DIY installation of window sills

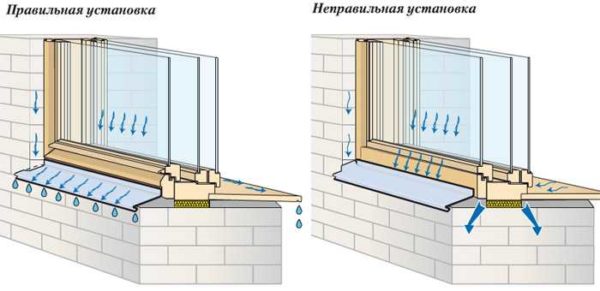

Low tide is an important part of the window. Thanks to this not very expensive part, water does not get inside the wall. That is, the ebb on the window prolongs the life of buildings, eliminates the occurrence of damp spots, mold and the whole complex of problems associated with high humidity in the walls. The installation of window sills does not obey any strict requirements or standards. There are no GOSTs regulating this procedure. But there is experience accumulated over the years, which must be able to apply in each case.

The content of the article

Types of window sills

An ebb is installed on any windows outside - this is a special board mounted at the bottom of the window opening. It is needed so that rain or melt water flows down on it. This is probably why this part is sometimes called drainage.

Window sills can be:

- Plastic.

- Metallic;

- galvanized steel, coated:

- polyester;

- plastisol;

- paint for metal.

- copper;

- powder coated aluminum.

- galvanized steel, coated:

- Concrete.

- Stone (granite, marble).

- From facade tiles.

Nowadays, there are almost no external concrete sills. Rather, they are made, but they are still covered with either plastic or metal. Concrete slopes can, of course, be whitewashed, and this was once done. But today, this type of window decoration is very rare.

If we talk about the exotic, you can remember the stone ebb. They are made from polished granite or marble. They look, of course, excellent, do not make noise, you can break them only with a sledgehammer. But their cost is not for every wallet.

There is one more interesting type of external window tides - from facade tiles. It works great with any window - both wooden and plastic. If your basement or the whole house is finished with similar tiles, on the windows it will look very "in the theme". At the same time, the house looks like a single ensemble. Such slopes are made extremely simply: the tile is cut so that it protrudes 1 cm beyond the wall, the desired slope is formed using a cement-sand mortar. Seams can be rubbed with cement laitance, or hydrophobic impregnation can be used. It's just better to mount such slopes before the exterior wall decoration.

Although window slopes come in different materials, the vast majority of homeowners choose two: plastic or metal. Each of them has its pros and cons, and we'll talk about them in more detail, as well as how to install ebb tides on windows.

Plastic: good or bad?

Plastic drips for windows are considered the most "quiet". When raindrops fall on them, there is almost no sound. They are also considered inexpensive, which is important if the budget is limited. Only unpainted galvanizing is cheaper, but its appearance, after several years of operation, is not very attractive, the paint holds very poorly.

What are the disadvantages of plastic moldings? The fact that plastic under the influence of ultraviolet radiation loses its elasticity, becomes brittle, can crack under load. And, even if there are no serious cracks, there are always microcracks. They form over time, dust gets clogged in them. After a couple of years, the once-white plastic becomes grayish or has a yellow tint. Nothing can wash it off.If installing window sills every five to ten years doesn't scare you, you can use them as well.

The next disadvantages of plastic moldings are flammability and significant thermal expansion. Plastic melts from high temperatures. If a cigarette butt falls on it, a hole will be provided. It may not happen so often, but there is a possibility.

Thermal expansion manifests itself if the installation of the ebb on the windows is made rigidly - the bar is fixed with self-tapping screws. Then, in hot weather, he "walks in waves", bends over. After, usually, it comes back to normal. In order not to worry about thermal expansion, in the edge of the ebb, for which it will be attached, you should first make oblong rather than round holes. When tightening the screws, do not press down on the plastic too much. Then, when changing the size, the plastic ebb will not "lead".

The second point is to leave a thermal gap on the sides, which is filled with silicone waterproof sealant (for outdoor use). In this case, thermal expansion will not cause a "wave" to appear. The plastic will simply expand slightly by squeezing the sealant, then return to normal. So the installation of plastic ebbs has its own nuances.

Metallic - types and features

Metal window sills are durable, there are no problems with them during operation. Installing metal window sills is usually not a problem. Their minus is "noise". Raindrops can knock out loud sounds from metal. The problem is partially solved during installation - all cavities must be carefully filled with polyurethane foam. Any void will work like a drum. So here we are trying to do everything as best we can.

