sheet material with a smooth surface is suitable for creating a shape. The smoother the shape, the less effort will be required to sand.The mold is assembled with sides that are several centimeters higher than the planned thickness of the table top. After assembly, the joints are sealed with a sealant, which must be carefully leveled. We wrap the finger with cling film, moisten it in water and smooth it to an ideal state. But this must be done quickly. Sealing must be thorough, otherwise the resin will flow out of the mold. And it is far from cheap, and it is not easy to remove traces.

You can make a form from laminated chipboard, or you can from plywood, but it will have to be covered with something. For example, wax, a special release agent. The easiest and cheapest option is to cover it with a film, but it should lie smoothly, without any waves and irregularities. Can be sealed with tape in two layers. Glue joint to joint, without overlaps. We glue the second row, sliding it so that the seams of the lower row are covered with tapes approximately in the middle of the length. The tape should also go smoothly. It can be replaced with vinyl, but will need to be warmed up in the corners to keep it flat.

You can make a glass mold by placing the sides on a sealant. For easier separation, grease the glass. Do not neglect lubrication - there will be much less problems. In general, making a table from epoxy resin, even during the preparatory processes, you can turn on imagination. The technology is very flexible, there are many options.

What epoxy resin to use for making countertops

There are a lot of epoxy resins and the range of prices is solid. Let's say right away that a cheap one will not work for a normal result. You need a transparent one, which does not grow cloudy over time, does not change color, and these are expensive compounds, for example, 3D MG-EPOX-STRONG. They are often categorized as epoxy resins for countertops. When choosing, you need to pay attention to the following parameters:

- Minimum layer.

- Maximum layer.

- Time to fill the second layer.

- Time to final dry.

Crystal 76 was used for this wood and epoxy table. It took 10 liters (for the river and the filled crack at the wall)

The fact is that there are resins that can only be poured in a small layer at a time. Let's say the maximum layer is 10 mm. And the next layer can be poured in 24 hours. If you need to make a tabletop 6-7 mm thick (4 cm wood, plus 1-1.5 mm each at the bottom and top), it will take a whole week. And that's just to fill in layers. There are epoxy resins that can be poured in layers up to 6 cm or more.

If you are going to make a table out of epoxy resin for the first time and have never dealt with this material before, it is better to choose those that are poured in a thin layer. It is easier to achieve the absence of bubbles with them. Although, you may like the "frozen soda" effect. If you want to tint the resin, you need to buy special dyes. In layering, the dye is diluted in one of the components before adding the hardener. This will make the color uniform.

How much resin is needed

How much epoxy is needed for a table? The answer is not easy. The table top can be of different sizes, it can be small or thick. Maybe there will be only a small "river", and perhaps most of it will be made of epoxy. Basically, you can roughly calculate the volume of the countertop that you plan to make. Estimate how much wood will take in percentage, the rest is epoxy. So how much epoxy is needed for the table, we consider for our case ourselves. Some who make only the "river" will need 4-6 liters, others may require 20-30 liters or more.

Let's take an example. We will make a rectangular tabletop measuring 100 * 60 cm, thickness - 7 cm. Most of it will be wood - about 2/3. We translate the values into meters and multiply: 1.0 x 0.6 x 0.07 = 0.042 m³. To convert this figure to liters, we multiply by 1000.We get 42 liters. That's a lot. But this is if you make the tabletop entirely of epoxy resin. Approximately 2/3 of the volume will be occupied by wood. The share of epoxy will be only 1/3. That is, we divide the resulting figure by 3 and we get 14 liters. That is, to make a table 100 * 60 cm, it will take about 14-15 liters of epoxy resin.

Technology of pouring epoxy resin on the countertop

The wooden base of the table was laid out in the prepared form. We put a load on it so that the wood pressed firmly against the base. The less it flows between the piece of wood and the base, the less consumption will be.

Epoxy resin is a two-component compound. Consists of resin and hardener. If you want to make the epoxy colored, add a few drops of the dye to the resin and mix until the color is uniform. Pour into another container and repeat mixing. If this is not done, along the edges, unpainted stripes will remain at the bottom, which will be visible. After finishing mixing, pour the required amount of toned resin into a separate container, add the hardener, mix for several minutes. Pour into a mold.

