Pumping station malfunctions and their elimination

Permanent pressure in the water supply system of a private house is usually created using a pumping station. It is clear that it is better if it works without problems, but breakdowns do occur periodically. To quickly restore the water supply and save on services, you can repair the pumping station with your own hands. Most of the breakdowns can be repaired on their own - you don't have to do anything super complicated.

The content of the article

The composition of the pumping station and the purpose of parts

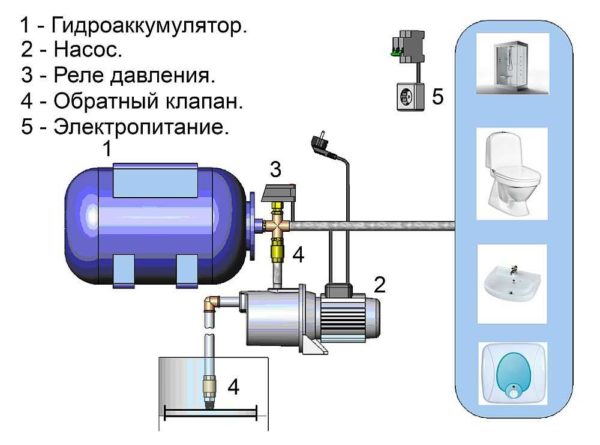

A pumping station is a collection of individual devices interconnected. To understand how to repair a pumping station, you need to know what it consists of, how each part works. Then troubleshooting is easier. The composition of the pumping station:

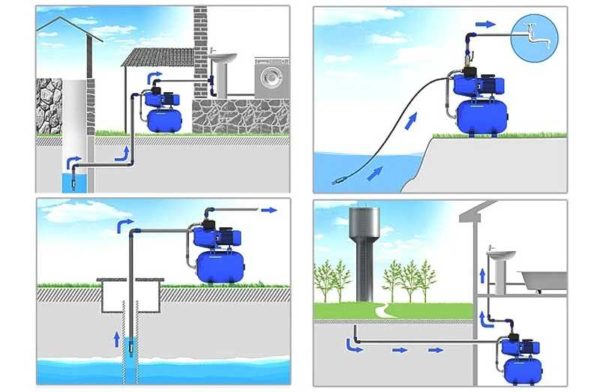

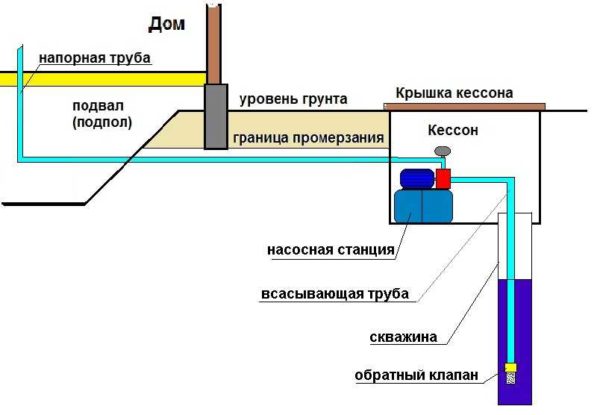

- Submersible or surface type pump. It pumps water from a well or well, maintains a stable pressure in the system. It is connected to the house with pipes.

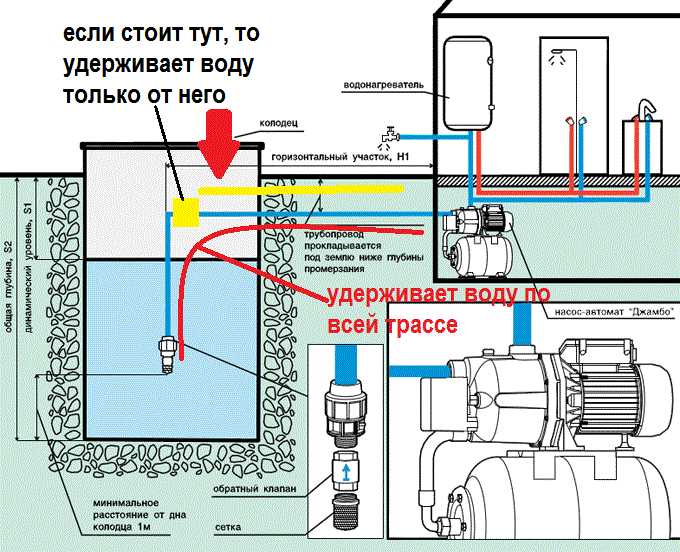

- A check valve is required on the pipeline. It prevents water from flowing from the pipes back into the well or well when the pump is turned off. It is usually installed at the end of a pipe dipped in water.

- Hydraulic accumulator or diaphragm tank. Sealed metal container, divided into two halves by an elastic membrane. In one, air (inert gas) is under pressure, in the other, until a certain pressure is created, water is pumped. A hydraulic accumulator is necessary to reduce the number of pump starts, extend its service life. Creates and maintains the required pressure in the system and a small reserve supply of water in case of station failure.

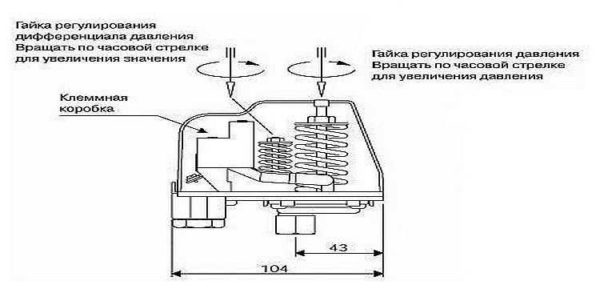

- Pumping station control and management unit. This is usually a pressure gauge and pressure switch, installed between the pump and the accumulator. A pressure gauge is a control device that allows you to assess the pressure in the system. The pressure switch controls the operation of the pump - gives commands to turn it on and off. The pump is turned on when the lower pressure threshold in the system is reached (usually 1-1.6 atm), it is turned off when the upper threshold is reached (for one-story buildings 2.6-3 atm).

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of various devices.

The principle of operation of the pumping station

Now let's take a look at how all of these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) equals the upper threshold set on the pressure switch. As long as there is no water flow, the pressure is stable, the pump is off.

Somewhere a tap was turned on, water was flushed, etc. For a while, water comes from a hydraulic accumulator. When its amount decreases so that the pressure in the accumulator drops below the threshold, the pressure switch is triggered and turns on the pump, which again pumping water. It turns off again by the pressure switch when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bathtub is typed, watering of the garden / vegetable garden is on), the pump works for a long time: until the required pressure is created in the accumulator.This periodically occurs even with all taps open, since the pump delivers less water than flows out of all the points of analysis. After the flow has stopped, the station works for some time, creating the required reserve in the gyroaccumulator, then it turns off and turns on after the water flow appears again.

Problems and malfunctions of pumping stations and their correction

All pumping stations consist of the same parts and their breakdowns are mostly typical. It makes no difference whether the equipment is Grundfos, Jumbo, Alco or any other companies. Diseases and their treatment are the same. The difference is in how often these malfunctions occur, but their list and causes are usually identical.

The pumping station does not turn off (does not gain pressure)

Sometimes you notice that the pump has been running for a long time and will not turn off in any way. If you look at the pressure gauge, you can see that the pumping station is not gaining pressure. In this case, the repair of the pumping station is a long matter - you will have to sort out a large number of reasons:

- In a well or well no water... If this is indeed the case, this situation is called "dry running" and threatens that the motor will burn out. The water pumped by the pump is used to cool the motor. There is no water, it overheats and burns out. To protect against such a situation, a special protection: water level sensors (float and electric).

- High resistance of the suction line (long length with small pipe diameters) or air leaks (connection leaks).

- To eliminate highway influence, lower the suction tube into the barrel next to the pump. If the pressure rises normally, the route is to blame and you need to either seal it at the joints, or lay thicker pipes or straighten the existing one (fewer elbows and joints).

- To check the tightness suction line, after turning off the station, observe the pressure gauge for a while. If the pressure drops when the taps are closed, there is a leak in the system. If not, the system is sealed.

- Clogged filter on a pipe or check valve... They are taken out, cleaned, checked for performance, lowered into place and carried out a test run.

