TISE foundation: we build ourselves

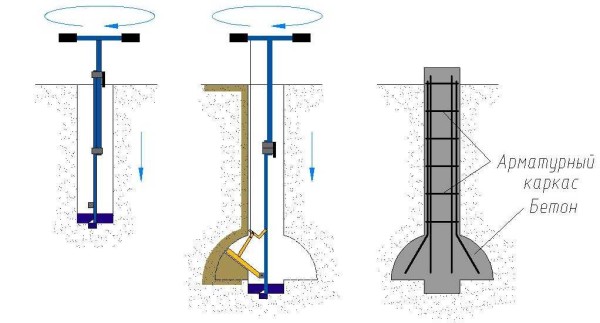

One type of pile or pile-grillage foundation is the foundation of TISE. Its main difference is that there is a hemispherical (domed) thickening at the end of the pile. This form allows the use of pile foundations on heaving soils, while the amount of land work remains very small.

The content of the article

TISE piles

The main disadvantage of the classic pile foundation is that, with strong heaving, the support can simply be pushed out. But since the idea itself is very attractive - it is built quickly at a minimum cost - on complex soils, they began to make a sole at the bottom of the pile - a rectangular reinforced plate. But with this option, the volume of land work immediately increased at times: for each pile it is necessary to dig a foundation pit larger than the planned sole. On the other hand, the building stands normally even on soils with strong frost heaving.

The pile foundation according to TISE technology has a dome-shaped thickening at the base of each support

Under the piles made using the TISE technology, a similar thickening is created. But there is no need to dig pits. This expansion is formed using a special knife that is attached to the branded drill. This knife forms an extended dome. Further, the entire technology almost exactly repeats the process of erecting a pile or pile-grillage foundation.

Previously, extensions were also practiced, but they tried to do them with the help of microexplosions or poking with a blade on a long pole. The main innovation in TISE technology is a drill with an opening adjustable blade. It makes the expansion of the sole much easier.

How to work as a drill TISE

Advantages and disadvantages

TISE foundations are rapidly gaining popularity: with minimal additional costs, a more reliable foundation is obtained. So, its advantages:

- increased resistance to heaving forces;

- the load from the house is transferred to a large area, which reduces the possibility of uneven subsidence;

- low prime cost with good characteristics;

- can be designed for houses of different materials, up to 3 floors in height;

- small amount of land work.

TISE pile manufacturing procedure

If a pile or pile-grillage foundation is recommended for your house, it makes sense to make TISE piles. With a small increase in workload, you get a significant increase in reliability. After all, designers do not like pile foundations because it is impossible to find out what kind of soil is under each support. Therefore, it will not work to predict how reliable and stable the foundation will be. And the TISE foundation has a wider support, which reduces risks. It is still impossible to predict anything, but a large load distribution area is always good.

However, there are also disadvantages. The main one: the heel of the TISE pile cannot be well reinforced. You can lower the reinforcing cage to the very bottom, but the reinforcement cannot be expanded. Therefore, the possibility remains that this thickening will collapse.

TISE piles - the basis of the TISE pile-grillage foundation

There is one more drawback, but from the practice of using borax: it is not easy for them to work. The construction itself is interesting. This is not a blade wrapped around a rod, but a container with a composite bottom. The plates that form the bottom are welded with four angled blades. When you spin the drill, they loosen the ground. Since the bottom is not solid, the soil enters the housing, from where it must be removed.

The order of work is as follows: they twisted the drill around its axis several times, took out, shook out the soil. They lowered it into the hole again, turned it several times, etc. The technology is not complicated, but the work is tedious. The device itself weighs 7-9 kg, plus the ground. Raise, lower it you need to often. In general, tiresome. Plus - no mechanisms are needed. The downside is that the work is physically difficult. Especially if the soil is rocky or made of dense clay.

Where can I use

There are no restrictions on the types and materials of buildings: you can make a TISE foundation for wooden, frame, brick and block buildings. Number of storeys - up to three.

On soils, the restrictions are the same as when using pile foundations: it is necessary that the piles transfer the load to the soil with normal bearing capacity. To decide whether it is possible or not to use TISE, a geological study of the site is necessary in the place where construction is planned.

