Connecting the oven independently

When buying a built-in oven, sellers recommend entrusting the connection of the equipment to professionals. But this service, even with normal wiring, costs about 1,500 rubles (about $ 25), which is already a lot. And if you have to pull the line from the flap, the cost increases even more, and it's solid. But an ordinary person who knows how to hold a screwdriver in his hands can connect the oven with his own hands. Laying a separate power line is more complicated, but you can also cope. The only drawback of such actions is that you will not have the corresponding column filled in your passport. Based on this, you may be denied warranty repair if a warranty case suddenly arises. So the choice is yours.

Electric ovens are of two types - dependent and independent. Addicts go with hob and connect together with it to one power source. They should be located nearby, usually the hob above the oven. They are connected to each other by cables, since the position of the oven controls affects the operation of the hob. All requirements are detailed in the instructions and must be followed exactly.

Independent ovens are completely self-contained appliances that connect independently. The choice of their installation location is also arbitrary. Because, probably, such models are more popular.

The content of the article

Connection procedure

Regardless of the type of device, the oven is connected in several stages:

You need to evaluate the existing wiring. You can connect the oven only if:

- Good physical condition.

- The cross-section of the conductors is not less than the required one.

- The line has a circuit breaker or at least a switch. They are needed to de-energize equipment in an emergency.

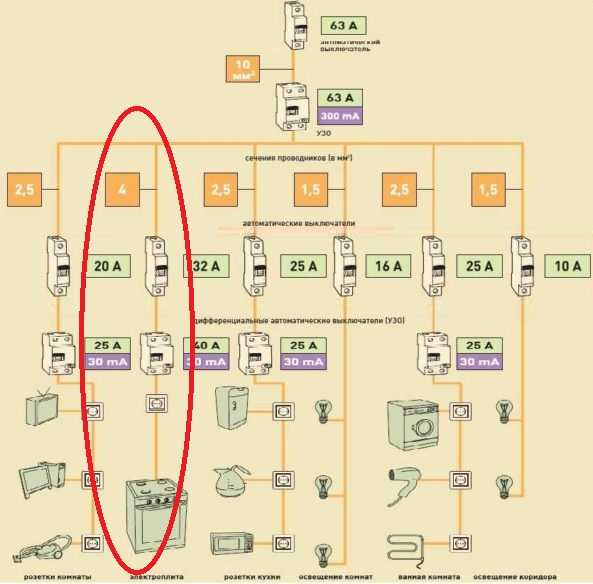

If the existing wiring does not meet the requirements, it is necessary to lay a new route from the panel to the proposed installation location of the oven. On this line it will be necessary to put automatic machine of suitable rating... We will talk more about the cross-section of wires and the ratings of the machines for them later.

What to do

First you need to prepare the oven for connecting to the mains. The oven may have a power cord. Sometimes it ends with a three-prong (grounded) plug, sometimes there is no plug. Depending on the connection method, you can install a plug on the cord, or you can do without it. You can even change the cord - it doesn't even affect the warranty.

It's all about which connection method you choose. You can - traditional through a three-pin socket with a plug. You can have one that is not so convenient, but is considered more correct. Through the terminal block. Depending on the chosen connection method, connect the electrical wires (more on this below).

- Prepare a place for a built-in oven. Manufacturers usually recommend that cold air flows from the back and bottom for ventilation. If the furniture has a back wall, a hole is made in it, or even cut out as much as possible. To ensure the flow of air from below, it is possible to lay linings on the sides with a height of several centimeters (it is important that there is also an air gap at the top between the oven and the worktop. In addition, the side racks of the cabinet must be adjusted to the size of the oven - it must be fixed to the sides with screws.

- The built-in oven is installed in place, we check the verticality and horizontalness of the installation with a building level, if necessary, we correct it. We open the door, there are holes on the side plates, we install self-tapping screws in them that will hold the oven in place. To prevent the walls of the furniture from breaking when screwing in the screws, first make a hole using a drill with a diameter slightly smaller than the diameter of the self-tapping screw.

This, in fact, is all. The oven has already been connected, but not everyone fully understands some of the nuances and, most likely, there are a lot of questions about the electrical part. Let's talk about them further.

Electrical connection

If everything is fine with the wiring, it was recently laid, there is a separate line for connection with a properly working grounding, and even the oven is not very powerful - about 2.5 kW, no questions - put the plug, turn it on and that's it. But if the wiring is already more than ten years old, in what state you do not know what section the wire is, it is not known, it is better to stretch a separate line, do everything according to the rules and only then connect the oven. In this case, you do not have to be afraid that something will happen to the wiring.

