Choosing the best putty

Modern standards for good renovation are flat and smooth walls. To do this, they are first leveled (plastered or used with gypsum plasterboard), then the surface is brought to perfection with the help of putty - a composition that closes even the slightest irregularities. How to choose a putty with all the variety of offers on the market and let's talk further.

The content of the article

Types of putty

Putty is the process of final leveling of walls or ceilings for finishing. Some compositions consist of the same components as plaster - cement, gypsum, sand, but smaller fractions. They also include various additives that add specific properties: increased resistance to water, antibacterial properties, etc. There are also polymer-based putties. This separate class is very easy to use, albeit more expensive. There are also putties based on glue, oils, etc.

According to the size of fractions, putties are divided into starting (rough) and finishing. Starter has larger components, is applied in a thicker layer. It aligns the curvature to 5-6 mm. The surface is brought to an ideal state with finishing compounds. In them, all components are ground very finely, they are applied with a layer of 0.5 mm to 2 mm.

| Name | Object type | Base type | Colour | Minimum / maximum layer thickness | Topcoat type | Price |

|---|---|---|---|---|---|---|

| Universal plaster putty Osnovit Versilk T-34 | Dry rooms | concrete, drywall, plaster | grey | 0.5mm / 3mm | For wallpaper, for painting | 290 rubles for 20 kg |

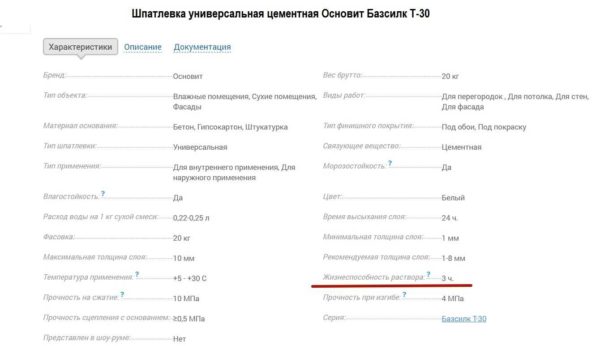

| Universal cement putty Osnovit Bazsilk T-30 | Wet and dry rooms, facades | concrete, drywall, plaster | white | 1 mm / 10 mm | For wallpaper, for painting | 310 rub for 20 kg |

| Finishing gypsum putty Osnovit Econcilk PG35 W | Dry rooms | Concrete, drywall and its seams, plaster | white | 1 mm / 5 mm | For wallpaper, for painting | 300 rubles for 20 kg |

| Finishing gypsum putty Osnovit Elisilk PG36 W | Dry rooms | Concrete, drywall, plaster | white | 0 mm (sdir) / 2 mm | For wallpaper, for painting | 380 rub for 20 kg |

| Polymeric finishing putty Osnovit Econcilk PP38 W | Wet and dry rooms | Concrete, plasterboard, foam concrete, plaster | white | 1 mm / 5 mm | For wallpaper, for painting | 430 rub for 20 kg |

| Finishing cement putty Osnovit Belsilk PC32 W | Wet and dry rooms, facades | Concrete, drywall, plaster, facades | white | 0.5mm / 4mm | For wallpaper, for painting | 390 rubles for 20 kg |

| Finishing cement putty Osnovit Graysilk PC31 G | Wet and dry rooms, facades | Concrete, drywall, plaster, facades | grey | 0.5mm / 4mm | For wallpaper, for painting | 340 rub for 20 kg |

There is a third type of putty - universal. For use as a starting material, they are diluted with less water, for the final leveling they are made more liquid. This type of putty can be used for wallpaper, for painting the requirements are more stringent and finishing with a finishing compound gives better results.

Usually, first, a rough leveling is carried out with a starting putty, then finally all irregularities are sealed with a finish

There are also special putties for certain types of work. For example, there are putties for sealing drywall joints. They have added microfibers to reduce the likelihood of cracking. There are decorative putties, but these are no longer construction, but finishing materials and belong to a different group.

To choose a putty by fraction, it is necessary to assess the degree of curvature of the walls. If the curvature is small - no more than 2 mm, you can immediately use the finishing ones.With a large curvature, it will be cheaper to first level it with a rough compound (it is cheaper), if necessary (for painting and thin wallpaper), bring it to the ideal finish.

Selection by type of base and operating conditions

Next, you will have to choose a putty according to the type of binder. It is selected depending on which base the putty will be applied to. Cement can be applied to cement substrates, bricks and concrete. You can't use plaster. So if the walls are plastered with a gypsum-based compound, you only need to use gypsum or polymer plaster.

Gypsum plaster can be laid on a cement base, you just need to pick up a soil for gypsum. Also, this type of leveling is suitable for bricks, concrete, wood, Chipboard, drywall, etc. The same area of application of polymer compositions. But, before buying, be sure to read the instructions for use. It indicates on which surfaces the type of putty you have chosen can be applied and for which rooms they can be used: gypsum is hygroscopic and not every composition can be used in wet rooms such as a bath or kitchen, and polymers are not used outside buildings or in unheated rooms.

Polymer putties are compatible with all substrates. They differ in fine grinding of the components, the minimum application layer is about 0.5-0.6 mm, so they are mainly used for finishing - to obtain an ideal surface for thin wallpaper or for painting. They are also used when leveling the ceiling. It requires good material adhesion, high elasticity and low weight. All these properties are inherent in polymer-based putty.

