How to make a profile bender with your own hands

When arranging a site or in preparation for the summer cottage and garden season, there is a need for arcs from a profile pipe. They are needed when arranging a greenhouse, assembling gazebos or a canopy. It is expensive to buy already bent arcs - the price is twice as high as for the same flat steel. The way out is to do it yourself, and in order to facilitate the process (it is very difficult with your hands) you need to make a pipe bender for a profile pipe. You will need channels or corners, rolling rollers and some more details. Of the tools - a grinder with a disc for metal, a welding machine, a ruler.

The content of the article

Profile bender design

The machine for profile pipe bending is structurally different from the usual one. This is due, firstly, to the greater resistance of the profile to bending loads, and secondly, to the fact that the bending radius is usually required to be large. Therefore, there are three rollers in the design. Two of them are permanently installed, one remains mobile. With the help of a movable roller, the radius of curvature changes.In general, there are two types of pipe bender for a profile pipe: with a middle movable roller and with an extreme one (right or left - optional).

Pipe bender device with middle movable roller

The two outer rollers are fixed to the body. They are raised above the base plane. A special U-shaped bed is cooked for the middle roller. In the middle of its lintel, a long, large-diameter clamping screw is installed. A third roller is attached to the lower end of this screw (can be welded). By turning this screw, the roller rises and falls, changing the bending radius of the profile pipe.

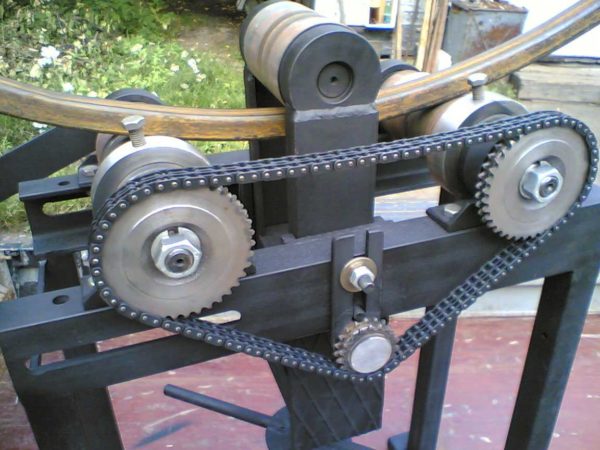

A cloud is welded to one of the fixed rollers, with the help of which the pipe is rolled through the machine. In order to use less force for rolling, the two stationary rollers are connected by a chain. For effective transmission of torque, sprockets are welded to the rollers (it is possible from a bicycle), a chain is selected to them. Such a simple mechanism makes the bending of a profile pipe much easier.

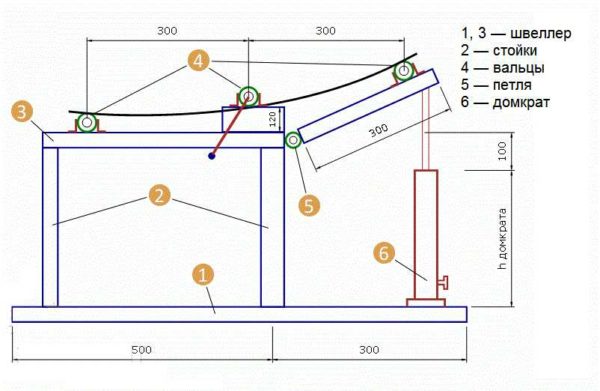

With extreme movable roller

In this design, the right or left roller is made movable. It moves with part of the base. This part is connected to the rest of the bed with heavy-duty metal hinges.

You can change the height using a jack, as shown in the drawing. The platform height in this case is selected depending on the jack height. The bending radius is changed by lifting the movable part of the table.

Unlike the previous design, this profile pipe bender is driven from a central roller - a handle is welded to it. To reduce the force required, you can also weld the sprocket to two stationary rollers and transmit the torque using a chain.

What materials and design nuances are needed

The base of the pipe bender is made from a channel or two welded corners. The thickness of the shelves is at least 3 mm, the width of the shelves and the back of the channel should be matched to the available parts. One rule is that the foundation must be solid and reliable.

Several holes can be made around the edges of the platform.Through them, you can fix the machine to some heavy base using large-diameter self-tapping screws. Fixation is necessary, since when bending pipes with a thick wall, the forces have to be made significant and it is more convenient to work if the machine is firmly fixed.

A few words about rollers. They should be made of good quality, preferably hardened steel. It is the rollers and the axles that hold them that bear most of the load.

I must also say about the shape of the videos. They should not be smooth - there should be rollers along the edges that will not allow the pipe to "walk" during rolling. Only under such conditions will the arc from the profile pipe be flat and not twisted. Ideally, each pipe size needs its own rollers. But then the design becomes more complicated - they need to be made removable, to think over a reliable method of fastening. The second option is to make videos of complex shapes, such as in the photo. Carve out several steps for different pipe sizes.

The same photo shows that the top of the bed is uneven and notched. With the help of such teeth, the rollers can be rearranged at different distances and thus also the bending radius can be adjusted.

In general, self-made bending machines for shaped pipes are assembled from what is at hand or what they find / buy inexpensively. Whoever has the opportunity - grinds the rollers, inserts the bearings. Those who do not have this opportunity use what they have - right down to the hubs from bicycle wheels. In general, you need to understand the design and

Tricks to make pipe bending easier

To make the rollers move better, bearings are used. But, in principle, for a homemade pipe bender, which will be used only from time to time, you can simply make holders from a corner or channel. Make a hole in them, which is slightly larger than the axis on which the roller will be mounted. Pass this axle with the roller on through the holes of the holders and fix them somehow (at least weld on a couple of points that will be stoppers). During operation, for a better stroke, lubricate rubbing places with a grease like Litola. This is not suitable for industrial and semi-industrial production, but for making arcs for a greenhouse or a gazebo with your own hands - just right.