- Another possible reason that the pump does not turn off is a pressure switch malfunction or an incorrectly set pump shutdown limit:

- The pressure limit at which the pump should turn off is too high, the pump is simply not able to build up the required pressure. Then we carry out pressure switch adjustment (lower the shutdown limit).

- Check relay contacts - clean them from scale (dark plaque) with very fine sandpaper (you can use a nail file).

- Eliminate the failure of the pressure switch by cleaning it (remove salts on the adjustment springsand clean the inlet and outlet). Only carefully, the membrane at the inlet cannot be damaged. If that doesn't work, a replacement is required.

If the shutdown limit of the pressure switch is much lower than the maximum pressure that the pump can create, and for some time it worked normally, but then it stopped, the reason is different. Perhaps at the pump the impeller worked... Immediately after the purchase, he coped with it, but in the process of operation the impeller worn out and "now there is not enough strength." Repair of the pumping station in this case is the replacement of the pump impeller or the purchase of a new unit.

Another possible reason is low mains voltage... Maybe the pump is still running at this voltage, but the pressure switch no longer works. The solution is a voltage regulator. These are the main reasons that the pumping station does not turn off and does not gain pressure.There are quite a few of them, so the repair of the pumping station may be delayed.

Pumping station repair: often included

Frequent pump starts and short intervals of its operation lead to rapid wear of the equipment, which is very undesirable. Therefore, the repair of the pumping station must be carried out immediately after the detection of a "symptom". This situation occurs for the following reasons:

- Accumulator volume too small... When choosing a pumping station for home and summer cottage often take a small volume accumulator - 24 liters or 32 liters. This is very small, since the water supply in such tanks is only 30-50% of its total volume, that is, only 7-12 liters of water can be pumped into a 24-liter tank. Naturally, such a volume of water is consumed very quickly, which is why the pump turns on often. The method of treatment is the installation of an additional accumulator (it is connected in parallel to the already installed one).

- Incorrectly set pressure switch limits. To avoid this situation, you can increase the delta (the difference between the pressure to turn off and turn on the pump) and thereby lower the threshold for turning on the pump (optimally 1-1.5 atm). One important point: the pressure at which the pump turns on should be 0.2 atm lower than the pressure in the accumulator. The pumping station can often turn on just due to the fact that pressure in the accumulator is lower than the set pump activation threshold... Because:

- Checking the pressure in the accumulator... To do this, remove the plastic cover, under it is a nipple (like a bicycle). We connect the pressure gauge, check the pressure. It is usually in the range of 1-1.5 atm. We bleed or pump (with a bicycle or car pump screwed to the same nipple) so that it is normal.

- We adjust the pressure switch. Having picked up the parameters, you should get a normally working system.

- Clogged check valve... If the valve does not shut off the water, it leaves the system, the pressure drops, the pump turns on. The frequency of switching on is about 10-20 minutes. Output - check and clean the non-return valve, replace if necessary.

- Also, the reason may be damage to the accumulator membrane... At the same time, in addition to the frequent switching on of the pump, water is also supplied in jerks: when the station is operating with a high pressure, when it is turned off, the pressure immediately drops. In this case, there are two options - the membrane itself or the fold has leakedwhich secures it to the body. In either case, you will have to disconnect the accumulator and change the faulty part.

- Its one reason for the frequent operation of the pump and the supply of water irregularly is a broken spool in the upper part of the accumulator... To replace it, you will have to remove the accumulator, remove the membrane and replace the nipple.

Now you know why the pumping station is often turned on and what to do about it. By the way, there is another possible reason - pipeline leakage or some kind of connection, so if all of the above does not apply to your case, check if the joint is flowing somewhere.

Air in water

A small amount of air in the water is always present, but when the tap starts to "spit", it means that something is not working properly. There may also be several reasons:

- The mirror of the water went down and the pump pulls water in half with air. The solution in this case is simple - to lower the branch pipe or the pump itself below.

- The pipeline became leaky and air enters through one or more connections. Elimination - checking connections and restoring tightness.

The pump station does not turn on

The first thing to check is voltage. Pumps are very demanding on voltage, at low voltage they simply do not work.If everything is normal with the voltage, things are worse - most likely the motor is faulty. In this case, the station is carried to a service center or a new pump is installed.

Other reasons include a malfunction of the plug / socket, the cord is frayed, the contacts burnt / oxidized at the point where the electric cable is attached to the motor. This is something you can check and fix yourself. More serious repairs of the electrical part of the pumping station are carried out by specialists.

The motor hums, but does not pump water (the impeller does not rotate)

Such a malfunction may be caused by low voltage in the network... Check it, if everything is normal, let's move on. It is necessary to check whether it has burned out capacitor in terminal block... We take tester, check, change if necessary. If that's not the reason, let's move on to the mechanical part.

First, it is worth checking if there is water in the well or well. Next, check the filter and check valve. Maybe they are clogged or faulty. Clean, check the functionality, lower the pipeline into place, start the pumping station again.

If that doesn't work, the impeller may have jammed. Then try turning the shaft manually. Sometimes, after a long downtime, it "sticks" - it becomes overgrown with salts and itself cannot move. If it was not possible to move the blades with your hands, the impeller may be jammed. Then we continue the repair of the pumping station by removing the protective cover and unblocking the impeller.

Some types of repair work

Some do-it-yourself pump station repair steps are intuitive. For example, it will not be difficult to clean a check valve or filter, but it can be difficult to replace a membrane or a bulb in a hydraulic accumulator without preparation.

Replacing the "pear" of the accumulator

The first sign that the membrane has been damaged is frequent and short-term switching on of the pumping station, and the water is supplied in jerks: either a strong pressure, or a weak one. To verify that the case is in the membrane, remove the plug on the nipple. If not air, but water comes out of it, then the membrane has broken.

To start repairs hydroaccumulator, disconnect the system from the power supply, release the pressure - open the taps and wait for the water to drain. After that, it can be turned off.

Further, the procedure is as follows:

- We loosen the flange fastening at the bottom of the tank. We are waiting for the water to drain.

- We unscrew all the bolts, remove the flange.

- If the tank is 100 liters or more, unscrew the membrane holder nut in the upper part of the tank.

- We take out the membrane through the hole in the bottom of the container.

- We wash the tank - there is usually a lot of rusty sediment in it.

- The new membrane should be exactly the same as the damaged one. We insert a fitting into it, with which the upper part is attached to the body (we tighten it).

- We install the membrane in the accumulator tank.

- If so, install the diaphragm holder nut at the top. If the tank is large, you cannot reach it by hand. You can tie the holder to a rope and so set the part in place by screwing a nut.

- We tighten the neck and press it with a flange, install the bolts, sequentially tightening them several turns.

- We connect to the system and check the work.

Replacement of the pumping station membrane is completed. It's a simple matter, but you need to know the nuances.

Hello! Recently we drilled a new well, bought a new pump, installed and connected (master), but on the same day the pump began to behave incomprehensibly. The pressure is good at first, then it drops and a thin trickle barely flows, after 7 seconds the pump turns on and the pressure is good again. The pump switches off quickly. I looked at what pressure the pump turns on and at what pressure it turns off. They opened the tap, the pressure drops at first smoothly, then at 1.2 it drops sharply to 0 and the pump turns on. The tap was turned off. Quickly dials 2.8 and turns off. Then they opened the tap again, again it decreases smoothly to 1.2 and sharply to 0, the pump did not turn on. There is no water in the tap. He turned off the tap. He turned on the tap in the toilet and the pump turned on. What could be the reason? Pump 2 weeks, well 3 days. Cum pump CAM 40/22 HL

Hello! Do you have a pumping station and have a hydraulic accumulator? If yes, then you need to check if the filter is clogged, then the pressure switch and its settings (read here), check the integrity of the accumulator membrane.

Good day!

Question; The well surface pump has been operating at normal rates since the beginning of the season. mode. A couple of days ago, it began to heat up and turn off. It worked for 2 minutes. and turned off for 10. Now, when heated, it works for 2-3 seconds, and turns off. The neighbor advised to remove the heating relay and connect directly, which he did. Now it does not pump water at all, they tried to manually pump it (although there was no dismantling, the check valve is new) pressure just barely, what to do? Pump BTS 1.1 I don't understand, but maybe we disconnected something wrong?

