Dimensions of concrete well rings: diameter, height, wall thickness

One of the easiest ways to make a well for any purpose is to assemble it from concrete or plastic blanks. Concrete is more familiar and reliable, so it is usually a priority. But in order to determine the design, you need to know the size of the rings for the well. They are defined by the standard, although, as usual, there is a mass of TU and DSTU.

The content of the article

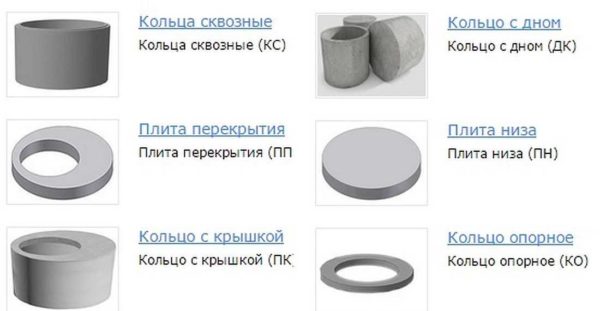

Types of concrete well rings

Concrete rings are used in the construction of wells for various purposes. They are used for collecting drinking, sewerage, sewage columns and sedimentation tanks, reservoirs. They are also used to build sewerage tanks and septic tanks. GOST 8020-90 defines all types of products for the manufacture of networks and wells in particular. Not all of them are used in everyday life. The following types of rings are most often used:

- KS - wall or through ring. It is a concrete cylinder. Installed one on top of the other, they form a column of a well. There are different diameters - from 70 cm to 200 cm, with a wall thickness from 5 to 10 cm. There may be:

- ordinary with a straight edge, standard wall thickness;

- with a formed ledge - for the lock joint;

- reinforced - with a large wall thickness for cases of deep laying;

- reinforced - with reinforcement introduced.

- KCD - concrete rings with a bottom. They look like a glass with a cast bottom. Installed when assembling sewer wells and sedimentation tanks, septic tanks. They guarantee tightness and speed up installation - no need to pour the bottom plate.

- КЦО - support ring. Installed on the assembled column under the neck. Allows you to bring the cover of the well to the desired height.

- KO - support ring. Installed as a foundation for a well. It has a small height, but thick walls.

According to the standard, the walls of the rings can have a technological slope of no more than 1.5%. But at the same time, the wall thickness and the inner diameter in the middle of the height must coincide with the normative ones. In general, even walls, the absence of cavities and cracks are a sign of normal quality.

Floor and base slabs

Even when constructing wells, plates may be needed. Some of them are placed on the bottom, others are closed on top. When constructing drinking wells, concrete slabs are rarely placed - more often they do well house... When assembling septic tanks from well rings, often the base plate is poured, and not laid ready. So you can do without these products, but their use reduces the time of work. In general, in GOST there are these types of slabs for wells:

- PN - bottom plate. This is a flat round pancake that is placed on the bottom of a dug pit.

- PO - support plate. It is a rectangular slab with a circular hole in the center. It is used to cover a well if a rectangular rather than a round platform is required from above.

- PD - road plate. Similar to software, only has rectangular dimensions and great thickness. They are placed on the upper ring of the well if it goes out onto the roadway.

- PP - floor slab. This is a round pancake with a round hole for the manhole cover. The hole is offset to one of the edges for easier access.

The standard allows the presence of a bevel on the side faces of plates made in one-piece forms. But the quality of the concrete, the absence of cracks, cavities and other serious flaws are all signs of normal quality.