What the TISE pile consists of

Since the base of the pile is widened and the resistance to pushing forces is greater, this technology can be used on heaving soils. But at the same time it is necessary to consider: it makes no sense to put piles closer than 1.5 meters. When placed closer, one outsole extension will overlap the other. On the other hand, you cannot make a pile diameter greater than 30 cm - there is no such drill. If the bearing area with such parameters is not enough, you need to use a different type of foundation.

Reviews of the brand storm

The main questions for developers are related to how realistic it is to drill wells by hand using a proprietary drill. Looking at the video, it seems that this task is not easy. But here are some reviews.

At my site, the soil turns out to be different: where is loam, where is dense clay, and such that you can only chop with an ax. At first I thought of renting a motor-drill, but decided to try it right away with a drill. And nothing, not very hard. As a result, I decided that the motor-drill would slightly speed up the process, so I made all 40 pieces by hand. During the day, 5-6 2-meter wells were obtained. They drilled easily, but with the expansion it was hard: I already had dense soil, I turned it with an open blade with difficulty.

Oleg, Kharkov

I modified the purchased TISE drill: I welded additional teeth, instead of a rope that opens the blade, I adapted a rod - now you can press on it, and not just pull. And most importantly, I lengthened the handle so that two people could twist it. While drilling the extensions, we twisted it 90 °, but the work became much easier. In general, I am satisfied.

Nikolay, Krasnoyarsk

Calculation of the TISE foundation

The calculation methodology is no different from the calculation in the general case. The load from the house is calculated and then compared with the total bearing capacity of the planned number and diameter of piles.

First, place piles on the plan of the house. They must be in the corners and at the junction of the walls. If the distance between the piles is more than 3 meters, intermediate ones are placed between them. So place all the supports on the plan, adhering to the rule:

- the minimum distance is 1.5 meters;

- maximum 3 m.

Then you calculate the load from the house. To do this, you first need to calculate the weight of the house (all building materials + furniture, plumbing, heavy household appliances).

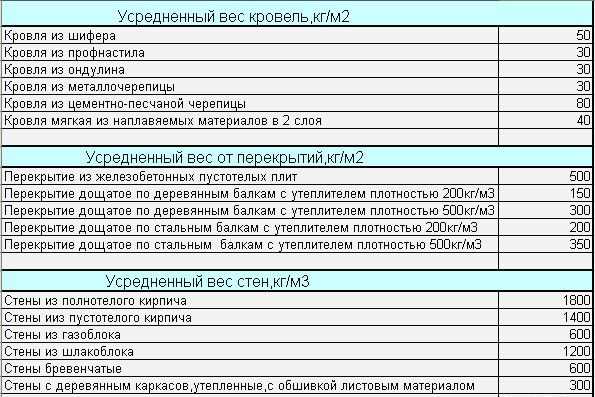

Average loads from different types of house nodes

If we talk averaged, then for buildings made of bricks or shell rock for each square of the area, you can take 2400 kg, from light building blocks (foam concrete, aerated concrete, etc.) - 2000 kg, from wood and frame frames - 1800 kg. These averaged norms can be pre-guided. If you decide to take everything seriously, you will need to follow the entire methodology: count the materials of the walls, floors, roofs, finishes, etc. Since technologies and materials can be used differently, the discrepancies can also be significant.

The resulting value is multiplied by a correction factor - 1.3 or 1.4. This is a margin of safety.The resulting figure is the load that will need to be transferred through the piles.

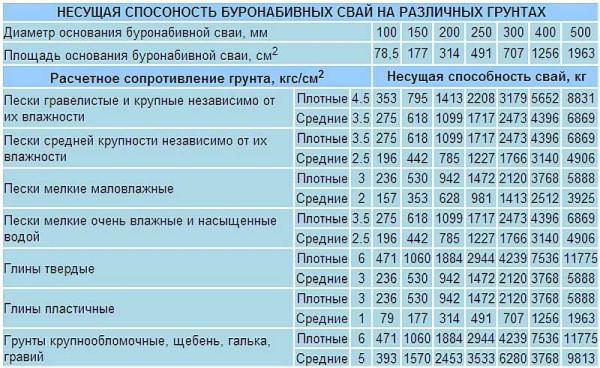

Now, according to the table, you select what diameter the pile should have so that it can transfer the required weight.