Hello. The pump began to hum differently. With a whistle. What could be the reason? Kapkt motor? It seems to pump water

the pressure switch needs to be adjusted

Hello, the station has recently started dispensing hot water, what could be the problem? Tell me please! thanks in advance

Hello! A very atypical situation. It is necessary to check all electrical components and especially the pump. Maybe he gets warm during work. It is hardly capable of heating a large volume of water, but still. It is also possible that somewhere along the route you have a heat source ... maybe the heating route passes nearby? No other ideas ...

your station is not disconnected.

Hello. The problem is this. Recently, the station has been working normally for some time, but then the water stops flowing and the pump does not pump. It starts pumping again and gaining pressure only after turning off / on the network. The station was purchased 2 months ago.

Check the pressure switch, the pump may be triggered by overheating (the power is selected incorrectly), the contacts could weaken (check, you can clean and tighten), and the filter could become clogged.

Good day.

When opening the taps on the 2nd floor, there is no pressure. Water flows out slowly. After 2-3 minutes, a click of the switch is heard at the bottom and the pressure gradually increases. When the taps on the ground floor are opened, the station turns on immediately.

Another symptom - before the click of the switch, there is a rather long "growl" of the hydraulic tank.

I would be very grateful for your consultation.

You need to raise the pressure in the hydraulic tank and change the pressure switch settings. Increase little by little until it works more or less normally, but you should not exceed the recommended parameters of the hydraulic tank.

When the pressure rises, the station stops shutting down. The pressure is less than one ...

Please tell me…. Why does it shock ... When the water is on

It's hard to say, you have to figure it out on the spot. Perhaps the reason is in the electrical part of the pumping station, but not only.If you do not understand the electrician, call a specialist. Anything can be. Just don't wait - the situation is dangerous.

Most likely, the ground wire is not connected either to the pump or at the power source (outlet, junction box, etc.)

Good evening. The station began to turn off every other time. It turns on and off normally, then it buzzes, water runs from the tap in different ways: either under pressure, then it barely flows out, then it spits. You unplug it from the outlet, after a couple of hours you turn it on and runs normally and turns off, then again the same story.

It looks like the pumping station is sucking in air somewhere. Check first the water level in the well or borehole. If not, the track has become leaky. The pressure switch can also go awry.

Hello. Please help me figure out the problem. The station shows that there is pressure in the system, but water does not flow from the tap. All connections were checked, the tap is also in order. What could be the reason? Thank you in advance.

Is there water in the accumulator? Maybe the pressure gauge is lying? And you also need to check the pressure switch, and the filters may be clogged.

The same problem, the pressure gauge shows pressure, the accumulator is empty, the pump is working, where to look?

Good afternoon, when you open the tap, the pump turns on immediately, what could be?

Pressure switch set incorrectly. Read about its adjustment here.

The accumulator membrane may have broken. Check - try to bleed the air a little, if water flows out - then the membrane is torn and you need to change it. In this case, there is no pressure reserve and the station starts to work as a simple water pump.

Hello. Vortex pumping station, but a submersible pump pumps water (I don't know the brand). That is, all the electronics work at the pumping station and from it the wires are connected to the pump in the well, the pump at the station itself is simply turned off (such a system due to a deep well). The water stopped flowing, looked at the station, the pressure was "0", no "vital" reactions. I checked the outlet, there is voltage. I myself do not understand all this at all, what are the possible causes of the problem? Thank you in advance.

The first thing to check is the pump. Does he show signs of life at all? Maybe there is no food on it? That is, the cord is damaged somewhere, or maybe it burned out. If everything is normal with the pump, watch the track, then everything in order: hydraulic accumulator (there is here), pressure switch (setting is described here). In general, first check the power cords so that they do not fall off or mice chew on them.

Good day! Please help me figure out the problem! Private house, two floors. Pumping station, well 10 meters. Roughly from the beginning of winter, the following began to happen. We turn on the water, especially on the second floor, and the water pressure practically disappears within 3-4 minutes. Then the pump builds up pressure for a very long time. 5-7 minutes. On the ground floor, the situation is better, but the same thing, the pressure disappears. There are no jerks of water. The pressure in the accumulator is normal. After the pump there is a cleaning system (deferrization column)

Have you checked the filter? If it pumps for a long time, the filter may be clogged, and you also need to check the check valve and pipes from the filter / to the filter. It doesn't look like air leaks along the highway, but as an option ...

After the pump has pumped up pressure is everything working properly? Those. does the problem appear after a long downtime? If so, I would still check the check valve and connections. I had something similar with the Jileks pumping station.The check valve is installed at the station itself, since the well is a plastic pipe with a diameter of only 32 mm. So, the problem was in the connection between the check valve and the pipe. He cured it with silicone sealant.

Hello! I had such a problem a week ago. The muddy orange water ran after the night. This water was lowered about a bucket. It was adjusted and flowed normally. The tap was turned on this morning and there is no water. and turned it off again so we did it 2 times. in an hour I plugged it in and it started working in the same mode. climbed into the well the water did not freeze and is normal. what is it

Hello! Check filter and non-return valve.

The pumping station does not supply water to the accumulator. The pressure in the tank is about 1.6 atm. In the pipeline, the water does not go away. What is the reason I do not know. Yesterday I worked normally until lunchtime, and in the afternoon the pressure went off and the pump went dry for some time. Today I checked everything, but the water does not come. What to do?

Apparently, the matter is in the pump - it cannot develop the required pressure. You can try to revive it ...

How?

Hello, such a problem, when you turn on the pumping station buzzing, but the water does not move, took off the water intake pipe, leaning his palm against the pump, his palm sucks somehow, you can say it doesn't suck! What is the problem?

It looks like the sediment is out of order.

Hello Admin, if you have any ideas, I ask for help. Such a situation, the electric motor burned out, sent it in for repair, they did everything, put it back to the station, but there is no pressure, the water seems to flow, but slowly. Thought air leaks, changed the connections on the suction pipe, did not help. Turning the relay - the same trouble. The accumulator is normal, there is air. What could be wrong with her, maybe what fresh ideas are there? I don't know what else to do. In the comments you write to check the filter, the question is, what is after the station in the pipeline, or is there a filter in it ?.

The filter is on the suction line. Maybe in a well / well, there are usually no filters in the station itself. Are you sure the motor was rewound properly? To determine the area of the problem, disconnect the suction pipeline, connect the hose, lower its other end into a large container of water (the volume must be greater than the capacity of the accumulator). Turn on the station for a while. If it pumps normally, the problem is in the pipeline, if not, something is in the station.

Hello there is such a problem. The pumping station is heating up, what could be? Tell me please. Speroni cam 40/22

Hello. I will not pump water into the station. cleaned the check valve. a pear a whole bought a new electric pressure relay in order without drops, pumped air into the pumping station (1.5 kg), a pipe was poured a pipe, a pipe was connected, it could not be the reason for not pumping water from the bottom

Is the pump ok? As mentioned earlier, turn off the suction pipeline, connect the hose, throw it into a container of water and see if it pumps or not. If it pumps, then the problem is either in the pipeline, or in the fact that the pump does not develop sufficient power.

and what is the role of the impeller in the pumping station

Pushes water.

Throwing a separate hose into a container with water, the pump does not pump, which may be the reason in the impeller (plastic impeller)

There may be a reason in the impeller, in a faulty winding. It looks like the pump is out of order.

Rusya, I had a similar problem with the JILEX Jumbo 70/50 pumping station - I stopped pumping water. Initially, the check valve was faulty, because of it the pump worked for a certain amount of time at idle speed. This led to the fact that the plastic suction pipe of the deflector (inside the pump housing) on which the O-ring is put on is deformed. There was no place to buy spare parts right away, so I used a regular plumbing sealant to seal the connection - the station worked properly all summer season last year. I bought spare parts, but have not installed them yet.

Hello! Tell me what could be the reason: we bought a new pumping station, connected it, first it worked, and then the motor works, but does not pump water. We changed the motor (we thought it was in it) for a new one, it didn't help, the same problem….

podskazhite.the station after the repair (replacement of the oil seal and bearing) began to pump on itself.that is, the motor is working. the pressure is gaining up to 2 atm. and everything continues to work without turning off. the water swings on a straight line and there is no pressure in the tank. pear 1.5 atm as it should be. water leaks are not observed anywhere. I don’t understand the reason.

