How to cook seams correctly: vertical, horizontal, ceiling

In electric welding, an electric arc is used to heat the metal. It occurs between the part and the electrode - a rod made of conductive metal (sometimes non-metal). The metal melts from the arc temperature. The fusion zone at the junction of parts is called a weld (weld) seam. For different metals and different types of joints, the welding technique, the position of the electrode, the speed of its movement, and the amplitude can vary. How to properly weld a seam so that the connection is not only reliable, but also beautiful, let's talk further.

The content of the article

Types of welds and joints

Seams have a fairly extensive classification. First of all, they are divided according to the type of union of the doers. Depending on the requirements for reliability, the seam can be applied from one or both sides. With double-sided welding, the structure is more reliable and holds its shape better. If there is only one seam, it often happens that the product is distorted: the seam "pulls". If there are two of them, these forces are compensated.

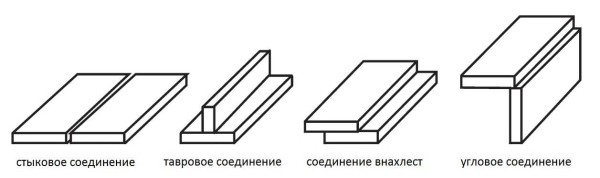

Welded seams, depending on the type of connection, are butt (butt), tee, overlap and fillet (To increase the size of the picture, click on it with the right mouse button)

It is impassable to note that in order to obtain a high-quality weld, the metal must not be rusty. Therefore, the welding places are preliminarily sanded or processed with a file - until the rust disappears completely. Further, depending on the requirements, the edge is grinded or not.

Butt joint (butt seam)

A butt weld is used when joining sheet metal or pipe ends. The parts are laid so that there is a gap of 1-2 mm between them, if possible, rigidly fixed with clamps. During the welding process, the gap is filled with molten metal.

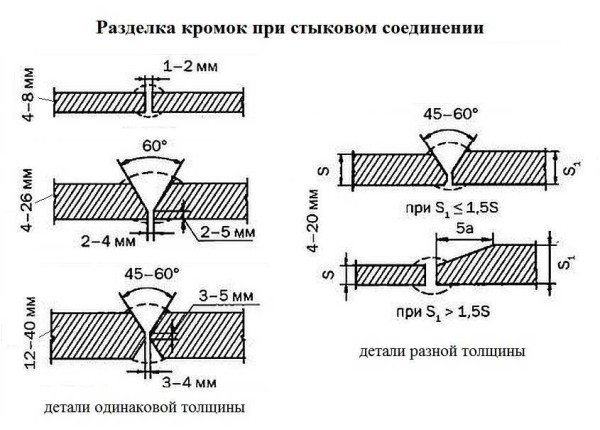

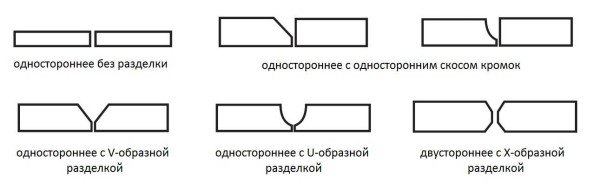

Thin sheet metal - up to 4 mm thick - is welded without prior preparation (rust removal does not count, it is mandatory). In this case, boil on one side only.For parts from 4 mm thick, the seam can be single or double, but edge sealing is required using one of the methods shown in the photo.

- With a part thickness from 4 mm to 12 mm, the seam can be single. Then the edges are cleaned in any of the ways. It is more convenient to do one-sided preparation with a thickness of up to 10 mm, and thicker parts are stripped more often in the form of a letter V. U-shaped stripping is more difficult to perform, therefore it is used less often. If the requirements for the quality of welding are increased, with a thickness of more than 6 mm, stripping on both sides and a double seam on one and the other side is necessary.

- When welding metal with a thickness of 12 mm butt, a double seam is definitely necessary, it is impossible to warm such a layer on one side. Trimming two-sided, in the form of the letter X. With such a thickness, it is unprofitable to use V or U-shaped trimming of the edges: they require several times more metal to fill them. As a result, the consumption of electrodes increases and the welding speed is significantly reduced.

