M400 concrete: composition, characteristics, proportions

During construction, repair, reconstruction, you often have to save money, since the budget is not rubber. Many processes and solutions can be done independently, and without compromising quality. But this is not always possible. Most often, they try to save money on the preparation of solutions. The price for concrete from the factory seems too high. If you calculate how much the "right" components cost, and not any (the cheapest), then the savings, if any, will be quite small. In general, if it is worth mixing concrete or mortar with your own hands, then the brands are not higher than M250. An ordinary concrete mixer can also cope with this task. Heavier ones - concrete M400, for example, are already difficult to make normally. Design strength will not be easy to achieve.

The content of the article

Characteristics of concrete M400

According to the new classification, the concrete solution of the M400 brand is designated as B30, but the old name, M400, is more common in our country. It is described in the standard as heavy concrete. The people refer to it as a "middle" class, although there is no such thing in the classification. It is definitely not "light", but also not heavy enough. This is probably why the weight of a cube of concrete M400 depends on the exact characteristics and averages 2310-2350 kg / m³. This brand has high performance in terms of strength, frost resistance, a low degree of surface wear. Here are the characteristics of concrete grade M400 according to GOST 7473-94:

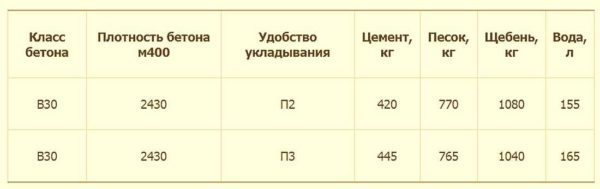

- mobility - from P 1 to P 4;

- water resistance - W6-W12;

- frost resistance - from F150 to F300;

- strength B30.

Most of all, any concrete stone is characterized by strength. This type can withstand a load of 400 kgf / cm² (according to the standard 293 kgf / cm²). All other parameters may vary depending on the requirements for a specific project. The flexibility of concrete affects the ease of placement. Somewhere a fluid mixture is required (so that it can get under the armature), somewhere a tough one is needed. More cement is added to flowable formulations (containing more water) to maintain design strength. To increase frost resistance and water resistance, special additives are used, which are strictly standardized.

Application area

M400 grade concrete is used where high strength and frost resistance are extremely important:

- In the manufacture of beams, piles, lintels and other elements of supporting structures of buildings.

- For filling sites for heavy equipment.

- When building swimming pools, dams, collectors, etc.

- In the construction of bank vaults, tunnels and other facilities where high strength and water resistance are required.

- Erection of monolithic walls for high-rise buildings.

- During the construction of bridges, viaducts, junctions.

That is, concrete M400 has mainly industrial applications. In private construction, even when building pools or foundations for cottages, it is excessive in strength and therefore is used very rarely by private owners.

In addition to being too strong, a high hardening rate also interferes. On the one hand, this is a plus: concrete quickly gains strength. So fast that you can walk 8-10 hours after pouring. But it can be laid without cold seams only with continuous feeding and the presence of a qualified team. In all other cases, delamination and cracks are likely to occur. The introduction of additives to increase the time to the onset of setting increases the already considerable price. And the price is high, because high-quality cement is needed to ensure the required strength, and even in large quantities.So private traders rarely use concrete M400.

Composition and ratio of components

Precisely speaking about the composition of M400 concrete can only be applied to specific materials: cement, sand and crushed stone. Replacing one of the components leads to a change in the content of the other two. The amount of water and plasticizing additives depends on how fluid or hard the solution is required. And the introduction of "softening" additives allows you to reduce the amount of water and cement. So the recipe (any) is given only approximately. The exact composition is determined in the laboratory, since M400 concrete is used in serious facilities, both the composition and the mixing process must be strictly controlled.

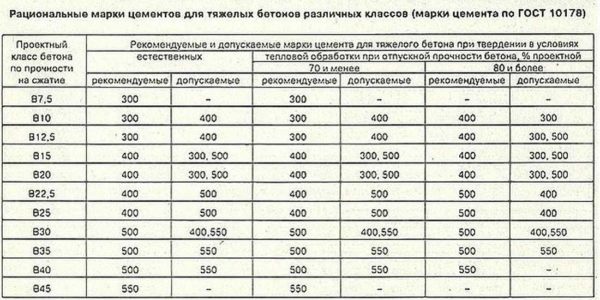

As for the choice of cement, we can say that only PC 400 and higher grades can be used. Optimal - PC 500. Lower ones are needed to obtain the required strength in very large quantities, which is economically disadvantageous. The cement must be "fresh" - no older than a week from the date of production. This is critical. And packing should be factory, not warehouse.

Requirements for fillers for self-production

When making high-quality concrete, the choice of aggregates is very important. Crushed stone must be of all factions. It cannot be crushed gravel, much less crushed boulders. The gravel must be clean, free of dust, dirt and other foreign matter. If it is dirty, it should be washed and dried.

For high-quality concrete, which includes M400 concrete, the composition and quality of the sand is important. The sand should be river sand, washed, free from clay, dust and other impurities. In order to obtain the required strength, the sand must contain fine, medium and coarse fractions. You can check the purity of the sand by taking it in your hand and rubbing it, as if you were salting a dish. If there is dirt on your fingers, you will need to either rinse and dry the sand, or slightly increase the amount of cement. The second option is risky - you can get concrete with a lower density.

How to cook yourself

If you want to get M400 concrete in a domestic environment, you will need a screw or rotary concrete mixer. An ordinary (such as a pear) will not cope with the task. After laying the mortar, additional sealing is also required. This requires a submersible or surface vibrator - depending on how thick the layer will be. Post-lay compaction is a must if you want to achieve close to design strength.

In order to make a concrete solution of high grades and at the same time achieve the design strength, you will need a rotary or auger concrete mixer

And the mixing process does not differ from the standard one. First, crushed stone is thrown into the concrete mixer, sand and cement are added in parts, achieving their uniform distribution. If dry additives are used, they are injected with sand. If liquid - together with water.

Water is added to the concrete solution in parts. It is measured based on the normalized water-cement ratio. For concrete, M400 is 0.47-0.54 parts of the amount of cement. First, about half of the liquid is poured into the mixer. The mixture is stirred until uniform, then water is added in small portions. As soon as the fluidity of the composition meets the conditions, the water is stopped adding.

It just seems that excess water will not interfere with the concrete. An extra bucket for one batch can reduce the strength of concrete by 10-40%. So it's very careful with water. Do not be afraid to underfill, be afraid to overfill. Even in semi-dry solutions, there is a sufficient amount of liquid to achieve the design hardness. But only on condition of proper care - maintaining a sufficient level of moisture in maturing concrete. For this, the concrete is covered with a film and periodically moistened.This is really important that the crystallization process goes on, and not the evaporation of moisture.