Well design: well house (open and closed)

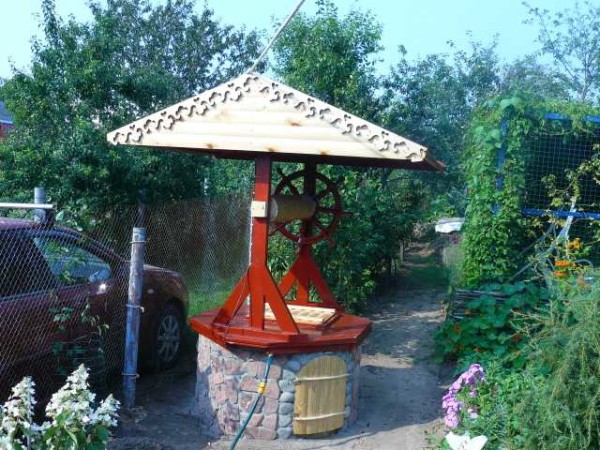

A well in the country, and sometimes near the house is a necessary thing. But just a concrete ring sticking out of the ground with some kind of cover pleases the eye a little, and the comfort of use is below average. To rectify the situation, it is required to refine it and put a gate, which will facilitate the rise of water. Ready-made well fences are on sale - with a roof and a gate, but they either have a solid price, or look pathetic. Therefore, most often a house for a well is built with your own hands. Then you can apply your imagination and arrange everything the way you need.

The content of the article

Types of well houses and their tasks

The primary task of the well house is to protect the water from the ingress of various substances - dust, foliage and other similar contaminants. This requires a tight-fitting lid. Open wells are possible only for industrial water - for irrigation. For other purposes, water cannot be used from them. So if you plan to at least wash the dishes, the well should be tightly closed.

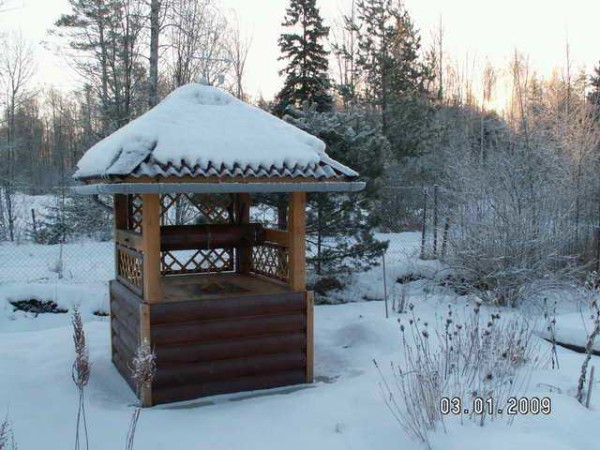

Protection from precipitation of any kind is also necessary: rain and melt waters carry with them very dirty water with fertilizers dissolved in it, animal waste, various garbage and impurities. If it gets into the well, it is fraught with serious pollution. To protect against precipitation, a canopy is made, most often a gable - it is easier to divert precipitation this way.

Another task of the well house is to protect from strangers, or at least provide safety for children. To do this, they make latches or cut locks.

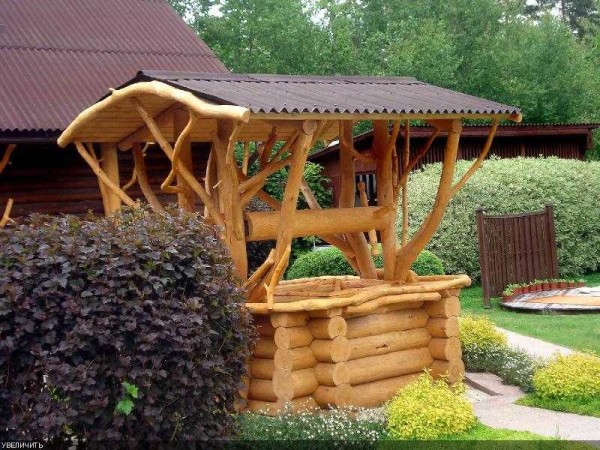

To make it easier to raise the water, posts and gates are installed - in the simplest case, a rotating log with a handle, to which a chain is attached. And all this together should still please the eyes of the owners, but at the same time require minimal maintenance.

