Aluminum skirting board - types and methods of installation

Any very high-quality repair can be ruined by poorly chosen little things. One of these little things is the plinth. It must be chosen so that it does not look foreign, but logically completes the picture. In this case, let's talk about an aluminum skirting board.

The content of the article

Advantages and disadvantages

Aluminum skirting board is one of the most durable. There are few substances that can destroy this metal, and very few of them are used in everyday life. The most unpleasant thing that can happen is a dark film will appear on the surface. It is a consequence of the reaction of aluminum with oxygen in the air. Modern processing methods make it possible to get rid of this nuisance. One of these methods is anodizing. After processing, a thin, durable film forms on the surface of the product, which gives the product an additional shine. She, at the same time, protects against oxidative processes.

Since aluminum is a soft metal, products of any shape and configuration can be made from it. And this is also an advantage. Softness, however, allows you to tightly press thin-walled skirting boards to uneven surfaces. This is very difficult in the case of composite materials (MDF, for example) and almost impossible with wood. On the other hand, the softness of aluminum is the possibility of damage. But pine wood is even softer, so aluminum skirting boards in this aspect wins over wooden ones.

There are also advantages: ease of maintenance, long service life. The best part is that there is no need to periodically renew the varnish or paint. Dirt on the surface can be easily removed with a wet cloth. Sometimes mild, non-abrasive detergents can be used. If you do not use acid-containing detergents during cleaning, nothing will happen to the aluminum skirting board, its surface will remain even, smooth and shiny.

There are also disadvantages. The first is the high price tag. You can't do anything with the price - aluminum is an expensive material. Manufacturers are trying to reduce the price by thinning the walls or creating combined skirting boards - from aluminum and wood composite, for example. But everything needs a measure. Too thin walls are also not an option, as this can affect the service life.

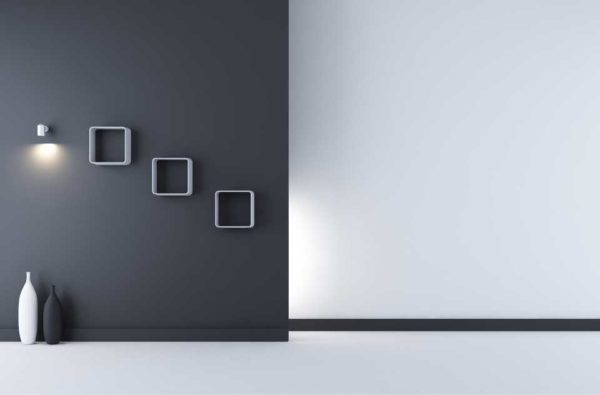

The second is a specific appearance that does not fit into any interior. For example, in a classic, ethnic or romantic interior, aluminum skirting boards do not look good in any scenario. But in high-tech and other modern styles, it suits better than others. There are also restrictions on compatibility with materials. It looks great in combination with tiles, some types of laminate. With "fleecy" coatings, you should look specifically at the interior.

For kitchen units

If we talk about the place of installation, then the aluminum skirting board is placed at the junction of the wall and the floor (floor) or at the junction of the kitchen countertop to the wall (kitchen). Since their tasks are different, they differ constructively.

Types and device

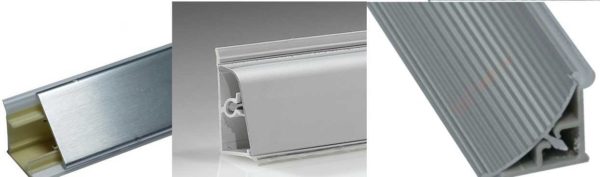

A kitchen aluminum skirting board should smooth the angle between the wall / apron and the countertop, prevent debris and moisture from entering the gap, therefore, it usually looks like a triangle in cross section. For a more intimate contact with the wall and countertop, elastic silicone sides are attached at the edges. During installation, the worktop skirting board is pressed so that the silicone strips cover all the irregularities.

Such a plinth usually consists of a body and a front strip. They are connected to each other using a lock, which can be single or double. A single one does not always give the necessary strength of fixation, and a double one is often difficult to "sit" in place. Until the plinth is installed, everything is connected "with a bang", but after installation problems begin. Sometimes you have to use a fist, a rubber mallet and other methods of "power mounting".

The front plate can be straight, curved and concave (pictured). In addition, its surface can be flat and smooth, rough, with various lines, with a pattern. In practical terms, it is easier to clean smooth, ribbed or patterned ones - this is more problematic. But often the choice of the type of surface depends more on the appearance. kitchen set.

Installation features

Before installation, the aluminum skirting board is cut into pieces of the desired length. Some systems have special corners, connectors, end caps. The length must be calculated taking into account these elements. The front plate is removed from the cut piece, the body is attached to the wall using dowels / self-tapping screws. For greater reliability and tightness, it is recommended to coat the back wall of the kitchen aluminum skirting board with silicone sealant. It is better to take it transparent (it looks like aluminum of the usual color) or black - if the baseboard is black.

Do not use white sealant - it quickly turns yellow and you can't do anything about it. To prevent mold from blooming on the surface of the sealant, use an aquarium sealant. They are perfectly adapted to a humid environment, they are durable and nothing grows on them. You don't have to worry about their safety either - aquarium fish are delicate creatures and do not tolerate harmful substances.

After the skirting board body is installed, the silicone has set (you should wait for the required time, which is indicated on the package), corners / plugs, connectors are installed. The front plate is installed in its place last.