Cutting metal edges when joining parts end-to-end (To increase the size of the picture, right-click on it)

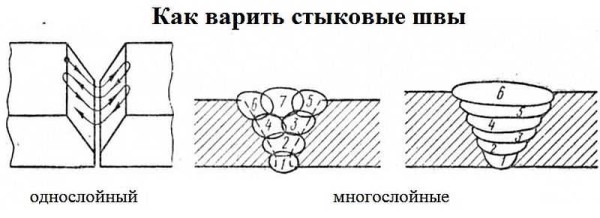

If, nevertheless, it is decided to cook metal of large thickness with one-sided cutting, it will be necessary to fill the seam in several passes. Such seams are called multi-layer.How to weld the seam in this case is shown in the figure below (the numbers indicate the order of laying the metal layers during welding).

Read about welding thin metal with an inverter welding machine here.

How to cook a butt seam: single-layer and multi-layer (To increase the size of the picture, right-click on it)

Lap joint

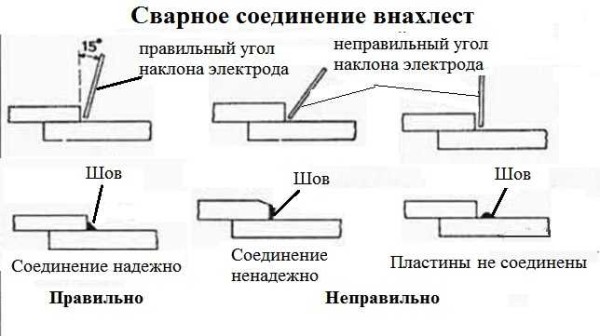

This type of joint is used when welding sheet metal up to 8 mm thick. It is boiled on both sides so that moisture does not get between the sheets and there is no corrosion.

When making an overlap seam, it is necessary to choose the correct angle of inclination of the electrode. It should be about 15-45 °. Then a reliable connection is obtained. When deflected in one direction or another, the bulk of the molten metal is not at the joint, but to the side, the strength of the joint is significantly reduced or the parts remain not connected at all.

How to hold the electrode correctly when overlapping welding (To enlarge the image, right-click on it)

Tee and corner connection

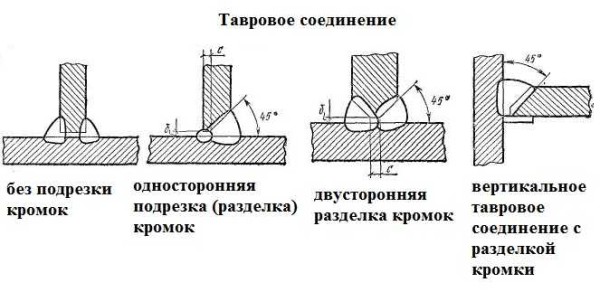

The T-joint in welding is the letter "T", the angular one - the letter "G". The T-joint can be with one seam or two. Edges can also be cut or not. The need for cutting the edge depends on the thickness of the parts to be welded and the number of seams:

- metal thickness up to 4 mm, single seam - without edge processing;

- thickness from 4 mm to 8 mm - double seam without edge processing;

- from 4 mm to 12 mm - single seam with a groove on one side;

- from 12 mm, the edge is cut off from two sides, and two seams are also made.

Types of welds: T-joint with and without cutting (cutting) edges

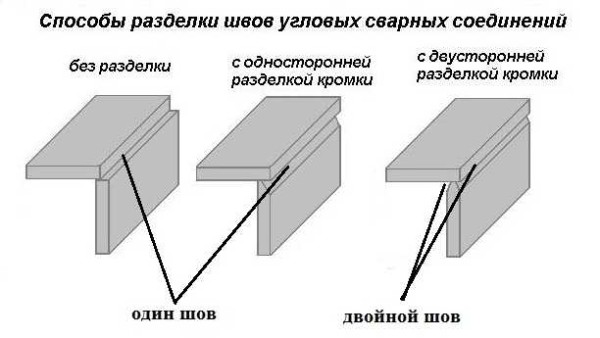

The fillet weld can be viewed as part of the T-joint. The recommendations here are exactly the same: thin metal can be welded without cutting edges; for greater thickness, you have to remove a part from one or both sides.

How to prepare metal for fillet joint (with one or two seams)

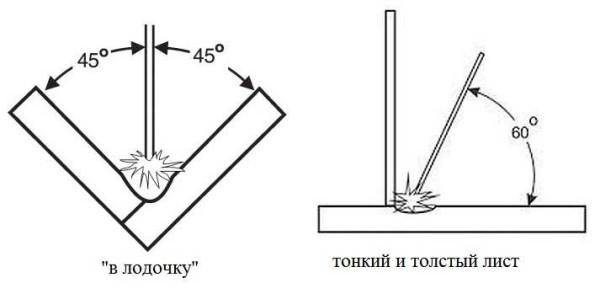

Corner and T-joints sometimes have to be welded on both sides (two seams). To properly weld such a seam, the parts are turned so that the metal planes are at the same angle. In the photo, this method is signed "in a boat". This makes it easier to calculate electrode movements, especially for a beginner with welding.

