Crumb rubber coating

Landscaping is a complex and expensive business. One of the headaches is how and what to pave the yard, paths, parking for the car. Paving slabs were popular for a while. But it has a significant drawback: it is slippery under the snow, and it is difficult to break off ice from it. So they are looking for a replacement. One option is a crumb rubber coating. For the yard of a private house, this is a very good choice. If you want to pre-evaluate the quality and characteristics of the coating, go to the playground near McDonald's. It is covered with just this material. The surface is soft, springy, puddles do not stand, ice does not hold in winter. The surface is porous, but can be easily cleaned with a jet of water. Otherwise, with so many children, it would be clearly "well-worn", but it always looks fresh.

The content of the article

What are they made of

Rubber flooring was originally used in manufacturing in noisy or traumatic areas. It turned out to be so convenient that it gradually migrated to houses, garages, and personal plots. But mats or tiles made of solid rubber are not very comfortable, and the aesthetic value is questionable. But the crumb rubber coating is much more attractive, practical, more convenient.

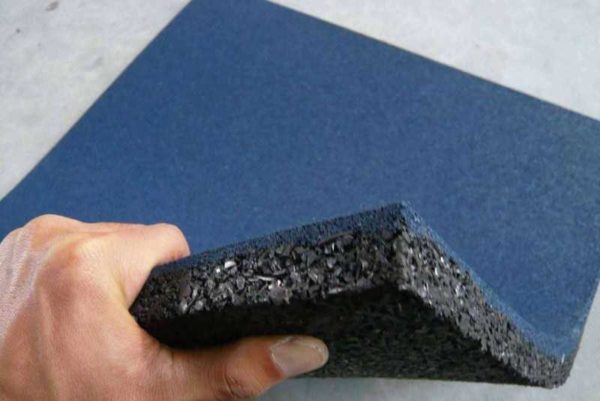

The crumb rubber coating is made from recycled materials. Rubber products are crushed. Car tires are considered the best for recycling. But such raw materials are more expensive, since it is necessary to remove the cord, which is metal or synthetic fibers. This makes processing more difficult and the coating itself more costly. However, using a different rubber can cause the surface to become sticky over time. It will decompose poor quality rubber. So when buying, pay attention to the uniformity of the composition. The fewer colored blotches in black chips, the better.

Properties

The crumb rubber coating is resilient and durable. The surface is slightly loose, porous. The water does not stand in a puddle, but seeps into the lower layers. Rather, to the base covered with polyurethane. So for the normal drainage of water from open areas - courtyard, porch, paths - do not forget about the formation of a slight slope (about 1 cm per 1 meter) and drain.

So that there is no doubt about durability and practicality: a treadmill at the racetrack made of rubber tiles. Laid on the sand

Despite the fact that the surface is loose, dirt can be washed off with a stream of water. Of course, paint and other similar substances cannot be removed that way, but sand, clay, etc. - easy. What's more, the ice crust on the surface breaks. The water certainly freezes. But under load, the ice crumbles and the surface is not so slippery because of this. Walking on it is quite comfortable.

Another plus of the crumb rubber coating is the wide range of operating temperatures. The material can withstand winter without problems down to -30 ° C, it can be heated up to + 50 ° C, which is also a good indicator. This means that this coating can be applied in the yard, in an open area.

Scope of use

Based on the properties described above, you can determine the scope:

- Playgrounds. Not every coating will endure the activity of children, but experience has shown that this coating copes with the load. And it's also safe. With a thickness of 10 mm, the shock absorption is sufficient so that the child does not receive abrasions when falling.

- In the garage.Resistance to oils, gasoline, solvents is normal, but it will be very inconvenient to remove such stains, and not everyone will succeed in washing with a jet of water. Only if there is water in the garage or it is located near the house. In general, not the best option.

- On an open or covered parking area near the house or in the country. You can lay out the entrance to the garage. If you do not expect to carry out repair work or abruptly start / slow down on the site, this is a good option. Cars and SUVs have no effect on this coverage.

