Expanded clay blocks: sizes, characteristics, advantages and disadvantages

Choosing material for building a house is very difficult. The house needs to be warm, reliable and durable. And also, it is very desirable that the material for the construction of walls is inexpensive. It is very difficult to “fit” all parameters in one material. One of the options is blocks of expanded clay concrete. The material is far from ideal, but warm, lightweight, inexpensive. Also, the size of the expanded clay concrete block can be different, which makes it easier to choose the optimal size.

The content of the article

What are expanded clay concrete blocks according to GOST

Expanded clay concrete is classified as lightweight concrete. A porous material is used as a filler - expanded clay. These are rounded baked clay granules. The composition of expanded clay concrete is cement, sand, expanded clay and water. When making up the mixture, more water is poured than in ordinary heavy concrete, since expanded clay is hygroscopic and absorbs liquid. In the production of blocks, the finished mixture is poured into molds, left until the initial hardening, after which they are removed from the mold. In principle, the blocks are ready, but they cannot be used until they have reached their design strength.

There are two technologies for pre-fabrication of products to normal strength - in an autoclave and vibrocompression. In the first case, the blocks are sent to an autoclave, where the material is treated with steam under pressure. This makes the expanded clay concrete blocks more durable. The second way is vibration with simultaneous pressure. When vibrating, all voids leave, the solution becomes more homogeneous and fluid, enveloping each of the expanded clay granules. The result is high strength indicators.

In handicraft production, the blocks are simply left to "ripen". In theory, it takes at least 28 days for the concrete to gain strength. But they can sell earlier so that they do not take up space. At the same time, no one guarantees strength.

On the surface of the block, rounded expanded clay granules are guessed. Depending on the brand, they can be of different sizes, more or less

The fact is that for the normal gain of cement strength, it is necessary to create a certain heat and moisture regime. Expanded clay concrete in this regard is more capricious than ordinary concrete. Due to the high absorbency of expanded clay, it can pick up too much water. And the liquid will not be enough for the concrete stone to gain strength, and not just dry out. Therefore, it is advisable to water and cover the finished blocks with a film at least for several days after production. Do not keep them in the sun and the temperature must be at least + 20 ° C. Otherwise, the expanded clay blocks will never gain the required strength and will crumble even under light loads and impacts.

In terms of price, factory blocks are more expensive. But still. If you are building a house, and not a utility block or a shed, you should not save and buy blocks of "garage" production. The quality is questionable here.

Pros and cons of a house made of expanded clay blocks

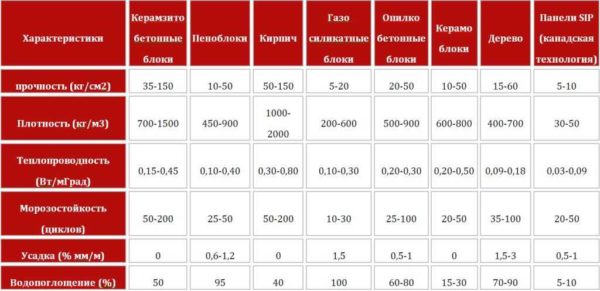

Expanded clay blocks many times more bricks... Even double. The size of a lightweight aggregate concrete block can only be compared with ceramic building blocks. But expanded clay blocks weigh less, have better thermal conductivity characteristics. And, importantly, much lower in cost. Durability and frost resistance are comparable to ceramic bricks.

Advantages of building from expanded clay concrete

The advantages of houses made of expanded clay blocks include the following points:

- Short terms for the construction of walls.

- For masonry, use a conventional cement-sand mortar.

- Claydite block masonry is well finished with any materials.

- The house is warm. But ceramic bricks are more heat-intensive - by about 20-30%, so it accumulates more heat. If we compare it with silicate brick, the expanded clay concrete block is more heat-intensive.

- The walls are lightweight, which reduces foundation costs.

- No shrinkage.

- They do not contain lime, which means that the fittings do not corrode.

- Good sound insulating properties. For external walls 47 dB to 55 dB, for internal walls - from 49 dB to 54 dB. Depends on the density and thickness of the walls.

The blocks can have a tongue-and-groove system, which improves the thermal performance of the masonry. The material is natural, breathable, so there will be no problems with humidity regulation in rooms.

disadvantages

Expanded clay houses also have serious disadvantages. They must be taken into account when choosing a building material.

