Cement cube weight

Making concrete yourself is not an easy job. Moreover, the problems begin at the start, when you begin to deal with the amount of materials that will need to be purchased. First, you have to guess how much concrete / mortar will be required. Then it turns out that the proportions are given in mass fraction. And even considering how much of the same concrete is required, it will not become easier, because they sell cement not in volume, but in bags of 25 kg and 50 kg. And in order to understand how much is needed, you need to find out how much a cube of cement weighs. But this is also not easy. There is specific gravity, volumetric weight, and there is true density.

The content of the article

Why know the weight of a cube of cement

In stores, cement is sold packaged in bags of 25 kg or 50 kg, and the proportions of concrete, plaster, mortar are given in volume fractions. That is, the components should be measured not by weight, but by volume, and this is the difficulty. That is, you need to know how many kg of cement in 1 m³, or buckets in a bag, how many kilograms of the same cement in a bucket, etc.

It is easier with buckets, since you can experimentally determine how many buckets of cement in one bag. We bought one bag of binder, poured it into buckets, counted the quantity. When pouring the bucket, we are not afraid, we do not seal the binder in any way. In general, everything is simple. This will not work with a cubic meter.

How many kilograms of cement per cubic meter

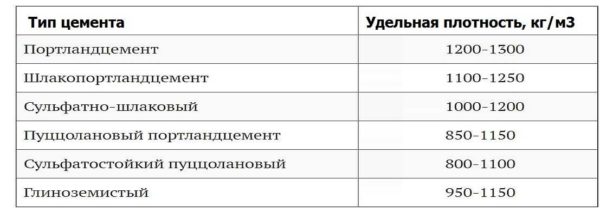

In general, the answer to this question is not as easy as it seems. First, the cement can be of different brands. Depending on the brand, it changes its density, and hence its weight. Portland cement weighs more than low grade cement and the difference is decent.

The second point, Portland cement is obtained by grinding a special clinker. As a result of grinding, a dusty substance is obtained, which is called Portland cement. The true density of cement is 3100 kg / m³. But each particle retains a certain amount of air and therefore the bulk density of the cement is less. But this is also a variable value. Right after production, cement retains the maximum amount of air and therefore weighs less. The mass of a cube of cement of the M400 and M500 brands immediately after production is about 1100 kg / m³.

During storage and transportation, it is compacted and moistened. So in one cubic meter of cement there can already be 1600 kg. For calculations, an average value is taken - 1300 kg / m³. So if you need to know how much a cube of cement weighs, we take the average values. For the M400 and M500, 1.3 tons per cubic meter are taken in the calculations. If you need to convert cubic meters of Portland cement to tons or kilograms, use these numbers.

How many kilograms of cement in a bucket

When mixing concrete in concrete mixer, components are often filled with buckets. You can find out exactly how much a bucket of cement weighs if you have a conventional scale. First, weigh the container, add binder. But it should not be compacted in any way. Just pour the substance from the bag or use a shovel to throw it from the heap. Put on the scales and subtract the tare weight from the resulting figure. According to statistics, there is 15.6 kilograms in a standard 12-liter bucket.

Volumetric weight table for building materials. Including how much a cube of cement and a bucket of cement weigh

If there is less cement in your bucket, or your container is not 12 liters, or the cement is fresh, which is very good, or you have been sold a low grade binder, one of the distinguishing features is the lower weight. You can also focus on color. Portland cement is grayish green in color, Portland slag cement is gray with a bluish tint. These are the brands that can be called good. The rest are gray, yellowish gray, or gray-brown.If, with a low weight, your material does not have a bluish or greenish tint, you have been sold a binder of lower strength.

A few words about strength

In recent years, cement has been used with the M400 grade and no lower, despite the fact that it is more expensive. The usual reasoning is that manufacturers claim strength more than they really are. Maybe so, but keep in mind that the manufacturer guarantees the declared strength for 2-3 months from the date of production. So when buying, pay attention to the "freshness" of the binder. During storage, the strength of cement decreases, and noticeably:

- after 3 months it becomes 20% lower;

- after 6 months of storage, it decreases by 30%;

- after a year, the drop in strength is 50%.

So buying cement for future use is a poor decision. If you have stale, when mixing, the amount should be increased by 2-4 times, depending on the shelf life. It is also desirable to add hardening accelerators to the composition. Since, in addition to the loss of strength, during long-term storage, the hardening time is greatly increased. That is, concrete is gaining strength very slowly.

So you shouldn't buy cement packaged in building materials warehouses, because it is not clear when it was produced. If Portland cement is packed at the plant, the date is immediately dated. It's easy to navigate here. It is not known how long the cement was in the warehouse. The date of packing, if they do, will give us nothing. So, we are looking for factory packaging with a production date.

The second point that makes us use high-quality cements is that they gain strength faster than low-quality cements. For example, concrete from Portland cement M500 will gain 50% strength after 3-4 days (at a temperature not lower than + 20 ° C and sufficient humidity). When using the M400 brand under the same conditions, it is necessary to wait for 50% of the strength for 7-8 days. If you are pressed for time, it may be more important than the higher price.