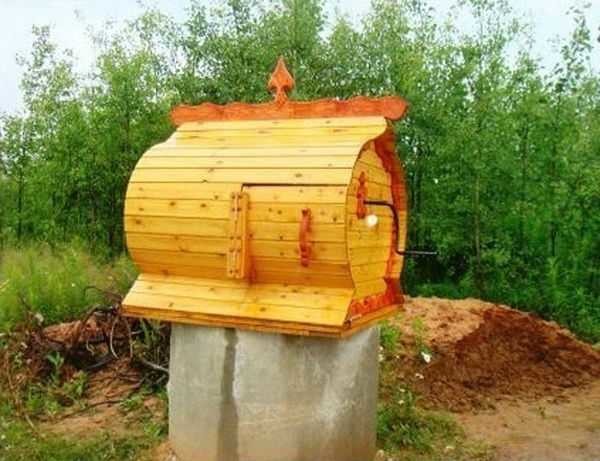

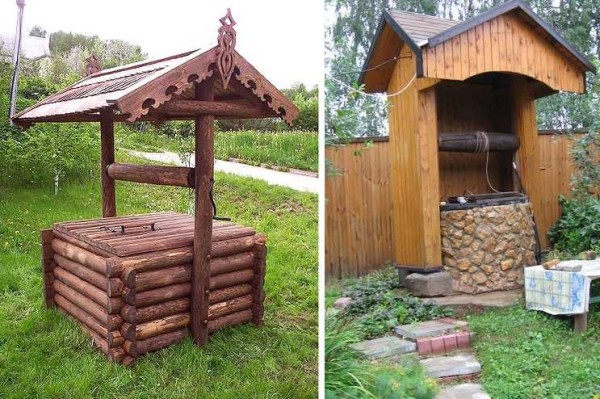

Open or closed

As you can see in the photo, a house for a well can be open and closed. It is cheaper and easier to make an open one: the well ring can be trimmed with stone or wood, the lid, posts and canopy - made of wood or metal - will cost someone less. Materials with such a structure require a minimum. There is only one "but" - in winter, water can freeze in such a well. If you don't plan to use it in cold weather - no problem.

But for winter use, an insulated well house is required. But even then it can be made open:

- buy a polystyrene "shell" for the well - they are of a suitable size, fix it, and put the finish on top of it;

- the overlap of the ring and the cover should be made of several layers of wood, and the boards should be laid in different directions, overlapping the joints.

Another option is to make a closed house. It is slightly larger in size than the well ring. The existing air gap is already a good heat insulator, but protection can be improved even further - by laying the gaps with foam, for example.

What to make

Choosing a look sometimes takes a long time The beautiful half of humanity especially "suffers" from the desire to decorate the well, going through numerous design options and spending a lot of time doing this. In fact, everything is simple: if there is a house, and the well is nearby, you should decorate it in the same style and, if possible, in the same color. Agree, it looks good.

What if the house is brick or plastered? Choose a finish that matches the stylesite registration... If this is one of the first buildings on the site, just do it as you like.

The question often arises: to make of metal or wood. Wooden look, of course, beautiful. But without proper care, they quickly lose all attractiveness and become gray and ugly. If you are not afraid of the prospect of regularly, at least once a year, renew the protective coating (remove old paint, then paint again), do it out of wood. If this is not for you, make it out of metal. The whole structure or just the frame is your choice. What is a bad option: a frame made of galvanized metal profiles, sheathed with siding. Especially if the house is decorated in the same way.

As you understand, there are a lot of options. First choose the type - open-closed, then materials and finishes to taste, understand the design, make a house for a well with your own hands.

The organization of the water supply from the well is described here.

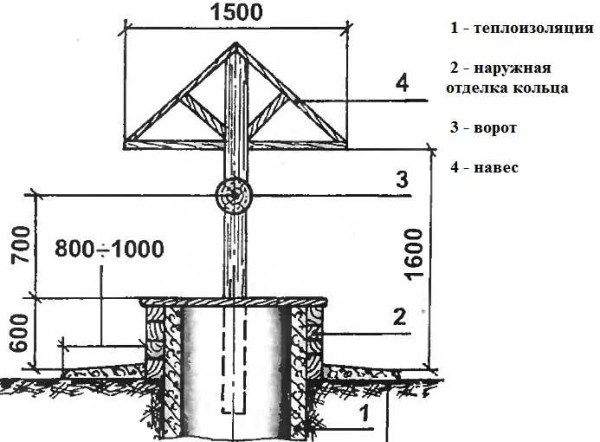

Well canopy with lid - open house

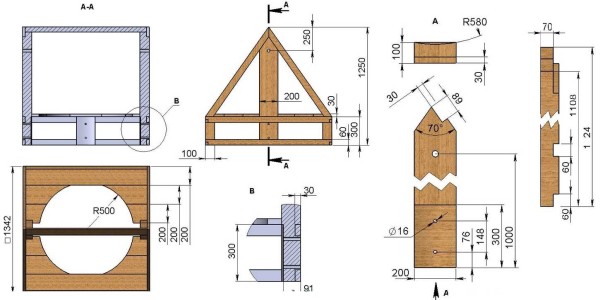

Structurally, the device is simple: there are two racks located one opposite the other. They serve as a support for the canopy, and also a gate is attached to them - a device for lifting buckets of water. See the drawing of an open house with dimensions in the photo below.

