DIY fence from a professional sheet: a step-by-step photo report

One of the most inexpensive fences for a summer cottage or a private house is corrugated board. Its design is simple - dug-in pillars, to which transverse lags are attached. A profiled sheet is attached to this lattice with screws or rivets. Everything is really simple, especially if you know how to use a welding machine. Although there is a technology without welding - on bolts or on wooden beams. In any case, you can build a fence made of corrugated board with your own hands. You can do all the work alone, if necessary, but when mounting sheets it is more convenient with an assistant.

The content of the article

- 1 Metal post construction

- 2 Methods for attaching the lag to the posts

- 3 Professional flooring for fences

- 4 How to attach a profiled sheet to the frame

- 5 DIY fence made of corrugated board: photo report

- 6 Fence made of profiled sheet with brick pillars

- 7 Photo of the design of fences from a professional sheet

Metal post construction

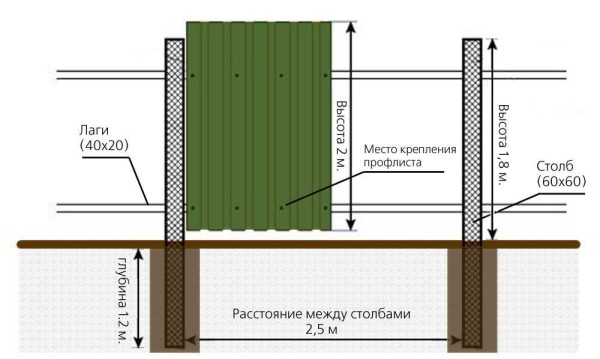

The simplest manufacture is a fence with metal pillars dug into the ground. You can use pipes of round or square cross section, but it is more convenient to work with square - profiled.

The length of the posts is taken depending on the desired height of the fence, plus from 1 to 1.5 meters is added for deepening into the ground. It is necessary to bury in the ground below the depth of soil freezing. For each region, the soil freezes to a different depth, but in Central Russia it is about 1.2 m. When determining the depth to which you bury the pipes, it is better to play it safe and make the holes deeper. Otherwise, the forces of the winter heaving of the rack will simply be pushed out, and your fence will fall (see photo).

For pillars, a profiled pipe with a cross section of 60 * 60 mm with a wall thickness of 3 mm is usually taken. The distance between the posts is from 2 to 3 meters. The thicker the profiled sheet, the less often the posts can be placed. If the soil is hard to dig, it makes sense to make the distances longer, otherwise you can save on the purchase of metal - the thinner, the cheaper and the difference in price is significant.

Lags for a fence from a profiled sheet are made from a profile pipe of 40 * 20 or 30 * 20 mm. The second option is wooden blocks 70 * 40 or so. When using wood, a significant amount is saved, but the wood disappears faster, and besides, it jars from moisture. Most likely in a few years you will have to change the lags, and they will already be metal. But as an economical option for several years it will go.

When making a fence from corrugated board with your own hands with wooden logs, do not forget to carefully treat the wood with an antibacterial compound (for example, Senezh Ultra). It is better to do this in the bathroom - immerse the bars for 20 minutes in the solution completely. This way they will last longer.

The number of lags depends on the height of the fence. Up to 2 meters - two are enough, from 2.2 to 3.0 meters you need 3 guides, even higher - 4.

Details about the choice and construction of the foundation for the fence, read here.

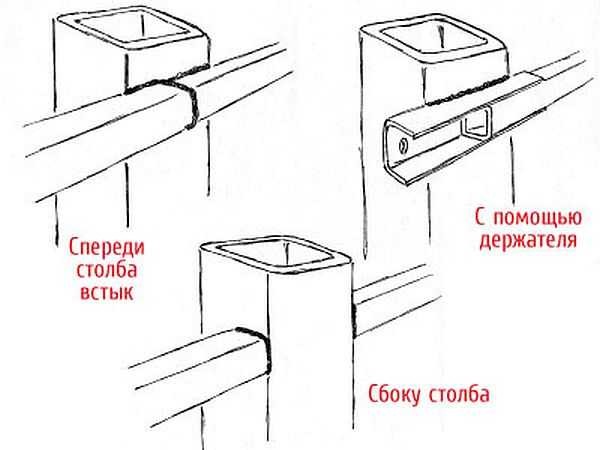

Methods for attaching the lag to the posts

Metal logs are welded either between the posts or in front. The first method is more laborious, and more waste is obtained: you have to cut the pipes into pieces. But with such an arrangement, the lag structure turns out to be more rigid: each pillar serves as a support for the sheet and it “walks” less, if desired, you can put a couple of additional fasteners along it.

