The device and principle of operation of self-priming pumps

Pumps are used to supply water to the house or water the garden. They are of different types and designs, and each of them finds its own field of application. If you need an inexpensive and reliable device for pumping water from a well, log or some kind of container, pay attention to a self-priming pump. These are relatively inexpensive devices that are installed on the surface, they can pump water from a fairly decent depth - 8-9 m. If necessary, the models are supplemented with ejectors, then the suction depth increases to 20-35 m.

The content of the article

Self-priming pumps: device and types

Self-priming pumps pump water from a depth of 8-9 meters, while they themselves are on the surface. Water rises due to the fact that in the central part of the body, due to the movement of the wheels with blades, a low pressure area is created. In an effort to fill it, the water rises. So it turns out that the pump sucks in water.

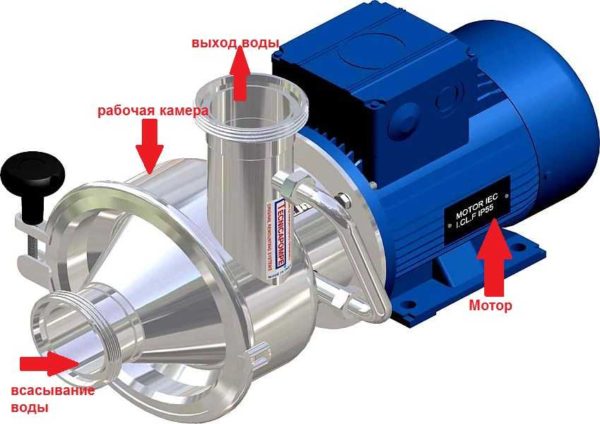

Like any other pump, a self-priming pump consists of a motor and a working chamber in which the delivery mechanism is located. The pump and motor shafts are connected through a coupling, the connection reliability and tightness is determined by the type of seal. There are two types of seals:

- stuffing box - cheaper and less reliable;

- face seal - more reliable, but expensive.

There are models of self-priming pumps with magnetic couplings. They do not require seals, since they do not have through connections. This is by far the most reliable design, but also the most expensive one too.

Structure and principle of operation

According to the mode of operation, a self-priming pump can be vortex and centrifugal. In both, the impeller is the key link, only it has a different structure and is installed in a housing of a different shape. This changes the principle of work.

Centrifugal

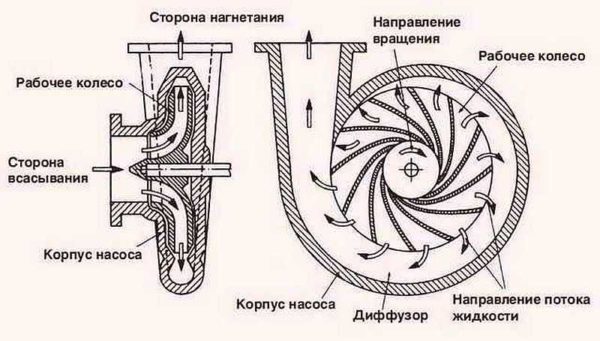

Self-priming centrifugal pumps have an interesting structure of the working chamber - in the form of a snail. Impellers are fixed in the center of the body. The wheel can be one, then the pump is called single-stage, there can be several - multi-stage design. Single-stage ones always work at the same power, multi-stage ones can change the capacity depending on the conditions, respectively, they are more economical (less power consumption).

The main working element in this design is a wheel with blades. The blades are bent in the opposite direction to the movement of the wheel. When moving, they seem to push the water, squeezing it to the walls of the case. This phenomenon is called centrifugal force, and the area between the blades and the wall is called the "diffuser". So, the impeller moves, creating an area of increased pressure on the periphery and pushing the water towards the outlet.

At the same time, a low pressure zone forms in the center of the impeller. Water is sucked into it from the supply pipeline (suction line). In the picture above, incoming water is indicated by yellow arrows. Further, it is pushed by the impeller to the walls and, due to the centrifugal force, rises up. This process is constant and endless, repeating as long as the shaft is spinning.

