What heat carrier is better for heating a private house

It is almost impossible to survive in winter without heating in our country, therefore, a lot of time, effort and money is devoted to its device. The most common type of heating in our country is water (liquid) heating. Its component is a coolant. How to choose a coolant for the heating system, how to download it - in the article.

The content of the article

What is a coolant and what should it be

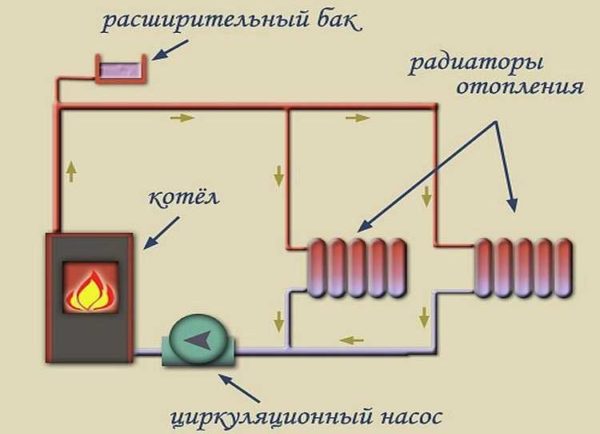

The coolant in a liquid heating system is the substance through which heat is transferred from the boiler to the radiators. In our systems, water or special non-freezing liquids - antifreezes are used as a heat carrier. When choosing, you must be guided by several criteria:

- Safety. From time to time, there are leaks in the heating or they require maintenance and repair. So that repair work is not dangerous, the coolant must be harmless.

- Harmless to the components of the heating system.

- Must have a high heat capacity to transfer heat effectively.

- Have a long service life.

Given these requirements, the most suitable liquid for a heating system is water. It is safe, harmless, has a high heat capacity, and the lines of operation are unlimited. But in heating systems where there is a high likelihood of downtime in winter, water can do a poor job. If it freezes, it will burst pipes and / or radiators. Therefore, antifreezes are used in such systems. At low temperatures, they lose fluidity, but the equipment does not tear. So it is easy to choose a heat carrier for a heating system from this point of view: if the system is constantly monitored and in good working order, you can use water. If the house is a temporary residence (dacha) or it can be left unattended for a long time (business trips, winter holidays), if frequent and / or prolonged power outages are possible in the region, it is better to pour antifreeze into the system.

Features of using water as a heat carrier

From the point of view of the efficiency of heat transfer, water is an ideal heat carrier. It has a very high heat capacity and fluidity, which allows it to deliver heat to the radiators in the required volume. What kind of water to fill? If closed system, you can pour water directly from the tap.

Yes, tap water is imperfect in composition, it contains salts, a certain amount of mechanical impurities. And yes, they will settle on the elements of the heating system. But this will happen once: in a closed system, the coolant circulates for years, replenishment with a small amount is required very rarely. Therefore, a certain amount of sediment will not bring any tangible harm.

If heating is an open type, the requirements for water quality, as for a heat carrier, are much higher. Here there is a gradual evaporation of water, which is periodically replenished - the water is topped up. Thus, it turns out that the concentration of salts in the liquid is increasing all the time. And this means that the sediment on the elements also accumulates. That is why purified or distilled water is poured into open-type heating systems (with an open expansion tank in the attic).

In this case, it is better to use distillate, but getting it in the required volume can be problematic and expensive.Then you can fill in purified water, which is passed through the filters. The most critical is the presence of a large amount of iron and hardness salts. Mechanical impurities are also useless, but the easiest way to deal with them is - several mesh filters with a cell of different sizes will help to catch most of them.

In order not to buy purified water or distillate, you can prepare it yourself. First, pour and stand so that most of the iron settles. Pour the settled water carefully into a large container and boil (do not close the lid). This removes the hardness salts (potassium and magnesium). In principle, such water is already well prepared and can be poured into the system. And then top up with either distilled water or purified drinking water. This is not as expensive as the initial fill.

Antifreeze for heating

In addition to water, heating systems are filled with special non-freezing liquids - antifreezes. Usually these are aqueous solutions of polyhydric alcohols. Not so long ago, glycerin-based antifreeze appeared on our market. So now there are three types of anti-freezing fluids for heating systems.

Types of anti-freezing liquids and their properties

Antifreezes are based on two substances: ethylene glycol and propylene glycol. The first is cheaper, freezes at lower temperatures, but is very toxic. You can get poisoned not only by drinking, but even simply by wetting your hands or breathing in vapors. The second antifreeze heating medium for the heating system is based on propylene glycol, which is more expensive but safer. It is sometimes even used as a dietary supplement. Its disadvantage (except for the price) is that it loses fluidity at higher temperatures than propylene glycol.