And check the settings and contacts of the pressure switch. It should turn off / turn on the pump. Another possible reason is a hydraulic accumulator. It is necessary to check the integrity of the pear (the absence of streaks is not an indicator).

the pear is whole. the water from the nipple does not go. yes, it keeps the pressure when you pump it. well, and the relay settings, and if the water does not flow into the tank. as if there is not enough power. can the impeller get worn out? although it is not visually visible. or all the same somewhere the air is leaking ?

Let's first decide whether the pipeline or the station itself is to blame. Disconnect the pipeline, connect the hose, lower it into the water tank. If everything is normal with the station, then the problem is in the pipeline.

I looked at the flange at the end where the threaded shank is a large sink in the end. the water did not seem to drip from it, but ... it replaced the flange. now it pumps 2.5 atm. but it does not turn off. but this will already be regulated by the pressure switch. probably the reason was in the flange ...

It's good that you found a reason and thanks for unsubscribing. Others may come in handy too.

Thanks. I'll try tomorrow.

The water in the tap runs out, then the pump is pumped, the pump will run, the water will run in 5 minutes again, and the same story is the problem?

There can be many reasons. The first thing that comes to mind is a pressure switch. But there may be a pear in the accumulator, a dirty filter, air leaks on the highway or at the junction of the station.

The vectorpump 5081 tire JI100 pumping station stops working the motor if there is no voltage network pulling out of the socket for a while and it starts working again because of a weak voltage, before there was another pump that always worked with a bad voltage but did not turn off the relay was constantly buzzing until the relay knock and here a new one does not turn on and then apyat turns on and lives its own life

Hey. the station is ok but - changed the pear, the relay unit, now it turns on, it pumps but does not gain more than 1.5 points, it does not turn off. I turn off the current, then it stops. the impeller is normal. put a new relay, there is no sense in the adjustment. what to do? so I change stations every two years. expensive.

Generally power off - the function of the pressure switch - over the upper limit.If your station does not gain the set pressure limit (set by twisting a large spring), then it will not turn off. And it can not gain pressure due to insufficient pump power, leaks somewhere on the highway or inside the station, a poorly working check valve. These are only obvious reasons. There are also more intricate ones.

Hello. I bought a pumping station alco 3000 classic. worked for a month and ran water from the holes of the pressure switch, from where the wires exit

If under warranty - hand over, if not - remove the relay and see what is wrong there. Well, or just replace it.

Good day! The problem is as follows.

The pressure in the tap is kept for about 30 seconds, more or less normal, then slowly drops, to the point that the gas column goes out - it does not have enough pressure. After, the pressure starts to rise slowly. On the pump pressure gauge, the pressure when turned off is 2.8 atm., It turns off normally. The pressure in the pear is 1.5 atm. What could be the reason for this drop? Why isn't there constant pressure? There is no filter, there is nothing to clog.

You can look at the check valve, then - if there is an air leak on the track or at the assembly points of the station itself, check if the accumulator is leaking (maybe not only a pear, but also a flange).

Good afternoon, please tell me, I have been using the pump wells for three years now and the other day there was a problem that when the taps are turned off, the pressure does not stay at the proper level and the pump turns on every 1-2 minutes and after gaining the required pressure turns off and so every 1-2 minutes and after turning off it began to hiss. The nipple is normal, the pressure in the accumulator is also. What is the trouble?

Look at the check valve. Maybe it's clogged, maybe the membrane has stopped holding. There may still be a leak somewhere along the highway.

Please tell me, our motor is running, but it is not gaining pressure and there is no pressure from the tap.

In your case, there may be a lot of reasons. Defective accumulator, problems with the tightness of the pipeline, the check valve does not work.

Good day. I need the help of a specialist! Eight years ago they drilled a well. Specialists installed the Unipump station (Aquarebot). Two years ago she died. I did not grieve and bought the same one again, but the new one does not have a pressure gauge or adjustment springs. automatics only a capacitor and microcircuits. About six months ago, when the Geyser filter tap was opened, the station stopped turning on. Opening the "vent valve", the station turned on and worked. Last night, it stopped turning on completely ... then it turns off. Itself does not turn on until you turn it off again from the outlet. The station has protection against "dry running", I thought that it would not work. I disassembled the station: I threw away the chip of this sensor, washed the check valve, it holds it. I did not find it. In the pear, the pressure is normal, the water does not flow through the spool. The contacts are like new, I tightened it up a little. I just didn't think to check the voltage ...

My thoughts are: since water does not flow from the pear, then the pear is intact. Once, when the power is turned off / on, the station starts up and pumps water, then the filter is not silted up and there is no air leakage. The motor is working properly. But commanding the motor does not work properly ... And guilty , in my opinion, this is the control unit.

Well, I kind of described everything as it was. I would be grateful for some practical advice.

how to change the capacitor in the terminal block ??

Hello! I connected the station after winter storage. It seems to have begun to swing, but it turns on once every 30 seconds. The pressure keeps. What could be the reason? Thank you.

It looks like somewhere there is an air leak (maybe the check valve does not yet hold) or problems with the accumulator (maybe the flange is not tight). To determine a problem on the track or in the station itself, disconnect the track, connect a hose to the station entrance, and into a barrel of water. Pump up, look. If the pressure does not drop, there is a line or check valve problem. If it falls, look in the station.

Good afternoon, question, the pump is collecting water. then, as the water runs out, it does not immediately begin to gain, but only after a few minutes.

Good afternoon. It looks like the problem is with the time relay. Try to tweak it, clean your contacts ...

The pump did not survive the winter.

Pour water through the discharge (at the top of which) water hole, it gurgles out through some kind of gap. Usually in such cases they say "the pump is inflated".

This once happened to me, and the "bloat" was visible to the naked eye, I bought a new pump.

Now the swelling is not visible to the eye.

The question is, what to do, is it possible to replace the pump cover (casing)? Or do you need to change the rubber seal?

Who can help with this?

With thanks.

Change the check valve

Gentlemen, advice is needed. I describe the situation.

Pumping station in the country. Installed after wintering in the garage. The pipelines are connected. The pressure switch is completely loose. Power contacts are closed. The pressure in the hydro-accumulator is 1.6. We turn on the machine. Next interesting things happen. The pump runs EXACTLY 15 sec. and turns off! Drives water. The pressure in the pipeline creates. In this case, the pressure switch, as it was closed, remains. Re-activation is possible ONLY by juggling the machine. And again: 15 seconds and stop. The pressure switch is silent.

Where to dig? Tell me?

At the pump outlet there is a plastic sleeve, to which two thin wires fit.

Is this some kind of protection? Maybe it affects?

Good day! Please help me solve the problem! I have a Whirlwind pumping station. Everything worked fine, but recently I noticed that the hose coming from the pump to the accumulator began to leak. I changed it to a new one. After assembly, as usual, he poured water into the pump through the hole at the top and turned on the pump, but it stopped gaining pressure to the upper limit and began to work constantly. It reaches 2.0 atm and continues to idle. There is no air in the system, I checked everything several times. Before replacing the hose, everything worked well. Help me find the reason I'm just stumped. Thank you in advance!

Maybe there is an air leak in the area of the hose attachment? Did you supply the same hose? Does its inner diameter match the old one? Also check the performance of the pressure switch. Perhaps the break contacts are clogged, stuck.

The hose is slightly larger, but not much. As for the air leak in the system, I assured by letting it out through the plug at the top of the pump, there is no air water. And about the relay, it does not work. the pressure does not reach the upper limit, but why does it not reach? That is the question!?

Maybe just a slightly larger diameter of the hose does not allow to get the required pressure a little. Reduce the trigger limit slightly. Yes .. you can still check the non-return valve ... it can slightly "bleed".

The situation is completely incomprehensible. After replacing the flange on the expansion tank with water, miracles began to happen. The pump pumps 3 atm and off it seems everything is fine, but the pressure in the taps is like 1.5. What just didn’t try the valve keeps the pressure in Akum-re there I did the connections with the sealant and flax again but there is no result

The only thing that comes to mind after replacing the flange is the native pipe that connects Akum-r and the pump does not fit, therefore, I changed it to a regular hose (taps, toilet bowl), of course, with adapters for the threads of Akum-ra and the pump, but the diameter of the hose is 2.5 times less than the original . Maybe this is the reason? Prompt !!!

