Dimensions and weight of bricks - single, one and a half, double

When ordering materials, you need to know their parameters. Even such a well-known material as brick has a large number of types and varieties. The good news is that its parameters are standardized. The standard size of the brick and its quality characteristics have been determined.

The content of the article

Types of building bricks

According to the material, bricks are ceramic (clay, red) and silicate (white). By appointment - private (construction) and finishing (front). The private is used for laying walls, assumes subsequent finishing, therefore a notch can be applied to the side edges (spoons) - in order for the plaster to hold better.

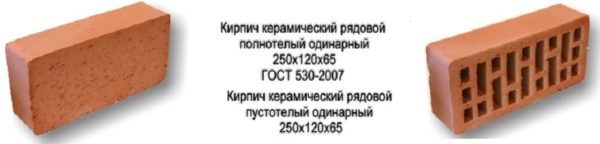

According to the method of molding, bricks are solid and hollow (hollow). Corpulent is molded from a homogeneous composition. They are used where mechanical strength is important - foundations, load-bearing walls.

Hollow has a certain percentage of voids, due to which the weight of the structure is reduced, and thermal conductivity characteristics are improved. But the presence of voids significantly reduces the performance of sound insulation - voids work as resonators. So you need to use them wisely.

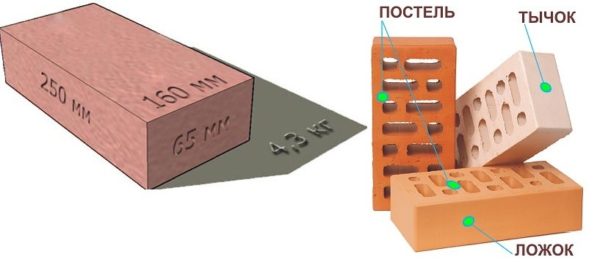

Ceramic brick size

Ceramic bricks are fired parallelepipeds molded from clay. The quality is largely determined by correctly maintained firing parameters, as well as the composition of the clay solution. High-quality ceramic bricks can be used for any construction operation: for the foundation (solid), for the construction of external walls and internal partitions.

Building bricks have certain dimensions defined by standards. The most commonly used single brick size - 250 * 120 * 65 mm

The main drawback of this building material is some variation in geometry. It is explained by the peculiarities of clay - it can be of different "fat content", which makes it difficult to predict exactly how much the size will decrease during drying / firing.

What to look for when choosing

When choosing a red brick, you should pay attention to its color. It displays the quality of the batch for the outfit with a parameter such as brick size. It can be unburned or burned out. The second option is not bad in operation (it looks darker than usual), and it is better not to use unburned brick (lighter and looser) at all - it falls apart very quickly.

The second point to which you need to pay attention is the absence of extraneous inclusions. Most often there are light points and expanded clay. Both of these lead to rapid destruction of the brick. So we choose only batches with a uniform color without any additives.

More quality criteria

- For solid building bricks:

- Chipped and blunt edges and corners are allowed in an amount of no more than 2 pieces, no more than 1.5 cm long.

- There may be a curvature of the edges of no more than 3 mm.

- On the spoon, a crack is allowed along the width of the brick with a length of no more than 3 cm.

- For a hollow private:

- No more than two chips at the corners with a depth of 1-1.5 cm, if they do not reach the voids.

- The presence of a crack in the entire thickness of the bed is allowed. Moreover, they can reach the first void.

- There may be one crack each on the butt and spoon sides (on the side faces).

That is, the requirements for ordinary building bricks are quite loyal.The presence of these defects does not affect the quality of the masonry, and the decorative component is unimportant, since the presence of finishing is assumed. Do not forget to check the size of the brick - in one batch, the run should not be more than 3 mm.

The requirements for finishing (facing) ceramic bricks are more stringent. Inadmissible:

- Chipped edges more than 1.5 cm deep.

- There should be no cracks.

- The ribs should not have bumps more than 3 mm wide and more than 1.5 cm long.

To comply with these requirements, the finishing bricks are laid on pallets, the corners are protected with boards knocked down by the corner, the entire structure is wrapped in foil. It is transported in this form.

