DIY knife sharpeners

It is quite difficult to sharpen a knife by hand correctly. It will take some time to develop the habit of maintaining a constant sharpening angle, which is not easy at all. A knife sharpening device can make the task easier. There are factory options. But for good copies you have to pay off a couple of hundred dollars, and this is clearly a lot. The good news is that these tools are easy to make with your own hands. Moreover, many homemade knife sharpeners are no worse in functionality than those from well-known manufacturers, but they cost many times cheaper.

The content of the article

Knife sharpening basics

Knives have different uses, and even in an ordinary kitchen there are several of them. There is for cutting bread and other soft foods, there is for cutting meat, chopping bones, and other hard objects. And these are only household ones. But there are still those who take on hunting and fishing. If you look closely, you will see that they all have a different sharpening angle (this is if they were not sharpened at home already). It is the sharpening angle that is the most important characteristic, which is determined by the purpose of the given blade.

At what angle

The sharpening angle is determined based on the main field of application of a particular blade:

- Straight razors are sharpened at 8-12 °. Such a small angle allows you to easily cut the hairs after finishing, but when you try to cut something else, the blade will become dull very quickly.

- Fillet knives are sharply sharpened almost as well - 10-15 °.

- For cutting food, it is best to sharpen the blade at 15-20 °.

- For hunting and general purpose knives, choose an angle between 20 ° and 25 °. A cutting edge of such sharpness will allow not only to cut soft products, but easily cope with bones, wood, etc. Some manufacturers of hunting and knives sharpen their blades in a wider range - 20-40 °. A knife with a 40 ° blade cuts much worse, but it copes better with opening cans or other similar work.

- Heavy knives for special purposes (machetes, for example) are sharpened at 30-50 °. It will be problematic for them to cut bread, but they cut trunks, vines and other similar objects perfectly.

These are general guidelines based on years of experience. There are, however, options: some blades have several zones with different sharpening. This wishes them more versatile, but the complexity of sharpening increases many times over.

From the above it follows that the device for sharpening knives should be able to set the required sharpening angle. And this is the main difficulty in its design and manufacture.

How to sharpen

Grinding stones of various grain sizes are used to sharpen knives. They are conventionally divided into rough, medium and small. Why conditionally? Because different countries have their own designation of grain size. The most convenient classification is by the number of grains per unit area. It is expressed in numbers: 300, 600, 1000, etc. Some firms also duplicate in English terms. Here's an approximate division:

- 200-250 - very coarse (extra coarse). They are not used for sharpening knives.

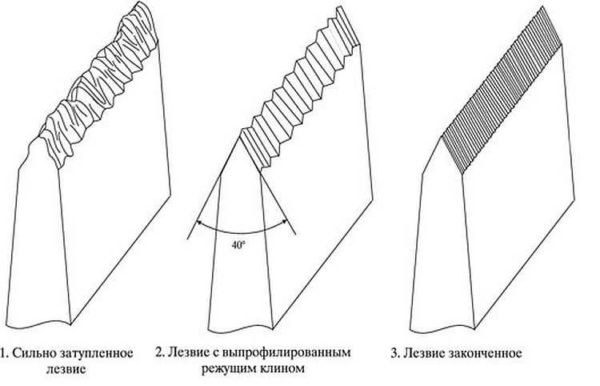

- 300-350 - rough (coarse). Used when profiling the cutting edge of a damaged or very dull blade.If the cutting edge has no visible flaws and you do not plan to change the sharpening angle, this abrasive should not be used.

- 400-500 - medium (medium). Many manufacturers do not have bars of this grain size, since they are easy to do without.

- 600-700 - fine. The main type of block used when sharpening knives. Knives that are dull during normal use are sharpened on them.

- 1000-1200 - very fine (ultra or extra fine). They bring the sharpened blade to a mirror finish.

