How to solder copper pipes

Fully plumbing or copper heating is rarely done today, but they still do it. If you count the number of years that copper can serve, it turns out not only inexpensive, but very cheap. Nevertheless, the material itself is not the cheapest, but you can save on installation - brazing copper pipes is not the most difficult task in the world. There are certain rules and features, knowing which you can achieve a high-quality connection.

The content of the article

Types of copper pipes and their uses

There are two types of copper pipes on the market: annealed and unannealed. After being annealed, they undergo additional heat treatment - they are heated to 600-700 ° C. This procedure returns elasticity to the material, which is lost during molding. Therefore, annealed pipes are more expensive, but also more flexible - they can even endure freezing of water. The disadvantages of these products include lower strength - it decreases due to heating.

Unannealed copper pipes are more durable, but practically not bend. When distributing water supply or heating, they are cut into pieces, and all taps are made using the appropriate fittings.

There are copper pipes with different wall thicknesses; they are sold annealed in bays of 25 and 50 meters, unannealed in runs of 3 meters. If we talk about the purity of the material, then according to GOST 859-2001, at least 99% copper must be present in the products.

Connection methods

Most often, copper pipes are connected using soldering and a set of special shaped elements - fittings. There are also fittings for pressure testing. They have grooves with a rubber O-ring fitted. They are crimped with special pliers. But this technology is used infrequently - soldering is considered more reliable.

There are two technologies for brazing copper pipes using different solders:

- Low temperature - soft solder. This is just our case. This type of connection is used for laying water pipes and heating systems with a working medium temperature of up to 110 ° C. Low temperature is a relative term. In the brazing zone, materials are heated to 250-300 ° C.

- High temperature brazing. This type of connection is used in networks with high pressure and temperature of the transported medium. In household networks - rarely (although no one forbids), more often in industrial ones.

What type of brazing copper pipes to use is your choice. Both types are suitable for both plumbing and heating. But the high temperature one requires a professional torch, while the soft solder can be melted even with a blowtorch or an inexpensive hand torch with a small disposable gas cylinder. For the connection of small diameter copper pipes more is not required.

Types of copper solder fittings

In general, there are more than two dozen different shaped elements for copper pipes - fittings, but three types are most often used:

- couplings - for connecting two pipes;

- corners - for turning;

- tees - to create branches in the pipeline.

The number of fittings used can be minimized - copper can be bent, which reduces the number of required corners. Also, if you wish, you can do without couplings: one end of the pipes can be expanded (using an expander) so that the pipe goes into it and there is a gap for solder to get there (about 0.2 mm). When creating an extension, the pipes should overlap by at least 5 mm, but better - more.

What is difficult to do without is without tees. There is equipment for tapping in a bend - a beveler, but it belongs to the professional and costs a lot. So in this case it is cheaper and easier to get by with tees.

There are two types of fittings - conventional, with sockets, which provide the required clearance for wicking solder. Solder is fed into the welding zone manually. There are fittings with embedded solder. Then a groove is formed on the socket, into which, during production, a piece of solder is installed, which makes the soldering process easier - you just need to heat the welding zone, but it leads to an increase in the cost of fittings.

Consumables and tools

In addition to pipes and fittings, you will also need a torch, solder and flux for the soldering itself. And also a pipe bender and a few related little things for processing before starting work.

Solder and flux

Brazing of copper pipes of any type occurs using flux and solder. Solder is an alloy usually based on tin with a certain melting point, but always lower than that of copper. It is fed into the soldering zone, heats up to a liquid state and flows into the joint. After cooling, it provides a tight and strong connection.

For amateur soldering of copper pipes with their own hands, solders based on tin with the addition of silver, bismuth, antimony, copper are suitable. Compositions with the addition of silver are considered the best, but they are the most expensive, the optimal ones are with a copper addition. There are also lead additives, but they should not be used for plumbing. All these types of solder provide good weld quality and easy soldering.

Soft solder is sold in small spools, hard solder in bundles, cut into pieces.

Before the start of soldering, the joint is treated with flux. A flux is a liquid or pasty agent that allows the molten solder to flow into the joint. There is nothing to choose from here: any flux for copper will do. Also, you need a small brush to apply the flux. Better - with natural bristles.

Burner

For soft solder applications, you can buy a small hand torch with a disposable gas can. These cylinders are attached to the handle and have a volume of 200 ml. Despite its diminutive size, the flame temperature is from 1100 ° C and higher, which is more than enough to melt the soft solder.

What you should pay attention to is the presence of a piezo ignition. This function is not superfluous - it will be easier to work with. There is a valve on the handle of the manual gas burner. It regulates the flame length (gas flow rate). The same valve turns off the gas if the burner needs to be extinguished. Safety is provided by a check valve, which, in the absence of a flame, will shut off the gas supply.

