How to make carved frames for windows in a wooden house

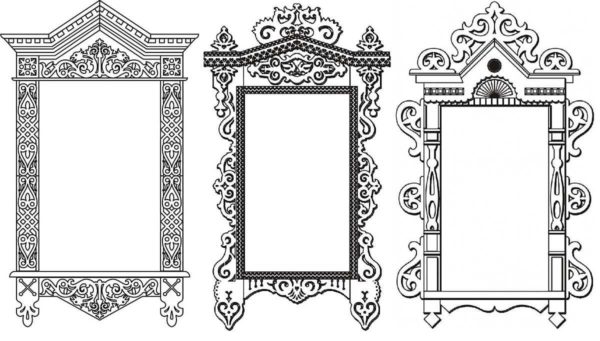

Any owner dreams of making his home memorable and beautiful. If the house is no longer new, it is not so easy. One of the possibilities is carved platbands. They will even turn an ordinary "box" into a masterpiece.

The content of the article

Material for platbands

Carved platbands are made mainly of coniferous wood. The best option is pine, it is normally cut, inexpensive, due to its high resin content, it is durable. In principle, you can use any other coniferous board, but it is better not to try with spruce: it is too fibrous, it cannot be cut even with the sharpest tool.

You can also make carved platbands from hardwood - linden (the softest), poplar, maple, oak, cherry, etc. But with each species you need to be able to work, get your hands on and there is no guarantee that something digestible will turn out, and hardwood is expensive. Therefore, window frames are often made of pine. You just need to pay attention to the quality characteristics.

If there is wood or a board that has lain for 3 years or more, you can use it: it is already definitely dry, only processing and calibration will be required. If the house does not have woodworking equipment (thicknesser and circular saw), an edged board will be needed. Wood of the first or highest grade is suitable for carved platbands. This means that there should be no knots, chips or resin pockets on the board. Take wood from a chamber drying, with a moisture content of no more than 8-12%. This is not for sale in the markets, you need to look at sawmills and in hardware stores.

Why chamber drying? Because it is dried in a special chamber, rapidly removing moisture. At the same time, some of the boards crack, bend - these go to rejection, the rest are sold. If you make carved platbands from oven-dried wood, they will definitely not be crumpled and they will not crack.

Tools

To make carved platbands with your own hands, you need the following minimum set:

- drill with a set of drills;

- an electric jigsaw with a smooth start and a bunch of different wood saws;

- chisels;

- sandpaper with different grain sizes;

- flap disc made of sandpaper for wood on a drill.

To reduce the time it takes to create carvings and sanding, it is best to have a router and sander.

One by one or in bulk?

Carved platbands usually consist of repeating elements. At least two vertical strips on each window are made the same. And since usually several windows are drawn up, many identical elements are required. If the platbands are going to be slotted, naturally there is a desire to cut several pieces at the same time, folding the boards in a pile and somehow fixing them.

The desire is understandable, but difficult to realize, and the benefits in time are not as great as it seems. The first difficulty is that home craftsmen usually have jigsaws that are not too powerful. To cut through several planks, you have to move the file more slowly along the intended pattern. On straight lines the speed is still tolerable, on curves it is low. And, the smaller the bending radius, the slower you have to move the file. If you are working with one board, there are no such problems. So, if there is a gain in time, it is quite small.

One more point. Even thick, good, expensive files are deflected with a large thickness of the workpiece.So, when cutting several boards at the same time, the quality of the cut on the bottom (or two) remains a big question.

The procedure for making a platband with a slotted thread

Using the template, transfer the desired drawing to the board (where to get it, how to enlarge it, how to make a template, read below). If necessary, we correct, draw the details well. Next, we will describe the procedure step by step.

Slotted thread without backing board. For the picture to be seen more clearly, a big difference in color is needed

We remove the wood in the slots of the picture

- To do this, we drill large-diameter holes in those places where the wood will need to be removed. The diameter of the hole should be slightly larger than the width of the jigsaw file (usually 12-14 mm). The drill should go vertically down, make sure that the hole does not go beyond the line (but small errors are not terrible).

- Insert a jigsaw file into the slots, cut a pattern along the outlined lines.

Since the carving will be viewed from afar, some inaccuracies are not fatal, but it is still worth striving for the ideal.

Making a curly edge

Some platbands have a straight edge. Then we skip this stage. If the edge is curly, you will still have to work with a jigsaw.

- After about 5-7 cm, we make perpendicular cuts of the “extra” part of the board to the intended line of the casing. Great precision or straight lines are not needed, we try not to cross the drawn line.