The metallic window sill will be even quieter if foam rubber or any other sheet of sound-absorbing material (for example, linotherm) is glued from below. But it must withstand significant temperature changes - outdoor operation. These two tricks together will make the metal tide not too noisy.

As already mentioned, metal sills can be made of galvanized steel coated with polyester or plastisol. Galvanized with polyester - metal tiles are made of this material, so the technology has been developed. Such ebb tides are not too expensive, but you need to look for them in firms that produce or sell metal roofing or similar roofing materials.

Plastisol coating is a more expensive option, but it has a greater thickness, due to which the metal is not so echoing. It is also interesting in that the surface can be not only smooth, but also "under the skin", with embossing, etc. If your budget allows, try a plastisol-coated galvanized metal molding. There are no negative reviews yet.

Another option for a "quiet" metal window sill is powder-coated aluminum. By itself, this metal is not so "sonorous", due to which the noise level is reduced. Everyone knows the advantages of operation, as well as the fact that the cost is not low. Installing sheds on aluminum windows is a good idea, but it's not easy to find. The aluminum ebb is not very popular, so you will most likely have to order online. Especially if you live in a small town.

Determining the size

Metal shims can be sold in long strips - up to 6 meters in length, you can find firms that will cut into pieces of the length you need. The second option is good, since you don't have to think about where to put the leftovers. The length of the window sill is determined by the width of the opening. The ebb board is usually made wider by 2-4 cm on each side. In preparation, the excess is cut off, leaving protrusions on both sides of the window opening.But you can cut it off exactly to the width of the opening. It depends on the exterior wall decoration and your desire / taste. In any case, if you order slats of a certain length, and do not cut them yourself, add a few centimeters - this can be corrected if the cut is crooked.

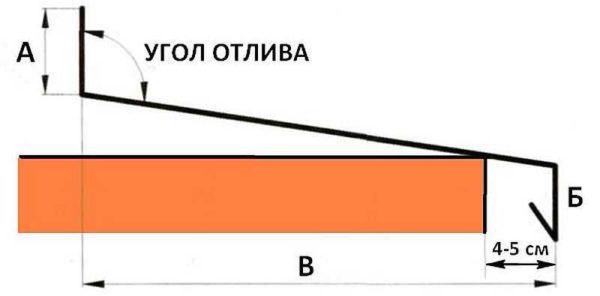

The depth of the low tide on the window should be such that its edge protrudes a few centimeters. Too large a ledge is not needed - it can interfere, but 4-5 cm is quite normal. In this case, the flowing water will not fall on the wall or under the foundation. With such a protrusion, moisture pours onto blind area around the house, then goes into storm sewer.

When choosing a plastic molding, you can face difficulties. The narrowest ebb is 15 cm, and then the increase goes with a certain step. Usually this pitch is 50 mm. So there may well be a situation - either too little or too much. It is necessary to make a decision according to the situation - how critical is the ingress of water close to the foundation, how often people walk along the windows. After evaluating these factors, you can choose a wider or narrower.

Installation of ebb profiles on PVC windows

Regardless of the material - metal or plastic - the ebb on the window is installed according to the same scheme. In the case of metal, spacers are needed to reduce noise, but the general procedure remains unchanged.

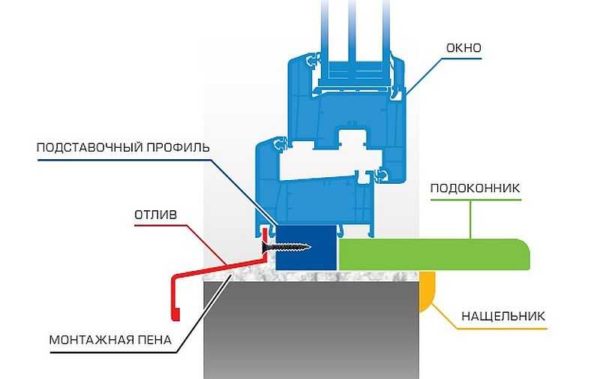

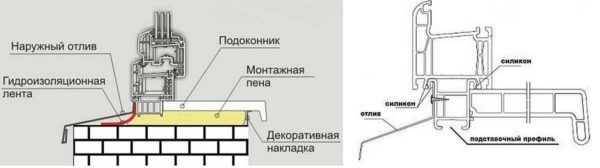

There is a special ledge in the frame profile for the installation of the ebb. The upper edge of the low tide is wound under it. But this protrusion is available only if the PVC window was mounted on a support (mounting) profile. Then the installation of the slope is quite simple. It must be cut to the width, if necessary, on the reverse side of the strip, "put" rubber or other material for "silence" on universal glue.