If you weld pipes in front of the post (from the side of the street), there is less work, but you still have to cut and waste will be: it is necessary that the welded seam of two sections falls on the post. Unless you guess the distance so that they lie flat.Then you purchase the materials in advance, and then calculate the step of installing the pillars.

To fasten wooden bars, holders are welded in front or on the sides - metal corners or U-shaped guides. Holes are then drilled in them and fastened with bolts or self-tapping screws.

There is an option to assemble a fence from corrugated board without welding. For this there is a special fastening element called the X-bracket. This is a cross-shaped plate with curved edges, which is attached to self-tapping screws.

Professional flooring for fences

For fences, a profiled sheet with C marking is used - for fences and walls. There are also H and NS, but they are not suitable for fences - these are more roofing materials. A and R markings are rare, A profiles can be used for fences.

In the marking after the letter there is a number - from 8 to 35. It indicates the height of the rib in millimeters. So C8 means that the profiled sheet is intended for a fence, and the wave height is 8 mm. The higher the wave height, the more rigid the surface will be. In strong winds, take at least C10, or even C20.

Sheet thickness - from 0.4 to 0.8 mm. The most optimal option is a thickness of 0.45 mm or 0.5 mm. They are suitable for fences up to 2.5 m in height. If you need a higher one, take at least 0.6 mm.

The height of the leaf is usually in the region of 2 meters, you can find 2.5 m.The width is very different - from 40 cm to 12 meters. Different factories produce corrugated board of different format.

Decking can be galvanized, can be painted (painted 15-25% more expensive than galvanized). Two types of paint are applied: powder and polymer coating. Powder coating is more durable but also more expensive.

There are sheets painted on one side - on the other there is galvanized coating, covered with gray primer, there are - on two. Double-sided coating is naturally more expensive than one-sided painting, but the look is better, and the service life is longer.

Support pipes and fence logs are usually primed, then painted. And somehow it happened that they were painted with dark paint. Having then attached to them a profiled sheet painted on one side, a clearly visible "skeleton" on a light gray background is obtained. In a small area, this can be critical. Pay attention, and when building a fence made of corrugated board with your own hands, paint the supporting frame in a light gray color. The result will please you: it looks much better from the yard.

How to attach a profiled sheet to the frame

The sheet is fastened with screws or rivets. Self-tapping screws for the profiled sheet are galvanized and painted. Pick them up to match the color of the fence. Tighten with a screwdriver using a nozzle.

The installation step depends on the wavelength and the height of the fence. The higher the fence, the more often you need to install fasteners. It holds well if fastened through a wave to increase strength, with two lags it can be staggered, and not one above the other.

When installing, it is important to set the first sheet vertically. Then all the rest will be installed without problems. When stacking sheets, the next one goes to the one already set on 1 wave. Attached to the bottom of the wave. The self-tapping screw must be installed strictly perpendicularly. Then the hole is closed with a washer and deposits will not cause the paint to peel off.

How one can attach a professional sheet to a fence, watch the video.

DIY fence made of corrugated board: photo report

A fence was built from neighbors and a frontal one. The total length is 50 meters, the height is 2.5 m. On the front one is used a brown profiled sheet, on the border - galvanized, thickness 0.5 mm, grade C8.

In addition, the following materials were sent:

- on the posts a profiled pipe 60 * 60 mm, wall thickness 2 mm, pipes 3 m long;

- 80 * 80 mm with a wall of 3 mm were placed on the posts of gates and wickets;

- lags 30 * 30 mm;

- gate and wicket frame 40 * 40 mm;

The fence is installed on metal pillars, between which the basement is then poured. It is necessary for the owners, since it is planned to break a flower garden in front of the fence (you can see the fence made under it). It is also needed so that water does not flood the courtyard during heavy rainfalls. The metal sheets are not attached immediately from the ground, but retreated a little. This gap is closed by a die cut - a tape that remains in some industries. This is done on purpose so as not to block the air supply, so that the earth dries out faster.

Metal preparation

The first stage is the preparation of the pipes. The pipe comes from the warehouse rusty, so that it will serve for a long time, you have to clean it off, then treat it with "Anti-rust" and then paint. It is more convenient to first prepare all the pipes, prime and paint, then just start installation. The rust was cleaned off with a metal brush mounted on a grinder.

The pipes in the warehouse were only 6 meters long. Since the height of the fence is 2.5 meters, you need to bury another 1.3 meters, the total length of the post should be 3.8 meters. To save money, they cut it in half into 3-meter pieces, and the missing piece was supplemented with various scrap metal available on the farm: cut corners, fittings, pieces of different pipes. Then everything was cleaned, primed and painted.

