Primer "Betonokontakt" - what is it and what is it for

Not all finishing processes can be called easy. The development of technologies allows them to be made not so physically difficult, and / or to reduce the time, to improve the result. But since the materials and technologies are new, there are many conjectures and errors in use. Today we will figure out what concrete contact is, what it is for, how to use it correctly.

The content of the article

Primer developers

This composition has about a dozen variants of the name: Betokontakt, Concrete-contact, Betonokontakt, contact-soil, soil-contact, etc. The inventor of this primer is the German company FEIDAL. In any case, this is exactly what is indicated on their official website, and since no one has yet disputed the information, this fact can be considered true. The original name is Betokontakt, in Russian - Betokontakt. Among the people, "Betonokontakt" has taken root more, since it is most often applied to concrete. So, strictly speaking, the original is the composition of only this company.

However, any company that produces building mixtures has a similar composition with the same or very similar name. Most likely, the name changes are intentional, so that no charges can be brought. In general, it is not so important for the consumer who came up with this composition. It is important that it fulfills its functions.

Structure

Each company adds something of its own to the composition, but Betokontakt in any variation contains the following components:

- Acrylic dispersion (copolymers). The basis of the composition, which is responsible for adhesion. It is she who leaves a sticky layer after drying. The quality of the primer largely depends on the quality of this component.

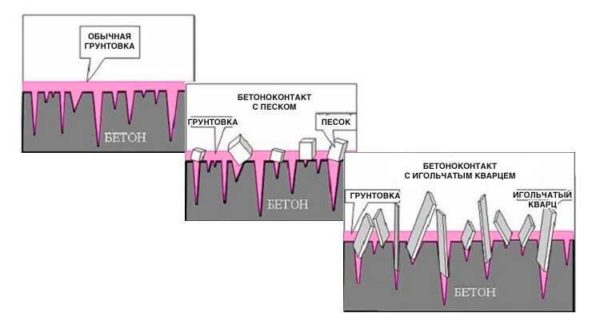

- Natural fillers. Usually quartz sand, but there are options. Creates a rough finish, which increases adhesion to the next coat.

- Supplements. Provide special properties (water resistance, antibacteriality, etc.).

Some companies add dye. This is to make it easier to control the application and not leave bald spots. By the way, you can add it yourself to formulations without dye.

As you can see, Betonokontakt does not contain harmful substances, has a neutral acidity level, therefore it does not react with alkaline materials, does not contribute to the oxidation of metals. Due to this ability, it can be used under both cement and gypsum plasters / putties.

Purpose and scope

Concrete Contact is a special type of primer for substrates that do not absorb water. If plaster is applied to such bases without preliminary preparation, it will most likely fall off when it dries, since the surface of these bases is usually smooth and the plaster simply has nothing to catch on. To prevent the plaster from falling off, use Beto-contact. And it really works, but you just need to know when it is needed.

The composition is not cheap, but it is advised to use it wherever it gets. In order not to waste money, it is worth knowing exactly its properties and scope. In general, there is information on each bank, but sellers (and some builders) advise a different application. But not everyone should be believed.

What surfaces to apply

Concrete contact forms a sticky, rough layer with abrasive inclusions on the surface. Plaster / putty adheres well to this layer.Abrasive particles - grains of sand or crystals - provide additional support for the finish layer. In general, the task of Concrete Contact is to increase adhesion to difficult substrates. But not all.

What should Betonkontakt be applied to? As already mentioned, it is intended for substrates that do not absorb water. There are not many of them:

- Smooth concrete with almost no pores. Usually these are concrete panels in panel houses, columns in modern monolithic ones. If the concrete is loose and porous, a different primer is needed.

- Ceramic tile. It is not necessary to knock down the old tiles before laying new tiles. Although, if possible, it is better to shoot down. If for some reason this cannot be done, go over the top of the tile twice with concrete contact and you can continue working.

- Wooden fragments. There is simply no other way to apply plaster to wood. But the wood must be dry.

- Metal. This base is 100% non-absorbent and in order for the plaster to stick to it, a layer of BK is needed.

That's what Betonokontakt is for. There are no other recommended surfaces. Tips to apply on plaster under putty, under decorative plasters - all this is superfluous. There is no need for this processing, because only the cost rises, and the result is not affected or only worsens the situation. On fresh plaster, the putty will fall "with a bang" like other finishing materials.

There is one piece of advice: it is better to take a concrete contact with a large grain, if you apply plaster and with a fine grain - under the putty.