In addition to grain size, whetstones are distinguished by their origin: they are of natural origin (shale, corundum, etc.), there are ceramic and diamond. Which is better? It's difficult to say - a matter of taste, but natural ones grind off faster and are rarely fine-grained.

Natural ones are soaked in water before use or simply moistened with it. They absorb water and, during sharpening, an abrasive paste is formed on the surface from the water and separated abrasive particles, which increases the sharpening efficiency. For the same purposes, you can use a special little (honing oil) or a mixture of water and soap (whichever you prefer). In general, with each of the sharpening stones, you need to try all these options and choose the best one.

The shape of the sharpening stone for sharpening knives is a bar, and it is desirable that its length be much greater than the length of the blade - it is easier to sharpen. Convenient bars with double grain - on the one hand, larger, on the other - finer. For sharpening ordinary knives, it is enough to have two bars with medium grain (different) and two small ones (one can be very small).

Manual sharpening procedure

The device for sharpening knives only facilitates the process of guiding the edge, therefore, knowledge of manual sharpening techniques is required. It is impossible to sharpen the knife correctly without them.

The order of sharpening knives is as follows:

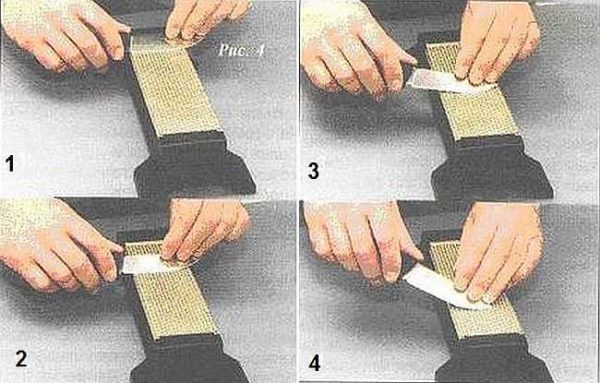

- First we take a bar of medium or coarse grain - according to the circumstances, we put it on the table. It is better if it is fixed - you will not have to worry about not moving it while working.

- We calculate the required sharpening angle - it is equal to half of the selected angle. We hold the blade at about this angle. Now the main task is to keep this angle constantly.

- All movements when sharpening a knife without strong pressure. Smoothly and evenly.

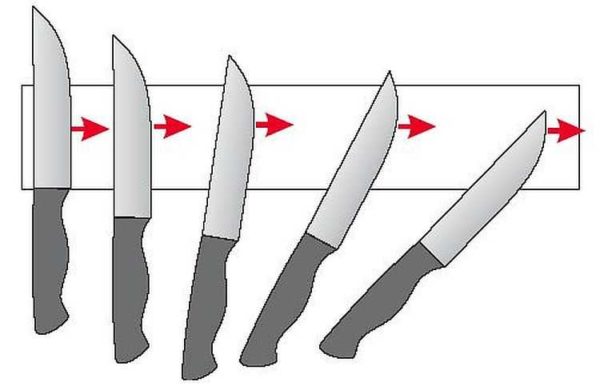

- We start sharpening by moving away from ourselves. In this case, in one pass, the blade must "pass" over the stone from beginning to end. There is also an important point here: at the point of contact with the bar, the edge should be perpendicular to the direction of movement. There are no problems with the straight part - you drive straight, but as the rounded edge approaches, the handle has to be turned to maintain perpendicularity (see photo).

- At the end of the movement, the tip should remain on the surface of the bar. It should not break off, as the tip may become dull, and its lateral surface may also be damaged. For this to be possible, the length of the bar should be 1.5-2 times longer than the blade. Then the movement will be smooth and uniform, as it should be.

- After the tip of the knife has stopped, we begin the reverse movement.

- We repeat the movements back and forth until a burr forms on the back of the blade - a thin edge wrapped inward. It is groped with your finger, passing perpendicular to the edge (not along - you will cut yourself). Ideally, it should be flat along the entire length of the blade. If not, work it over again, and not in areas where there are no burrs, but along the entire length.