- Expanded clay block is not suitable for houses without heating in winter. Remember that expanded clay is hygroscopic and blocks of expanded clay concrete too. Frost resistance is not so great, so, firstly, insulation is required, and secondly, finishing, which will protect the material from water ingress. It is also imperative to maintain a positive temperature. In general, the frost resistance of blocks that are processed in an autoclave or in a vibrating press is about 100 cycles and this is more than enough. But for private traders, no one controls this parameter.

- Due to hygroscopicity, it is better not to use it for walls in rooms with high humidity. That is, it is better to look for other material for baths. It's just that when building from expanded clay concrete blocks, they must be covered with waterproofing agents from the inside.

- The size of the expanded clay concrete block can "float". This is inconvenient during construction.

- Manufacturing technology is simple, which allows you to open a "garage" production. Everything gets in the way "by eye", no control of characteristics and parameters, and then the blocks fall apart, the walls crack.

The main disadvantage is high hygroscopicity. Clay pellets can absorb a lot of water. Blocks that are kept outdoors for a long time weigh several times more than those that remain in dry rooms. Cement from moisture only becomes stronger. But damp walls are unlikely to please you. Therefore, it is important to make high-quality waterproofing of the foundation, to cut off all possible sources of moisture "suction". It is better to make the roof with large overhangs and build a high-quality drainage system.

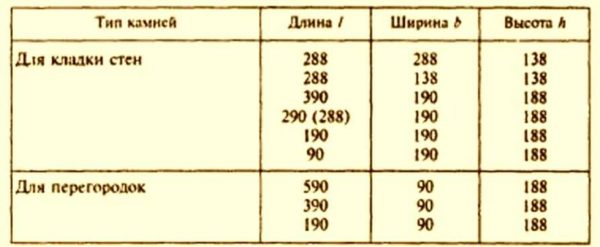

The size of the expanded clay concrete block according to the standard

The fact is that there is no separate standard for expanded clay concrete blocks. This type of material is described by a group of standards that standardize lightweight concrete and products from them. So the dimensions of wall blocks made of lightweight concrete are established by GOST 6133-99.

Limit deviations are also indicated. They are ± 3 mm in length, ± 4 mm in height, the thickness of the walls between the partitions can be 3 mm thicker (it cannot be thinner).

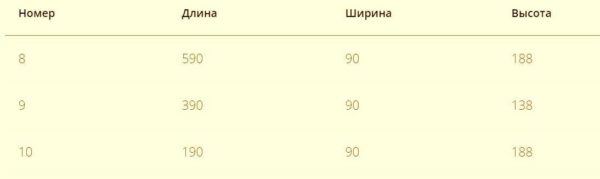

Popular size of expanded clay concrete block for walls and partitions

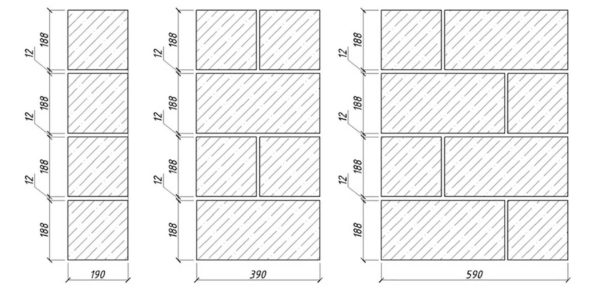

Most often, expanded clay concrete blocks with a size of 390 * 190 * 188 mm are used for masonry walls. It turns out very conveniently, since for central Russia, the optimal wall thickness is 400 mm. That is, the laying is carried out “in one block”. Partitions usually require a smaller thickness of 90 mm. The length and height remain the same. That is, the size of the expanded clay concrete block for partitions is 390 * 90 * 188 mm.This does not mean that partitions cannot be made from longer or shorter partition plates. It is possible, but shorter ones - more seams, more mortar consumption, and longer ones are heavier, more difficult to work with.

If you want to have the best parameters for sound insulation between rooms, partitions can also be folded from wall blocks. Either the standard width is 190 mm, or those that are thinner are 138 mm. But the costs are higher.

Custom dimensions

The standard contains a postscript that, as agreed with the customer, the size of the expanded clay concrete block can be any. So you can find products of any format.

The size of a lightweight aggregate concrete block of this format cannot be exactly referred to as standard

In addition, there are also technical specifications (TU), which are developed and registered by the enterprises themselves. If you are going to buy a large batch and the marking is not GOST 6133-99, but TU, it is better to familiarize yourself with this document so that there are no surprises.

Types of expanded clay blocks

The ends of the blocks can be grooved, flat, or groove / tongue. For use in corners, one edge can be smooth. In addition, corners can be rounded or straight. On the supporting surfaces (where the mortar is placed), grooves can be formed for laying reinforcement. These grooves should be located at a distance of at least 20 mm from the corner.