Moreover, the advice to apply Betokontakt on wooden and metal surfaces is precisely on the fragments. For example, beams, protruding parts of structures. This is again the moment where the bookmaker is needed. There are other technologies for plastering wooden walls, and if there is only a fragment, it is advisable to use this composition.

Do I need concrete contact over oil paint

Finishers also use Betonkontakt on oil paint. Most of them advise to peel off the paint, because with or without concrete contact, the plaster under its mass can separate from the paint. If the composition has eaten tightly and is not removed by any methods, it is necessary:

- Be sure to thoroughly degrease the surface.

- Remove the smoothness by abrasive processing - with coarse sandpaper, a metal brush. It doesn't matter what, if only it worked.

- Make notches with a chisel, ax.

- Dust off. You can wash, you can vacuum. The main thing is thorough.

- Apply the first layer of concrete contact.

- Dry.

- Apply a second layer of concrete contact.

- Dry.

- You can putty, plaster, lay tiles.

In this case, it is also clear what Betonokontakt is for and how it works. But it is quite possible to stop already before the first application of Concrete Contact. With enough notches, both plaster and tiles will stick. Use a suitable primer to treat the “chips” in the wall and, after drying, apply the following material.

Many people assume that with the sticky surface that Betokontakt leaves, it will stick better. In general, it works, but only if you do everything as written. And yes. Drying is complete and final. The term is indicated on the bank and differs depending on the manufacturer. The shortest drying period is 3-4 hours for Betonkontakt Fedal, the longest is about 24 hours for some cheap one.

Where it is absolutely not worth using the composition

It is important to know not only what Concrete Contact is needed for, but also where it is not needed and even harmful. For example, you should not listen to advice on impregnating loose or loose substrates with the composition. Other deep penetration primers are needed here.And Concrete Contact adheres to a smooth surface, not particularly trying to penetrate into it. It makes no sense to cover whitewash, ordinary DSP with a loose structure, gas and foam concrete, plaster, etc.

Often, Betokontakt is bought for priming a wall or floor before laying tiles. If the surface is absorbing water, do not do this. And that's why. Look at the characteristics of tile adhesive and BC. For glue, adhesion is 0.8-0.9 MPa, for BK - 0.4-0.5 MPa. That is, by adding a layer of concrete contact to a normally absorbent base, you worsen the situation for your own money, and considerable money. Although some manufacturers write in the instructions that the composition can also be used for laying tiles. But the situation with adhesion turns out to be similar ...

If you want the tiles to not fall off for sure, take good glue. Yes, it is more expensive, but a pair of BK + cheap glue costs no less, and the result is unpredictable. When in doubt (not a very solid base), it is better to use a deep penetration primer and / or a better adhesive. It is usually positioned "for difficult surfaces" and holds tight, as it penetrates deep into the base.

The use of Betokontakt will bring harm rather than benefit when applied under Self-leveling floors... Cement will have worse adhesion than it could be, and gypsum will simply have to "pull". On a sticky base, they practically do not spread. The result is cracks, swelling and other very unpleasant moments. These are not the surfaces and cases for which Betonokontakt is needed.

What not to do

If you wish, you can find reviews or videos stating that the plaster / tile fell off Betonkontakt. To prevent this from happening, apply primer only on recommended substrates. Also, don't do the following:

- Dilute the plaster or filler with more water than indicated on the package. Yes, it's easier to work, but as a result, the putty can fall off.

- Do not apply the composition to frozen ground.

- Do not apply Concrete Contact on an unprepared surface (remove all loose parts, degrease, remove dust).

- Do not apply BC to wet surfaces. Only dry.

- When working, do not forget to periodically stir the contents, as sand particles (granules from some manufacturers) sink down.

- Do not continue work until the primer layer is completely dry (indicated in the instructions).

- Do not work at temperatures below + 5 ° C. This does not mean that it cannot be used for outdoor work. It is possible, only it must be applied at positive temperatures.

- Dust must not be allowed. It adheres very well to the adhesive surface, but then falls off along with the plaster. If the surface is dusty, another treatment is necessary.

- Do not use the composition with an expired expiration date, frozen. The exception is frost-resistant compounds (there are some). Before use, they must be defrosted, wait until the temperature rises above + 5 ° C, then you can work. By the way, the inscription "frost-resistant" does not mean that it can be applied at sub-zero temperatures. It can only endure several defrost / freeze cycles before application without loss of properties.