Dimensions

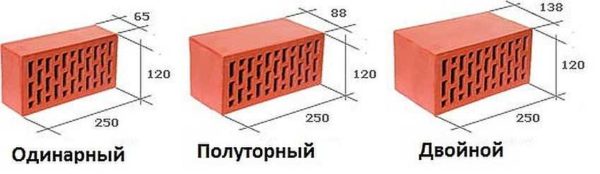

The optimal size of a clay brick (red, ceramic) has been determined historically. It has been produced for thousands of years, and as a result, the ideal combination of lengths has been worked out, which is reflected in the standard. It was adopted only in the last century. There are three standard options:

- single - 250 * 120 * 65 mm (513 pcs per cubic meter);

- one and a half - 250 * 120 * 88 mm (in a cube 379 pcs);

- double (ceramic stone) - 250 * 120 * 138 mm (55 pieces in a cube).

Of the features - a single brick is solid, hollow. One and a half and double - only hollow, otherwise they turn out to be too heavy for comfortable work.

In addition to the standard ones, there is a reduced brick. It is produced in Europe, but it also comes to us. Its parameters and international designation are summarized in the table.

| Marking | Brick size | Consumption |

|---|---|---|

| DF | 240 * 115 * 52mm | 64 pcs / m2 |

| RF | 240 * 115 * 65mm | 54 pcs / m2 |

| NF | 240 * 115 * 71mm | 48 pcs / m2 |

| WDF | 210 * 100 * 65mm | 59 pcs / m2 |

| 2DF | 240 * 115 * 113mm | 32 pcs / m2 |

Which size is better

In the post-Soviet space, a single brick is most often used. It is very familiar to our eyes, many masonry schemes have been developed for it. Master DIY bricklaying worth it with such material.

One and a half brick is used less often. It provides some economic benefit. Firstly, a cubic meter is slightly lower. Secondly, since the fragments of the masonry are larger, less mortar is consumed. Third, work is progressing faster. The larger size saves time. But working with a one-and-a-half brick is more difficult, even hollow - it's hard to hold in your hand. And the appearance of the wall is unusual.

Double brick is more commonly referred to as ceramic building stone. When using it, the most noticeable effect is the speed of construction. In addition, the saving of the solution is still increasing. But you won't be able to grab such a brick with one hand. Therefore, it is better to work with an assistant. The appearance of the masonry is poor, so an exterior finish is desirable.

If we talk about other countries, then in Europe the most popular are NF and DF. Imported ceramic bricks NF have almost the same proportions as domestic ones. The DF category is thinner, the masonry looks elegant.

Dimensions of sand-lime brick

Silicate bricks are made from quartz sand (9 parts) and lime (1 part), a certain amount of additives. This building material has better thermal conductivity characteristics (less heat conduction), less weight. The technology is such that it is easier to maintain the geometric dimensions, so there are usually no problems.

But it is not as hard as red brick, besides it is afraid of moisture - with prolonged contact with moisture, it begins to crumble. Because of this, the main area of use is for the construction of walls and partitions. It cannot be used for the foundation, basement floor, or chimney laying.

The second area of application is as a finishing material. The basic composition has a white, slightly grayish color. You can add any dye to it and get a colored brick.

The dimensions of building silicate bricks are the same as those of ceramic: single has a height of 65 mm, one and a half - 88 mm, double - 138 mm.

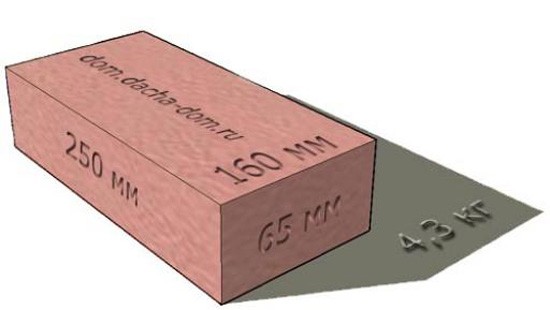

Single and one-and-a-half silicate bricks can be solid and hollow. Single corpulent weighs 3.6 kg, hollow - depending on the size of the voids 1.8-2.2 kg. A full-bodied one-and-a-half has a mass of 4.9 kg, and a hollow one - 4.0-4.3 kg.