- For stairs. It is very important that the steps are non-slip in rain or cold weather. A crumb rubber coating is one of the best options in this sense. If you make a slight slope so that the water runs off, there will be no problems.

- Sports facilities: treadmills, sports corners. For these objects, shock-absorbing ability and ease of cleaning are important, which is just characteristic of this material.

- For entrance, entrance, yard, terrace, garden paths. The coatings for these areas of a private house are subject to high aesthetic requirements. Even a solid color finish looks very good. You can also make various patterns.

As you can see, the area of use is wide. But that's not all: crushed rubber slabs can be used as paths in the garden, placed between the beds. It can be used on the entrance, not only outside, but also inside - in the hallway.

Release forms

The crumb rubber coating is available in three types:

- Crumb in bulk per kilograms. Before laying, it is mixed with a special binder on a polyurethane base, applied to the surface with a spatula. Forms a seamless finish.

- In the form of tiles. Sizes are usually 50 * 50 cm, but there may be options with a side from 20 cm to one meter. Depends on the shape in which these tiles are made.

- In the form of a tape. The width of the tape is 30-50 cm and more, the length is up to 10 m.

An important characteristic of a crumb rubber coating in the form of slabs and bands is thickness. The thinnest slabs and strips are 10 mm, then in 10 mm increments - 20 mm, 30 mm and 40 mm. How thick the rubber cover to use depends on where you will be installing it. For a pedestrian zone - paths, a porch - a thickness of 10 mm is sufficient. On playground 20 mm thick slabs or mats can be laid. Garage parking will go the same or greater thickness.

The rubber crumb coating can also be different. The main parameter is grain size. Better if it is small or medium. This coating can be colored or black. Black is cheaper, and twice. It's about the pigment - a high-quality coloring pigment is expensive. And it must be of high quality, otherwise the color will quickly go away. You also need to look at the homogeneity of the crumb. It is desirable that the rubber is homogeneous.

How to choose a tile made of crumb rubber

As already mentioned, there can be any raw material for making tiles and mats from crumb rubber. The best performance has been shown by a coating made from recycled car tires. No impurities. If we talk about tiles or rolls, then on the one hand the tiles are colored, on the other - black. You can assess the presence of impurities on the black side. If there are no colored particles, most likely there are no impurities.

What else should you check if you're going to buy crumb rubber tiles? A number of parameters:

- Run your hand several times along the edges of the tile, along its back and front sides. If the product is of normal quality, with a sufficient amount of binder, nothing will fall off it. If the technology is broken, crumbs will fly off.

- Examine several tiles.If the corners of the goods from storage and transportation are chipped, sidewalls crumbled, cracks appear, look for something else.

- Assess the geometry. You can look visually or stack two or three tiles face to face. If you have a ruler or level at hand, you can use them. Ideally, there should be no deviations. In reality, very small ones are permissible - a millimeter or less.

- Fold the tile in half, press the fold with your palm. If it is of normal quality, nothing will happen, if it is bad, cracks will go, it may fall apart.

- Take a look at the face layer. The color should be uniform, the surface is flat, not loose, slightly "smoothed".

If all tests are passed successfully, you can buy. There is one more criterion by which the quality of the tiles can be roughly determined - this is the price. Unfortunately, cheap options usually fail the tests.

Laying rubber tiles and mats

Rubber crumb rubber covering in the form of slabs and mats should be laid on a dry, flat surface. The maximum allowable drop is 3-5 mm per meter of surface. Moreover, it should be a smooth rise or fall, without pits and humps. If necessary before laying the coating install curbs and limiters. Before laying, the surface is cleaned of dust, dirt, if there are greasy spots, they must be removed, washed and dried.

Mats, rubber crumb tiles are glued with two-component polyurethane glue. Sometimes it is advised to replace it with bitumen - it is cheaper and easier to work with. But bitumen has a lower adhesion, so the rubber covering for the yard of a private house may come off. If you want a durable finish, use a polyurethane adhesive.