You can connect the built-in oven to a normal line. It is better to have it dedicated - only for this unit

Cross-section of conductors and rating of the circuit breaker

The latest models of ovens have become not very "voracious" - the struggle for economy is yielding results. If you look at their characteristics, then the average installation power for a built-in oven is in the range of 2.6-3 kW. But this is a question of rather expensive products. Equipment in the cheaper segment can have significantly higher power. Also, models with pyrolytic cleaning will be more powerful.

That is why it is recommended to connect the oven to a dedicated line with a large cross-section of conductors on which a circuit breaker is installed. Recommended section - 6 mm2... Such a conductor can withstand a continuous load of 10 kW, which is more than enough. It is recommended to install an automatic circuit breaker of class C 32 on this line. This is with a very large margin of safety - lines with such parameters are often installed at the entrance to a dacha or a house in a village. Its laying will require a substantial investment - and the cable is not cheap and the machine is worth enough.

| Cross-section of copper wires | Permissible continuous load current | Maximum load power for a single-phase 220 V network | Rated current of the circuit breaker | Limiting current of the circuit breaker | Approximate load for a single phase circuit |

|---|---|---|---|---|---|

| 1.5 sq. mm | 19 A | 4.1 kW | 10 A | 16 A | lighting and signaling |

| 2.5 sq. mm | 27 A | 5.9 kW | 16 A | 25 A | socket groups and electric floor heating |

| 4 sq. Mm | 38 A | 8.3 kW | 25 A | 32 A | air conditioners and water heaters |

| 6 sq. Mm | 46 A | 10.1 kW | 32 A | 40 A | electric stoves and ovens |

| 10 sq. mm | 70 A | 15.4 kW | 50 A | 63 A | introductory lines |

If your oven has a power of much less than 8 kW (even if all available devices are turned on at the same time), you can lay the cable with a cross section of 4 square meters. mm, and put the machine gun C 25. It will be no less reliable, but more economical. By the way, for greater safety when installing the oven, it is recommended to use two-pole circuit breakers. When triggered, they will disconnect not only the phase, but also zero, which in some cases is important (in case of insulation breakdown).

Cable can be used VVGng or NYM. The parameters are respectively 3 * 4 or 3 * 6. Only when buying, be sure to measure the diameter of the conductor - too often manufacturers, trying to make products cheaper, save on copper. As a result, instead of the declared 4 sq. Mm, we have, at best, 3, and this is already unsafe - the wiring can heat up, which can lead to a short circuit and a fire. So, check the diameter of the conductor. For a cable with a cross section of 4 sq. mm it should be 2.26 mm, for 6 sq. mm - 2.76 mm. Read more about how and what to measure, how to calculate here.

UZO - is it necessary or not?

In addition to the circuit breaker, it is recommended to install an RCD on the line to which the oven can be connected. The machine protects the wiring from overheating and short-circuit currents, and the RCD, a protective grounding device, will protect users. In the event of an insulation breakdown to ground or in case of touching the phase wire, it will cut off the power supply. Electricity is an area in which it is better to play it safe and an RCD is usually a reassurance, but it is better if it is. Safer.

The selection of RCD parameters is simple - its rating is one step higher than the rating of the circuit breaker. That is, if you installed the machine at 25 A, take the RCD at 32 A, if the bag is at 32 A, the RCD will be needed at 40 A. The second parameter is the cutoff current. Everything is simple with him - for the lines to which one device is connected, they take it 10 mA.

We still need to discuss the type. Better to install class B (B 25, for example), but class A (A 25) will do. But don't take the AC class. Although they are cheaper, they do not provide the required degree of security.

Once again: if you want to connect the oven correctly and securely, use a large wire, a circuit breaker and an RCD. Such an installation will guarantee a long and safe operation of the equipment.

Socket or socket

The oven can be connected to the power line in two ways: using a power plug and socket with suitable parameters (selected according to the maximum current, which must be indicated in the technical specifications) or in the section "Safe operation". Generally speaking, with a power of 3-3.5 kW, you need a plug and a socket with a maximum current of 15 A, for an oven with a power of up to 5 kW, you will need an outlet with a 32 A plug.

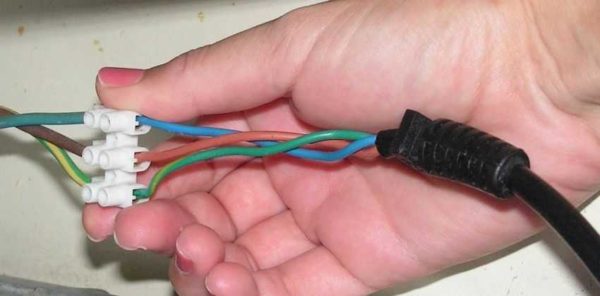

A ground wire (usually yellow-green) is connected to the bottom connector, phase and zero (blue or blue) to the other two. When connecting, do not confuse - the phase and zero on the socket and plug must match.