- When there is a burr, turn the blade to the other side and repeat everything too. The burr will move to the other side, but will be slightly smaller.

- Change the block, and continue sharpening the blade with movements "away from you" (there is no more reverse movement).Smaller grain leaves smaller grooves on the edge and slightly less burr.

- Work the other side on the same grindstone.

- Change the abrasive to an even finer one. Again, repeat everything (the movement is still from yourself). And so on until you achieve the "specularity" of the edge, and it is achieved on a very small block. This means that the grooves left by the abrasive are very small and the cutting edge is sufficiently polished to cut well.

- But even after that, a burr remained on the back of the blade. We remove it on the smallest block that you have. We do the already memorized movement "from ourselves" once for each side, gradually reducing the pressure. Thus, it turns out to reduce the burr to a minimum, which almost does not interfere with the work.

On this we can assume that the sharpening of the knife is finished. Some are still finishing the edge on the old belt. A piece of belt can be fixed on a wooden block (glue, do not nail), rub with goy paste. Then carry out several times alternately with one or the other side, but with the cutting edge turned back. So the last grooves left by the abrasive are polished and the belt is not "cut" at the same time.

How to make a homemade knife sharpener

All homemade knife sharpeners solve the main problem - they allow you to accurately maintain a given angle of inclination of the bar to the blade, which is very important for obtaining a good cutting edge. There are very simple devices, there are a little more complicated ones, but they allow you to work more comfortably. Choose according to your taste.

Simple knife sharpener

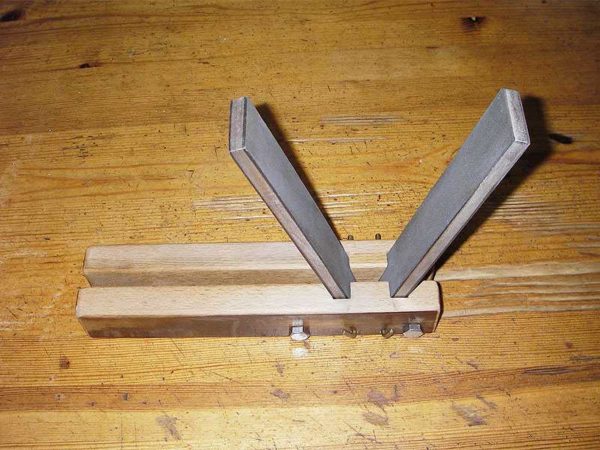

Basically it is a sharpening stone holder. Everything is elementary: two triangles made of wood, which are connected by pins with "lambs". A bar is clamped between the corners at the required angle. You can set the angle using a protractor, a special program on a smartphone, or using the rules of trigonometry (right-angled triangle).

When sharpening on such a device, the knife must be kept strictly vertical at all times. This is much easier than holding it at a certain angle.

The same idea has another embodiment: on a reliable base, make movable holders, into which the bars are inserted and fixed in the desired position. The corporate prototype is pictured below.

This homemade knife sharpener is made of wooden blocks. It turns out to be light, so that it does not move from its place, it must be fixed with something. To avoid holding it with your hand, you can use clamps.

Such a device for sharpening knives, of course, facilitates the work, but it is still quite difficult to maintain an angle: you have to control the verticality of the blade all the time. This habit develops over time, but it's difficult to get started.

The device on wheels

An interesting version of a manual knife sharpener with a fixed bar and a trolley on wheels, on which the knife is fixed. It is made on the basis of knife sharpeners, chisels and planers. Such a device also works well with a knife, but you need to adapt to sharpening a rounded edge.

In this embodiment, as in manual sharpening, the bar is stationary, and the blade of a knife fixed on a movable cart moves. The angle is set by the height of the bar relative to the platform on which the blade is mounted. The peculiarity of this device is that the table must be flat. It can be a table top made of natural stone, you can put glass on a regular table.

