How to make a plow

When cultivating land, one of the most tedious operations is plowing and preparing for sowing. If you have equipment - a walk-behind tractor or a mini-tractor - everything can be shifted to them, but a plow is needed for plowing. Buying ready-made is too expensive. Prices for finished products are considerable. To save money, you can make a plow yourself. And there are two ways. First: do everything yourself completely. This is a difficult path - the shape of the parts of the plow is non-linear, with bends of a certain radius, and it is very difficult to bend thick metal at home. The second way is to buy ready-made bodies, and assemble the frame and all other auxiliary parts yourself. This is a simpler option, which is relatively easy to cope with.

- Homemade plow frame for mini tractor

- Two-body homemade plow for a mini tractor

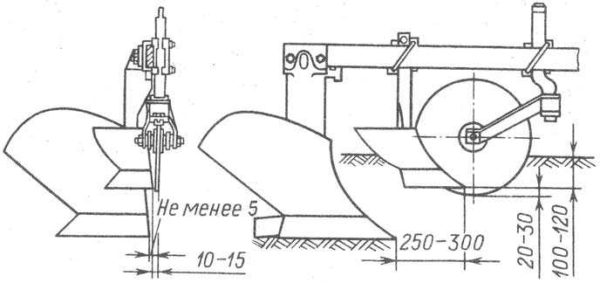

- Installing the support wheel

The content of the article

Types and classification of plows

There are several designs of plows:

- plowshares;

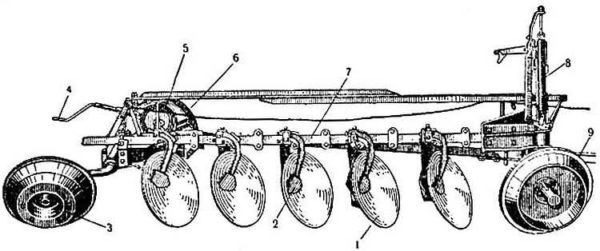

- disk;

- rotary;

- combined;

- chisel.

The most common are plowshares. They were used by our ancestors and to this day they work on most fields. For plowing heavy lands, areas with high or insufficient moisture, disc plows are used. Combined and rotary - more complex in the device, suitable for the cultivation of virgin lands. Chisel - these are special devices that do not provide for the circulation of the formation. They are conventionally referred to as plows and are rarely used, especially in private households.

According to the type of traction, plows are divided into several categories:

- Tractor. At this time, this is the most common type of plow. They are produced for different types of equipment, including for small-sized mini tractors and even walk-behind tractors.

- Horse-drawn. This group is rare today. Such plows are used to cultivate those areas where it is difficult or impossible to drive the tractor.

- Rope-traction. They are used in places where even a horse will not enter - in swampy areas, with a steep slope, etc.

And that is not all. There is also a classification by purpose: general and special. General purpose plows operate on most reclaimed land. Special-purpose plows include:

- For stony soils. They have built-in safety mechanisms (lifting), which prevent large stones from damaging the plow.

- Negotiable. They have two identical plows in a mirror image. Allows to get a flat surface without pronounced humps and furrows (smooth plowing).

- Tiered. They are used to increase soil fertility.

These are not all varieties, but the most popular and used ones. They differ constructively, and sometimes seriously.