Despite the high toxicity, ethylene-glycol coolants are more often bought. This is most likely due to the price - propylene glycol is twice as expensive. But ethylene-glycol antifreezes in their pure form are also chemically active, they can foam, and has increased fluidity. Foam and activity are fought with additives, and the increased fluidity is not corrected in any way. Paired with toxicity, it is a dangerous combination. If there is the slightest possibility somewhere, this antifreeze will leak. And since his fumes are poisonous, this will not lead to anything good. Therefore, if possible, use propylene glycol.

| Name | Substance | Weight | Working temperature range | The beginning of crystallization | Thermal decomposition temperature | Life time | Can be diluted with water | Price |

|---|---|---|---|---|---|---|---|---|

| Dixis 65 | monoethylene glycol | 10 Kg | -65 ° C ~ + 95 ° C | -66 ° C | + 111 ° C | 10 years | Yes | 850 rbl |

| Warm House - Eco | propylene glycol | 10 Kg | -30 ° С to + 106 ° С | -30 ° C | + 170 ° C | 5 years | Yes | 1050 rbl |

| Dixis TOP (Dixis TOP) -30 | propylene glycol | 10 Kg | -30 ° С to + 100 ° С | - 31 ° C | + 106 ° C | 3 years | Yes | 960 rbl |

| ANTIFROST based on glycerin | glycerol | 10 Kg | -30 ° С to + 105 ° С | 4 years | no | 700 rbl | ||

| PRIMOCLIMA ANTIFROST based on propylene glycol | propylene glycol | 10 Kg | -30 ° С to + 106 ° С | -30 ° C | + 120 ° C | 5 years | Yes | 762 rbl |

| THERMAGENT 30 | ethylene glycol | 10 Kg | -20 ° С to + 90 ° С | -30 ° C | + 170 ° C | 10 years | no | 650 rbl |

| Teplocom (glycerin) | glycerol | 10 Kg | - 30 ° С to + 105 ° С | 8 years | no | 780 rbl |

Another important drawback is that ethylene glycol reacts very poorly to overheating, and overheating occurs at a rather low temperature. Already at + 70 ° C, a large amount of sediment forms, which settles on the elements of the heating system. Deposits reduce heat transfer, which again leads to overheating. In this regard, such antifreezes are not used in systems with solid fuel boilers.

Propylene glycol, on the other hand, is chemically almost neutral. It reacts least of all coolants with other substances, overheating occurs at higher temperatures and does not lead to such consequences.

At the end of the last century, glycerin-based antifreeze was developed for heating systems.He is a cross between ethylene and propylene heat transfer fluids. It is safe for humans, but does not have a very good effect on gaskets, and also reacts poorly to overheating. In terms of price and temperature characteristics, it is approximately in the same range as propylene heat transfer fluids (see table).

Features of systems with antifreeze as a coolant

When designing a heating system, the heat carrier must be taken into account from the outset. This is due to the lower heat capacity of non-freezing liquids, as well as their other properties. If all equipment was designed for water, and antifreeze is poured into it, the following problems may arise:

- There will not be enough power and it will be cold in the house. This is due to the lower thermal conductivity of antifreezes. This problem can be solved with a little blood - to increase the speed of movement of the coolant by installing a more powerful circulation pump. But in an amicable way, it takes an increase number of radiator sections.

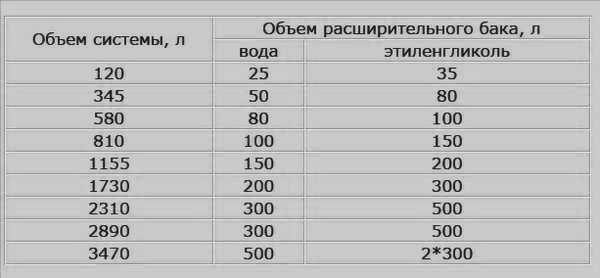

- In closed systems, it may not be sufficient expansion tank volume... This is due to the fact that when heated, non-freezing joints expand more than water. The way out is to put another tank. The total volume should be slightly more than required (the volume can be taken from the table).

- If ordinary rubber gaskets are used, when using ethylene glycol or glycerin, they will deteriorate and flow after a short time. Therefore, before pouring antifreeze in all detachable joints, the gaskets are replaced with paronite or Teflon ones.

As you understand, the best coolant for a heating system is water. It is better in performance and several times cheaper. If the heating is threatened with defrosting, it is necessary to fill in antifreeze, but not automobile, but special - for heating. In this case, if you have enough funds, it is better to use propylene glycol. Ethylene non-freezing is an extreme case. They are suitable in closed systems with special gaskets and automated boilers to prevent overheating.

To make it easier for buyers to navigate, dyes are added to the coolants. In ethylene - red or pink, in propylene - green, in glycerine - blue. After a while, the color may not become so intense or disappear altogether. This is due to the thermal destruction of the dyes, but does not affect the properties of the antifreeze itself.

How to pump coolant

Problems usually only arise with closed systems, since open ones are filled through an expansion tank. The coolant for the heating system is simply poured into it. It spreads through the system under the influence of gravity. It is important that all air vents are open when filling the system.