There is one more trick that helps to reduce the required force when bending a profile pipe. You can use the principle of increasing the gear as in a bicycle. By the way, you can use bicycle sprockets. In this case, the handle that drives the rollers is welded to a small sprocket. It is installed somewhere on the body. Larger sprockets are welded on the shaft axis (but teeth with the same pitch). All this is connected by a suitable chain.

And one more improvement - with the constant use of a pipe bender for a profile pipe, it makes sense to mechanize it. In this case, a motor is installed that runs at low speeds.

The procedure for bending a profile pipe on homemade machines

You will hardly be able to get the required bending radius at once - too much effort is required for this. It is unrealistic to create it manually. The required bend is obtained in several passes:

- First, the rollers are set so as to obtain a slight bend, the pipe is rolled in one direction, then removed from the rollers, unrolled and inserted on the other side. It is necessary to unfold in order to obtain an evenly curved pipe.

- With the same position of the rollers, it is pulled several times, until the curvature is no longer added.

- If the required bend radius is not reached, change the position of the roller and repeat the steps again.

The change in the bend radius is obtained gradually, otherwise you cannot make an arc from a profile pipe on a homemade pipe bender. What if you need to repeat the same bend? Make a graduation - note the height to which the roller moved, how many times it was rolled in each position. When repeating, the differences, if any, are insignificant.

The difficulty in bending lies in the fact that there is no scale and it is difficult to obtain the intended bending radius without experience. You will get it sooner or later, but you can spoil a lot of material.

Video materials

Explanations and photos are good, but seeing the assembly process or the operation of the finished unit is much more useful. The first video shows the process of assembling (welding) a manual pipe bender for a profile pipe. Option with movable middle roller selected.

The second video is about the work of a simple pipe bender with a movable platform. This option is not suitable for large sections, but it is able to bend a pipe of a small section up to 40 * 40 mm.

How to bend a profile pipe without a machine

You can get an arc from a profile pipe without a profile bending in two ways - using welding and a template. Let's start with welding.

Get an arc by welding

The profile pipe is cut with a grinder on one side. They are made every 15-30 cm, depending on the required radius, section and wall thickness. The cuts should not touch one side - the one on the outside.

The spare part prepared in this way is bent, giving the desired bend. For reliability, the edges of the arc can be fixed by welding a rod to them. Then they are welded along all the cuts, welding them. And the last stage is grinding of the welding places and treatment with anti-corrosion compounds.

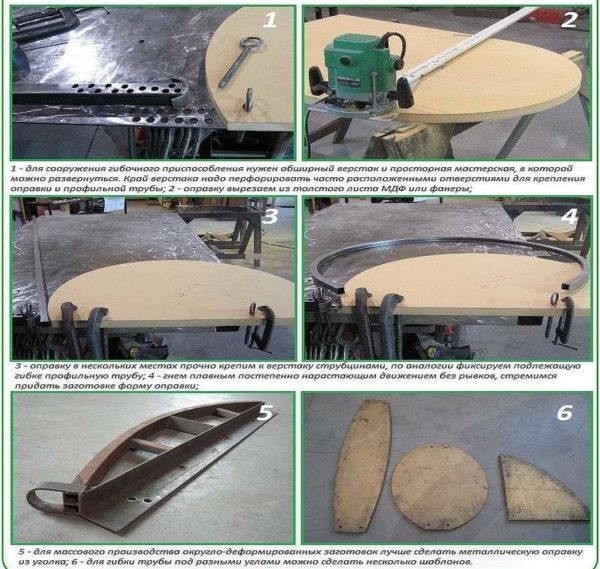

Using a template

Thin-walled profiled pipes can be manually bent using templates. If you need some special shape, it can be cut from a piece of thick plywood or chipboard, and fixed on the table with clamps. On the workbench, where we will bend the pipes, they make 8-10 holes. The template is placed near these holes.

At one end of the pipe, the holes are repeated, with their help the pipe is attached to the workbench. Now the free end of the pipe begins to pull smoothly, forming a bend that repeats the shape. It is necessary to pull smoothly, without jerking.

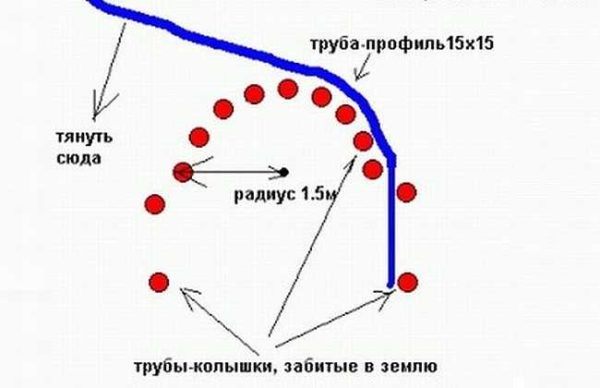

The template can also be made on the ground. Peg pipes are hammered into the ground (depth not less than half a meter). They form the required arc. For an emphasis, two additional stakes are hammered, which are located to the side of the arc. The distance you need to retreat to the side is slightly more than the width of the pipe.

After inserting the pipe, it is pulled towards the arc. Great efforts are needed, the work is hard. It can only work with a thin-walled seamless pipe. The seam has too much resistance in the seam area. It is very difficult to overcome it manually.