- Do not add water, even if the composition seems too thick. Unless the manufacturer described this possibility in the instructions. But so far they have not seen one.

And for Betonokontakt to work, it must be "real". There are a lot of fakes, so you need to be careful. And to be sure, you can check. Pre-process the BC a small piece of the wall according to the instructions. Apply a planned layer of plaster / putty. Wait until it dries and try to tear it off.If done correctly, you will fail. They say that high-quality Betokontakt allows you to apply plaster even on glass. You can try it by the way.

How to apply

It is necessary not only to know what Concrete Contact is needed for, but also how and how to apply it. It just seems like there is nothing complicated about it, but try it first. The composition is often thick, approximately like kefir, and sometimes thicker. Moreover, it contains grains of sand, crystals, which are very desirable to be evenly distributed over the entire surface, and not collected in one place. In general, it is not that simple. There are some tips:

- It is best to work in protective clothing, and it is advisable to cover everything. It is washed from the skin with big problems, from the hair it is removed only together with the hair. To make it easier to rinse off unprotected skin, cover it with a greasy cream or some kind of oil. When processing the ceiling, it is advisable to protect the face, even if the skin is smeared with cream / oil. At least glasses are required.

- For large areas, it is easier to apply with a roller. It is more convenient to take it in such a size that it fits into a bucket. Better to work with a fleecy - with a pile of 12-18 mm. Yes, a certain amount of the composition is absorbed, but it is really more convenient to work this way than foam rubber, which very quickly becomes "wooden". Moreover, even in this case, after a while, the pile will become clogged with sand. In the process, remove sand on the edge of the bucket, you can try with a spatula. In general, clean up. If it is not already cleaned and "does not work", take a new one.

- For processing not too large surfaces or in corners, it is more convenient to work with a brush. Pile - medium or even short. Here it is more convenient for someone. Only the long one is hard to manage when it is packed with sand. In the process of application, the sand must be periodically removed (on the edge of the bucket). The brush wears off quickly, so with large volumes of work, you will have to change it several times.

There is one more trick - attach a brush or roller to a stick with a meter in length - and a stepladder is not needed when processing walls, and away from yourself - fewer drops fly to clothes and to your face.

Manufacturers and possible replacement

As already mentioned, almost any manufacturer of building mixtures has Betonokontakt, Beto-Kontakt, Beton-Kontakt or something similar. If you like other blends from this manufacturer, it makes sense to try this one too. There are local companies that, with good quality products, are represented only in some regions. So not all of them were included in the list, but those who have a wider "coverage". According to the reviews, I liked working with Betokontakt of the following companies:

- FEIDAL (Feydal). This is a roster developer, so no surprise. And the price is not too exorbitant, and the quality is high.

- Knauf (Knauf). Just keep in mind that the composition is not waterproof. That is, it is very important to properly seal the plaster mixture or putty - do not overdo it with water.

- Eskaro (Escaro). Work only in a ventilated area, as it has a strong ammonia smell. But it is convenient to work, the composition fits well.

- Ceresit. A lot of fakes. Has a pink pigment, which makes it easier to control the quality of processing.

- Plitonite. After stirring, the solids settle slowly, so the composition is not bad. Copes with the task, too, at five.

- Pufas. It will stick a little less, but overall not bad.

- Osnovit. It is called Bettokont. It requires constant stirring, and dries for 1-2 hours, the result is normal. Recommended only for gypsum plasters.

- Olympus. Despite the low price, it gives a good result.

- Prospectors. Composition with coarse fraction, drying time - 2-4 hours.

- Bolars. Very thick, difficult to apply, dries at least 24 hours.

The list includes firms operating in different price segments. The more expensive ones tend to apply slightly better.The cheaper ones will have to be mixed more often, and they are more difficult to apply. When processing, try not to leave bald spots. If found already during drying, apply a coat and wait for the full drying time. It's better than reworking the peeled piece later.

They often ask whether it is possible to replace Betonokontakt with something. The only possible option is Ceresit ct-16 primer. It gives a similar effect, but the cost is probably more expensive.

A few words in conclusion

Please read the instructions carefully before purchasing. Some formulations of acrylic primers for smooth dense substrates can be used under both cement and gypsum plaster. Others - only for plaster. Some are suitable for indoor use only, others can be used outside. In the same way, there are compositions, the instructions for which are prescribed for use with old paints, others are suitable for tiles ... In general, carefully read the recommendations for use.