How to cook a seam: "in a boat" and when joining metals of different thicknesses

When connecting thin and thick metal, the angle of inclination of the electrode should be different - about 60 ° to the thicker part. In this position, most of the heating will be on it, thin metal does not burn through, which can happen if the angle of inclination is 45 °.

Welding fillet welds

When welding fillet welds, observe the position and movement of the electrode. You should have a well-filled seam. It is easier to implement this if you put the parts for welding "in a boat", but this does not always work out.

If the bottom plane is horizontal, it often turns out that there is little metal on the vertical plane, as well as in the corner itself: it stacks down. This happens if the electrode is at the top of the corner for less time than near its lateral surfaces. The movement of the electrode tip should be uniform. The second reason is the too large diameter of the electrode, which does not allow to go down below and warm up the joint normally.

To avoid the appearance of this defect, the arc is ignited on a horizontal surface (at point "A"), moving the electrode to the vertical surface, then return it to its place in a circular motion. When the electrode is above the joint, it has an inclination of 45 °, as it moves up, the angle decreases slightly (picture in the picture on the left), when moving to a horizontal surface, the angle increases. With this technique, the seam will be filled evenly.

Fillet weld - electrode position and movement

When welding fillet joints, make sure that the time spent on the electrode in all three points (on the sides and in the center) is the same.

Read about the choice of electrodes for inverter welding machines here.

Position in space

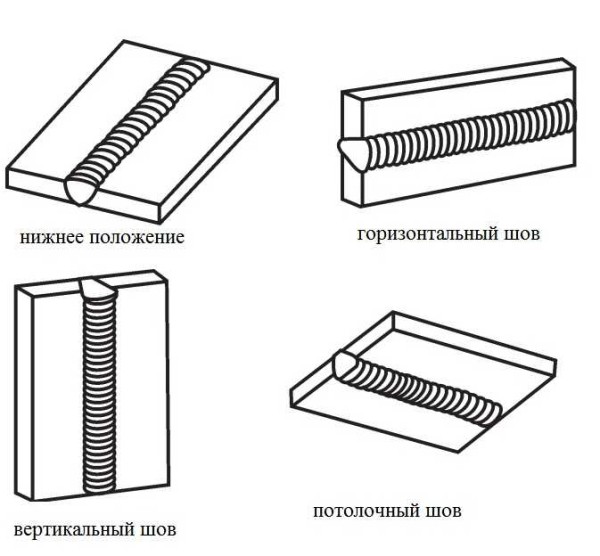

In addition to different types of joints, seams can be located in different ways in space. They are in the lower position. This is the most comfortable for the welder. This is the easiest way to control the weld pool. All other positions - horizontal, vertical and overhead seam - require some knowledge of welding techniques (read below how to weld such seams).

Types of welds by position in space: vertical horizontal, ceiling

How to cook a seam

When welding in the lower position, no difficulties arise even for a novice welder. But all other provisions require knowledge of technology. There are recommendations for each position. The technique for making each type of weld is discussed below.

Welding vertical seams

When welding parts in a vertical position, the molten metal slides down under the influence of gravity. To prevent droplets from coming off, use a shorter arc (the tip of the electrode is closer to the weld pool). Some craftsmen, if the electrodes allow (do not stick), generally support them on the part.

Metal preparation (cutting edges) is carried out in accordance with the type of connection and the thickness of the parts to be welded. Then they are fixed in a given position, connected with a step of several centimeters with short transverse seams - "tacks". These seams prevent parts from moving.

The vertical seam can be cooked from top to bottom or bottom to top. It is more convenient to work from the bottom up: this is how the arc pushes the welded pool up, preventing it from dropping down. It's easier to make a high-quality seam this way.

