Do-it-yourself gates from a professional sheet: photo report + video

Gates and a wicket made of corrugated board belong to the budget category: it does not take much time and materials to make them. However, if you choose a model of conventional swing gates without artistic additions. There are also options with forging elements, here the complexity of the work is greater, the costs are much higher. Even an amateur welder can make simple swing gates from corrugated board with his own hands: there are few seams, they are simple.

The content of the article

Sash constructions

Even in such a simple structure as a gate leaf or a wicket, you can make it in different ways, and there are many options. First of all, the location of the jumpers differs:

- obliquely;

- horizontally;

- crosswise.

Each method has been tested and works to provide a sufficient degree of rigidity. Here you choose what seems more correct or reliable to you.

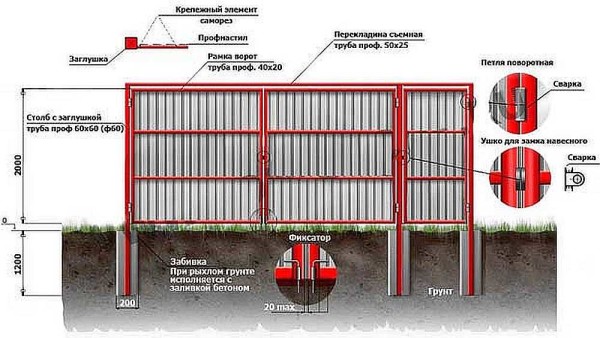

There is a difference in the design of the doors themselves - with or without a fixed frame (upper crossbar). With a frame, the gates are more stable, but then there are restrictions on height: tall cars - trucks or special equipment - will not be able to enter the yard. With proper reinforcement of the racks (pillars) and normally made doors (with reinforcement in the corners), the gate without a frame will also be reliable.

When installing a door with a frame, the metal consumption is greater - by the length of the lintel, but at the same time it is possible not to reinforce the posts additionally: the load on them is less.

To make it more convenient to fix the profiled sheet, a thin-walled metal profile 1 cm wide is welded along the outer (sometimes, inner, as in the picture above) perimeter of the flaps. This must be taken into account when determining the dimensions of the blanks for the flaps.

To make the structure as rigid as possible, so that it does not "walk" and does not make noise in the wind, reinforcement is made in the corners. And again there are two ways. The first is to weld on the corners cut from the sheet metal.

The second is to put short corner braces from the same pipe that welded the frame of the shutters.

There is a difference during assembly: from the joints, the pipes are connected at an angle of 45 ° or just butt. More professional - at 45 °, easier - end-to-end. Some assembly methods do not provide for the possibility of joining at an angle at all (if both sashes are assembled in one piece, and only those hung on the posts are sawn into two parts).

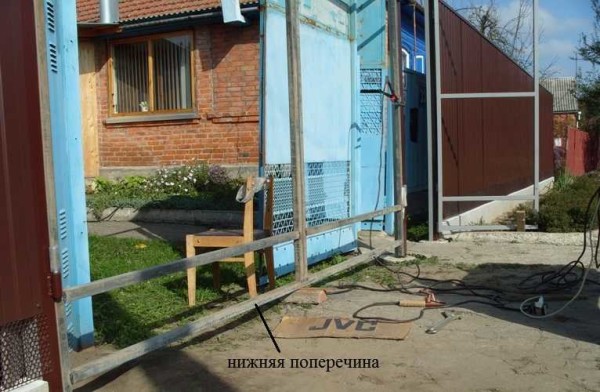

Another subtlety that depends on the amount of snow in winter. As you can see in the photo, the lower bar of the flaps is raised to different heights from the ground - somewhere a few centimeters, somewhere 20 cm and higher. Depends on the height of the snow cover in winter: if the snow piles up, and the gate is from the ground itself, you will not open it. To prevent any living creatures from climbing into this gap in the summer, after the snow melts, the bar is screwed onto the screws, in late autumn it is removed again.

Automation can be installed on swing gates... Then you can control them from the remote control and you don't need to go out under the snow and rain.

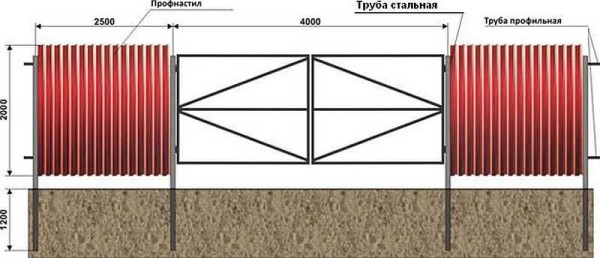

Materials

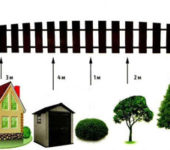

For pillars, they usually take a profile welded pipe 80 * 80 mm, with a wall thickness of 3 mm. They are dug in below the depth of soil freezing, set strictly vertically and poured with concrete mortar. Gate installation work begins after the concrete has gained about 50% strength. If the temperature outside is not lower than + 20 ° C, it will take 5-6 days, if colder - up to two weeks.