Yes. Maybe this is the reason. The difference is too big. We need to find a hose with a similar diameter. Ideally, the same.

Hello, we turn on the pump, it buzzes in a completely different way, then the sound is quieter, quieter and all the sound does not work. What to do?

Hello! Check voltage. If it is normal, take the pump for repair.

Good afternoon guys!

Please consult on my problem.

The Grunfos pumping station (with a hydraulic accumulator, I don’t know the brand) stands on a well 17 meters deep

In the fall, we noticed a breakdown of the check valve (it stands on the well pipe at the top of the pump itself).

The valve was removed during the winter, the well stood with an open pipe (the water column is kept at a depth of 8 meters).

In the spring, everything was assembled with a new check valve, the station is working, but it cannot raise water, because 8m of empty pipe at the pump suction. I'm afraid the pump will burn out.

Tell me what to do?

Have you tried pouring water into the pipe? Try to run it the way new ones start - with preliminary filling of the track with water.

There is no check valve at the bottom and therefore water flows out of the pipe. The return path stands at the very station at the top

Hello. I have such a question. The station turns on together with the water, but after gaining one atmosphere, is it normal? And what could be the reasons?

Hello! This not normal. The reason for the breakdown of the pumping station may be incorrect operation of the pressure switch. First, clean the contacts, if it does not help, try replacing.

Hello! An incomprehensible situation arose. There was a 1200-watt station replaced by 900 watts (there was no other one and was suitable in terms of parameters), the new station does not even gain 1 bar! house 1-storey well 5 meters swampy area. all details working water in the pipes is filled (does not leak)

It looks like there is not enough power ... Look also, maybe there are gaps in the pipes, a check valve, maybe there is an air lock somewhere ...

Good afternoon, help solve the problem. Gorden's station has been working constantly for 8 years, but very capricious, here again it gave out a trick with which I cannot cope. The station works but does not pump water from the well, tried to pump the system forcibly with another pump, it keeps and works, but then it stops pumping water and again in a circle I start to dance, can tell me what else may be faulty. (filter clean check valve works and keeps the voltage normal ????)

Good day. There may still be problems with tightness. Check the route for leaks. Disconnect the track from the station, connect the hose, lower its other end into the barrel, turn on the station. If it works normally, there is a problem with the track (air leaks). If the problem persists, look in the station itself. It can be a pressure switch, a hydraulic tank (and not only a membrane, but also a flange).

Good afternoon, I have such a question, the pumping station is buzzing but the impeller is not spinning, at the beginning I thought that the problem was in the relay, but I tried to supply power directly bypassing the relay and the same buzzing but the motor does not spin, what could be the problem?

According to the description, it looks like a problem in the motor itself. Does the impeller turn by hand? If yes, then the motor ...

good day

pumping station Belamos XK08.Water flows at the junction of the plastic housing with the support. The gasket was replaced, missed with sealant, but water still runs. The body itself is intact.

Tell me, what could be the problem?

Good day. Perhaps the gasket is incorrectly selected, the material is not elastic enough ... Before installing a new gasket, clean the body of all dirt, degrease it. Also with gasket. Then lay and tighten well. And it is also worth looking at the case through a magnifying glass ... maybe somewhere there is micro-damage through which water seeps under pressure.

Good day. I have been using the Metabo 3300/25 G pumping station for 2 years at my dacha. I pump water from a well of 29 meters. This year I connected the station. When I turned it on, it worked, but the water did not rise. Eliminated air leakage in the well hose and connection to the pump. When water began to rise from the well, water flowed under pressure between the pump casing and the flange. Then I turned it off. Which spare part is out of order, because the engine itself is running.

Most likely a flange, but maybe a hydraulic tank. We'll have to disassemble ...

Hello! Tell me please, where does the water come from in the accumulator, if the pear is whole ???

Hello! Sometimes the flange leaks.

When water is collected and the lower pressure limit is reached, the pump does not turn on. It turns on only when the pressure drops to 0. I can not achieve normal turn on.

This is a pressure switch and its settings. Is it faulty? Have you tried to change it?

Summer resident

05/05/2017 at 12:56 - Reply

Good afternoon guys!

Please consult on my problem.

The Grunfos pumping station (with a hydraulic accumulator, I don’t know the brand) stands on a well 17 meters deep

In the fall, we noticed a breakdown of the check valve (it stands on the well pipe at the top of the pump itself).

The valve was removed during the winter, the well stood with an open pipe (the water column is kept at a depth of 8 meters).

In the spring, everything was assembled with a new check valve, the station is working, but it cannot raise water, because there is 8m of empty pipe at the pump suction. I'm afraid the pump will burn out.

Tell me what to do?

Administrator

05/07/2017 at 07:51 - Reply

Have you tried pouring water into the pipe? Try to run it the way new ones start - with preliminary filling of the track with water.

Summer resident

05/10/2017 at 12:11 - Reply

There is no check valve at the bottom and therefore water flows out of the pipe. The return path stands at the very station at the top

When the station is started, it is filled with water and the entire route from the station to the check valve. Did you do that?

The station was filled with water. But how to fill the well pipe with water if the check valve is at the pump, and not at the bottom of the well pipe?

Here's the thing ... what worries you? With this method of installing a non-return valve, every time the station was turned off, the water from the pipe was drained back ... If before the pump could lift it, now it can.

Summer resident

05/11/2017 at 16:33 - Reply

The station was filled with water. But how to fill the well pipe with water if the check valve is at the pump, and not at the bottom of the well pipe?

Administrator

05/11/2017 at 17:07 - Reply

Here's the thing ... what worries you? With this method of installing a non-return valve, every time the station was turned off, the water from the pipe was drained back ... If before the pump could lift it, now it can.

And as I understand it, before the check valve held the water column and did not let it go down (after all, this is what is needed for this), but now everything has changed, because the water has flowed out, and it needs to be raised again and then the valve will hold the post again.So the main question is how to raise the water column by 8 meters ???

The check valve passes water from the well to the pump, and blocks the return flow. That is, it keeps water in the area between itself and the station.

Good evening! We are trying to install our first pumping station CMI 1000W. Tell me, please, what could be the problem with the new station, does it work without shutting down? I had to turn it off. The water pressure in the tap is good, there is no check valve, since water enters it from a storage tank installed above it. Maybe the station itself is defective? How much does the tightness of the pipeline affect this, did you notice a few droplets in the places of some joints? It is written about the relay in the instructions that you can only increase the pressure, about the decrease - contact the service center.

Good day! Of course, leaks, even minor ones, need to be eliminated, the second is to install a check valve. Even in your case. Without it, the system does not create the necessary pressure. This is why your pump runs all the time.

Thank you very much for your advice! You helped us a lot, everything worked! True, not for long, the next day the pumping station itself leaked (((We disassembled it, did not notice anything special, the gasket was in place, tightened the bolts harder, but, unfortunately, this did not help!

Possible defective station. Better her in the service or exchange.

Good day. There was such a problem. An Abyssinian well was drilled. I put a hydrophore, pumps water, everything seems to be fine. But when it stands for half an hour, after the water has been drained and the pump has started, the pipeline becomes empty, and you have to pour water into the pump so that it can pump it again. The check valve is located directly next to the pump and has cut another one near the entrance to the well. It seems that all connections are sealed. Although I myself understand that there is most likely an air leak somewhere, I don’t know how to fix it. Can you tell me if the joints themselves can be somehow sealed, maybe what kind of sealant happens?

Hello. The Jileks Jumbo 60/35 pumping station installed in my plant worked properly for 7 years, not counting the replacement of the pear. Now an incomprehensible problem arose: the pump turns on for a second, then turns off for a split second (as if it wedges), turns on again until the set pressure is reached ... The pear is intact, there is no air leakage, the check valve is working properly, the pressure in the tap does not change during a short-term shutdown. What could be? Thank you.

Check the contacts of the electrical part and the pressure switch. May have weakened / oxidized.

Tell me please. After installing the station for water, there is a problem, the water disappears when the pump is turned on, when the pump turns off, water appears, water is drained somewhere in a bucket, water disappears

Most of all it looks like a leak in the route or a malfunction of the check valve. There may also be problems with the gyroaccumulator.