How to choose the size

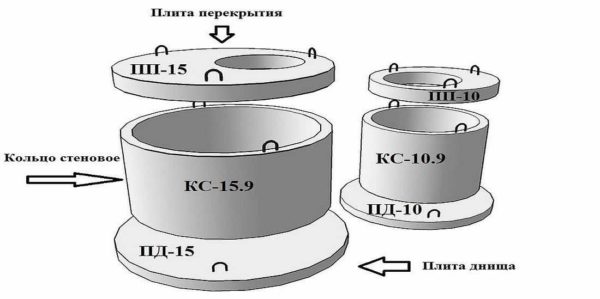

When you have decided on the design of the well, you know what kind of bottom you want, how and with what you will cover the well, the most important thing is to determine the size of the CC. All other elements are selected from the same standard size. They are designed to fit together. And the number of links is determined based on the required volume or approximately calculated based on the depth of the aquifer. For sedimentation tanks, septic tanks, storm wells, they are considered based on the required storage volume.

If we talk about drinking wells, they are collected from KS with a diameter of 100 mm (KS-10) to 150 mm (KS-15). A ring with a bottom or a bottom plate is not placed - open access to the aquifer is required. When assembling a well for drains, a sump, or a septic tank, it is better to take the lower link right from the bottom - and installation is easier and tightness is ensured. Another option is a bottom plate and a KS or KO ring installed on it. KO is placed if there is a need to make the lower part heavier.

The size of the rings for the well according to GOST

For the manufacture of well rings, concrete of the M200 brand is used. Its components are cement, sand, gravel and water. To improve the strength characteristics, steel reinforcement is installed in the mold. Please note that concrete products with reinforcement inside are a separate category. So if you need reinforced concrete rings for a well, they must be looked for separately. Not all factories produce such products.

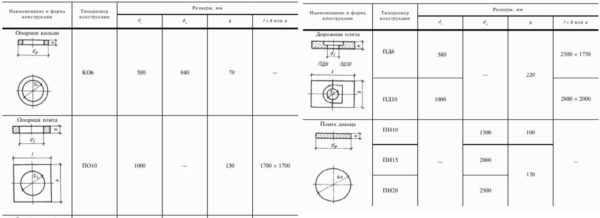

Decoding of marking

For drinking wells, only one type of well rings is often used - KS. In the marking, there are two numbers further separated by a dot. For example, COP 10.6. The first number is the inner diameter, indicated in decimetres. One decimeter is equal to ten centimeters. To find out the diameter of the ring in centimeters, this first number must be multiplied by ten (in fact, just add a zero at the end). For example, KS 10.6 - internal section 10 * 10 = 100 cm. KS 15.9 - 15 * 10 = 150 cm.

The second figure in the marking of the rings for the well is the height in decimeters. The translation is similar: you need to multiply by 10 (after the number add zero), we get centimeters. Consider all the same examples: KS 10.6 - height 60 cm (according to GOST, height 590 mm, that is, 59 cm). For KS 15.9 - the height of the ring is 9 * 10 = 90 cm (according to GOST - 890 mm, that is, 89 cm).

The paragraph below contains an excerpt from GOST 8020-90, which indicates the exact dimensions. If you look at the numbers, we see that the height is rounded everywhere in the marking. Shown more than it should be according to the standard. So keep in mind that in fact the height will be 1 cm less. And this is not a deviation, but compliance with GOST. For example, KS 10.6 is 59 cm high according to the standard, and if you decipher it, it turns out 60 cm.This should be taken into account when measuring.

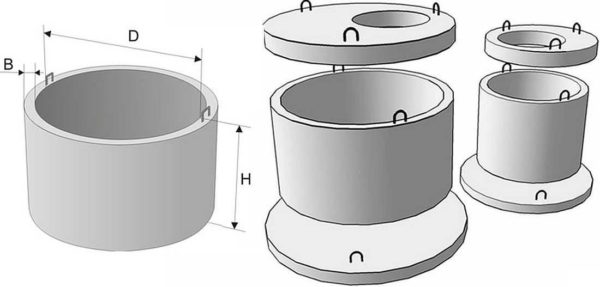

What are the sizes of well rings

It is customary to determine the size of the rings for the well by the inner diameter. It is he who is indicated when marking. The outer diameter can be larger or smaller, depending on whether the ring is of normal strength or reinforced. The table shows the parameters for normal strength products.