- Starting from the right or left, we cut along the marked line. The sawn-off pieces fall off in the process, so it's not too difficult to work.

If the cut is difficult, it may not be very attractive places. It's not scary, then we will process them where necessary - with chisels, the same jigsaw, emery. When you are satisfied with the result, you can move on.

Final revision

The owners of wooden houses probably know everything about how to handle wood. But, just in case, let's repeat the general rules again.

- Grinding. Grind with any available method. Faster and best of all - eccentric grinder, slower - with an emery wheel on a drill and a petal nozzle, very slowly - with your hands and sandpaper. Ideally, we combine two methods - using a grinder we process a horizontal surface, and the recesses with a petal nozzle and, where it is lacking, with our hands.

- We prime. Since the wood must be protected from fungal beetles, exposure to rain and sun, it must be covered with a protective impregnation. Look for any for external use. It is best to soak the workpiece for a few minutes in the solution bath. If this is not available, brush well through all the slots with a brush.

- We paint.

The choice of paints and varnishes is very wide. Any for outdoor work. But keep in mind that opaque paints will have to be updated periodically - just like that once a year. And this means removing old paint, priming, painting again. The situation is simpler with oils for wood - they do not give a film on the surface of the wood, but are absorbed into the fibers. It is also necessary to renew the coating, but just remove dust and cover with a new layer. And the processing frequency is less. Cons of oil for wood - higher price, fewer flowers.

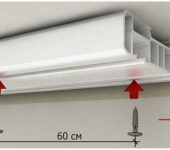

And then - the installation of the carved platband. It depends on the type chosen: you can directly on the wall, or you can - on the backing board, and then on the window.

How to enlarge a template

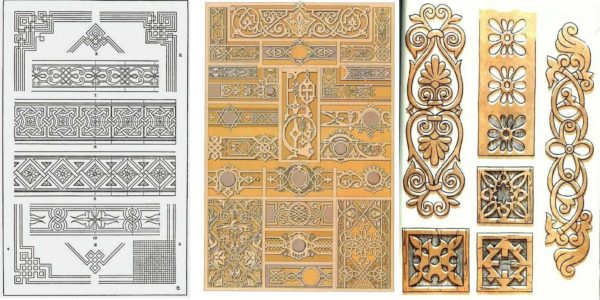

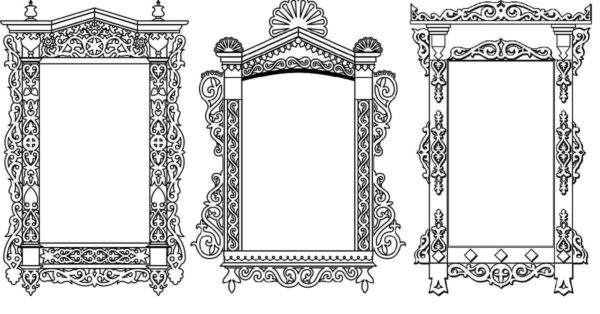

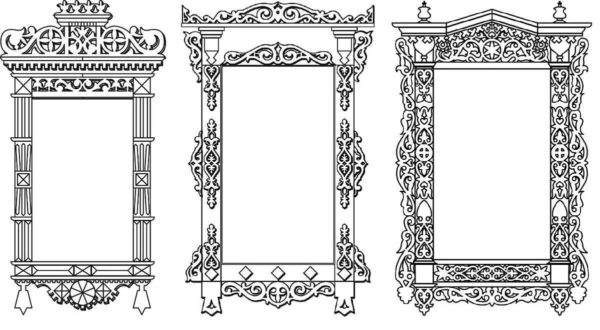

Simple carved platbands can be made without templates. Several examples will be in the video - it shows how to outline, how to cut. But not everyone will be able to draw more or less complex patterns on their own. You need skill, and talent. The easiest way is to find a diagram, print it in the desired size, transfer it to cardboard and cut it out. This will create a pattern that you can trace.

The second way is to sketch from a photograph. Not all schemes can be found.Some, especially the old window frames, you won't find anywhere. If you have at least some drawing ability, you can sketch them.

There may be questions about how to increase the size of the found schema or template. There are three options:

- Using any graphics editor. The simplest one - Paint - is in any computer running Windows (the "Image" tab, the "Resize image" line, select "centimeters" and put the desired length (height) in the box. The resulting file can be printed. If the printer is small format, it may be necessary to split into several pages, then glue them together and, based on the resulting picture, make a template.