Double silicate bricks are usually made hollow. Its weight is 6.7 kg. Corpulent ones are rare - because of their large mass (7.7 kg) it is difficult to work with them.

Weight of one piece: ceramic, silicate, ordinary, face

The weight of the brick is needed firstly, for calculating the foundation, this parameter is especially important when determination of the parameters of the tape-type foundation; secondly, for cargo transportation; and thirdly, to determine the quality and compliance with GOST requirements.

| Brick type | Appointment | View | Nominal dimensions | Emptiness | Weight | Water absorption |

|---|---|---|---|---|---|---|

| Ceramic GOST 530-2007 | private (worker) | single, corpulent | 250*120*65 | 0% | 3.3 - 3.6 kg | 10 -12% |

| single, hollow (hollow, slotted) | 250*120*65 | 30-32% | 2.5 - 3.0 kg (with a void of 6%, weight 3.8 kg) | 12 -17% | ||

| one and a half, full-bodied | 250*120*88 | 0% | 4 - 4.3 kg | 12 -17% | ||

| one and a half, hollow | 250*120*88 | 30-32% | 3.5 kg (with a voidness of 6% - 4.7 kg) | 12 -17% | ||

| double, corpulent | 250*120*140 | 0% | 6.6 - 7.24 kg | 12 - 17% | ||

| double, hollow | 250*120*140 | 30-32% | 5.0 - 6.0 kg | 12- 17% | ||

| facing (front) | single, corpulent | 250*120*65 | 0% | 2.6 kg | 9 - 14% | |

| single hollow | 250*120*65 | 30-36% | 1.32 - 1.6 kg | 9 -1 4% | ||

| one and a half hollow | 250*120*88 | 30-36% | 2.7 - 3.5 kg | 9 - 14% | ||

| Silicate GOST 379-95 | private (worker) | single corpulent | 250*120*65 | 0% | 3.7 - 3.8 kg (according to GOST) | |

| single hollow | 250*120*65 | 15-31% | 3.1 - 3.3 kg | |||

| one and a half corpulent | 250*120*88 | 0% | 4.2 - 5.0 kg | |||

| one and a half hollow | 250*120*88 | 15-31% | 4.2 - 5 kg | |||

| double hollow | 250*120*140 | 15-31% | 5.3 - 5.4 kg | |||

| facing (front) | single corpulent | 250*120*65 | 0% | 3.5 - 3.9 kg | ||

| one and a half corpulent | 250*120*88 | 0% | 3.7 - 4.3 kg | |||

| one and a half hollow | 250*120*88 | 15-31% | 3.7 - 4.2 kg |

In addition to standard size bricks, there are a large number of lightweight finishing bricks. For example, there is a silicate one and a half, which weighs only slightly more than a standard single - 4.1-5.0 kg.

There is a so-called "American" - with a standard single size and weighing only 2.5 kg. Lightweight versions can be used for facade finishes in case of lack of bearing capacity of the foundation. Although, it is better to use a lighter finish - facade slabs, for example.

Fireclay brick parameters

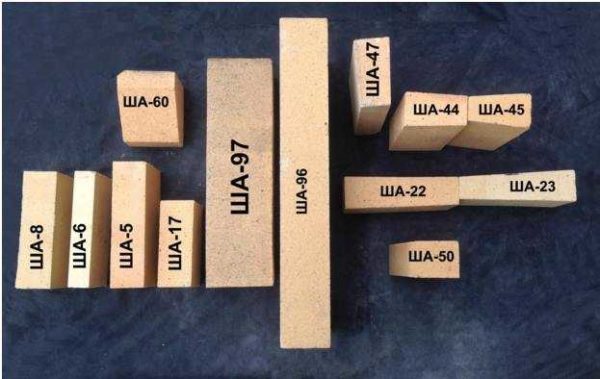

For the construction of stoves, fireplaces in the area of contact with fire, special fire-resistant bricks are used. In its production, a special type of clay is used - chamotte. Therefore, such a brick is also called fireclay. The production process is the same as building red bricks - molding, drying, kiln firing. But, due to the special properties of chamotte, the resulting building material can withstand prolonged contact with open fire. In everyday life, two brands of general-purpose refractory bricks are used - ША and ШБ. ША can withstand temperatures up to 1690 ° C, ШБ - up to 1650 ° C, all other parameters are identical. Therefore, they have the same field of application - it is the molding of the firebox of fireplaces and stoves.