There is a drawback associated with the principle of operation of centrifugal pumps: the impeller cannot create centrifugal force from the air, therefore, the casing is filled with water before operation. Since the pumps often operate in an intermittent mode, so that water does not flow out of the case when stopped, a check valve is installed on the suction pipe.These are the features of the operation of self-priming centrifugal pumps. If the check valve (it must be required) on the supply pipeline is at the bottom, the entire pipeline has to be filled, and this will require more than one liter.

| Name | Power | Pressure | Maximum suction depth | Performance | Body material | Connecting dimensions | Price |

|---|---|---|---|---|---|---|---|

| Caliber NBTs-380 | 380 watts | 25 m | 9 m | 28 l / min | cast iron | 1 inch | 32$ |

| Metabo P 3300 G | 900 watts | 45 m | 8 m | 55 l / min | cast iron (stainless steel drive shaft) | 1 inch | 87$ |

| ZUBR ZNS-600 | 600 watts | 35 m | 8 m | 50 l / min | plastic | 1 inch | 71$ |

| Elitech HC 400V | 400W | 35 m | 8 m | 40 l / min | cast iron | 25 mm | 42$ |

| PATRIOT QB70 | 750 watts | 65 m | 8 m | 60 l / min | plastic | 1 inch | 58$ |

| Jileks Jumbo 70/50 H 3700 | 1100 Wt | 50 m | 9 m (built-in ejector) | 70 l / min | cast iron | 1 inch | 122$ |

| BELAMOS XI 13 | 1200 watts | 50 m | 8 m | 65 l / min | stainless steel | 1 inch | 125$ |

| BELAMOS XA 06 | 600 watts | 33 m | 8 m | 47 l / min | cast iron | 1 inch | 75$ |

Vortex

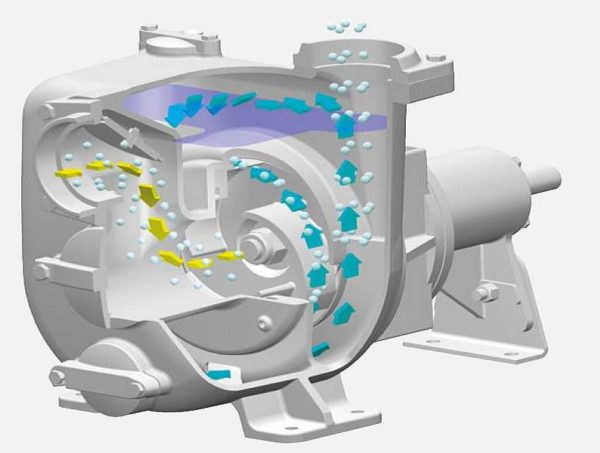

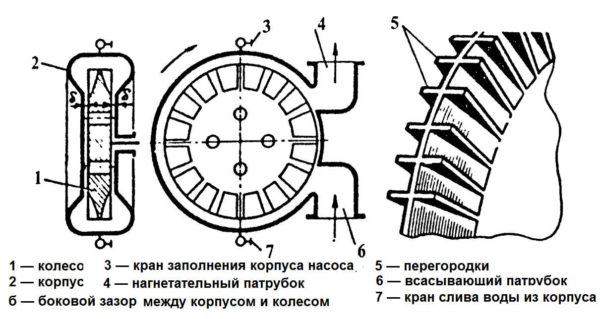

The vortex self-priming pump differs in the structure of the housing and the impeller. The impeller is a disc with short radial baffles located along the edges. It is called an impeller.

The body is made in such a way that it quite tightly covers the "flat" part of the impeller, and a significant lateral clearance remains in the area of the baffles. When the impeller rotates, the water is carried away by the bridges. Due to the action of centrifugal force, it is pushed against the walls, but after some distance it again falls into the zone of action of the partitions, receiving an additional portion of energy. Thus, in the gaps, it also twists into vortices. It turns out a double vortex flow, which gave the name to the equipment.