Note that the racks can be dug in after the well ring has been finished. Depending on this, the order of work changes, but the design in any case remains the same.

About the manufacture of tracks on the site is written here, about benches can be read here.

How to make a canopy

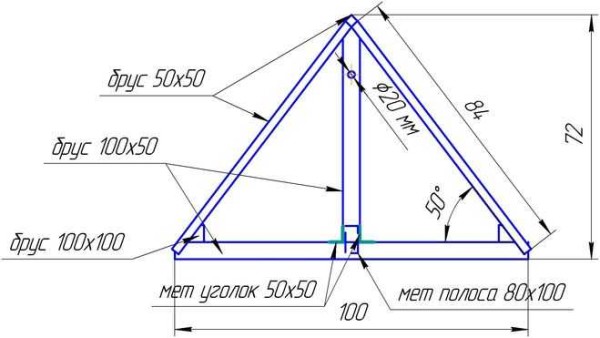

First, the canopy is assembled. Two side triangles are made according to the required dimensions. In the drawing above, only an approximate spread of the two extreme points is given. You can make more of it if necessary. The length of the canopy depends on where the racks will stand - close to the well ring or behind the casing. The approximate dimensions of the canopy with a ring diameter of 100 cm are shown in the photo below.

You can assemble the structure from a galvanized profile, a metal profile pipe or a wooden bar. To prevent the profile from bending, it is reinforced at the points of attachment of the door - you can put a wooden block or a metal corner inside.

To ensure that the rain does not get inside, the scatter must be made much larger than the size of the ring - at least 20 cm on each side.

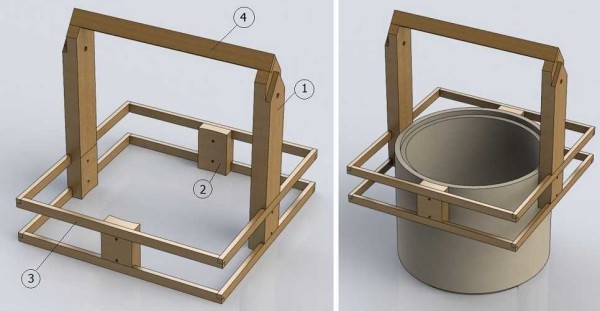

If the posts will be attached directly to the concrete ring, the work procedure is slightly different. First, a frame is assembled that encloses the ring. In the photo, it is made of a 30 mm thick board. The posts are also made of the same board, the place of attachment to concrete is reinforced with overlays. They also play a decorative role.

If the canopy is heavy, it is advisable to use a thicker timber, otherwise it will not withstand the load.

After that, the previously assembled roof is attached to the racks. You can make triangles right on the spot, but it is more convenient to prepare them in advance, assemble the rafter system, and put them on the racks in finished form.

Next is the finish. Sew up with a board, clapboard, roofing material. Just keep in mind that the boards, if you use damp, will dry out after a while, between them gaps up to 5 mm thick are formed. Then we are not talking about any hygiene: both rain and dust will get in ... Using a dry board is also not very good - in wet weather it will swell, the flooring will "go in a wave". In general, if you want to have clean water, build a house with doors - closed. There are more chances to protect moisture from pollution.

Read how to build a woodshed with your own hands here.

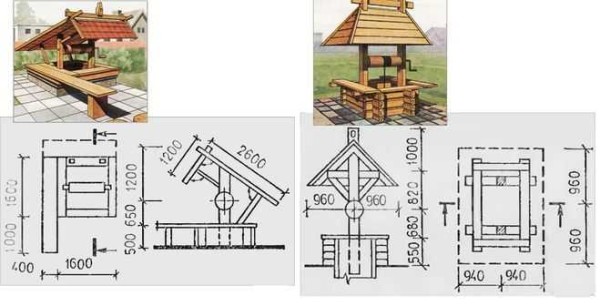

Do-it-yourself closed house for a well

We are talking about this type of shelter for a well - with a door. If you still make a lid inside, as if dust will not get in.

A frame is built, then it is put on the head of the well and fixed with anchor bolts.

- support post from 100 * 200 mm

- short support posts from the same timber 100 * 200 mm

- fixing bar 30 * 60 mm

- triangular bar

We assemble the frame, fasten it to the ring with the help of short bars. Then we proceed to the assembly of the pallet. Collect the flooring from a board of 30 * 100 mm or so. The frame is sheathed with boards or sheet material, such as waterproof plywood.