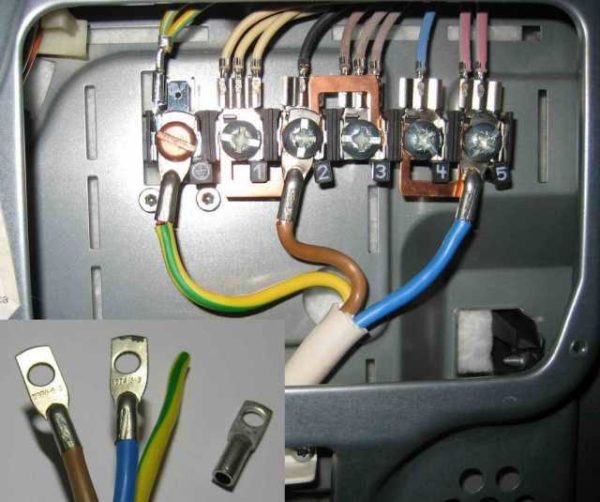

The second connection option is a terminal block. This is a simple and reliable way. There is a heat-resistant plastic compound plate on which several pairs of contact plates and screw clamps are mounted. The wires of the two cables are connected on two opposite sides. When connecting, observe the color coding: the yellow-green wire is "ground". These conductors are connected strictly opposite one another. The same with blue wires - this is neutral or "zero". The remaining wires are a phase and they are also connected opposite one another.

Naturally, it is necessary to work with the voltage off - put the machine in the off position. The wires are connected simply - a conductor stripped by 7-9 mm is inserted under the top plate. It can be previously loosened by turning the clamping screw a couple of turns. The screw is then tightened to ensure good contact. After tightening the screw, tug on the conductor with sufficient force several times - make sure it is well secured.

Such terminal blocks can be used, but they must withstand the appropriate current (15 A or 25 A) depending on the power of the oven.

To ensure that the terminal block with the wires is not open, it can (and very desirable) be packed in a case. You can use a regular junction box, or you can use a small plastic wiring cabinet that you can pack everything very neatly.

Jumpers

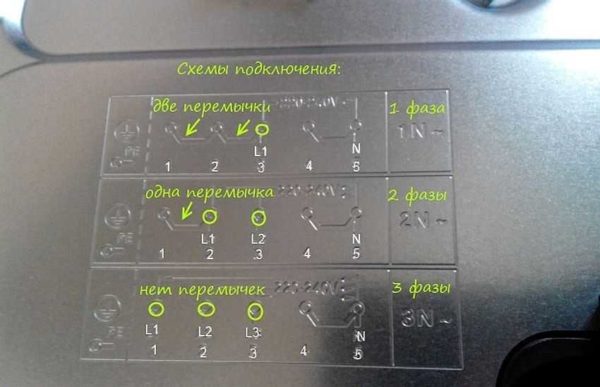

In most cases, the oven is delivered from the store with the power cord already attached. Naturally, in this case, jumpers have already been installed in accordance with what kind of network you have - single-phase or three-phase. But if there is no cord, the jumpers must be set independently.

If you look closely, you will see that the jumpers are already in place. These are copper plates, similar to the letter "P"

It's not difficult at all.On each device and in the operating instructions there is a table in which it is drawn which jumpers must be installed for which network. An example of such a table is shown in the photo below. In this case, it is squeezed out on the back cover, but can be glued near the place where the leads from the oven come out and where the cord is attached.

As follows from this diagram, the first diagram is suitable for a single-phase 220 V network. She is signed by 1N. It is shown that in this case it is necessary to connect three pins labeled 1, 2 and 3. For this, two jumpers must be installed. Note that the ground pin in this model is on the right. A yellow-green conductor should come up to it, we connect the same there from the cable / cord.

The far left is the terminal for connecting neutral or "zero". Please note that there must also be a jumper. It is usually the default (always), but it doesn't hurt to check. A blue wire is suitable for this conclusion, we connect the conductor of the same color from the cable.

The remaining reason is phase. Having installed two jumpers on the remaining three free contacts, we connect this wire. It can be any color other than yellow, green and blue. Most often it is black, brown or red, but not necessarily.

If you have a three-phase input (380 V) in your house or apartment, then besides the jumper on the neutral wires, others are not needed. In this case, it is also better to connect first the protective wires - ground and neutral - and then the phase ones. The order of connecting the phase wires is not important, but it is desirable that they be connected in the same order as on the electrical plug. It's just that the less confusion the better.