The size of the refractory brick is to be encoded in the number after the abbreviation:

- ШБ-5, ША 5 - 230 * 114 * 65 mm;

- ШБ-6, ША 6, ША 14 - 230 * 114 * 40 mm (flask);

- ШБ-8, ША 8 - 250 * 125 * 65 mm;

- ШБ-9, ША 9 - 300 * 150-65 mm;

Most often they use ША 8 or ШБ 8. They coincide in length and thickness with the ceramic red brick from which the rest of the furnace is laid. There is also a wedge-shaped refractory brick - for the formation of furnace arches and smooth curves in the horizontal plane.

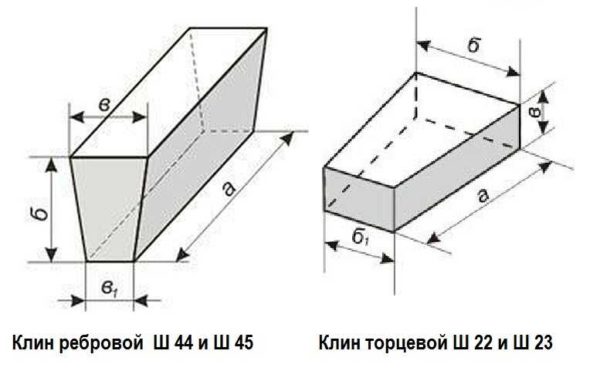

There are two types of wedge refractory bricks:

- end - to form curves in the horizontal plane

- ША, ШБ 22 - 230 * 114 * 65/55 mm;

- ША, ШБ 23 - 230 * 114 * 65/45 mm;

- ША, ШБ 48 - 250 * 124 * 65/45 mm;

- rib for the formation of arches

- ША, ШБ 44 - 230 * 114 * 65/55 mm;

- ША, ШБ 45 - 230 * 114 * 65/45 mm;

- ША, ШБ 49 - 230 * 114 * 96/65 mm;

- ША, ШБ 50 - 230 * 114 * 76/65 mm;

- ША, ШБ 51 - 230 * 114 * 56/65 mm;

- ША, ШБ 52 - 345 * 150 * 125/75 mm;

- ША, ШБ 53 - 345 * 150 * 90/75 mm;

- ША, ШБ 54 - 345 * 150 * 80/75 mm;

These are far from all sizes and types of fireclay bricks. You will find more in GOST 8691-73.

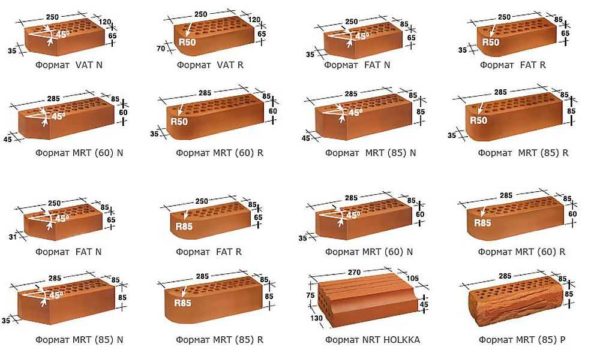

Clinker brick

Clinker brick is another special type of ceramic brick. In its manufacture, a special type of clay is used - refractory shale. The formed blocks are fired at a very high temperature of 1200 ° C. As a result of this treatment, the clay acquires the properties of ceramics, the color - from dark red to deep brown.

Clinker brick has a very high strength and abrasion resistance. From it you can pave roads, decorate a porch. And they will serve for centuries. The clinker surface is smooth, smooth and shiny. That allows it to be used also as a finishing brick - for finishing facades, masonry pillars etc.

The shape and size of clinker bricks can be very different - there are a lot of them, since there are not only standard ones - in the form of a parallelepiped, but also with beveled at different angles, rounded edges.