Installation of pillars

Two corner posts were placed first. The holes were drilled with a store-bought drill. The soil is normal, it took about 20 minutes for one hole 1.3 meters deep.

The first pillar was set horizontally and so that it rose to a height of 2.5 meters above the ground. To set the second one, it was necessary to recapture the height. Used a water level. It must be poured so that there are no bubbles - from a bucket, not from the tap, otherwise it will lie.

We set up the second post along the broken mark (put it on the bar, which was placed next to the hole) and concreted it. When the cement seized, a string was pulled between the posts, along which all the others were aligned.

The filling technology was standard: a double-folded roofing material was installed in the hole. A pipe was placed inside, poured with concrete (M250) and placed vertically. The level was controlled with a plumb line. Correctly positioning the pillars is very important, otherwise the entire fence will skew.

In the process of work, it turned out several times that the concrete was poured not inside the rolled roofing material, but between it and the walls of the pit. Raking it out of there is a small pleasure, because the protruding part was cut into petals, nailed to the ground with large nails. Problem solved.

After the concrete had set, a portable formwork was made from boards covered with a dense film. With their help, the basement was poured. To make it stronger, reinforcement rods are welded to the posts on both sides along the bottom. Formwork was placed around them.

Jumper setting

The cleaned, primed and painted crossbeam pipes were cut and welded. Cooked between the pillars. They are also tedious to put in a level to make it easier to fix.

After the welding is over, all welds are cleaned with a wire brush, treated with "Anti-rust" and then painted.

Installation of profiled sheet

Since the upper lintel runs along the very top of the fence, and it is welded exactly to the level, there were no problems with aligning and installing the sheets. They were fastened first along the edges, then intermediate screws were installed. To make it easier to place them evenly, a thread was pulled between the extreme ones.

Then the gate was welded and attached. As a final touch, additional elements are installed on top - a U-shaped profile that covers the top of the fence and plugs for pipes.

As you understand, there is nothing particularly difficult. It is important to set the pillars straight and weld the frame.This is the main task. A lot of time - about 60% is spent on preparing pipes - cleaning, priming, painting.

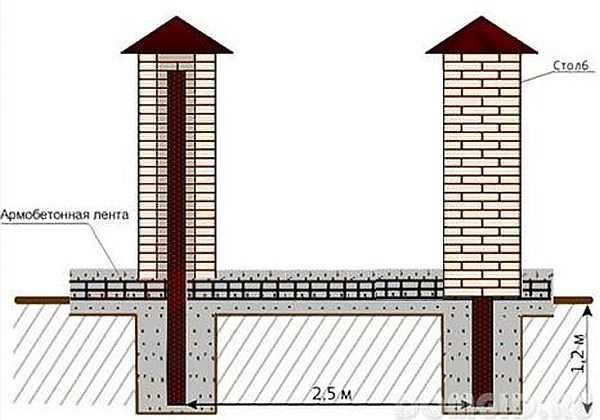

Fence made of profiled sheet with brick pillars

Of course, a fence with brick pillars looks more decorative. If you wish, you can do it, but it will take more time. There are two options:

- Make a full-fledged strip foundation. But it is long and expensive. On well-drained soils, you can make a shallow foundation, on heaving soils you will have to dig below the depth of soil freezing. And although the tape will not be wide, there is a lot of work - to dig a trench for the entire length of the fence, put formwork, knit reinforcement, pour and then finish. Put brick pillars on top. Strong, reliable, but expensive.

- Make according to the scheme described above: bearing pillars with a base. Brick is laid around the pillars. This method is less expensive. About, read how to lay brick pillars here.

The whole technology is the same, only more rigid reinforcement is required - two belts of two rods with a diameter of 10-12 mm. It will be necessary to install embedded elements in the pillars, to which the guides will be attached. They (mortgages) can be welded to the pipe, after it has been exposed and the mortar has set.

Photo of the design of fences from a professional sheet

Often a profiled sheet is combined with forging, sometimes a frame is cooked from a profiled pipe, a profiled sheet is mounted into it, and all this is decorated with metal patterns - forged or welded. Another option to make the fence non-standard is to install the wave not vertically, but horizontally. Seemingly small change, but the view is different. Some ideas in the photo gallery below.

- Horizontal fence made of profiled sheet

- A beautiful combination of stone, forging and red-brown leaf

- Pillars made of a round metal pipe, strips are welded to them from the back side, to which the sheet is attached

- Forging and polycarbonate inserts

- More variations on forging

- Coloring may be uneven.

- Non-linear top needs some tinkering