Floor

Aluminum skirting boards differ in shape. They look more like a rectangle in cross-section, they do not have silicone sides. But there is an abundance of sizes, shapes and installation methods.

Dimensions and application

First, let's talk about sizes. The height of the aluminum skirting board for the floor can be from 40 mm to 120 mm. Thickness - from 5-6 mm to 30-40 mm. Thin ones look very stylish in some interiors, but not suitable for all floor coverings. Some materials have significant thermal expansion, therefore they are laid with a gap of at least 1 cm from the walls. For such cases, super slim aluminum skirting boards are not suitable, since they simply do not cover this gap.

Wider aluminum skirting boards may not be as elegant, but they are useful: they often hide a cavity for laying cables. Power cables (through which 220 V is supplied) are hardly worth laying in this way, but small points (TV cables, Internet, low-voltage power) are very convenient.

Special types

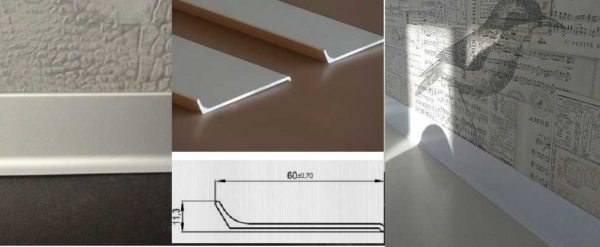

There are also concealed aluminum skirting boards. They are installed prior to finishing. As a result, they are obtained either on the same level with the finishing material or, as it were, "hiding" under it. There are options that serve as a support for sheet finishing materials. For example, an aluminum plinth for plasterboard. The lower part of the sheet rests on the shelf of the plinth. It is used if the gypsum board is mounted on a wall without lathing.

For more sophisticated interiors, there are aluminum skirting boards with decorative trims or illuminated. In terms of stylistic performance, they are different. Decorative ones are rare. They are only available at Fezard. The pads are also made of metal.The floral pattern "softens" the utility of the material. In this version, you can try to fit it into some "softer" interiors, in which floral ornaments are used in other types of decoration.

In the aluminum skirting board with LED illumination, a groove is formed on the front side, into which the LED strip is placed. The groove is closed with a strip of transparent or matte plastic. Accordingly, the light is brighter or more diffused. Such skirting boards give an interesting effect - the walls "float" in the air. If they are installed in the corridor, there is no need for additional lighting at night.

Since the LED strip is in an enclosed space, it will keep warm. Since with an increase in temperature, the LEDs quickly grow cloudy, then burn out, it is better to initially take a small glow power. By the way, there is no backlighting in skirting boards made of other materials, because the LEDs in them will overheat very quickly, which will lead to their burnout. Aluminum has good thermal conductivity and removes excess heat. Other materials build up heat and may even catch fire. So it's best not to experiment.

There is a second option - when in the upper part of the plinth a shelf is cast in the form of the letter "L" laid on one side. Attached to the end of this shelf LED Strip Light... It turns out that the light is directed not to the side, as in the previous version, but down. The advantage of this type of backlit skirting board is that the tape is open, so it cools better, which means you can use more powerful LEDs.

Colors and surfaces

Do not think that aluminum skirting boards can only be silver-gray. During the anodizing process, it can be painted in any color, but most often you can find black, white, bronze, brass and several shades of gray.

Standard metallic colors may vary in gloss. There is a color that resembles a lacquer coating, there are options with different degrees of "satin" - matt, with "traces of grinding".

Aluminum skirting boards are available in different colors. "Metallic" colors are made with varying degrees of gloss

The color and gloss level are selected based on the overall style and prevailing interior colors. Bright gloss is appropriate only in high-tech, all the others tend to be more matte or semi-matte color options.

Installation methods

Aluminum skirting boards can be attached to walls in different ways. Thin types are mounted only and exclusively on glue: drilling a hole in the strip will spoil the appearance, but there is no other way to do it. The glue is selected based on the material of the walls, but most often they use universal compositions such as "liquid nails".

The wider skirting boards have two fixing systems:

- The support is fixed at a certain distance from the floor, the plinth itself is put on it (like on rails). These are usually low thickness options.

- The skirting board consists of two parts - the body and the front decorative strip. The body is attached to the wall, then, with a lock, the front plate is fixed. This mounting method is usually found on wider models in which cables and wires can be laid. The front panel can be removed, so this is a fairly convenient way.

When choosing duralumin skirting boards, pay attention to the presence of elements that allow you to assemble any configuration. These are external and internal corners, connectors and plugs. When installing, it is advisable to fix parts of the plinth in the element, since often the corners (especially the outer ones) and end caps fly out, causing inconvenience. You can put the junction on the glue, coat it with sealant.In the case of glue, an inseparable connection is obtained, which is not very good, since they usually leave the opportunity to remove the skirting board during repairs. Therefore, it is advisable to use a sealant - it will hold the parts together, but they can be torn from each other without damage. Just don't use acidic sealants - they will leave marks on the aluminum.

Features of work

It is better to cut an aluminum baseboard with a cross-cut saw, if it is not there, you can use a grinder or an ordinary hand saw with a metal blade. A straight line is not easy when using a hand tool. If there are flaws somewhere, it will be necessary to correct it with a file; you can remove the burrs with it or with a bar wrapped in sandpaper.

For a smoother cut when working with a hand saw, you can use a regular carpentry miter box... It is easy to make 45 ° and 90 ° corners in it.