Hello. Can you please tell me how to remove the Jilex Jumbo 60/35 pressure switch? For some reason, water gets into it, and, accordingly, it does not work correctly, there is a smell of insulation. Thank you.

Hello! There are three fittings below. Two for cable entry and one for water hose.

They must be unscrewed. Just turn off the power supply first (unplug the power cord). You can view the photo here.

the pump motor runs for a minute and then turns off, then I remove the plug from the socket, put it back in and the same situation. the pressure switch works as expected, the hydraulic accumulator is normal, tell me the possible options please ...

There are only two electrical components in the pumping station: the pressure switch and the pump itself. So there is little choice - either a relay or a pump. You can check the voltage in the network - if it is low it may well be such a situation.If normal, inspect the cord, plug / socket, contacts at the point where the pump cord is connected (terminal block, contacts could oxidize, strip them to pure metal, screw in a new way). It will not help - look at the contacts of the pressure switch. They could oxidize. Then you need to remove the plaque. You can use a strip of fine-grain sandpaper, or a nail file. Just don't try too hard - until the metal is clean. No more. If everything is normal, you need to look at the pump, and this is already a problem ...

Good afternoon. Someone might come in handy. I inserted a new pear into the old one. It turned out in a "tire". Has been in service for three years, the only thing is that it changed the clamping bolts a little longer.

A good idea! It happens that the membrane (pear) breaks twice a year. Often due to the fact that somewhere on the inside of the accumulator there are protrusions and burrs on the metal. In such cases, the additional protection in the form of an old membrane clearly does not hurt.

Good day!

The crux of the matter is, after replacing the bearings and the gland, cleaning the pump chamber, removing / installing the diffuser on the AJC125 aquarium, the following pump does not work, it does not gain pressure more than 1.5 atm, and when the water tap is opened, the pump noise increases, and the jet pressure jumps more then less and this is when the pump is running. What could be the reason???

Thanks in advance

Symptoms similar to air leaks

Initially, I would start with the simplest thing - check the check valve and the tightness of the suction pipe connections. If everything is fine, then there is clearly a problem with the pump itself. Everything is clear with the oil seals, but how is the connection of the diffuser to the body sealed? If the O-ring, then it would be necessary to check its condition.

Good day! When the water is drained from the toilet tank, the pumping station turns on and after 2 seconds it turns off and immediately turns on again and so on 15-20 times until the tank is full. This began to happen recently, before it worked without shutting down until the tank was full. What is the reason? Water is pumped from the tank, which is on the same level with the station. And sometimes it turns on by itself, although the taps are all closed.

Check the pressure switch, there may still be a leak in the accumulator.

Good day!

A neighbor in the country, an elderly man, has ASV-800/19. When the starting device is turned on, the hum comes from a transformer, but the engine or pump does not work. I suppose it's an electrician. Where to look?

First check the voltage, if it is low, the pumping station may not turn on. Then look at the cord, pressure switch contacts. If everything is normal, the pump itself may have closed itself ...

Good day! Pumping station metabo hwwi 4500/25.

1) when the pump is turned on, the water goes into the house, the filter flask is emptied, while the pump works and sometimes turns off because water has left the filter flask and it takes some time to fill it. it seems that the water goes back into the well. please tell me what could be?

2) the filter flask is always fogged up and the PPR pipes too, should it be so or not?

thank you in advance!

Misted over from temperature differences. The water is probably cool. If water goes into the well, it does not hold the check valve. Check it out.

Such a problem .. the pump does not raise the pressure to the required level .. the water does not pump .. what am I doing wrong? With a column I raise water to the check valve. The valve holds. Then I pour water into the pipe and the pump .. until it starts pouring out of the hole to be filled .. I close it .. on the pump, the pressure will rise by 0.2 atm. Then it stands still and does not grow.then after 2 minutes the pump turns off .. checked the hydroacamulator from the nipple the water does not flow .. the pumps pumped air from the pipes nothing flows .. what could be the problem?

Check if the line is leaking. It looks like ... Another reason is a faulty accumulator.

Pumping station, the pump starts to pump somewhere to one and abruptly breaks down at increased speed. What is it?

hello. please tell me what to do - we have us. The vortex station worked normally for six months, then suddenly stopped. pulled out - the valve is normal, but the impeller did not turn - manually turned it. they checked everything on the ground (they pulled out the pipes from the well, replaced the valve. and pumped it over) everything was fine. they let it start pumping, but sucked in air a little. checked all the connections for sealing. it worked. Yesterday it stopped turning off, the motor is running, there is no water. We checked the impeller of the connection, everything was as it was (but for some reason there was hot water in the pump), the outlet was not connected to the house, but it pumps through the hose, but does not turn off. the pressure does not rise above 1. connected to the house - it worked without switching off, but as soon as the boiler was turned on, the water stopped flowing again (the station was running, the motor was buzzing) disconnected from the network the night stood - in the morning the water went, but after an hour it stopped again. tell me what to do? the second in a year is very expensive. thanks.

The main problem is that the station is not gaining pressure? If so, check the function of the pressure gauge. If he is not lying, check the accumulator - it can poison somewhere. If everything is in order with him, look at the pressure switch.

Good afternoon. The problem is: the water pressure is rather weak - I plugged in a pumping station and a cube storage tank in case the water is turned off. In the absence of water, the station draws water from the tank only if the tank is full. If less than half, it does not pull. It buzzes and everything. If there is even a little water in the track, it takes both from the half-empty tank and from the track, all the rules. The tank is a little higher than the pump. I was already tired of carrying buckets from the pool to the tank.

Have a question? How is the part-tube of the pumping station embedded to the tank? I assume that the hose is simply thrown over the neck. If you make a sidebar at the bottom, it will swing without problems. The second solution is to put a pump that increases the pressure (read here), but it also crashes into the track ...

Hello! The pump pumps water 2.4 into the accumulator, turns off, open the tap - the water drains slightly, from half a liter, the pressure drops to 1.4 about and that's it. The pressure gauge shows, the taps are open - there is no water, the pump does not turn on. I read all the comments - no one has this. Depth pump - stands at 43m, GA tank - 80l. What options?

Check the accumulator. It looks like the pear has leaked out.

Tell me, the pumping station, when connected to the network, emits a hum-ringing, but the engine itself does not start - accordingly it does not pump anything

Check voltage, cord. If ok, there is a problem with the pump.

Hello. Hammer flex station nst900. It worked fine. Recently a malfunction occurred after (we assume) frequent power outages. The station has a built-in filter. From under its cover, water began to break through at the moment the pump was turned off when the pressure was reached. As soon as the pump turns on again, the water stops flowing until the next shutdown of the pump. Disassembled, examined, did not notice anything suspicious. The inlet was slightly loose in the housing. After assembly, the situation has not changed. What to do is not clear.

Try to put a seal under the cover. The water must not flow. Another option is to smear it with silicone sealant, but it will be problematic to disassemble the filter.

Good evening!

The pump station does not gain pressure, even if you turn off the valve immediately after the pump.

What could it be?

Most likely a problem with the pump. But there may still be problems with the gyroaccumulator or somewhere on the suction line. Check the pump itself first. Disconnect the station from the suction line, leave everything else as it is. Connect a hose to the station inlet and lower it into the water tank. Turn on for a minute, watch. Further conclusions can be drawn.

Thank you very much!

I will definitely try it next weekend.

I will unsubscribe by the result.

The most interesting thing is that it works and does not work.

Hmm. Then you still need to check the check valves. Maybe the problem is in them.

So he is alone, at the end of the intake pipe? (Check valve) Or should it still be?

Do you have a suspicion that the problem lies with her?

It can work normally all day, and in the evening the arrow jumps around 3 and it does not turn off. You could try to twist the setting, but the pump is still under warranty.

When I open the filler plug, water comes out from there with very strong pressure, with the pump turned off.

Hello! please tell me what to do? Marina, after the rains, flooded it in the well, dried it, but it does not work, there is only a quiet hum of the motor.

It is necessary to disassemble, clean, watch ...

Hello! The pumping station pumps water from a storage tank of 100 liters, but as soon as there is half water in the tank, the station does not turn off for a long time, it works for 10-15 minutes. The capacity is below the station. Tell me what's wrong.