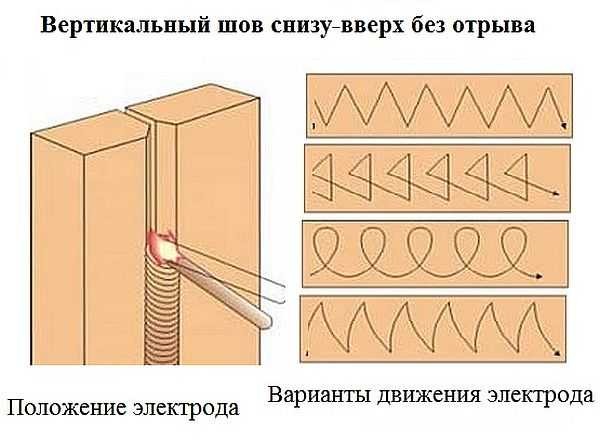

How to weld a vertical seam from bottom to top: electrode position and possible movements

This video shows how to properly weld a vertical seam by electric welding with the movement of the electrode from bottom to top without tearing. The short roll technique is also demonstrated. In this case, the electrode moves only up and down, without horizontal displacement, the seam is almost flat.

It is possible to connect parts in a vertical position with a separation of the arc. For novice welders, this may be more convenient: during the separation time, the metal has time to cool down. With this method, it is even possible to rest the electrode on the ledge of the welded crater. It's easier. The pattern of movements is practically the same as without separation: from side to side, loops or "short roll" - up and down.

How to weld a vertical seam with a separation, see the next video. In the same video tutorial, the effect of current strength on the shape of the seam is shown. In general, the current should be 5-10 A less than the recommended one for a given type of electrode and metal thickness. But, as shown in the video, this is not always true and is determined experimentally.

Sometimes a vertical seam is boiled from top to bottom. In this case, hold the electrode perpendicular to the surfaces to be welded when igniting the arc. After firing up in this position, heat the metal, then lower the electrode and cook in this position. Welding a vertical seam from top to bottom is not very convenient, it requires good control of the weld pool, but in this way you can achieve good results.

How to weld a vertical seam with electric welding from top to bottom: the position of the electrode and the movement of its tip

How to cook a horizontal seam

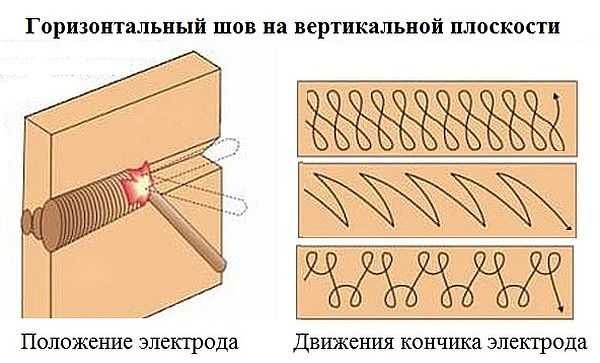

A horizontal seam on a vertical plane can be carried out both from right to left and from left to right. There is no difference, whoever is more convenient, he cooks like that. As when welding a vertical seam, the tub will tend downward. Therefore, the angle of inclination of the electrode is large enough. It is selected depending on the speed of movement and current parameters. The main thing is that the bath remains in place.

Welding horizontal seams: electrode position and movement

If the metal flows down, increase the travel speed, heating the metal less. Another way is to make arc breaks. During these short intervals, the metal cools down a little and does not drain. You can also lower the amperage slightly. Only apply all these measures in stages, and not all at once.

The video below shows how to properly weld metal in a horizontal position. The second part of the video is about vertical seams.

Ceiling seam

This type of welded joint is the most difficult. Requires high skill and good control of the weld pool. To complete this seam, the electrode is held at right angles to the ceiling. The arc is short, the speed of movement is constant. Mainly circular movements are performed, expanding the seam.

Cleaning welded seams

After welding, spatter of scale, drops of metal and slag remain on the metal surface. The seam itself is usually convex and protrudes above the surface. All these disadvantages can be eliminated: cleaned up.

Cleaning the seams after welding is done in stages. At the first stage, with the help of a chisel and a hammer, scale and slag are knocked off the surface. On the second, if necessary, the seam is compared. Here you need a tool: a grinder equipped with a grinding disc for metal. Depending on how smooth the surface should be, use different grit sizes.

Sometimes, when welding plastic metals, tinning is required - covering the weld with a thin layer of molten tin.

Defects in welds

Beginner welders often encounter mistakes when making seams that lead to defects. Some of them are critical, some are not. In any case, it is important to be able to identify the error in order to correct it later. The most common defects among beginners are uneven joint width and uneven filling. This happens due to uneven movements of the electrode tip, changes in the speed and amplitude of movements. With the accumulation of experience, these shortcomings become less and less noticeable, after a while they disappear altogether.

