How to connect a boiler (water heater) indirect heating

Hot water in taps has long ceased to be a luxury. Today it is one of the essential requirements of a normal life. One of the possibilities for organizing hot water supply for a private house is the installation and connection of an indirect heating boiler.

The content of the article

What is an indirect heating boiler and what they are

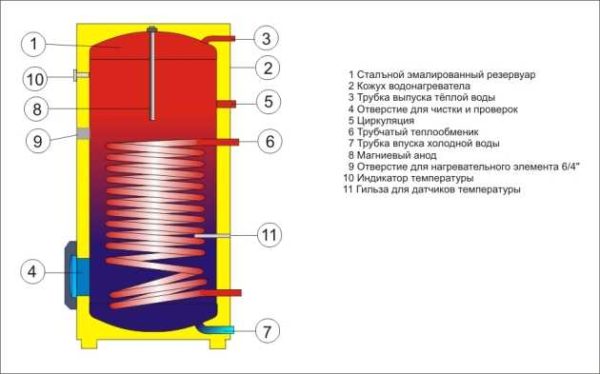

A water heater or an indirect exchange boiler is a water tank in which a heat exchanger is located (a coil or, like a water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other heat carrier circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not take place directly, then such a water heater is called "indirect heating". The heated water is consumed as needed for household needs.

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Views

There are two types of indirect heating boilers: with and without integrated controls. Indirect heating boilers with integrated control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting equipment of this type, all that is needed is to bring the supply and return from heating to the corresponding inputs, connect the cold water supply and connect a hot water dispenser to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a specific place (there is a hole in the body) and connect it to a specific boiler inlet. Next, the piping of the indirect heating boiler is made in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special circuits (see below).

That it must be remembered that the water in the indirect heating boiler can be heated slightly below the temperature of the coolant circulating in the coil. So if your boiler is operating in a low-temperature mode and produces, say, + 40 ° C, then the maximum water temperature in the tank will be just that. You cannot heat it anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good when paired with solid fuel boilers - the water will be warm even when the fuel is burned out.

What else can you say about the design features? In large volumes, several heat exchangers are installed - this reduces the time for heating the water. To reduce the heating time of water and for a slower cooling of the tank, it is better to choose models with thermal insulation.

Which boilers can be connected to

Indirect boilers can be operated with any hot water source.Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. You can connect any type of gas boiler, electric or liquid fuel.

It's just that, as already mentioned above, there are models with their own controls, and then their installation and strapping is an easier task. If the model is simple, you have to think over a temperature control system and switch the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor or hung on the wall. Wall-mounted versions have a capacity of no more than 200 liters, and floor-standing ones can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall version, the mount is standard - brackets that are mounted on a suitable type of dowel.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (connection nozzles) are brought out from behind. It's easier to connect, and the look is better. On the front of the panel there are places for installing a temperature sensor or thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of lack of heating power.

By the type of installation, they are wall-mounted and floor-standing, with a capacity from 50 liters to 1500 liters.

When installing the system, it is worth remembering that the system will work efficiently only if the boiler power is sufficient.

Schemes and connection features

There are two principles for connecting an indirect heating boiler: with and without hot water heating priority. When heating with priority, if necessary, the entire heating medium is pumped through the boiler heat exchanger. Heating takes a little time. As soon as the temperature reaches the set one (controlled by a sensor, thermostatic valve or thermostat), all the flow is directed back to the radiators.

In schemes without priority of water heating, only a certain part of the coolant flow is directed to indirect water heating. This leads to the fact that the water is heated for a long time.

When connecting an indirect heating boiler, it is better to choose a scheme with a priority - it provides hot water in the required amount. At the same time, heating does not suffer much - 20-40 minutes is usually enough to heat the entire volume of water, and 3-8 minutes to maintain the temperature at a flow rate in general. During such a time, no house can cool down enough to feel it. But this is provided that the boiler capacity is comparable to the boiler capacity. Ideally, the boiler is more efficient, with a margin of 25-30%.

General rules

To ensure the normal operation of all appliances connected to the hot water rail, an expansion tank for hot water is installed at the outlet of the boiler (not for heating). Its volume is 10% of the tank volume. It is required to neutralize thermal expansion.

Also, shut-off valves (ball valves) are installed in each branch of the connection. They are needed so that every device can be used - a three-way valve, a circulation pump, etc. - if necessary, disconnect and service.

Check valves are usually also installed on the supply pipelines. They are necessary to eliminate the possibility of counterflow. In this case, the connection of an indirect heating boiler will be safe and easy to maintain.