Release form

The putty is produced in the form of a dry mixture, to which a certain amount of water must be added before use. Dry putty is packed in paper bags weighing 5 kg, 10 kg, 25 kg or 30 kg. The second form of release is a ready-to-use composition in buckets. It is already diluted for the required consistency. Before use, you just need to stir and you can work.

If we talk about the price, then dry putty is cheaper, but you waste time mixing (adding water) and mixing the composition. Another plus of the ready-made formulations: the absence of lumps. On self-mixing, their elimination takes a lot of time.

It is simple to choose a putty on this basis: you need to save money - buy a dry composition, you need to save time - ready-made in buckets.

Uptime

The easiest way is to work with polymer plaster. In a closed container, it retains its properties for several days. The diluted cement composition should be used within 2 hours, and the least time for working with gypsum - no more than an hour, but more often 30-40 minutes.

The exact working time of the solution is indicated in the technical specifications. If work experience is small, this is very important

Important note. It is impossible to work with a grasped composition of any type. Yes, if you add water to it and stir it, it will look like a normal one. But the processes that have already passed are irreversible and this putty will not hold well, it may fall off and crack. Therefore, one more important point: before kneading a new portion, thoroughly clean the dishes, it is best to wash well (and tools too). This ensures that there are no lumps of frozen mixture that interfere with the work.

Application conditions

Most plasters should be applied at temperatures between + 5 ° C and + 30 ° C. There is also a limitation on humidity - no higher than 60%. And one more condition for normal, no cracks, drying is the absence of drafts. It is also worth covering the windows - sun spots lead to uneven heating of the surface, which can provoke the appearance of cracks.

What else you need to focus on - the minimum and maximum layer of putty application. The thinnest layer is usually for polymer plaster - from 0.5 mm. In gypsum and cement ones, it depends on the fineness of grinding, but a little more. The maximum layer can vary from 2 cm (for finishing) to 5 cm (for starting).

To select a plaster based on this feature, it is necessary to estimate the size of the irregularities to be repaired. If the deviation is less than 2 cm and a flat surface is required, the finishing compound can be used immediately. If there is more - first start, and finish - finish.

Putty color

The color of the putty can be gray, white, pinkish. It depends on the pigment found in the binder. If you plan to stick thick wallpaper (vinyl, for example), or they are dark in color, the shade of the walls is not so important, and gray putties are usually cheaper, so you can save money.

| Name / type | Binder / type of base | Minimum / maximum layer | Drying time | Price |

|---|---|---|---|---|

| Weber-Vetonit VH white / finishing | cement / concrete, drywall, expanded clay block, brick, foam concrete, plaster | 1 mm / 3 mm | 24-48 h | 580 rub for 20 kg |

| Weber-Vetonit VH gray / finishing | cement / too | 1 mm / 3 mm | 24-48 h | 380 rub for 20 kg |

| Weber-Vetonit LR + / finishing | polymer / concrete, plasterboard, plaster | 1 mm / 5 mm | 24-48 h | 650 rub for 25 kg |

| Weber-Vetonit KR / finishing | glue / drywall, plaster | 1 mm / 4 mm | 24-48 h | 490 rubles for 20 kg |

If the wallpaper is thin (silk-screen printing) or the surface is painted, you will have to use compounds that give white color.

By the way, there is a way to correct the dark surface of the putty on the wall: paint it with diluted white water-based paint. This layer will be considered a primer and, at the same time, will make the walls lighter (and under the wallpaper, too).

Manufacturer's choice

The hardest part of choosing a plaster is to decide on a specific company, and then choose the material you need from all the products.

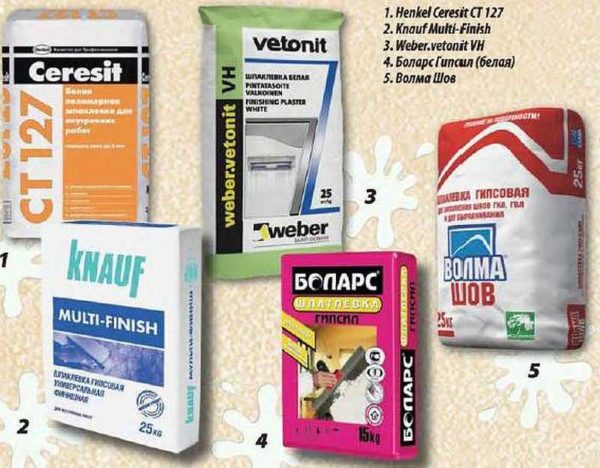

As for the choice of manufacturers, there are several leaders in this industry: Knauf (Knauf), Vetonit (Vetonit), Ceresit (Ceresit), Sheetrock (Sheetrock). All these brands have been on the market for a long time, produce products of consistently high quality, operate in approximately the same price range.

If we talk about domestic brands, the most popular are Volma, Osnovit and Prospectors. Moreover, Volma has the same prices as the brands described above, and Osnovit and Prospectors are significantly cheaper. There are still many smaller manufacturers, but they are represented in certain regions and little known in others.

All these brands have good reviews, each has its own fans, you can choose any putty from this list. Professionals prefer to work with leaders. The customer pays for the materials, and the product is proven, the technologies are worked out, the result is known. Therefore, their choice is predetermined. DIYers who level the walls with their own hands usually try to spend less money and not really lose in quality. They prefer to work with Volma and Prospectors. What will be your choice - it's up to you.

No options. The best in my humble opinion is polyfill. She never had any problems with her. Self-leveling, pasty. Doesn't smell like anything.