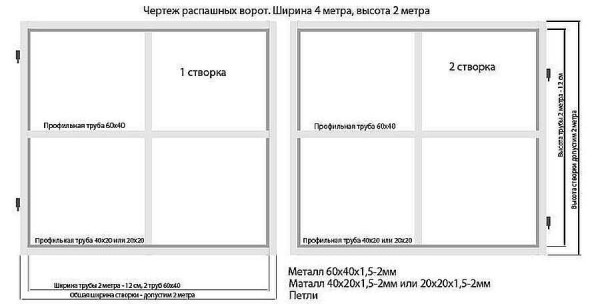

For the shutters, a profile pipe of different sections is used: depending on the strength of the winds and the span of the gate: there is an option of 60 * 40 mm, there is 40 * 20 mm. You choose based on your own conditions. On the lintels, either the same pipe or a slightly smaller section is taken, up to 20 * 20 mm. All these pipes can be taken with a wall thickness of 2 mm, or 3 mm. Thicker ones are more expensive (they sell by kilograms) - they are heavier, but 3 mm metal is easier to weld, which is important for beginners in welding.

ABOUT thin metal welding read here.

The material for the gate is the same as for fence made of profiled sheet, attach it to the same screws. Before starting work, the metal must be prepared: remove all rust (grinder with a metal brush), prime it with "Anti-rust" and paint. Once dry, you can start working.

Photo report on the manufacture and installation of the gate

This is one of the options for how you can make a gate from corrugated board with your own hands. The technology is not the best, but not the worst: everything has been functioning without problems for six years now.

Hinges are welded to the installed pillars of 80-80 mm, the counterparts are welded at the required distance on the vertical parts of the racks from a 40 * 40 mm pipe - on the right and left. We hang the racks on the hinges on the pillar, put a layer between them and the pillars of the required thickness and fix it with a clamp.

We measure the required height and cut off the excess, from above to the posts, not to the posts, we weld a cross member from the same pipe 40 * 40 mm. Welding quality is not important at this stage. We are still grabbing the details without worrying about the thoroughness of the suture - then we will bring it to normal. The main thing is that everything should be smooth and kept together. Therefore, we grab it with dots in several places.

In the same way, we grab the pipe along the bottom.

Find the middle of the cross beams. Set aside 3 mm from the middle to both sides. We make clear marks. We measure the distance between the upper and lower beam, cut off two segments, weld along the marks (a gap of 6 mm should remain between the two vertical pipes).

We measure the distance between the two posts of one half of the goal. They should be the same, but it is better to measure separately. Cut the pipes to the correct length and grab them at the correct height. If you need more crossbars, install them too.

Along the marked center with a grinder above and below, we make through cuts, dividing the gate into two halves. So very simply we got a gate that will open and close without any problems.

The gate frame is ready. We remove it, lay it on a flat horizontal surface and weld the seams well. Here the quality of welding is already important, we monitor the fullness of the bath, we try not to burn holes. We clean the finished seams, prime, paint.

We start assembling the support for attaching the profile sheet. To reduce the windage, it was cut into two parts, so that the sheet is not solid, but cut. For this we use a profiled pipe 20 * 20 mm. We cut it into pieces of the desired length, so that it can be fixed along the inner perimeter.

We expose them in the same plane with the outer part - the sheet will be screwed on from the inside. We fix it on self-tapping screws, having previously drilled holes of the required diameter.

We paint the finished frame - inside with light gray paint, outside - red-brown, to match the color of the corrugated board. We leave to dry.

We proceed to the installation of the profiled sheet on the gate.It is cut to a slightly smaller size than the main frame - there should be an indent of 2-3 mm along the perimeter. They are laid on prepared supports and fixed from the inside along the perimeter with self-tapping screws.

You can take special ones, with hats and gaskets, but they put them on ordinary ones.

We can say that the gate is ready.

It remains to establish constipation. You can, of course, embed a lock and a handle, but the quality of inexpensive ones is very low, and taking expensive ones is an unaffordable luxury at the moment. Therefore, bolts are welded from the remains of pipes and fittings. They work exactly under any conditions.

One (upper) is set on self-tapping screws with a counterpart on the sash, the two lower ones are attached to the posts. Small holes were drilled in the soil in the right places, in which sections of round pipes were concreted, the diameter of which was greater than the diameter of the rod. The gate is made using the same method, only a lock is cut into it.

With this manufacturing technology, the gate wings are guaranteed to open and close. If there were some distortions when installing the posts, they are taken into account. In a step-by-step presentation, the whole process does not look complicated, and it is. If you cook all the parts separately, the geometry should be perfect, and you also have to make sure that the pipe does not lead during welding. For several different technologies for making gates from corrugated board, see the next section, where video lessons are collected.

From a professional sheet you can make sliding gates and equip them with automation.

How to make a gate from corrugated board: video tutorials

If the work is new, then even after the photo report, questions may remain. Some of them may clarify video tutorials on the topic. To begin with, repeating the technology described above: we assemble the frame directly on the installed pillars.

The same technology in the photo sequence.

The second video is about how to properly weld the frame when connecting pipes at an angle of 45 °. The approach is professional.

Those who have not encountered welding of gates or doors before may have questions about how to weld the hinges. It's not as easy as it seems. Watch the next video tutorial.

For a more accurate explanation of what movements to make during welding of the gate hinges, where to direct the electrode and other nuances, see the next video.