It can be laid on a rigid base, on compacted sand. If the soils do not drain water well, another layer of compacted gravel is placed under the sand

Before laying the tiles, the surface must be primed. The primer is the same glue, only diluted in half with a solvent (white spirit, for example). A thin layer of primer is applied to a prepared, even and dry base. It is allowed to dry, then styling begins. The glue is mixed, applied to a rubber coating (less convenient) or to a platform (more convenient), the coating is laid, trying to prevent air from getting under the surface. The tile is leveled, pressed evenly. You can proceed to the next fragment.

Why is roll coating and crumb rubber tiles good? They can be placed on tamped sand, leveled and compacted soil, making sand and gravel bedding and tamping. To prevent gravel and sand from mixing with the soil, separate them with a layer of geotextile (density 200 g / m2 or more). You can lay tiles without sides, but it looks better with borders. A convenient option if, for example, there is no hard surface on the tracks.

Installation of a seamless crumb rubber coating

A crumb rubber yard cover does not require an even base. It itself perfectly hides and evens out irregularities, but at the same time it is worth remembering that the minimum crumb layer is 4-5 mm. If it is thinner, there is no guarantee that it will retain its properties. That is, if after applying crumb rubber you want to have a flat surface, the cavities will have to be filled with it. This will increase consumption, which means that the rubber covering will be more expensive. Therefore, it is better to pre-seal the largest depressions, cut off the protrusions. Dirt and crumbling fragments must also be removed. Otherwise, during operation, problems may arise - peeling from the base, followed by the destruction of the rubber coating. The prepared base is also primed with a mixture of glue and solvent, after which you can start laying.

When the base is ready, the crumb is mixed with glue. For small areas, this can be done in large buckets using a drill with an appropriate attachment.For work, you will need spatulas - metal or plastic - as it is convenient for anyone. The mass sticks to any surface - and to the spatulas too, so it will be necessary to lubricate them with something. It can be a multipurpose grease (WD type) or a solvent. With this composition, you will have to wipe the spatula constantly - otherwise you will not even out the applied crumb layer. The applied layer remains elastic for about 40 minutes. This time is enough to eliminate all the blemishes allowed during application, to connect the areas so that the seams are not visible. The monolithic coating of crumb rubber dries for about a day, then it can be used.

Why is a seamless crumb rubber coating good? High maintainability. Even if a piece comes off somewhere, it is cut out with a knife, the remains are cleaned off with a chisel, the surface is cleaned, primed (a mixture of epoxy glue and white spirit). You can apply a patch. The only negative is the difference in color. It will wear off over time, but the new patch will stand out. There is a way to turn this disadvantage into an advantage: to make a patch in the form of a picture. You will get a decoration.

Tile, roll or seamless?

Even having decided to use a crumb rubber coating on the site, it is not always easy to decide which one is best for you. In this paragraph, we will briefly describe the features and capabilities of each of the forms of release. This will help you make your choice.

- Chit. This type is the cheapest in terms of cost per square meter (with a layer thickness of 10 mm). But this is without taking into account the preparation of the base, but only for the components of the coating itself. Of the features: fits only and exclusively on a rigid base, although it is not at all necessary that it be even.

- Tile. Due to its great thickness, it is the most wear-resistant material, but expensive. It can be laid both on a rigid base (but necessarily - even), and on sand or sand and gravel bedding.

- Tracks (rolls). Thickness 10-15 mm. Convenient to lay - just roll out onto a prepared base. Can be laid on a hard base or on sand. They are not as durable as tiles, they can get lost, when laying on sand, you need to fix the edges. More suitable for vegetable gardens, greenhouses - for laying between beds. In the garden or on the lawn, they are no longer very convenient, since smooth lines cannot be realized with their help.

In general, you need to select the type of crumb rubber coating depending on where you are going to lay it, what kind of base you already have or what you are ready to make.

During visual inspection, you should also pay attention to the thickness of the tile: it should be the same at the edges and in the center. If the middle of the stack of rubber plates in the pallet sags, then the tiles there are thinner than at the edges.