Bearing capacity of piles of different diameters in different soils

If the planned number of columns with the expansion of the selected diameter can transfer the required load, you do not need to redo anything. If the transferred mass is too small, it is necessary either to increase the number of piles or to make a "heel" of a larger diameter.

TISE foundation: work order

The TISE method itself contains some recommendations:

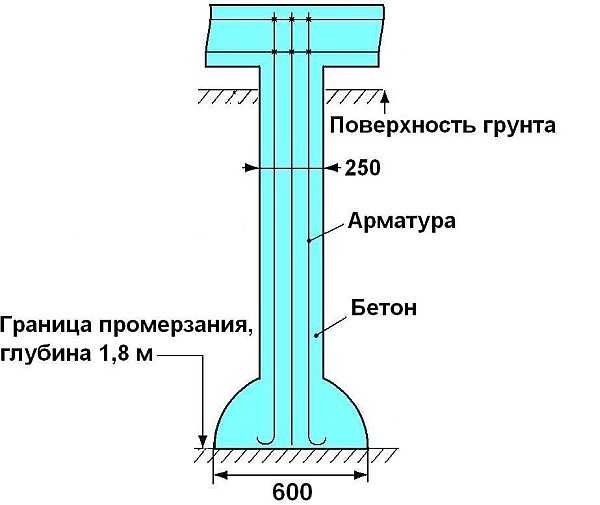

- Piles deepen about 20 cm below the freezing level for the region.

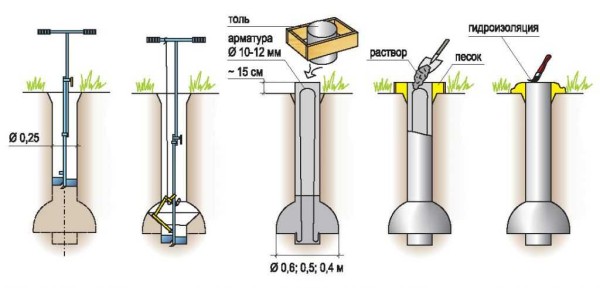

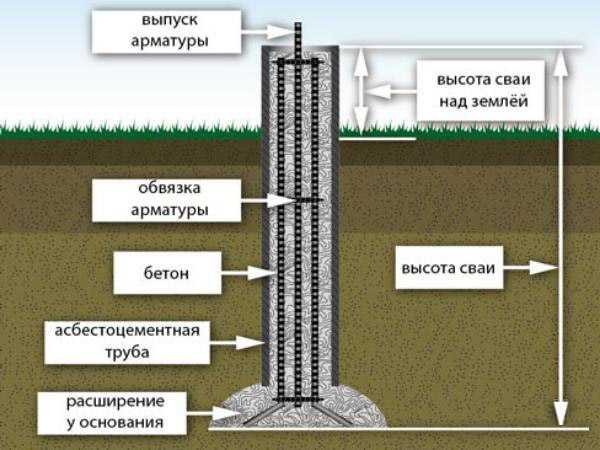

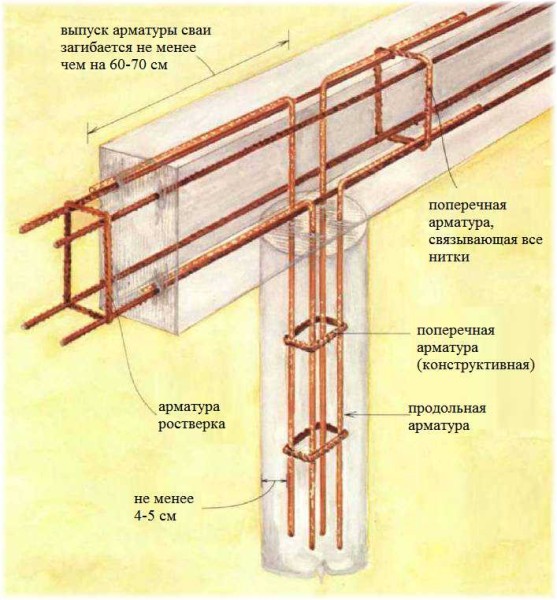

- To reinforce the pile, four ribbed rods with a diameter of 10-12 mm are used. The rods should be placed no closer than 4 cm from the edge.