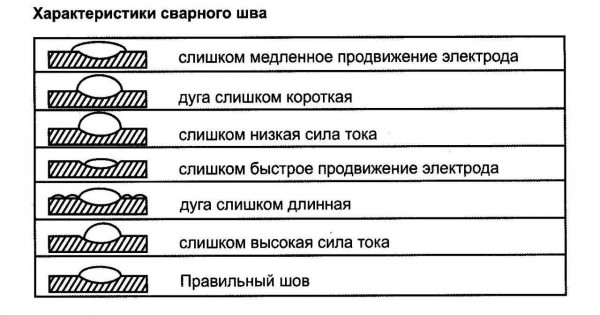

Other mistakes - when choosing the current strength and the magnitude of the arc - can be determined by the shape of the seam. It is difficult to describe them in words, it is easier to portray them. The photo below shows the main defects of the form - undercuts and uneven filling, the reasons that caused them are spelled out.

Errors that can occur when welding

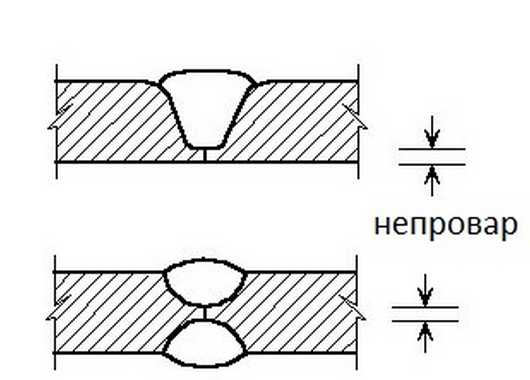

Lack of penetration

One of the mistakes novice welders make: lack of fusion

This defect consists in incomplete filling of the joint of parts. This disadvantage needs to be corrected, since it affects the strength of the joint. Main reasons:

- insufficient welding current;

- high speed of movement;

- insufficient edge preparation (when welding thick metals).

Eliminated by adjusting the current and reducing the arc length. Having selected all the parameters correctly, they get rid of this phenomenon.

ABOUT to choose an inverter welding machine for home and summer cottages, read here.

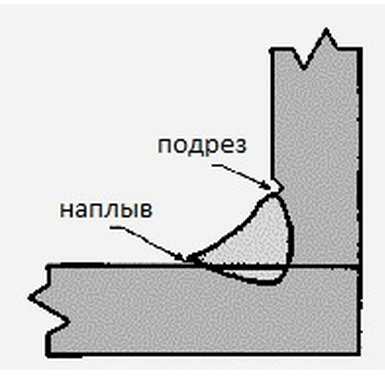

Undercut

This defect is a groove along the seam on the metal. Usually occurs when the arc is too long. The seam becomes wide, the arc temperature for heating is not enough. The metal at the edges quickly solidifies, forming these grooves. It is "treated" with a shorter arc or by adjusting the current strength upwards.

Corner undercut

With an angled or T-joint, an undercut is formed due to the fact that the electrode is more directed to the vertical plane. Then the metal flows down, a groove forms again, but for a different reason: too much heating of the vertical part of the seam. Eliminated by reducing the current and / or shortening the arc.

Burn

This is a through hole in the weld. Main reasons:

- too high welding current;

- insufficient movement speed;

- too much gap between the edges.

It looks like a burn-through when welding

The correction methods are clear - we are trying to choose the optimal welded mode and the speed of the electrode.

Pores and sagging

The pores look like small holes that can be clustered together or scattered across the entire seam. They are an unacceptable defect, since they significantly reduce the strength of the connection.

Pores appear:

- with insufficient protection of the welded pool, an excessive amount of shielding gases (poor quality electrodes);

- a draft in the welding zone, which deflects shielding gases and oxygen enters the molten metal;

- in the presence of dirt and rust on the metal;

- insufficient grooving.

Sagging appears when welding with filler wires with incorrectly selected modes and welding parameters. They represent numb metal that has not bonded to the main part.

Main defects of welded seams

Cold and hot cracks

Hot cracks appear during metal cooling. Can be directed along or across the seam. Cold ones appear already on a cold seam in cases where the loads for this type of seam are too high. Cold cracks lead to destruction of the welded joint. These deficiencies can only be treated by repeated welding. If there are too many flaws, the seam is cut and reapplied.

Cold cracks lead to product failure

Hello. Good article, everything is detailed. The ceiling seam is the most difficult.