There are blocks with and without voids. Voids can be through or not, they are evenly spaced, perpendicular to the working surface. The maximum permissible weight of a lightweight concrete building block is 31 kg. The standard normalizes the thickness of the walls that enclose the voids:

- outer walls - at least 20 mm;

- partition over blind voids - at least 10 mm;

- between two voids - 20 mm.

Voids are often made flat - in the form of cracks. The number of "lines" with voids determines the thermal conductivity of the material. The more void lines there are, the warmer (and quieter) the wall will be. Air, as you know, does not conduct heat well. In any case, worse than concrete. Therefore, splitting the block with voids gives a good result.

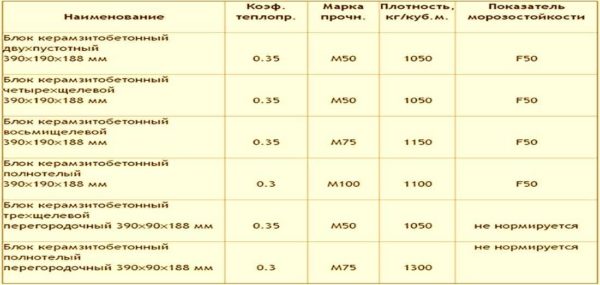

Density and compressive strength grades

In terms of strength and thermal conductivity, expanded clay concrete blocks are divided into two categories: structural and structural and thermal insulation. Each of the groups may contain products of different density. Density is the dry weight of one cubic meter of material. The approximate value is after the letter D. For example, D600 - the mass of a cubic meter is 600 kg, D900 - 900 kg. Etc.

- Structural and thermal insulation:

- D500 B0.75 to B1.75;

- D600 B1.0 to B2.5;

- D700 B1.5 to B3.5;

- D800 B2.0 to B3.5;

- D900 B2.5 to B7.5;

- D1000, 1100 B3.5 to B10;

- D1200, 1300, 1400 B5 to B10.

- Structural:

- D1100 12.5V;

- D1200. 1300 B12.5 to B20;

- D1400. 1500 B12.5 to B30.

In private housing construction, structural and thermal insulation blocks are usually used. For the construction of the outer walls of one-story houses, expanded clay concrete blocks of the D700 or D800 brand are used; for internal unloaded partitions, lower grades can also be taken.

Standard solutions for the middle lane

When building a house, it is most correct to order a project. Here everything will be taken into account for you, they will register all the nodes, materials, including the size of the expanded clay concrete block, its parameters and quantity. It remains only to buy everything according to the list. But few do that. The project is a cost, and there is little money. Therefore, they themselves try to "estimate" without calculation. The position is also understandable, but it does not always lead to savings, because "standard solutions" are made with a margin of safety, and this is a waste of material. But, in general, there are proven options for the composition of the cake of the outer walls from expanded clay blocks for Russia.

- Only blocks without insulation. Wall thickness - 600 mm. The size of the expanded clay concrete block for the outer wall is 590 * 290 * 200 mm, the blocks are hollow, structural and heat-insulating. Place blocks with voids up, fill them with heat-insulating material. The most convenient thing is with expanded polystyrene chips. Finish from the inside - plaster or drywall, outside - plaster.

- Expanded clay block 400 mm + insulation. For the outer wall, it is more convenient to use an expanded clay concrete block with a size of 390 * 190 * 200 mm. When laying with a bandage, we get 40 mm thickness. The insulation layer must have a thermal conductivity coefficient of 0.05 W / m ° C. For mineral wool and expanded polystyrene, it is about 50 mm.

- Multi-slot block of expanded clay concrete 500 mm thick without insulation... The dimensions of the expanded clay concrete block must be selected, since they often come in non-standard sizes. Can be found 500 mm long and 250 mm wide. It will be convenient to lay it in the usual scheme with dressing. Or you can use other formats, but you will need to develop a masonry scheme.

- Expanded clay wall 290 mm thick + insulation. For this option, you can use a large format block. According to GOST, its size is 288 * 288 * 138 mm, but it weighs a lot, it is more difficult to work. You can use a narrower one - 138 mm wide, which will almost give the required thickness. Insulation needs about 100 mm, interior decoration - plaster or drywall.

When choosing expanded clay blocks, we look at two indicators: the compressive strength class - for load-bearing walls it must be at least B3.0 (with a margin). The second indicator is the thermal conductivity coefficient. The lower it is, the better.