- Using a photocopy. Copier has a zoom function.

- Taking graph paper, transfer the drawing to the desired scale. To do this, divide the original image into squares with a side of 0.5 or 1 cm (you can print it on a piece of paper in a cage). Then we transfer the lines to graph paper, increasing them in the desired proportion.

The first two methods are faster. But when scaling, the picture may turn out to be fuzzy and blurry. It can be corrected by hand, you can draw it in some editor, for example, CorelDRAW. How to do this, see the video. Just an example of drawing a diagram for a thread.

Related Videos

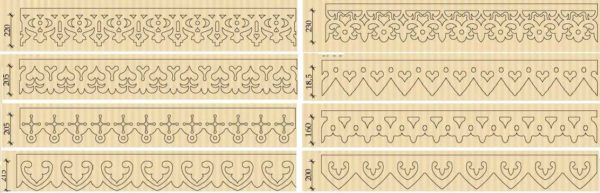

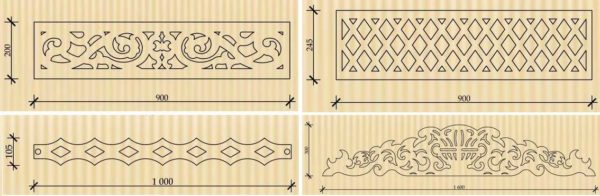

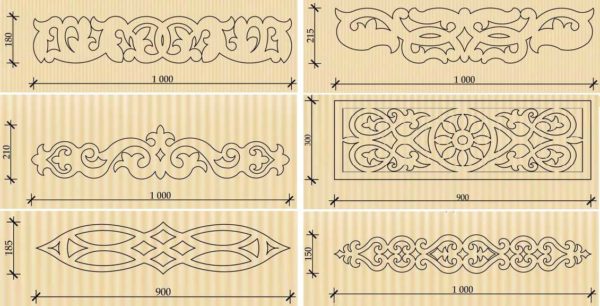

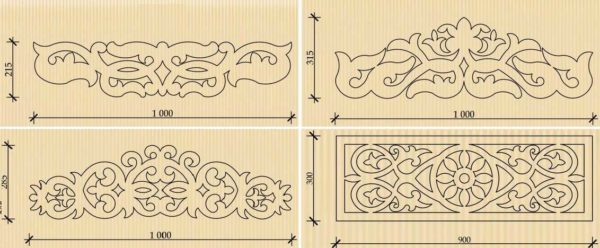

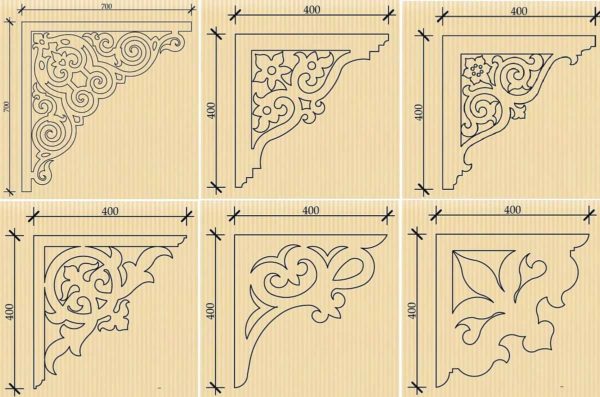

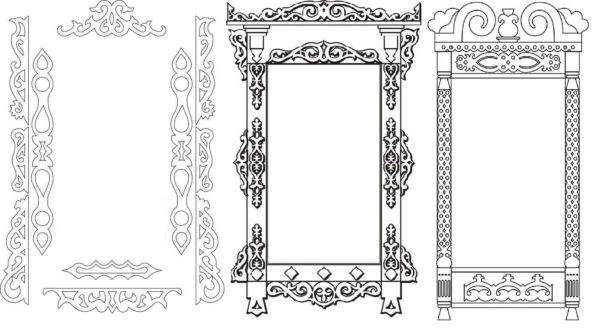

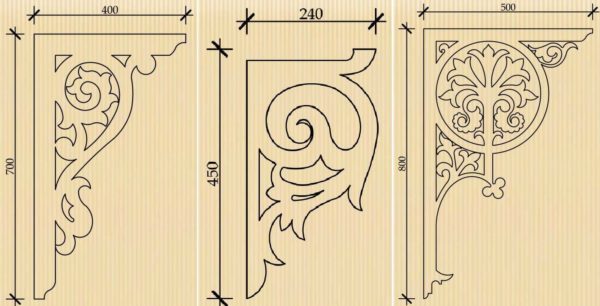

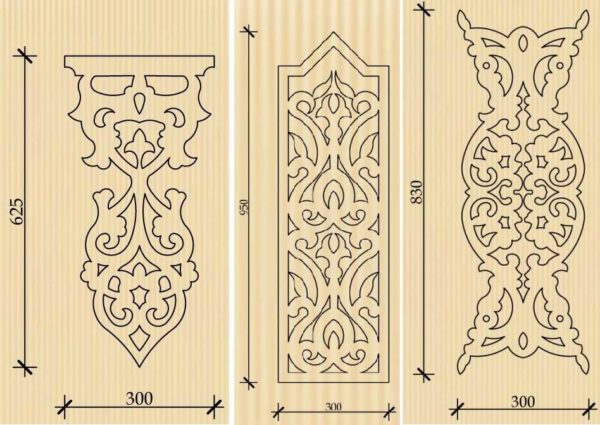

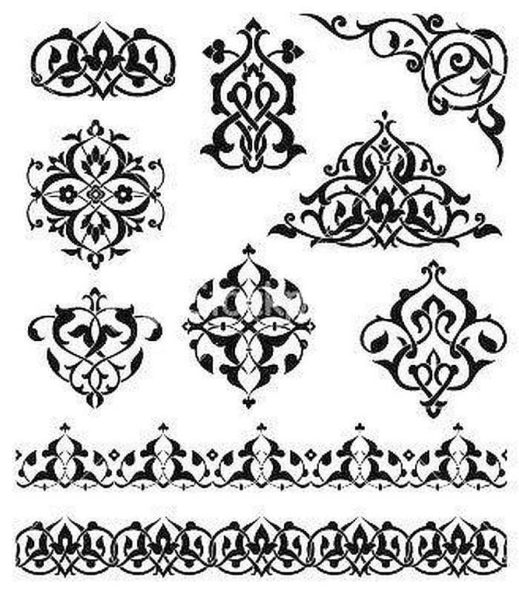

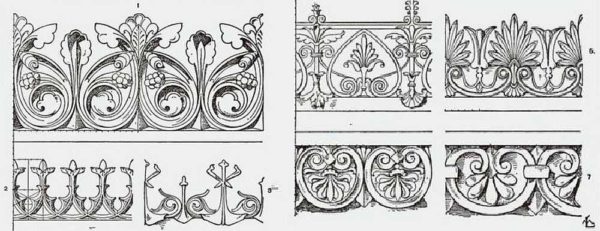

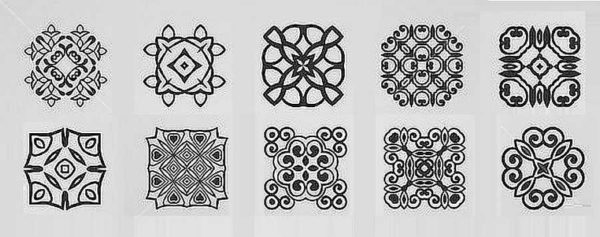

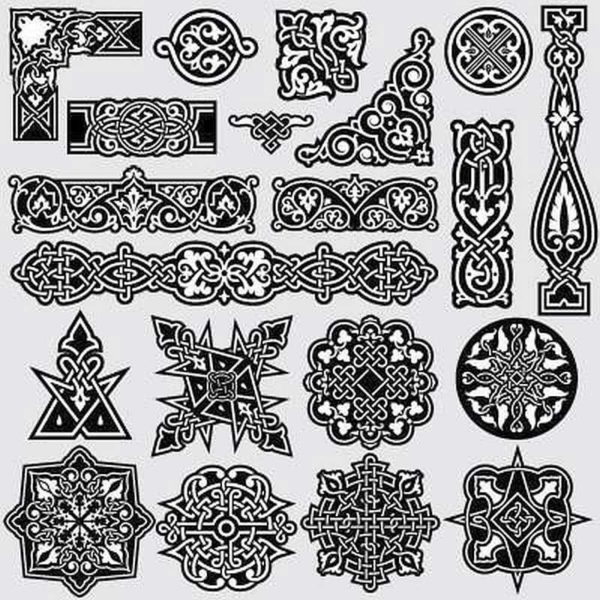

Schemes, templates, patterns

A wonderful lesson for me. I was really on fire. Thank you very much.

Thank you for your feedback)) we try