The first layer is base. Part still flows under the wood. It should not be less than the minimum allowable. The resin is flowing and evens itself out, but you shouldn't pour it in one place. It is better to distribute more or less evenly over the entire surface. We wait for the allotted time before applying the next layer and repeat the operation. So until we get the desired thickness.

How to pour without bubbles

Basically, there is epoxy resin, which is not very susceptible to the formation of bubbles - from the Art-Massive series. But the bubbles come from the wood. If you haven't covered it with a thin layer of resin, there will be more. If processed - less. But be prepared for what they will be. Therefore, for the first time, we recommend using thin layers of resin. This makes it easier to avoid bubbles.

The trick is to warm up the resin for two to three hours after pouring. This will allow the bubbles to come to the surface. You can use a construction hair dryer for these purposes. Some people use gas burners, but open fire and epoxy are a dangerous combination. Better, after all, a hairdryer. So, after pouring each layer, warm it up with a hair dryer.

Polishing and finishing to a high gloss

After final hardening, the epoxy and wood table needs to be polished. The resin doesn't look transparent - that's okay, don't be discouraged. If you filled in a transparent compound, it will be so. But careful grinding is needed. For a start, it is better to use tape - it captures more area, eccentric is more suitable for the finish. But you can also cope with a grinder with speed control and the corresponding nozzle.

At first we take large grain, then smaller and smaller. If there are more or less significant differences, start with 80 or 100, then reduce the grain step by step. Finish is already 1000, 1500 and 2000. Not all resins polish equally well. If even after using 2000 skins the gloss is not enough, try polishes for cars, headlights. You can make a homemade polishing paste: goi paste + grease. And rub first with a rag, and polish with a soft polishing attachment.

Polishing isn't the only way to achieve shine. This does not mean that there is no need to grind. It is necessary. But if the shine is not enough, and the surface is already smooth, you can cover the tabletop with a glossy varnish and, preferably, water-based. And even better - yacht. Then the surface will not be afraid of moisture and hot. To varnish as usual - in several layers. Intermediate sanding is hardly necessary, unless puddles have been made or debris has got into. Sand the last layer to the desired gloss level.

Other filling options

A table made of epoxy resin and wood does not have to be made of only expensive slab. Radial tree cuts can be perfectly adapted. And the radius is far from the main thing here. You can make a frame out of wood, which you can install on a tabletop - on plywood 10 mm or so. Put cuts into this frame - according to the pattern or randomly. In this case, the tabletop will not need to be removed from the base - this is the simplest option. For DIY production for the first time - the simplest solution.

Please note that it is better to choose wood with flaws. In this case, these are not defects, but a highlight. Rotten so generally look exotic. Especially if you emphasize the difference in colors and textures using deep color.

A very interesting effect when using not only tinting, but also various additives. For example, glitter, powder that gives a metallic effect, even broken colored glass or mirror shards give a very interesting picture.

You can use stone instead of wood. The weight of such a table will be solid, but the strength will also be great. Layered rocks look great. It is advisable to have skills in working with stone. This is more difficult than sanding wood. When preparing, you need to fill the voids well so that all the air comes out.

Use pebbles, natural or colored gravel. These stones can be laid out in a fairly thick layer - the resin will still flow into the gaps. Often found in combination with wood. By the way, if you "missed" the amount of epoxy resin, you can add stones to the filled resin. This way you can get the desired level.

Human imagination is limitless. They make furniture from epoxy, pouring in various pieces of iron. Car parts, wrenches, bicycle or moped chains, etc.

Chairs or stools can be made according to the same principle. Can be cast in the same style of pedestal legs. They even started to pour LED garlands into epoxy. What is not a night lamp or a leg with soft illumination. There are, by the way, glow-in-the-dark additives in epoxy resin.

Cool article!

Some points maybe I would like more details for beginners)

Artillery array is not bad, it just gets cold for a very long time. I take epoxymaster wood, it is also bubble-free and thick layers can be cast. But it hardens in 2 days) That's it)

I want to make a tabletop from saw cuts, the price of resin bites