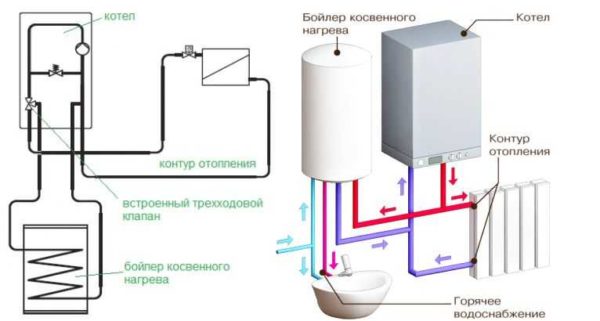

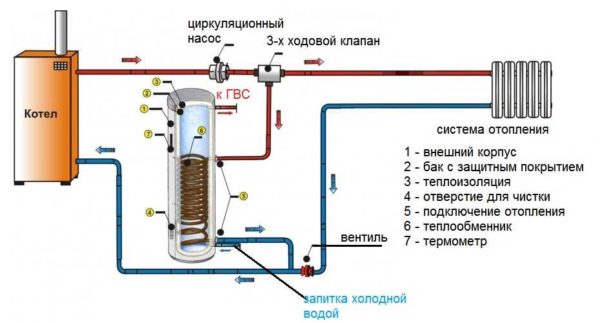

Installation next to the boiler in a forced circulation system (with 3-way valve)

If there is already a circulation pump in the system, and it is installed on the supply, and the forced heating boiler can be placed next to the boiler, it is better to organize a separate circuit that goes from the heating boiler.This connection of an indirect heating boiler is realized with most wall-mounted gas or other boilers, in which a circulation pump is installed on the supply pipe. With this connection scheme, it turns out that the water heater and the heating system are connected in parallel.

With this method of piping, after the circulation pump, a three-way valve is installed, controlled by a temperature sensor (installed on the boiler). One of the outputs of the three-way valve is connected to the boiler branch pipe for heating connection. A tee is cut into the return pipeline before entering the boiler, a branch pipe is connected into it to drain water from the heat exchanger. Actually, the insert into the heating system is over.

The procedure for this scheme is as follows:

- When the sensor receives information that the water temperature is lower than the set one, the three-way valve switches the coolant to the boiler. The heating system is turned off.

- The entire flow of the coolant goes through the heat exchanger, the water in the tank is heated.

- The water heats up enough, the three-way valve redirects the coolant to the heating system.

As you can see, the scheme is simple, its operation is also clear.

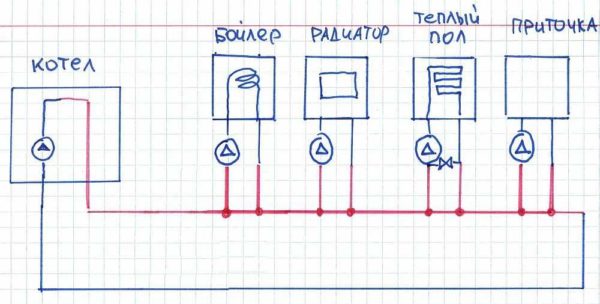

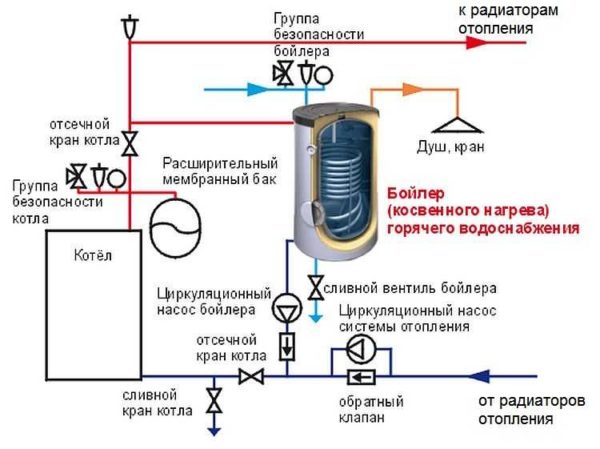

Scheme with two circulation pumps

When installing a water heater into the system in a circulation pump, but not next to it, but at some distance, it is better to install a circulation pump in the circuit on the water heater. The connection of an indirect heating boiler for this case is shown in the diagram below.

The circulation pump can be installed either on the supply pipe, or on the opposite. In this scheme, there is no three-way valve, the circuit is connected through ordinary tees. The switching of the coolant flow is carried out by turning on / off the pumps, and it is controlled by a temperature sensor, which has two pairs of contacts.

If the water in the tank is colder than the one set on the sensor, the power circuit of the circulation pump in the boiler circuit is turned on. When the specified degree of heating is reached, the contacts of the pump are closed, which drives the coolant into the heating system.