Is there a check valve? It looks like his antics ...

There is a check valve. Or maybe due to the fact that the storage capacity is under the station, but it should be at the level, or even above it?

The pumping station can draw water from a depth of several tens of meters, so the fact that the tank is lower should not affect its work. Check the non-return valve. It looks like it's the reason. It should let water flow in only one direction - into the house. In case of reverse flow (when the pump is turned off), the spring should press the valve and block the outflow of water.

The station does not turn on for a long time, and when it finally works, it buzzes not like before.

It is necessary to look at the power supply, the pressure switch (its contacts, which include power). If the situation does not improve, bring it to the service.

Good day. Pumping station Parma SN-1000Ch. In operation 3 months. When the pump was operating, an extraneous noise such as squealing began to appear. What is the reason and how to eliminate it?

If under warranty, it is better to carry it to the workshop. If not, try lubricating.

And how to lubricate and with what?

Hmm. Lubricate with machine oil, for example, and where - in rubbing parts. More specifically, not to say in absentia - you need to look at the design of the pump. If you have no idea at all where and what ..., take it for repairs. Shouldn't take a lot ...

Hello, I have such a problem in the system, the pressure of the hydraulic tank has abruptly ceased to press, the tank has removed all the norms, the rdm and the membrane have been cleaned, when the pump is turned on, the pressure reaches 2.4 and turns off, then you open the tap, the pressure drops gradually to 1.9 and then sharply in a second to 1 and the submersible pump is on and when the pump is on, there is no pressure in the tap. Voltage norm.The pump separately pumps water to the garden as usual with high pressure.

And I forgot to add pressure to the hydraulic tank pumped up 1.6-1.8

Hello! And yet it looks like damage to a hydraulic accumulator. Maybe not a pear, maybe the flange has lost its elasticity ... You can also look at the pressure switch - clean the contacts, the relay itself from contamination ...

Hello, this is the situation, the alco 4500 pumping station, pumps water into itself, stops, open the tap, the red lamp lights up, the water is discharged, the pressure is zero, the pumping station does not turn on automatically, you have to manually start

The flange is plastic, the relay is completely disassembled, cleaned and confused. When the hydroaccumulator was removed by 24 liters, it contained 8-9 liters of water and a pressure of 1.5 points

Good day. At the pumping station MARINA, the email began to heat up. motor, even at normal line voltage. What's the matter?

There are many reasons. The first thing that comes to mind: engine wear, water has entered, a lot of dust has accumulated, it's time to change the lubricant. We must look at the pump itself.

Can you please tell me why the water leaves the station in 1-2 days? When no water is consumed from the station, the pump pumps up water. The non-return valve is located in the well, hose 1 ″ is approximately 10 meters long. Valves were changed, Europe for Cuatro Elementi. without a hydraulic accumulator and a relay, it works normally and water does not drain. I do not know what to do!

According to the description, it seems that the accumulator is poisoning. Check it out. It is also possible the connection points of the relay or the relay itself is overgrown with salts. Check if there are any salts and if the gasket is in a normal state. Maybe it's time to replace them.

Hello. I don't understand why the water is flowing down. If it passes somewhere, the pressure drops and the relay should turn on the pump. That is, in theory, the pump must constantly pump up water. There should not be such that the water would come off or I don't understand something.

hydroaccumulator wester 80 liters. pump akuario 1100 watts, pressure switch watts. I fill in water it works normally 1-2 days it pumps up and then once and there is no water. what could it be? while only the washing machine was connected, I did not connect anything anymore, as it was necessary to solve this problem.

Most of all, it looks like an unstable check valve. Maybe there is less water and sludge / sand sucks in? Does it clog and the valve periodically does not hold water? ... There are no other visible reasons.

if the water leaves the pump should it turn on or not? I don’t know and don’t understand.

The pump should turn on when there is a water flow - when the pressure in the hydraulic tank falls below the lower limit of the pressure switch. That is, the pump turns on after some time in the house they have used water. The presence of water in the pipes is not controlled by anything (it is only held by a check valve) and the pump does not turn on.

As for the reasons, you have three candidates: a check valve, a pressure switch, a hydraulic accumulator (connection points, the devices themselves).

I have two pumps, one at the station, the second for irrigation. the station is underground and the second pump is in the well. At first I thought that sand gets into the check valve, but the second pump has the same check valve and the water does not come off. the problem began after connecting a hydraulic accumulator with a pressure switch and dry running. in the underground, nothing or where does not flow. and even after connecting the hydraulic tank, condensation appeared.

Please tell me the reason for the malfunction: the pump stopped turning on when the tap was opened, it turns on only from the outlet.

See pressure switch

Thanks, we will look.

Good day! Grundfos pump, worked for a year. Suddenly a puddle began to form under the plastic impeller, where it flows - we cannot understand. What can it be, and how to fight?

Look first of all the accumulator. Not only a pear but also a flange. It loses its elasticity and washes to leak. You can also see the pressure switch - the connection points.

Good day. Help is needed. Well water. 2 weeks ago I installed the (master) pumping station pentair nocchi and everything was fine, but yesterday, for no apparent reason, the problem started: opening the tap, the pressure is normal for the first 3-5 seconds and then drops, the pressure gauge shows a gradual drop in pressure, then the pump turns on 1.5 atm, but the pressure in the tap is not normalized.

Hello, I have such a problem at my dacha, the pumping station barely pumps water, after turning on and opening the tap, at first the pressure is good, and after a few seconds the pressure drops and flows in a thin stream, the system goes through the boiler, the water comes from the well. Thank you

Hello. It is not clear how it is: "the system goes through the boiler." Clarify please…

The pump goes to the heater and from the heater to the tap

I understand correctly? Do you have a tee in the line, from it one pipe to the heater, one to the tap? If so, everything is fine, normal pattern. There may be several reasons for low pressure: lack of pump power, problems with a check valve, hydraulic accumulator, pressure switch, loss of tightness of the route or connections. All nodes must be checked sequentially. You can start with the tightness of the joints - sort out, clean from deposits, change the gaskets.

Yes, everything is correct, even at such a moment the pump was pumping for a long time, the pressure was raised to 2.7, now the pump pumps quickly, and the water jet is very small. The diaphragm is not torn air is escaping from the nipple. And it happened, that is, a thin stream very quickly, it was normal then this problem immediately appeared. The pump runs through a stabilizer.

We found the reason, the whole thing is in the heater, it clogged up, so the water from it did not flow well into the tap. Thanks a lot for your help

Hello! Our station gardena. Weak pressure. According to the passport, 3 cubic meters per hour, but in reality it will pump 3 cubes for 10 hours. When I pick up the capacity, bubbles come out, that is, the air pumps up. The suction line has been checked. Maybe the well is old fault? The debit is small? How to figure it out?

Hello! speroni 40/22 gained 5 liters at the beginning of operation. between motor starts. 1 year has passed. It began to turn on often and picks up little water between the engine starts (2.5 liters). I check the pressure in the accumulator filled with water - 0.3 bar. without water 0.2 bar. Pumped up with a pump, with water - 3 bars., Without water, 1.5 bars. I began to draw more water (3.5 liters). 5 months have passed - I check the pressure again without water 0.2 bar. I check the nipple - bleed the air - no water comes out. What can you tell about these symptoms? Thank you!

Hello! It looks like salt deposits are interfering with performance. Try to sort out and clean the pressure switch, all the grids, filters, the nipple in the accumulator ... In general, everything that is available .. Look at the state of the gaskets right away. If they become inelastic, replace.

Hello, the electric pump itself is working, it pumps water, but after it does not turn off, an uncharacteristic sound appears (looks like a buzzing) and high pressure, what could be the reason?

Hello! Most likely the pressure switch is floundering. Clean the inside of salt (remove the hoses and see, clean what is available), look in what condition the gaskets are, if necessary, change them. You also need to clean the electrical contacts. They usually oxidize. You can take a thin nail file and "joke" slightly with it. But don't get carried away too much. You can also try changing the pressure switch settings (read here). If all this does not help, just change the pressure switch. You can first ask your friends / neighbor to make sure that the reason is in the relay.