Some models have a flame deflector. It prevents the flame from scattering, creating a higher temperature in the soldering zone. Thanks to this, the burner with a reflector allows you to work in the most inconvenient places.

When working in household and semi-professional models, you must be careful - do not overheat the unit so that the plastic does not melt. Therefore, it is not worth performing many rations at a time - it is better to let the equipment cool down and prepare the next connection at this time.

Related materials

To cut copper pipes, you need a pipe cutter or a hacksaw with a metal blade. The cut must be strictly vertical, which ensures the pipe cutter. And to guarantee a smooth cut with a hacksaw, you can use a regular carpentry miter box.

When preparing pipes, they must be cleaned. For this, there are special metal brushes and brushes (for cleaning the inner surface), but you can get by with sandpaper with medium and fine grain.

To remove burrs from cuts, there are bevelers.The pipe worked out by them fits better into the fitting - its socket is only a fraction of a millimeter larger than the outer diameter. So the slightest deviation leads to difficulties. But, in principle, everything can be eliminated with sandpaper. It will only take more time.

It is also advisable to have safety glasses and gloves. Most do-it-yourselfers neglect these safety measures, but burns are very frustrating. These are all the materials and tools needed to solder copper pipes.

Step-by-step copper soldering technology

Brazing copper pipes begins with the preparation of the joint. The reliability of the connection depends on the quality of the preparation, therefore, devote enough time and effort to this process.

Preparing the connection

As already mentioned, the cut of the pipe should be strictly vertical, without burrs, the pipe should not be jammed, the edge should be even and smooth. If there are even small deviations, we take a beveller or sandpaper and bring the cut to the ideal.

Next, we take the fitting, insert the pipe into it. the part that goes into the socket needs cleaning. We take out the pipe and use the sandpaper to remove the upper oxidized layer from this part of the pipe. Then we carry out the same operation with the inner surface of the bell.

Flux application

The flux is applied to the entire cleaned surface - outside the pipe and inside the fitting. There are no difficulties - the composition is evenly distributed with a brush.

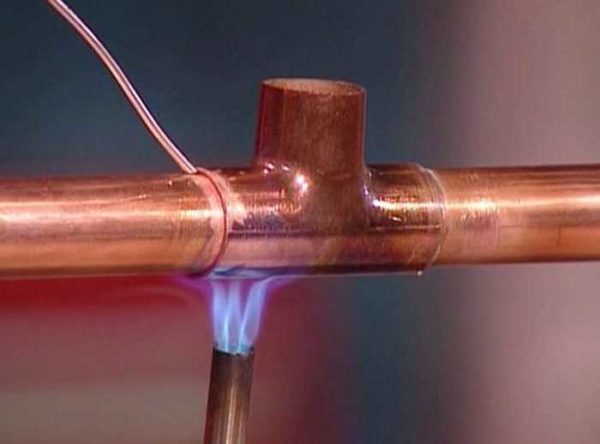

Soldering

The processed pipeline fragments are inserted into one another and fixed. If there is an assistant, he can hold the parts motionless. If not, you will have to contrive yourself. Then the burner is ignited, the flame is directed to the junction. The flame temperature is from a thousand degrees and above, and it is necessary to heat the junction up to 250-300 ° C, and this takes 15-25 seconds. At the same time, you can focus on the color of the flux - as soon as it darkens, it's time to inject the solder.

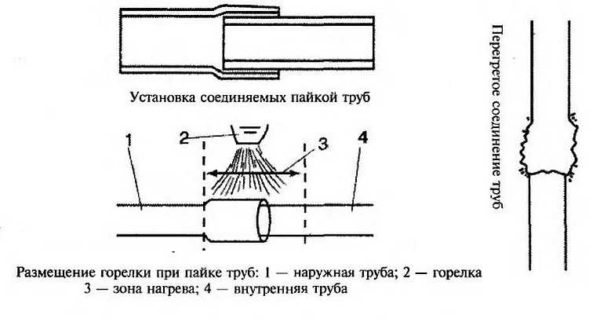

To ensure uniform heating, direct the burner flame in the middle of the joint. Then the entire welding zone is heated more evenly.

The solder is injected into the joint - where the fitting and the pipe join. As it heats up, it begins to melt, spreads and fills the gap between the elements. It can be applied only half the length - when it melts, it will flow into the rest of the connection. Actually, that's all - the brazing of copper pipes is over. All other connections do the same.

When using hard solder, everything is almost the same, only other burns are used - gas-flame ones, and during the soldering process it is necessary to turn the pipe, winding the softened solder onto the pipe.

The only site where everything is clear, clear, understandable, the main thing is without any water. Thank you!!!