Then it remains only to bring the ebb ledge into the groove, blow out the required amount of foam, fix the ebb to the support profile with three or more self-tapping screws. In order not to leak from the sides, the places where the low tide adjoins to the window opening should be smeared with silicone sealant. Better to take transparent - it will be less noticeable.

And if you play it safe?

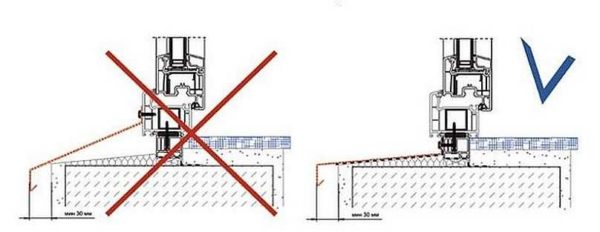

To be on the safe side, before installing the ebb into the groove, you can apply the same silicone sealant. This will definitely prevent water from getting inside, even with a very strong wind directed towards the window. The second "control shot" also concerns waterproofing. It is relevant for materials that are very afraid of getting wet. For example, this is exactly what it is desirable to do when installing slopes on windows mounted in a frame house... In this case, a waterproofing tape is laid before installing the window sill. It is desirable that the tape hang over the wall - then even if some part of the water gets on it, it will still be outside the walls.

For waterproofing, you can use any roll material that is suitable for the street, can withstand frost and heat. Installing window tides in this way will prevent the area under the window from getting wet, even if the rain is very heavy.

If the plastic window is installed without a support profile

What if the plastic window is installed in violation of the technology and the groove is not available? During installation, the plastic window is often leveled using triangular bars. After alignment, the window is attached to the opening, and the bars are left. If this is your case, you can attach the slope to these bars. They can be trimmed if necessary. But you need to work carefully so as not to move them.

If everything is already installed and repaired, only the frame of the frame is available, you can screw the ebb to the frame. For sealing, you can use a sealing gasket (rubber band), coat with the best possible sealant. Additionally, you can screw on top of some kind of cover strip.Maybe he will save the situation a little.

But even with this approach, there is no certainty that water will not flow. Maybe initially everything will be fine, but over time, moisture will obviously get in. So, if possible, it is better to dismantle an incorrectly installed plastic window and reinstall it according to the rules.

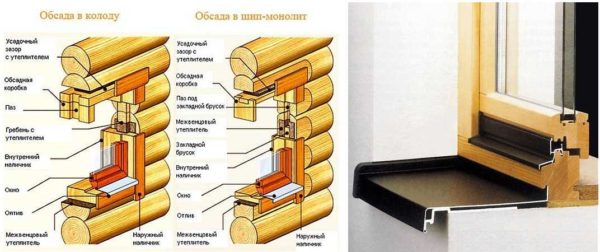

Features of drips for wooden windows

A groove must also be made in the frame of the wooden window for installation. In this case, there is no problem and installing ebbs on windows is no different. For reliability, you can also lay a waterproofing strip under the ebb tide by tucking it into the same groove. When using a sealant, you need to look for one that has good adhesion (adhesion) to wood and metal or plastic - it depends on the type of reflux chosen.

If there is no ebb groove in the wooden window, you can make it yourself. The groove is not made too deep and wide. This can be a narrow cut, into which only thin metal can be tucked. To prevent the destruction of wood, treat the cut with protective agents before installation. In extreme cases, you can walk through the paint.

Semicircular or curly windows

Not all windows are linear. But what are the best ebb tides for semicircular windows? All the same metals can save. But only this time, the ideal option is copper tides. Copper is a ductile material and a slight curvature can simply be given by tapping with a hammer.

If copper is too expensive, there are factories that make radius ebbs to your size. Since this is an individual order, the cost of such an ebb will also be calculated in each specific case.

If there is a need to save money, it is possible to make ebbs for curly bay windows from ordinary galvanized ebbs with a polymer coating. In this case, they are cut into pieces with which you can create the desired bend.

With this method, one piece should go over the next one (3-5 cm) - this will make leakage less likely. To further reduce the likelihood of water ingress, a layer of sealant is spread on the joint.