To keep the doors well, you can put additional jibs. We hang the doors - one or two, as desired. To make it easier to navigate, below are the dimensional drawings.

Using the same scheme, you can make a metal roof for a house. If there's welding machine, you can use a profile pipe. It is easier to attach finishing material to it.

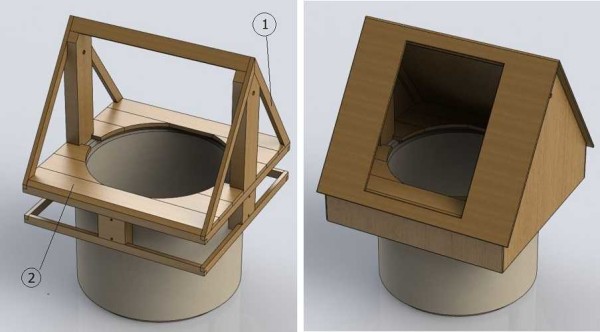

How to make a fully enclosed frame

You can hide a concrete ring in the house. In this case, the gates are usually placed separately, and then the frame is assembled. Choose the dimensions so that the design freely covers the ring. Height - 20 centimeters higher than your height: so that you can safely bend over and take out the bucket.

We take the profile from thick galvanized metal. From the guide we collect two identical frames - the "floor" and the upper level of the ring. They are connected by racks (profile for racks). The result is a cube with filled sides.

We cut the sidewalls of the guide profile, leaving the "back" intact. This will make a triangle. We fasten the rack, which is equal to the height of the entire house. If you want to have equal ramps, the rack mounts in the middle. You can make the far slope steeper, then the stand is moved 15-20 cm from the center.

We attach the notched profile to the fixed rack. We get one of the elements of the rafter system. We do the same operation on the other side. We connect the resulting tops of the triangles with a crossbar.

Add racks from the side of the door - on both sides. It is better to strengthen them - put wooden blocks inside and fasten with self-tapping screws.

We fix the roofing material, for example a profiled sheet, and sheathe it with plywood. Then soft tiles are laid and nailed onto the plywood - who has what technology. "Foot" and roof sides are finished with any material. If you want - you can use wood - clapboard, imitation of a log or a bar, if you want - with siding.

In this case, the same materials were used as when facing the house: so that everything looks like a single ensemble.

Another video example of an assembly from a drywall profile in video format.

The construction of a metal gazebo is described here.

Making a well ring with your own hands

If a canopy or canopy is made, the gray concrete ring remains visible. The view is not the most attractive, and I just want to decorate it.

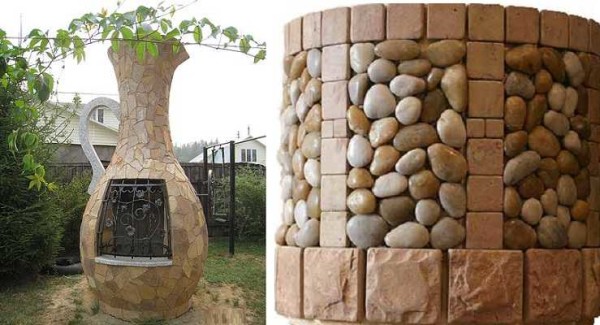

Stone decoration

The most popular way to decorate a well is finishing with stone - pebbles or medium-sized rubble. If everything is more or less clear with the finishing material - to buy or assemble, then the question of what to attach it to remains. There are several recipes:

- Bag of tile and natural stone glue 25 kg + bag of dry mix 300 - 50 kg. We mix everything, dry, dilute to a pasty state with water. Soak the stones in water. Apply a thin layer on the ring - a vertical strip from top to bottom, select and lay stones, sinking them into the solution. When a piece is made, until the solution has dried, the stones are cleaned, the seams are rubbed.

- Cement brand M500 - 1 part, sifted medium-grained sand - 3 parts, PVA glue - 1/3 part, water - about 1 part. Work at approx. + 20 ° C, wearing heavy rubber gloves: corrodes hands. Mix a small batch of solution at once: 1 part is a 500 ml can. This amount can be worked out before the solution sets. The technology is similar: stones are soaked, but the well ring is also moistened. Then a layer of solution is applied to it, stones are pressed in.

We offer the third recipe for how to cover a well with a stone in video format. The composition of the mixture is very similar here, but before applying the solution, a mesh is fixed on the ring. With this technology, nothing will definitely fall off.

An interesting version of a hinged cover for the well is offered in the following video: it leans back almost completely, but whether such a device is needed is up to you.