There are several ways to fill a closed heating system with coolant. There is a way of filling without using technology - by gravity, there is withsubmersible pump type "Kid" or special, with the help of which they make system pressure testing.

Fill with gravity

Although this method of pumping a coolant for a heating system does not require equipment, it takes a lot of time. You have to squeeze out the air for a long time and gain the required pressure just as long. By the way, we pump it up with a car pump. So the equipment is still required.

Find the highest point. Usually this is some of the gas vents (we remove it). When filling, open the valve to drain the coolant (lowest point). When water runs through it, the system is full.

With this method, you can connect the hose from the water supply, you can pour the prepared water into the barrel, raise it above the entry point and so pour it into the system. Antifreeze is also poured, but when working with ethylene glycol, you will need a respirator, protective rubber gloves and clothing.When a substance gets on a cloth or other material, it also becomes toxic and must be destroyed.

When the system is full (water ran from the drain tap), we take a rubber hose about 1.5 meters long, attach it to the entrance to the system. We select the entrance so that the pressure gauge is visible. At this point, we install a check valve and a ball valve. To the free end of the hose we attach an easily removable adapter for connecting a car pump. After removing the adapter, pour the coolant into the hose (keep it raised up). After filling the hose, using the adapter, we connect the pump, open the ball valve and pump the liquid into the system with the pump. Care must be taken not to pump air. When almost all the water contained in the hose is pumped in, the tap closes and the operation is repeated. On small systems, to get 1.5 Bar, you will have to repeat it 5-7 times, with large systems it will take longer.

Fill with a submersible pump

To create working pressure, the coolant for the heating system can be pumped in with a low-power submersible pump of the Malysh type. We connect it to the lowest point (not the drain point of the system). We connect the pump through a ball valve and a check valve, put a ball valve at the drain point of the system.

Pour the coolant into the container, lower the pump, turn it on. In the process of work, we constantly add a coolant - the pump should not drive air.

In the process, we monitor the pressure gauge. As soon as its arrow has moved from the zero mark, the system is full. Until this moment, the manual air vents on the radiators can be opened - air will escape through them. As soon as the system is full, they must be closed.

Next, we begin to raise the pressure - we continue to pump the coolant for the heating system with the pump. When it reaches the required mark, we stop the pump, close the ball valve. We open all the air vents (on the radiators too). Air escapes, pressure drops. We turn on the pump again, pump a little coolant until the pressure reaches the design value. Let the air down again. We repeat this until their air vents stop leaving air.

Then you can start the circulation pump, bleed the air again. If at the same time the pressure remains within the normal range, the coolant for the heating system has been pumped in. You can run it.

We use a pump for pressure testing

The system is filled in the same way as in the case described above. In this case, a special pump is used. It is usually manual, with a container into which the coolant for the heating system is poured. From this container, liquid is pumped through a hose into the system. You can rent it from companies that sell water pipes. In principle, it makes sense to buy it - if you use antifreeze, it will have to be changed periodically, that is, you will have to fill the system again.

This is a hand pump for pressure testing, with which you can pump the heating medium for the heating system

When filling the system, the lever moves more or less easily; when the pressure rises, it is harder to work. There is a pressure gauge both on the pump and in the system. You can follow where it is more convenient. Further, the sequence is the same as described above: pumped up to the required pressure, deflate, repeat again. So until there is no air in the system. After - we also start the circulator for five minutes (or the entire system, if the pump is in the boiler), bleed the air. We also repeat several times.

And in my dacha it has been 6 years since Hotstream propylene glycol coolant was poured into the system with a Buderus gas boiler. So far, I'm completely satisfied, there are no leaks, it keeps the temperature in winter, it swings without problems in the most severe frosts, the declared service life is 10 years, so I'm not going to change it. For some reason, he is not mentioned in the article, but from myself I can recommend him.

I bought a coolant from an office that sells all three types of coolant.

There I was told that propylene glycol and ethylene glycol are the same in thermal properties, and glycerin is more viscous.

Since I have a system with natural circulation, then glycerin is not suitable.

Therefore, I took propylene glycol. I have been using it in the country for 4 years. Heating is periodic. Pipes - metal-plastic and copper, radiators - steel panel.

It's okay for now. No drips.

Do you have a propylene glycol coolant from the table of the article?

PRIMOCLIMA ANTIFROST, Dixis TOP, Warm House which one, if yes?

I would like to take a proven option

We use Thermagent -30 coolant in the heating system. We chose it because it contains anti-corrosion additives, which is especially important since the system is constantly filled, roughly speaking, is constantly exposed to the effects from which this antifreeze perfectly protects.

Think other antifreezes do not contain such additives?

I will not argue about others, I have not used them.

Almost all modern coolants contain anti-corrosion additives. It is also worth separating industrial coolants, such as, for example, XNT, SAV, Spektrogen, TPN, etc. and for household (private) use. In the above article, only household brands are described. Industrial ones are distinguished by an increased service life and a more complex composition with the largest amount of additives.