The structure and types of plows

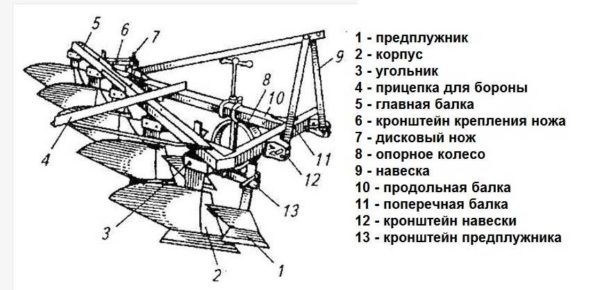

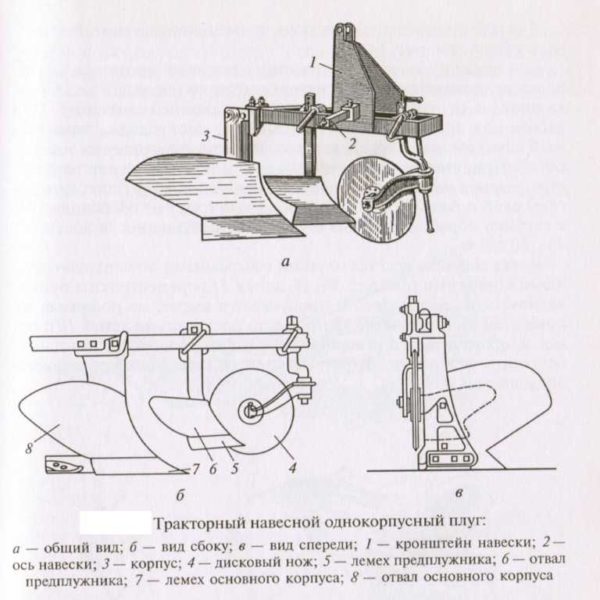

To make a plow with your own hands, you must have information about its structure and the purpose of the parts. General purpose arable implements are most commonly used. It consists of several parts, which can be roughly divided into working and auxiliary parts:

- workers:

- body - consists of a rack to which a share with a blade and a field board are attached;

- knife - the main cutting part;

- skimmer - an additional cutting part that cuts off the soddy layer of soil;

- auxiliary:

- frame - the base on which everything is mounted, consists of longitudinal beams, stiffening beams and struts;

- support wheel adjustable in height;

- hitch - a system of attachment to a tractor or other moving vehicle.

How does such a plow work? The skimmer removes the top layer of soil with the plants growing on it, turns it over and places it on the bottom of the furrow, which is the result of the work of the body. The body with the equipment cuts off part of the soil from the side of the furrow, loosens it, wraps it at an undefined angle (depending on the design), and places it on top of an inverted sod layer (laid with a skimmer). To level the furrow wall, a knife is placed in front of the last plow body.

General purpose plows can provide plowing depths from 20 cm to 30 cm, share plows - from 16 cm (they also do not have a knife and skimmer).

Housings

According to the number of bodies, plows are single-body, double-body and multi-body. The body consists of several parts:

- rack;

- working surface - share and blade;

- field board.

The share and the blade are the working surface - this part is responsible for the quality and type of plowing. The soil layer is trimmed with a share, along which it rises to the dump. Here the soil crumbles and turns over. The degree of seam rotation depends on the shape of the dump. A field board is attached to the bottom of the case. Its task is to prevent the plow from moving towards the already plowed area.

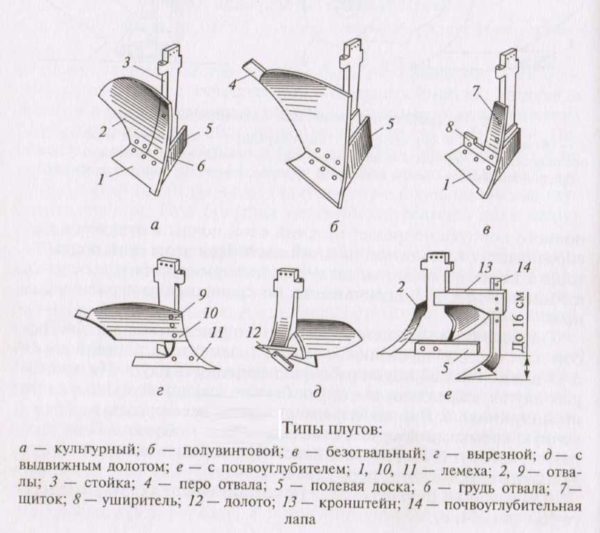

If you are going to make a plow with your own hands, you need to choose a design taking into account the type of soil you are going to work with. Plow bodies are:

- Dump. For plowing with full or partial seam rotation. Such plows promote soil formation (grown plants are cut off, laid on the bottom of the furrow, where they rot), enrich the soil with oxygen (due to loosening).

- cultural - it is used for long-term cultivated land, it crumbles the soil well, wraps it in a medium degree;

- semi-screw moldboard bodies are used for cultivating virgin lands, plowing heavily soddy soil, it wraps the soil well, crumbles it moderately (models with an elongated feather wrap the layer completely);

- screw - good when cultivating virgin lands - the layer is completely wrapped;

- Moldless. Used in arid climates to retain moisture and in regions with a risk of wind erosion.

- Cutout. Suitable for soils with a small plow horizon. The lower part only loosens, not rising outward, the upper part is removed and thrown onto the previous furrow, in which the podzolic layer loosened during the previous pass lies.

