How to determine the cross-section of a cable (wire) by diameter

In theory, the diameter of the conductors should correspond to the declared parameters. For example, if it is indicated on the marking that the cable is 3 x 2.5, then the cross-section of the conductors should be exactly 2.5 mm2... In fact, it turns out that the actual size can differ by 20-30%, and sometimes even more. What is the threat? Overheating or melting of insulation with all the ensuing consequences. Therefore, before buying, it is advisable to know the size of the wire in order to determine its cross section. How exactly to calculate the cross-section of the wire by diameter and we will find out further.

The content of the article

How and how to measure the diameter of a wire (wire)

To measure the diameter of the wire, a vernier caliper or any type of micrometer (mechanical or electronic) is suitable. It's easier to work with electronic ones, but not everyone has them. It is necessary to measure the core itself without insulation, so first move it aside or remove a small piece. This can be done if the seller allows it. If not, buy a small piece for testing and measure on it. On a conductor stripped of insulation, measure the diameter, after which you can determine the real cross-section of the wire according to the dimensions found.

Which measuring device is better in this case? If we talk about mechanical models, then a micrometer. Its measurement accuracy is higher. If we talk about electronic options, then for our purposes they both give quite reliable results.

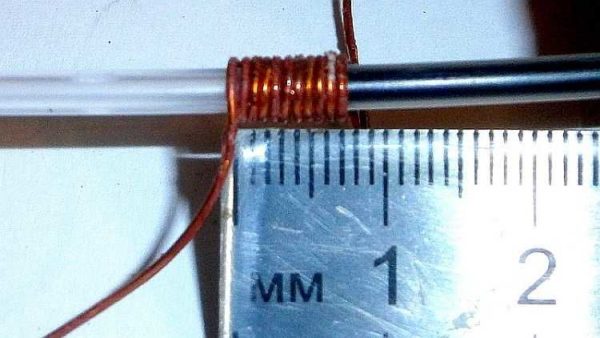

If you don't have a caliper or micrometer, take a screwdriver and a ruler with you. We'll have to clean up a pretty decent piece of conductor, so you can hardly do without buying a test sample this time. So, remove the insulation from a piece of wire 5-10 cm. Wrap the wire on the cylindrical part of the screwdriver. Lay the coils close to one another, without a gap. All turns must be full, that is, the "tails" of the wire must stick out in one direction - up or down, for example.

The number of turns is not important - about 10. You can do more or less, it's just easier to divide by 10. Count the turns, then apply the resulting winding to the ruler, aligning the beginning of the first turn with the zero mark (as in the photo). Measure the length of the section occupied by the wire, then divide it by the number of turns. Get the wire diameter. It's that simple.

For example, let's calculate the size of the wire shown in the photo above. The number of turns in this case is 11, they occupy 7.5 mm. We divide 7.5 by 11, we get 0.68 mm. This will be the diameter of this wire. Next, you can search for the cross section of this conductor.

We are looking for a wire cross-section by diameter: formula

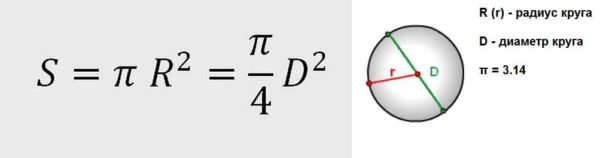

The wires in the cable are circular in cross-section. Therefore, in the calculations we use the formula for the area of a circle. It can be found using radius (half the measured diameter) or diameter (see formula).

For example, let's calculate the cross-sectional area of the conductor (wire) according to the size calculated earlier: 0.68 mm. Let's use the radius formula first. First, we find the radius: we divide the diameter by two. 0.68 mm / 2 = 0.34 mm. Next, we substitute this figure into the formula

S = π * R2 = 3,14 * 0,342 = 0.36 mm2

It is necessary to count like this: first we square 0.34, then multiply the resulting value by 3.14. Received the cross-section of this wire 0.36 square millimeters. This is a very thin wire that is not used in power networks.

Let's calculate the diameter of the cable using the second part of the formula. You should get exactly the same value.The difference can be in thousandths due to different rounding.

S = π / 4 * D2 = 3.14/4 * 0,682 = 0.785 * 0.4624 = 0.36 mm2

In this case, we divide the number 3.14 by four, then we square the diameter, multiply the two numbers obtained. We get the same value, as it should be. Now you know how to find out the cable cross-section by diameter. Whichever of these formulas is more convenient for you, use that one. No difference.

Correspondence table of wire diameters and their cross-sectional area

It is not always desirable or possible to carry out calculations in a store or in the market. In order not to waste time on calculations or not to be mistaken, you can use the table of correspondence of diameters and sections of wires, which contains the most common (standard) dimensions. You can rewrite, print and take with you.

| Conductor diameter | Conductor cross section |

|---|---|

| 0.8 mm | 0.5 mm2 |

| 0.98 mm | 0.75 mm2 |

| 1.13 mm | 1 mm2 |

| 1.38 mm | 1.5 mm2 |

| 1.6 mm | 2.0 mm2 |

| 1.78 mm | 2.5 mm2 |

| 2.26 mm | 4.0 mm2 |

| 2.76 mm | 6.0 mm2 |

| 3.57 mm | 10.0 mm2 |

| 4.51 mm | 16.0 mm2 |

| 5.64 mm | 25.0 mm2 |

How to work with this table? As a rule, the cables have a mark or tag on which its parameters are indicated. The marking of the cable, the number of cores and their cross-section are indicated there. For example, VVNG 2x4. We are interested in the parameters of the core and these are the numbers that stand after the "x" sign. In this case, it is stated that there are two conductors having a cross section of 4 mm2... So we will check if this information is true.

How to work with a table

To check, measure the diameter using any of the methods described, then check with the table. It indicates that with such a cross section of four square millimeters, the size of the wire should be 2.26 mm. If your measurements are the same or very close (there is a measurement error, since the devices are imperfect), everything is fine, you can buy this cable.

But much more often the actual diameter of the conductors is much smaller than the stated one. Then you have two ways: look for a wire from another manufacturer or take a larger section. Of course, you will have to overpay for it, but the first option will require a fairly long period of time, and it is not a fact that you will be able to find a cable that meets GOST.

The second option will require more money, since the price depends significantly on the declared section. Although, it's not a fact - a good cable made according to all standards may cost even more. This is understandable - the cost of copper, and, often, for insulation, subject to technology and standards, is much higher. Therefore, manufacturers are cunning by reducing the diameter of the wires - in order to reduce the price. But such savings can turn into disaster. So be sure to take measurements before purchasing. Even trusted suppliers.

And one more thing: inspect and feel the insulation. It should be thick, solid, of the same thickness. If, in addition to changing the diameter, there are also problems with insulation, look for a cable from another manufacturer. In general, it is advisable to find products that meet the requirements of GOST, and not made according to TU. In this case, there is a hope that the cable or wire will serve for a long time and without problems. Today this is not easy to do, but if you breed house wiring or connect electricity from the pole, quality is very important. Therefore, it is probably worth looking.

How to determine the cross section of a stranded wire

Sometimes conductors are used stranded - consisting of many identical thin wires. How to calculate the wire diameter in this case? Yes, exactly the same. Carry out measurements / calculations for one wire, count their number in a bundle, then multiply by this number. Here you will find out the cross-sectional area of a stranded wire.