In the above version, the angle changes slightly, which is usually enough for sharpening the same type of knives - kitchen knives, for example.If necessary, the design can be improved by adding holders (pictured below).

All this is implemented very simply, as it resembles an ordinary constructor: strips, holes in them, everything is assembled on bolts and screws.

To ensure the immobility of the bar, there is also a device.

The plus of this whole design is that it is easy to turn the knife while maintaining perpendicularity in the rounded section, and also very easy to process from the other side: you need to turn the cart over. For this, four pairs of wheels are made.

Homemade manual knife sharpening machine

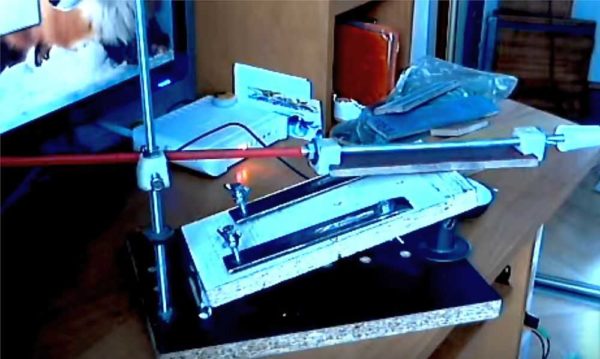

Slightly more complex and much more convenient home-made devices that are made on the basis of well-known proprietary devices. They have an adjustable platform on which the knife is fixed. The platform is exposed at a given angle. The block is mounted on a movable bar attached to the rack.

Hand-made devices are somewhat similar to the design presented above, but there are some differences. There are many options. Here are some.

Option one: a fixed platform on which the blade is fixed

This fixture is made from remnants of laminate (you can use Chipboard), two steel rods with a diameter of 8 mm and a movable mount.

This design has a fixed base, to which a platform with a knife holder is attached to ordinary hinges. The near edge of the platform can be raised at an angle that is convenient for work. But otherwise she is motionless.

On the vertically mounted steel bar, there is a movable retainer, in which a loop is attached to the side. A rod is inserted into it, on which the bar is fixed. This loop is a simple, but not the best solution: there is no rigid fixation, which means the corner will "walk".

Particular attention should be paid to the block retainer. An emphasis is placed on the rod at some distance from the edge (about 30-35 cm). This will be a fixed retainer. The second is made movable, it is fixed after installing the bar with a screw and a thread cut in the body of the holder. The second option is to cut a thread on the rod and tighten the installed bar with a nut.

Knife holder - one or two steel plates fixed on a movable platform. They are fixed movably - with screws and "thumbs". Having loosened the fasteners, insert the knife blade, clamp it. It is very difficult to move it. Then, having installed a hairpin with a fixed bar in the loop, adjust its height so that the required angle is set.

You can, as in the photo, make templates with the desired angles and achieve the coincidence of the planes. After the transverse bar is fixed, you can work - hold the bar in the desired direction.

This device for sharpening knives works well, but you can only move the abrasive along the blade when sharpening a kitchen knife. Classic sharpening - movement perpendicular to the cutting edge. This can be achieved on the straight edge of the blade. If the blade is short, it will be almost perpendicular, but this will not be done on the rounded part on the fixed holder. And all such devices "suffer" from this drawback. Once again: they are a great option for sharpening kitchen knives (below is another good option from the same series).

Option two: with a movable platform and magnetic holder

In this version of a homemade knife sharpening device, the problem of previous sharpening is solved. Here the frame remains motionless, which sets the angle of movement of the bar. The bar holder moves freely along a guide set at the desired angle. The knife is mounted on a movable table. You can, as in the presented version, make a magnetic holder, you can - the usual one from a metal plate and "lambs".Move the table so that the movement of the abrasive is perpendicular. Actually, everything is in the video.

One clarification: in this case, it is very important that the surface on which the table with the fixed knife moves is horizontal and even. You can put glass or use a polymer countertop (marble will work too).