We sorted out the pressure, misunderstood at the beginning, everything is in order

Hello! I have a Dzhileks 60/30 pumping station, it has worked for 10 years, now such a malfunction has appeared, it works for 10-15 minutes, then it is not the pressure switch that turns off, but an unknown reason, because the pressure switch contacts remain closed. It costs 1-3 minutes and then turns on. And so it repeats itself. Help me please!

Maybe the pressure switch contacts? There may be an oxide film that sometimes gives a similar effect. Try cleaning your contacts. If it doesn't help, you will have to think further.

Hello! What could be? The station was often switched off, then started to smoke. When turned on again, the motor hums but does not work.

It looks like the motor is covered ... or rewind or buy a new pump

Good day! We have such a situation, when the crane is turned on, the reckless operation works properly, as it should work ... but when you close the tap, an uncharacteristic sound appears and the recklessness shakes ... the pressure switch was changed just yesterday, what else could be the reason?

Hello. 100 liter hydroaccumulator. The relay often turned on and off every 2 seconds (low pressure inside?). I checked the pear, pumped up 1.5 atm. When the relay was turned on, it was easy to click, like a machine gun - turn on and off the pump. The pressure gauge, like a madman, jumps to 6 atm. The battery is empty, no water flows into it. When I open the tap in the washstand, 200 grams of water and air flow down. Advise what to do ?, what is the reason? Thanks in advance.

If the pear is intact, is there a problem with the pressure switch? Try changing it. Another option is a leaky flange.

Hello!

Before turning on the pump, water disappears for a while, tell me how to notice what exactly the malfunction is, and what measures need to be taken to restore normal pump operation, thanks for your attention.

Hello! Try lowering the pressure switch lower limit. May I help. Read about its settings here.

Good day. Tell me please. The pumping station was one year old, worked flawlessly. A few days ago, a working station began to turn off the machine, only one station was connected to it. I decided to check if the machine was to blame and connected the station to another outlet with another machine and the situation with turning off the machine was repeated. Tell me what could be the reason? Perhaps something with the electronics of the pump?

Something is wrong with the electrical part. Start simple: check the electrical connections. First, the cord with which you connect the pumping station. Then - the place of its attachment at the pumping station (on the pressure switch). Then the contacts on the pressure switch. Inspect everything, if there are bare wires - insulate, if there are dirty contacts - clean. And yes, you do everything with the power off. The best thing is to unplug the plug.

Good afternoon, When the tap is open, the station is constantly turned on and off while the water is being drawn, what could be the problem?

Similar in the pressure switch settings. The lower limit should be further lowered. The pressure switch adjustment is described here.

Good day. The pumping station starts pumping water after 2-3 minutes after the water has stopped flowing out of the tap, what could be the problem?

Good day! It looks like the problem is in the pressure switch. Try first to clean its contacts (electrical, which supply power to the pump). If it does not help, try changing the pressure switch settings (read here). If it does not help, most likely it will have to be changed.

Hello! Such a problem: I turn on the toggle switch ON, the indicator does not light up, remove the cover of the pressure regulator, close the contact, the indicator lights up, the station starts to work. When the required pressure is reached, the engine turns off and the ON indicator goes out, after the water is drawn off the station does not turn on again. The whole procedure has to be repeated. What is the reason? Stations are only 2 months old!

It looks like a problem in the pressure switch

Hello.

I have the same problem. Not all the time. Washes work normally for the day, and then do not turn on (usually this happens in the morning). Yesterday I replaced the pressure switch with a new one, after a couple of hours it did not turn on again. Works fine all day.

Maybe something else? There is water in the tank, there is no air leakage, I don’t know about the accumulator.

Another possible reason is low voltage. Have you noticed? You can do prophylaxis to the pump - clean it from salts. Maybe after a long period of inactivity, it pins down due to deposits. It doesn't look like a hydraulic accumulator, but anything can happen.

The pump is almost 3 years old, the operation is constant. BUT the question is different, why, when it did not turn on, if it is immediately disconnected and turned on, then it always turns on?

You can sin on low voltage. Or maybe the contacts in the relay should be cleaned or adjusted. Even new ones have them oxidized. Try to sand with a thin strip of suede, remove plaque. If there is no suede, you can clean it up with a thin metal nail file, but it is better not to get carried away with the second option.

P.S. Before that, I sinned on the relay itself in the pressure unit, but it does not work out. The voltage really sags at me, even a boiler connected through a stabilizer periodically gives an error.

Good afternoon. I urgently ask for help. I tried everything. I changed the relay. I checked the hydraulic accumulator. There are no leaks anywhere. I turn on the pump. The water runs well and is quickly pumped into the tank. The relay works. I hear a click but the pump does not turn off. Is there something with the pump?

Good day! It looks more like the pressure switch contacts are not opening. See them at work.

how to check it please explain. I'm not really thinking.

Hello! The problem is the following! Several times the pump did not turn on when the hydraulic accumulator was empty! I had to manually turn off the pump I / O. After turning on, everything returned to normal. Coincidence or not, but these misunderstandings occurred at the time the washing machine was running. Do I understand correctly that the relay is closed?

Yes, it looks like a pressure switch blowout. There may also be a voltage drop (due to the operation of the washer). At low voltage, the pump simply does not start.

Hello! Pumping station aquarium adp355, I have a weak water pressure at the station, the station does not turn off.I turn on the button on the relay, the station is being eaten, but the pressure is very weak, the station is turned off, the water from the tap does not flow at all, even the residues from the system do not flow out, what could be the cause of the breakdown?

It looks like a hydraulic accumulator failure.

Good day !

Suddenly, such a problem arose: the station is gaining pressure normally, water analysis begins. The station gives all the water to a minimum and does not turn on for pumping. What is the problem ? Tell me how and what to fix.

It looks like the pressure switch is to blame.

Need a new relay or can be repaired

Try cleaning it first. Remove, clean from salt, change gaskets. Then take a strip of suede or a thin metal nail file and carefully remove the plaque from the electrical contacts (do not overdo it, otherwise you can cut the contact pads and do not unbend the plates). Install and try. May I help. You may also find it useful to read about adjusting the pressure switch. it here.

Hello. Please tell me what is the reason. Installed a new station grundfos mg 3-45. During the operation of the station and after stopping, water flows from under the base. Approximately 15 liters per 100 liters of sour water.

Check the tightness of all hose connections. If it does not flow from them, carry the station for exchange.

Hello. A few days ago I installed a 650 W station for one draw-off. Periodically, it does not gain pressure 2.8, but continues to work at a pressure of up to 2.5, I have to pull out the plug. At the same time, some kind of parasitic rustling noise is heard in the pump, similar to that when starting, when the air was bleeding from the system. Bought two weeks ago. What could be the reason?

It looks like an air leak. See all connections. To make sure that it is not the pump's fault, disconnect the suction line from it, connect a short hose. Lower that hose into a tank of water (the capacity is larger than the capacity of the accumulator), turn on the station. If everything is fine, there are definitely problems with the line (or at the point of connection to the station.

And one more question, the above station is my second one from one water intake from a well. The first station has been operating for eight years and everything would be fine, but a couple of years ago the water smelled of hydrogen sulfide, you don't use it for a couple of days and the water gets a disgusting smell that disappears as the water passes through. Last winter, the station was dismantled in order to find the cause, but it turned out to be almost perfectly clean. At the suction, I used a twisted translucent hose 25 mm from the well to the 22 meter station. On the second (which is discussed in the previous comment), I used the HDPE of the same section, the distance from the well to the station about 10 meters, the depth of laying the suction pipes is just over a meter. Maybe there are any considerations and how to solve this problem?

And if you get a bucket of water from the same source, does it stink? Maybe the problem is in the well? If not, then it remains only the hose station you disassembled.

Hello, we bought a new station. Everything was connected correctly. When the tap is open, the pump does not turn off. In the service center, after diagnosing the pumping station, they said that it was in good working order. They brought it in, connected it, now it also leaks. What to do?

My Jileks also does not turn off when the tap is fully open, I think that it should be so. What did the service center say about the leak? Where does it leak?

Hello, please tell me, the metabo pumping station, the pressure in the tank dropped, changed the spool, pumped 1.5 points, checked the spool does not let it through, in the morning there is no pressure again and the pump often turns on again, I pump it again, everything works well, but after 8 hours there is no air pressure again, and the pear completely filled.