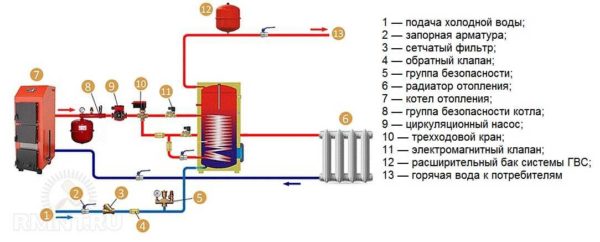

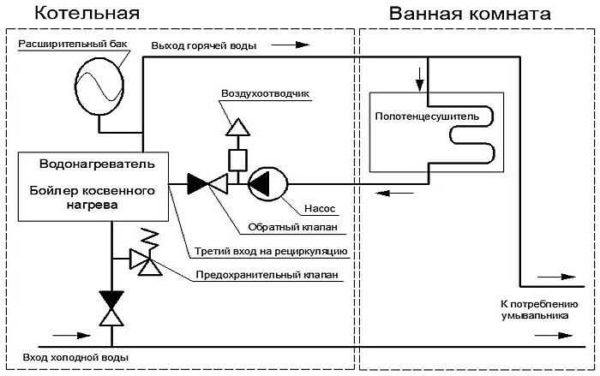

Scheme for a non-volatile boiler

In a scheme with a non-volatile boiler, in order to ensure the priority of the boiler, it is desirable that it be higher than the radiators. That is, in this case, the installation of wall models is desirable. Ideally, the bottom of the indirect water heater is above the boiler and radiators. But this arrangement is not always possible.

The circuits will also work when the boiler is located on the floor, but the water will heat up more slowly and in the lower part it will not be hot enough. Its temperature will be comparable to the degree of heating of the return pipe, that is, the supply of hot water will be less.

With non-volatile heating, the movement of the coolant occurs due to the force of gravity. In principle, it is possible to connect an indirect heating boiler according to the traditional scheme - with a circulation pump in the circuit for heating it. Simply in this case, with the electricity off, there will be no hot water. If you don't like this turn, there are several schemes that will work with gravity systems.

When implementing this scheme, the circuit that goes to the water heater is made with a pipe with a diameter of 1 step larger than the heating one. This is what gives priority.

In this scheme, after a branch to the heating system, a thermostatic head with a clamp-on sensor is installed. It runs on batteries and does not require external power. The desired temperature of water heating is set on the regulator of the thermal head (not higher than the temperature at the boiler supply). While the water in the tank is cold, the thermostat opens the supply to the boiler, the flow of the coolant goes mainly to the boiler.When heated to the required degree, the coolant is redirected to the heating branch.

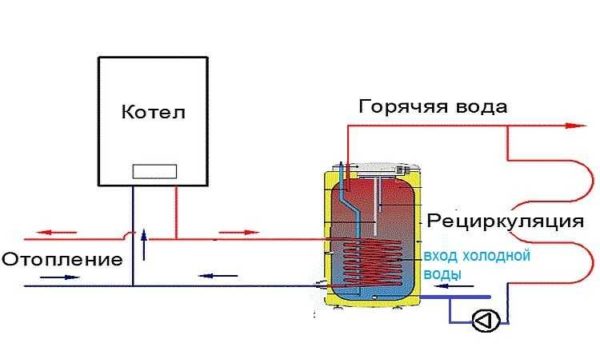

With heat transfer medium recirculation

If available in the system water heated towel rail constant circulation of water through it is necessary. Otherwise it won't work. All consumers can be connected to the recirculation loop. In this case, hot water will constantly be chased around by a pump. In this case, by opening the water at any time, you will immediately receive hot water - you will not need to wait until cold water drains from the pipes. This is a positive point.

The negative is that by connecting recirculation, we increase the cost of heating water in the boiler. Why? Because running along the ring, the water cools down, therefore the boiler will often be connected to heating the water and spend more fuel on it.

The second drawback is that recirculation stimulates mixing of water layers. In normal operation, the hottest water is at the top, from where it is fed to the DHW circuit. With stirring, the overall water supply temperature drops (at the same settings). Nevertheless, for a heated towel rail, this is perhaps the only way out.

How to implement the connection of an indirect heating boiler with recirculation? There are several ways. The first is to find special indirect devices with built-in recirculation. It is very convenient - the heated towel rail (or the entire loop) is simply connected to the corresponding pipes. But the price of such options for water heaters is almost twice as much as the price of an ordinary tank of the same volume.

The second option is to use models that do not have an input for connecting a recirculation circuit, but connect it using tees.