- If the slope of the site is more than 10%, the release of the reinforcement must be connected to the grillage.

- Use either a high grillage - raised 150 mm above the ground, or make a pile-strip foundation with a shallow-buried strip. The second option is used for heavy buildings, the weight of which cannot be transferred by means of piles, then a tape is made, which increases the transmission area.

Scheme of reinforcement of a pile-grillage foundation with a reinforced concrete grillage (pile-tape)

- You should not do a sand bed at the bottom of the well: it will not have a normal density and will not work.

- Use a concrete vibrator to keep it secure. Manual vibration with a rebar is ineffective. If the farm does not have such a device, rent it for the time of pouring the foundation: the strength increases significantly.

- The pile formwork is made of roofing felt, roofing material or glassine rolled into a tube. It is better that it has several layers (2-3). They do not need to be fastened with anything: they twisted a little less than the diameter, inserted. The height of this formwork is 15 cm above the ground level, regardless of whether there is a slope on the site or not. It is advisable to sprinkle this protruding piece with sand or soil, and compact it around. This will prevent the roofing from collapsing when pouring concrete.

TISE foundation is a subspecies of pile-grillage foundation. And the technology of its manufacture is no different. The whole difference is in the drilling process. No others. The order of work and the technology of manufacturing the pile-dew foundation are described here... And in this article, we'd better give some practical advice.

Difficulty drilling

If the soil is very loose - fine sand - the walls of the well may crumble. To prevent this from happening, pour water. The sand will be compacted and keep its shape. Water will also help if the soil is very dry and dense. After drilling a few tens of centimeters, pour water into the well. It will soften the soil, it can be chopped up with a shovel or other device, and then removed with a drill.

It is not easy to drill wells under the TISE foundation with your own hands, but it is possible even alone

The powerful roots of trees and bushes create difficulties. They need to be chopped up. To do this, the handle is welded (attached) to the handle. By sharply lowering it into the hole, the roots are crushed.

How to form an extension

After reaching the design depth of the well, a plow is attached to the drill. It can be fixed in two positions: to form a heel of 50 or 60 cm. The plow is tied to a rope.

This is the plow that forms the domed expansion.

Lower the drill down, the rope is taut, the plow is pressed down. The rope was released, and under its own weight it descends. You start to rotate (it goes hard - the cutting surface is large), the blade cuts the ground, forming a thickening.

You can rotate both clockwise and counterclockwise. If clockwise, then try not to press down: you do not need to go deeper. When rotating counterclockwise, only the soil is cut without deepening, but another problem arises: the soil is poured under the drill, pushing it up.

The optimal order of work is as follows: scrolled counterclockwise several times. As you feel that the blade has rested against the arch, make a few turns clockwise, picking up the cut soil into the drill body. You take out the drill, pour out the soil. Repeat several times until the expansion is formed (the soil will stop accumulating).

On hard ground, working with an open plow can be problematic. Then you can form the extension in stages. First set the plow to the smallest distance, then increase it to the required size.

Filling with concrete

If the groundwater level is not high, no problems arise: you fill it in, process it with a vibrator. All.

If the water table is high, the heel can be poured immediately after it has been formed. You just need to insert the reinforcement. Then knit it before drilling. The filling of the main part of the well can be left for later.

Having exposed the reinforcement and formwork, they begin to pour concrete

If there is a lot of water and it arrives quickly, you will need a large bag of thick film with a hole at the bottom. Insert it into the hole and pour concrete. Since it is denser, it displaces water. After filling the heel, take out the bag. It will come in handy for the following piles.

The video below demonstrates the technology of building a foundation with TISE piles and a high grillage.