- With a subsoiler. They are used mainly on marginal lands. The subsoiler loosens the podzolic layer, which increases the thickness of the fertile layer.

- With a retractable chisel. They are used on clays, loams, soil with a lot of stones. The chisel, fixed on the tine in front of the share, prevents damage to the cutting edge. As you grind, the chisel is pushed forward - for this there are special holes on it.

- Disk. With its help, waterlogged soils are cultivated, it is also good with a large number of roots.

When planning to make a plow with your own hands, the design of the plow body is chosen based on the type of soil and the goals set. Sometimes the choice depends on the type of plantation being grown. For example, for root crops, enhanced loosening is required, which none of the above plow bodies gives. Then a special one is used - combined. It has a shortened blade and share, as well as a rotor. When plowing, the rotor additionally crushes the soil that comes from the share.

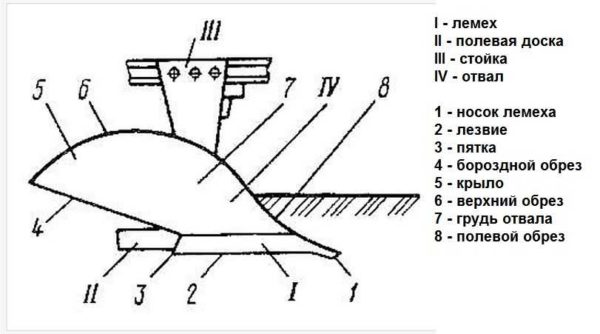

Dump

The plow blade is one of the working parts of the plow (part of the body). His job is to cut off a layer of soil from the wall, crush it and turn it over (wrap it). That is, how well the soil will be prepared depends largely on the quality of the dump. When making a plow yourself, this is worth remembering.

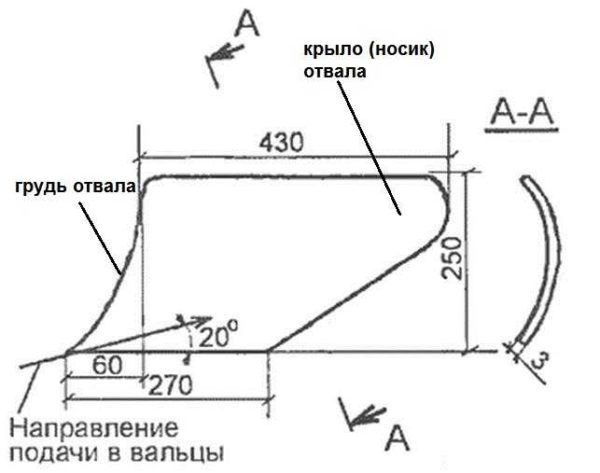

The blade is made of carbon steel sheet or a special three-layer.It has a complex curved shape, which determines the degree of soil crushing and its turnover. Structurally, the chest and the wing (nose) are distinguished in the plow blade.

The dump chest cuts off a layer of soil from the furrow wall, crushes it, and begins to wrap the cut layer. The dump wing completes its turn. As you can see, the breast does the bulk of the work, and therefore wears out, on average, twice as fast. Therefore, the dump is made in two parts. In this case, the blade chest can be replaced if it is heavily worn. Another nuance: at the factory, to reduce the friction of the formation on the surface, it is polished.

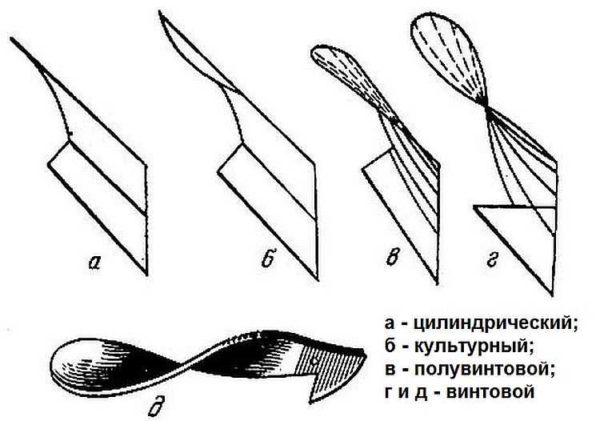

There are four main moldboard shapes, each of which imparts specific characteristics to the plowing:

- Cultural dump. It crumbles the layer well and wraps it quite fully. It is used for plowing large areas of long-developed lands.

- Cylindrical. It crumbles the soil well, but does not wrap it well. As a result, plant residues in this case are uniformly mixed with the soil. Use a similar dump on light soils.