Due to the peculiarities of their work, vortex pumps can create a pressure 3-7 times more than centrifugal ones (with the same wheel sizes and rotation speed). They are ideal when low flow and high pressure are required. Another plus - they can pump a mixture of water and air, sometimes even create a vacuum if they are filled with only air. This makes it easier to start up - no need to fill the chamber with water or just a small amount of it. The disadvantage of vortex pumps is low efficiency. It cannot be higher than 45-50%.

| Name | Power | Head (lifting height) | Performance | Suction depth | Body material | Price |

|---|---|---|---|---|---|---|

| LEO XKSm 60-1 | 370 Wt | 40 m | 40 l / min | 9 m | cast iron | 24$ |

| LEO XKSm 80-1 | 750 watts | 70 m | 60 l / min | 9 m | cast iron | 89$ |

| AKO QB 60 | 370 Wt | 30 m | 28 l / min | 8 m | cast iron | 47$ |

| AKO QB 70 | 550 watts | 45 m | 40 l / min | 8 m | cast iron | 68 $ |

| Pedrollo PKm 60 | 370 Wt | 40 m | 40 l / min | 8 m | cast iron | 77$ |

| Pedrollo PK 65 | 500 watts | 55 m | 50 l / min | 8 m | cast iron | 124$ |

Ejector

The greatest depth from which surface vortex and centrifugal pumps can lift water is 8-9 meters, often it is located deeper. To "get" it from there, an ejector is installed on the pumps. This is a tube of a special shape, which, when water moves through it, creates a vacuum at the inlet. So such devices are also self-priming. A self-priming ejector pump can lift water from a depth of 20-35 m, and this is more than enough for most sources.

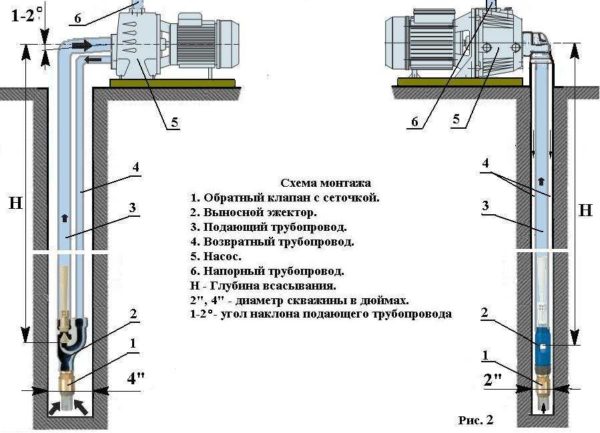

Remote ejector connection diagram for wells of different diameters - two-inch on the right, four-inch on the left

The disadvantage is that in order to ensure operation, part of the understood water must be returned back, therefore, the performance is significantly reduced - such a pump can provide not very large water consumption, but no less electricity is spent to ensure operability. When installing the injector into a well or a well of sufficient width, two pipelines are lowered into the source - one supply with a larger diameter, the second, returnable, smaller. An ejector is connected to their outputs, and a filter and a check valve are installed at the end. In this case, the disadvantage is also obvious - double pipe flow, which means a more expensive installation.

In small-diameter wells, one pipeline is used - the supply, and instead of the return one, the well casing is used.Thus, a rarefaction zone is also formed.

Vortex and centrifugal - comparison and scope

Common features first:

- maximum suction depth - 8-9 meters;

- installation method - superficial;

- there must be a pipe or a reinforced hose on the suction pipe (do not install a regular hose, it will be flattened by negative pressure).

Now about the differences between vortex and centrifugal models. Vortex pumps are more compact, cost less, but generate more noise during operation. Centrifugal - quieter, they create little pressure at the outlet. Vortex with the same impeller size and speed of rotation can create pressure 3-7 times more. But it cannot be said that this is their advantage - far from always a great pressure is required at the exit. For example, it is not needed when watering the garden and vegetable garden. High pressure water will simply wash out the soil and expose the roots. Therefore, it is better to take a self-priming centrifugal pump as a pump for irrigation.

High outlet pressure may be required when organizing a water supply system at home. This is where the characteristics of vortex pumps are required. They only have one drawback: they cannot provide a high flow rate. So more often for these purposes they use the same centrifugal, but paired with hydroaccumulator... True, then it turns out already pumping station.

The main disadvantage of surface centrifugal self-priming pumps is the need to fill them with water before starting. Not the most enjoyable activity that adds to the hassle of using such a water pump.