- COP 7.3 and COP 7.9. Inside size - 70 mm, two heights - 29 cm and 89 cm. They are rarely used, as they are too small. Can be used for small storm water systems. But plastic is more often put there - they are more practical and lighter.

- The next size is the meter KS 10.3, KS 10.6 and KS 10.9. Internal section - 100 cm, three possible heights: 29 cm, 59 cm and 89 cm. These are practically the most popular dimensions. The optimal size of KS is 10.6 - they are easier to install than those that are 90 cm.

- The size of COP 13.9 is rare. For some reason, factories ignore him.

- The next running position is one and a half meters in diameter. COP 15.6 and COP 15.9. This ring size is suitable when large volumes are to be stored. It is sometimes used for drinking wells, but more often for septic tanks or sedimentation tanks.

- Two-meter well rings are available in three sizes: KS 20.6, KS 20.9 and KS 20.12. They are usually used for septic tanks. Sometimes they also collect drinking wells if it is necessary to ensure a large flow of water. As you can see, the ring height 119 cm (in marking 12 after the dot) is first encountered here.

- The largest size of the well rings is two and a half meters. COP 25.12. In everyday life, they are rarely used, since it is unrealistic to install them without special equipment.

If we talk about the mass of the rings, then it depends on several factors. The first is the grade of concrete, the type of aggregate. The second is the number and dimensions (weight) of the reinforcement. The third is the wall thickness. So each manufacturer has its own weight. Above is a table of one of the factories. Please note: the wall thickness is indicated from 70 cm to 100 cm. If you look at the GOST table, there is a minimum wall thickness of 14 cm for KS 7. For KS 10, it is already 16 cm, and then 18 cm, 20 cm. So those that will be made to the standard will be about twice as heavy.

How to check the size of rings for a well according to GOST

Choosing a well ring manufacturer is usually a headache. There are usually several manufacturers of different sizes. Who should you give preference to? You can collect reviews from neighbors and so choose a couple of manufacturers. Then you should take a ride and see with your own eyes, because everyone has their own "normal quality". What to look for and how to inspect well rings? This is how the same GOST defines a check.

Measurements are made at two perpendicular diameters. This means that one of the points is selected. Opposite it, the second will be located, and the other two on the perpendicular (a straight line drawn at an angle of 90 ° - as in the figure).

- The wall thickness is measured at four points opposite each other in pairs. Moreover, it is advisable to check this parameter from below and from above. If the rings are locking, the parameters of the spike / groove are also checked - they must match. And control must also be done from above and below.

- Also at four points, the height of the ring is checked.

Slabs and rings are checked using the same technique. Four points are selected - two on perpendicular lines and measurements are taken in them. The measured values must match. Permissible deviations - no more than 1.5%.

Which is better and how to determine the quality

There are two technologies for the production of concrete rings: by vibrocasting and vibrocompression. In the first case, concrete is poured into collapsible forms, compacted with a submersible vibrator and left until set. This usually happens after 6-8 hours. Then the molds are removed and the rings are left to “ripen” so that they gain strength sufficient for sale - 50%. They can be mounted after 28 days, so it's better not to buy "fresh" rings. Another point: cracks may appear in the last days of ripening. So it is best to buy well rings "cured" in the warehouse. As you can see, the technology is simple, except for the forms of no equipment. This allows us to open small workshops that make these products. In this case, the quality completely depends on who mixes and pours the forms.

You need to choose according to the quality of the walls and edges, the absence of defects and deviations in size.

For the manufacture of well rings by vibrocompression, special equipment is required. Not only the forms, but also the vibropress itself. It creates a certain pressure and vibration frequency at each stage of the process. The result is more homogeneous concrete, smoother and even edges, a perfectly formed edge or lock. But the price is higher - more expensive equipment.