- Semi-screw and screw. The layer is completely wrapped (plant residues are stacked with roots up), but crumble very poorly. After plowing with a plow with such a blade, the field has pronounced "waves". Before sowing, it must be additionally processed - leveled (harrows, cutters, etc.).

When choosing materials, keep in mind that both the blade and the ploughshare must have almost the same thickness: the allowable step size is 1 mm. Also, the gap at the joint of the share and the blade can be very small - no more than 0.5 mm.

Ploughshare

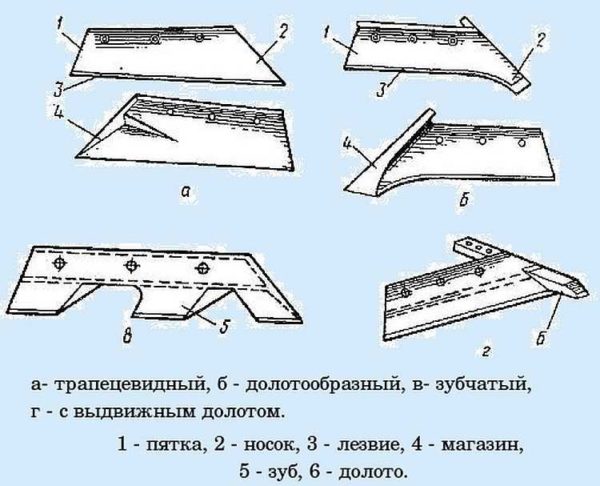

To make a plow with your own hands, you need to decide on the shape of the share. A ploughshare is a part that cuts a layer of soil, along which the cut layer of soil also rises and falls on the dump. For its manufacture, high-strength hardened steel is used.

Place the share as follows:

- to the bottom of the furrow at an angle of 22-30 °;

- the choice of the angle of inclination in relation to the plane of the furrow depends on the type of blade:

- for a cultural dump - 40 °;

- cylindrical - 45 °;

- screw and semi-screw - 35 °.

This arrangement gives the least resistance when advancing, while the blade cuts the roots well, breaks up lumps of earth that slide along its surface.

Plowshares come in different shapes (pictured above). When making a plow with your own hands, they are chosen depending on the type of soil and the complexity of manufacturing:

- Trapezoidal. The easiest to manufacture, good because when using it, the bottom of the furrow is flat. The disadvantage is quick wear and difficulty in penetration. Therefore, most often trapezoidal shares are used on long-cultivated land. To compensate for the rapid wear, some stock of material is made on the reverse side - a store. With its next pull, part of the stock goes away.

- Serrated and retractable chisel. These types of shares are used on heavy soils (clay, loam) and where there are many stones.

- Chisel. Differs in the presence of a sharp protruding nose. This protrusion protrudes 5 mm towards the margin and 10 mm downward. Such a bend contributes to the fact that the plow with such a share is better and faster deeper and smoother. To compensate for wear, a "magazine" is also made - a stock of length. Plows with a chisel share are used on heavy soils.

Of all these types, chisel-like shares are the most common. They are more stable in work, there are no problems with them when deepening: the plow is easily lowered to the required depth.

As they wear out, the plowshares pull back and sharpen the cutting edge. This is done regularly, since with a dull blade (width more than 3 mm), the resistance of the plow increases by 50%. Therefore, it is more profitable to inspect and maintain equipment on time.

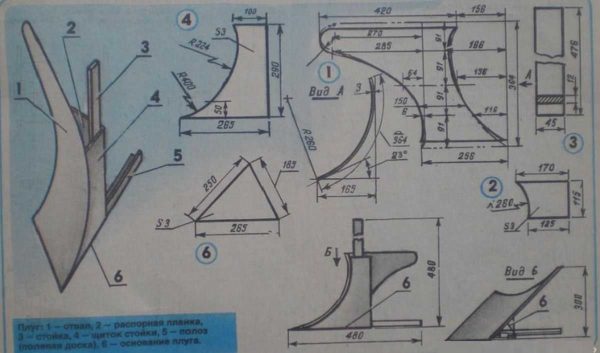

Blueprints

If you are going to make a plow with your own hands, you need to have some kind of role model.If you have an old plow, you can make new ones in its image. And if this is not the case, drawings will come in handy. Just take into account the parameters of your equipment on which you will hang it.

Detail of some sizes.

Video tutorials on making plows